自动切管机及送料机构设计【14张CAD图纸和说明书】

收藏

资源目录

压缩包内文档预览:(预览前20页/共21页)

编号:6045866

类型:共享资源

大小:1.73MB

格式:ZIP

上传时间:2017-10-31

上传人:俊****计

认证信息

个人认证

束**(实名认证)

江苏

IP属地:江苏

40

积分

- 关 键 词:

-

自动

切管机

机构

设计

14

cad

图纸

以及

说明书

仿单

- 资源描述:

-

- 内容简介:

-

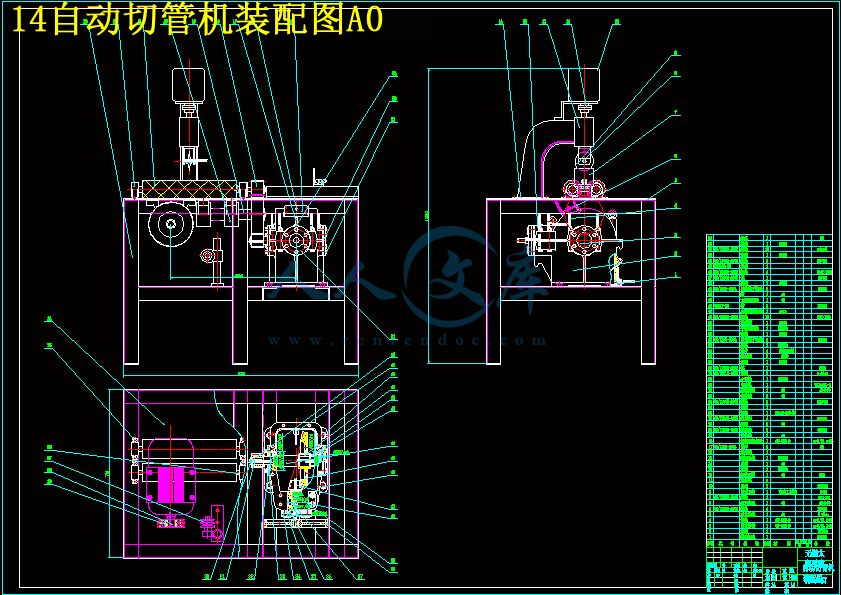

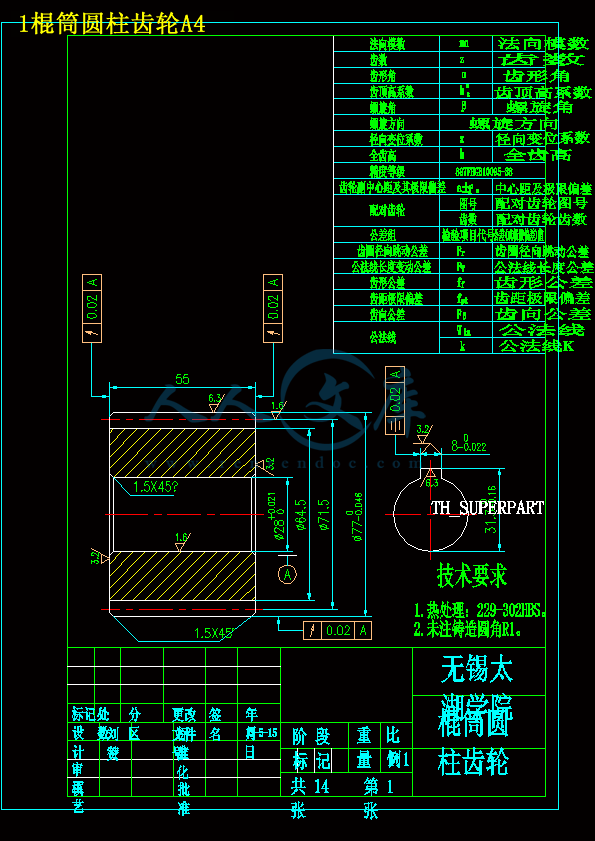

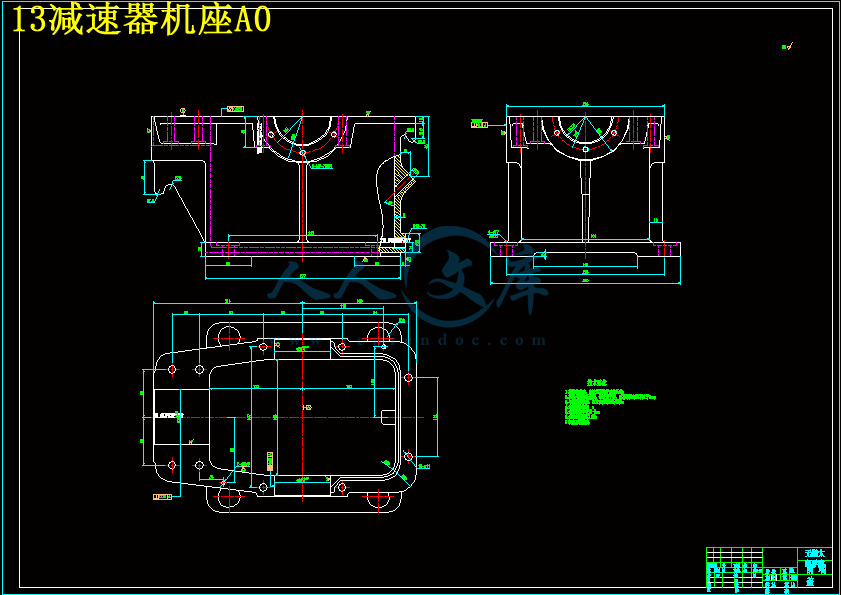

编 号无锡太湖学院毕 业 设 计 ( 论 文 )相 关 资 料题目: 自动切管机及送料机构设计 信 机 系 机 械 工 程 及 自 动 化 专 业学 号: 0923267学生姓名: 刘 赞 指导教师: 高汉华 (职称:副教授 )(职称: )2013 年 5 月 25 日目 录一、毕业设计(论文)开题报告二、毕业设计(论文)外文资料翻译及原文三、学生“毕业论文(论文)计划、进度、检查及落实表”四、实习鉴定表无锡太湖学院毕 业 设 计 ( 论 文 )开 题 报 告题目: 自动切管机及送料机构设计 信 机 系 机 械 工 程 及 自 动 化 专 业学 号: 0923267 学生姓名: 刘 赞 指导教师: 高汉华(职称:副教授)(职称: )2012 年 11 月 25 日 课题来源课题来源于生产实际。科学依据(包括课题的科学意义;国内外研究概况、水平和发展趋势;应用前景等)(1)课题科学意义众所周知,机械制造技术的先进与否直接与生产成本,产品的加工的精度,生产工作劳动的效率有着直接关系。机械产品的生产技术快速发展,人们对机械产品的加工要求也越来越高,主要体现在精度,效率,经济等方面。本次设计的要求就是设计自动化、高效、加工精度比较高、加工速度快的自动切管机,适合大批量生产加工管件的工厂和需要短期内加工大量管件的情况使用。自动切管机在生产中应用可以提高产品质量和经济效益,同时也可以降低劳动强度,提高生产效率。(2)国内外研究概况、水平和发展趋势现如今,日本在纸管机、卷筒纸分切机、切管机、纸管机设备的更新换代遥遥领先,在这个领域占领市场大量份额,同时赚取了大量外汇。在欧共体中,意大利的包装机械装备和生产线更新换代的步伐远远比其它成员国来得快。在东南亚几个快速发展的国家也继日本后,在生产线的制造方面和包装机械装备有非常快的发展。自动化的切管机在这些国家中也有一定的发展。伴随着制造业的快速发展,自动化机器的需求也越来越大,中国作为一个全球制造业中心大国,需要先进的生产技术,研发先进的、自动化的切管机意义重大。(2)应用前景自动切管机的用途很广泛。在钢管家具、运动器材、箱包行业、汽车摩托车、自行车、童车、空调配管、门业、不锈钢管、石油化管、文体用品、卫浴设备、工艺品。五金行业、制管等行业都需要大量的切管作业。中国恰恰是这些产品的主要生产国家,使用自动化切管机需求是相当大的。另外,塑料管、橡胶管、复合管、铜管、铝管等各种软硬材料的管道加工也需要多种切管机。研究内容 熟悉机械设计的发展历程,特别是近十几年来自动化机器及电器控制在制造业的广泛应用; 熟练掌握机械设计原理和方法; 熟练掌握机械制图在机械设计中的应用; 掌握注自动切管机上各个部分的作用; 对于机械设计,能够掌握其中各个机构及零件的设计原则以及合理分析各因素对设计的影响。 拟采取的研究方法、技术路线、实验方案及可行性分析在毕业实习调研以及查阅有关资料的基础上,结合零件的外形及加工要求,经反复对各方案对比分析,采用以自动切管机与送料机构配合的方式,实现自动加工管件。设计自动切管机中圆锥齿轮减速器、切管机棍筒、机架及自动送料机构的工作方案。两者结合实现自动切割管件的工作。研究计划及预期成果研究计划:2012 年 11 月 12 日-2012 年 12 月 2 日:按照任务书要求查阅论文相关参考资料,填写毕业设计开题报告书。2012 年 12 月 3 日-2012 年 12 月 23 日:填写毕业实习报告。2012 年 12 月 24 日-2012 年 12 月 30 日:在老师指导下制定设计方案。2012 年 12 月 31 日-2013 年 3 月 24 日:在老师指导下进行设计计算及结构设计。2013 年 3 月 25 日-2013 年 3 月 31 日:在老师指导下绘制零件图。2013 年 4 月 22 日-2013 年 4 月 28 日:编写设计说明书。2013 年 4 月 29 日-2013 年 5 月 5 日:在老师指导下修改设计内容及设计说明书。2013 年 5 月 6 日-2011 年 5 月 15 日:在老师指导下修改设计内容及设计说明书,按学校要求进行编排打印材料。预计成果:完成自动切管机的设计和送料机构的设计方案。特色或创新之处适用于本厂的某生产线的优化设计,力求在不影响加工的前提下最大限度的减少成本,提高产品生产加工速度,并降低工人的劳动强度和生产成本。自动切管的同时,使用压轧式切割,不产生切削。已具备的条件和尚需解决的问题所学的机械理论设计、制图及加工工艺知识。对机构的与机器设计更多理解,综合所学的各方面机械理论设计、方法及工艺装备,提高开发和创新机械产品的能力。指导教师意见指导教师签名:年 月 日教研室(学科组、研究所)意见教研室主任签名:年 月 日系意见主管领导签名:年 月 日英文原文MECHANISMS AND MACHINE THEORY1.Introduction to Mechanism:The function of a mechanism is to transmit or transform motion from one rigid body to another as part of the action of a machine. There are three types of common mechanical devices that can be used as basic elements of a mechanism.1、Gear system, in which toothed members in contact transmit motion between rotating shafts. 2、Cam system, where a uniform motion of an input member is converted into a nonuniform motion of the output member. 3、Plane and spatial linkages are also useful in creating mechanical motions for a point or rigid body. A kinematic chain is a system of links, that is, rigid bodies , which are either jointed together or are in contact with one another in a manner that permits them to move relative to one another. If one of the links is fixed and the movement of any other link to a new position will cause each of the other links to move to definite predictable position, the system is a constrained kinematic chain. If one of the links is held fixed and the movement of any other link to a new position will not cause each of the other links to move to a definite predictable position then the system is an unconstrained kinematic chain,A mechanism or linkage is a constrained kinematic chain, and is a mechanical device that has the purpose of transferring motion and/or force from a source to an output. A linkage consists of links (or bars), generally considered rigid, which are connected by joints, such as pin Cor revolute) or prismatic joints, to form open or closed chains (or loops). Such kinematic chains, with at least one link fixed, become mechanisms if at least two other links remain mobility, or structures if no mobility remains. In other words, a mechanism permits relative motion between its rigid links; a structure does not. Since linkages make simple mechanisms and can be designed to perform complex tasks, such as nonlinear motion and force transmission they will receive much attention in mechanism study.Mechanisms are used in a great variety of machines and devices. The simplest closed-loop linkage is the four-bar linkage, which has three moving links (plus one fixed link) and four pin joints. The link that is connected to the power source or prime mover and has one moving pivot and one ground pivot is called the input link. The output link connects another moving pivot to another ground pivot. The coupler or floating link connected the two moving pivots, thereby coupling the input to the output link.The four-bar linkage has some special configurations created by making one or more links infinite in length. The slider-crank (or crank and slider) mechanism is a four-bar chain with a slider replacing an infinitely long output link. The internal combustion engine is built based on this mechanism. Other forms of four-link mechanisms exist in which a slider is guided on a moving link rather than on a fixed link. These are called inversions of the slider-crank, produced when another link (the crank, coupler, or slider) is fixed link.Although the four-bar linkage and slider-crank mechanism are very useful and found in thousands of applications, we can see that these linkages have limited performance level. Linkages with more members are often used in more demanding circumstances. However it is often difficult to visualize the movement of a multiloop linkage, especially when other components appear in the same diagram. The first step in the motion analyses of more complicated mechanisms is to sketch the equivalent kinematic or skeleton diagram. The skeleton diagram serves a purpose similar to that of the electrical schematic or circuit diagram .Organization movement analysis second step: Draws a graphic chart, is must determine the organization the number of degrees of freedom. Based on degree of freedom, but Italy refers needs certain independent inputs the movement number, by determined organization all components are opposite in the ground position. The people have thousands of different types conceivably the link motion gear. You may imagine a bag containing massive link motion gear the component: Two pole groups, three pole groups, four pole groups and so on, as well as components, rotation, motion, cam follower, gear, tooth chain, chain wheel, leather belt, belt pulley and so on. (Sphere movement, screw vice-as well as the permission three dimensional relative motion other connections not yet includes, here, discusses in parallel planes merely plane motion). Moreover you conceivable put these components various types link motion gear possibility which forms in the same place. How exists helps the people to control forms these organizations the rule? In fact, the majority organization duty is requests a sole input to transmit to a sole output. Therefore the single degree of freedom organization uses most one kind of organization type. For example, namely may see by the intuition: Four pole organizations are a single degree of freedom link motion gear. The picture motion diagram and the determination organization degree of freedom process, is the movement analysis and the synthesis process first stage. In the movement analysis, adds on its characteristic according to the organization geometry shape which possibly knew (for example input angle, speed, angle acceleration and so on) studies the determination concrete organization. On the other hand, the movement synthesis is designs an organization to complete the duty process which an institute requests. In this, chooses the new organization the type and the size is a movement synthesis part. Conceives the relative motion ability, can guess the reason that designs an organization the reason and makes the improvement to a concrete design ability is like this a successful organization scientists symbol. Although these abilities come from the congenital creativity, however more is because has grasped the technology which enhances from the practice. 1.1The movement analysis:simple one of most useful organizations is four pole organizations. In on following elaboration majority of content centralism discussion link motion gear, but this procedure is also suitable for the more complex link motion gear. We already knew four pole organizations have a degree of freedom. About four pole organizations, has the useful more contents which must know? Indeed is some! These pull the Xiao husband criterion including the standard, the transformation concept, the blind spot position (divergence point), branch office, transmission angle, with theirs movement characteristic, including position, speed and acceleration. Four pole organizations may have one kind of being called as crank rocker organization form, one kind of double rocking lever organization, one kind of double crank (tension bar) does the organization, which one form send in is called as the organization, is decided in two pole movement scopes which (fixed component) connects with the rack. The crank rocker organization input component, the crank may revolve through 360 and the continuous rotation, but outputs the component to make the undulation merely (i.e. swing member). As an exceptional case, in the parallel four pole organization, inputs the pole the length to be equal to outputs the pole the length, the go-between length and the fixed link (rack) length, also is equal. Its input and the output all may make the complete alternation rotation or transform the being called as antiparallel quadrangle organization the overlapping structure. The standard pulls the Xiao husband criterion (theorem) to indicate that,If in four pole organizations, between two poles can do willfully relatively rotates continuously, that, its longest pole length is smaller than sum of with the shortest pole length or is equal to sum of the other two pole length.Should pay attention: The same four pole organization, may have the different form, which pole is this decided in was stipulated (i.e. makes fixed link) as the rack. The movement transformation process is in the fixed organization transmission chain different member has the different organization rate process. Besides has about the component rotation scope knowledge, but also must have how causes the organization before the manufacture on energy “the revolution” the good measure, that will be very useful. Hardenbergh (Hartenberg) speaks of: “The revolution” is terminology, its significance passes to outputs the component the movement validity. It meant the revolution is steady, in which can in output in the component to have a strength or the torque biggest force component is effective. Not only although the final output strength or the torque are the connecting rod geometric figure functions, moreover also is generally the power or the force of inertia result, that is frequently big to like static strength several times. In order to analyze the idling or in order to easy to obtain how can cause any organization “the revolution” the index, the transmission angle concept is extremely useful. In organization movement period, the transmission angle value is changing. The transmission angle 0 may occur in the special position. Will output the pole but in this special position the movement with not to exert inputs on the pole the strength many to have nothing to do with greatly. In fact, as a result of the movement vice-friction influence, the general basis practical experience, with the transmission angle planning board which is bigger than the rating. The weight link motion gear transmission movement ability matrix foundation definition already studied. A determining factor value (it includes regarding some assigns organization graph, position output movement variable to input variable derivative) is a this link motion gear in concrete position mobility criterion. If the organization has a degree of freedom (e.g. four pole organizations), then stipulated a location parameter, if the input angle, completely determined this organization stops position (neglect branch offices possibility). We may study one about four pole organization component absolute angular position analysis expression. When analyzes certain positions and (or) certain different organization time, this will be must be much more useful than the geometric figure analysis program, because this expression will cause the automated computation easy to program. The realization organization speed analysis relative velocity law is the speed polygon is one of several effective methods. This end (goes against) the spot to represent on the organization all spots, has the zero speed. From this the line which stipples respectively to the speed polygon in is representing the absolute speed which this organization photograph well should select respectively. In a line connection speed polygon random two points represents is taking on this organization two corresponding spot relative velocity. Other method is the instantaneous center law, namely the instantaneous center law, this method is extremely useful moreover is frequently when the complex link motion gear analysis quick method. The instantaneous center is a spot, this spot in that flash, on between the organization two components does not have the relative motion. In order to discover known organization certain instantaneous centers the position, Kennedy the (Kennedy) three center theories extremely are useful. It is said that,Each other relative motion three object three instantaneous centers are surely in a straight line. The organization various components acceleration is makes one be interested, because it affects the force of inertia, subsequently affects the machine part the stress, the bearing load, the vibration and the noise. Because the final goal is the machine and the organization force of inertia analysis, the all acceleration various components all should the disposable picture - - in the organization fixed component inertial coordinate system express in the identical coordinate system. Should pay attention: Is opposite in rotates on the vice-rotation rigid body an acceleration component usually to have two fixedly. A force component direction cuts in this path, its direction is same with this object angle acceleration direction, and is called the tangential acceleration. Its existence is completely because the angular speed rate of change causes. Another component, always aims at the object the center of rotation, is called the standard the centripetal acceleration, because this component the velocity vector direction has the change to exist. The movement comprehensiveGanization is forms many mechanisms the basic geometry structural units, these mechanisms including automatic packaging, printer, mechanical toy, textile machinery and other machineries and so on. The typical organization must design causes the movement which the rigid component relative datum component produces hoped. The organization movement design is the movement synthesis, first step frequently designs the entire machine first. When consideration stress, must ask dynamics aspect question, the bearing load, the stress, the lubrication and so on the similar question, but the major problem is the machine structure question. The movement scientist defines the kinematics as “the development facility movement and the foundation organization method”. This definition first part involves the kinematic analysis. The known organization, its constitution state of motion determined by the kinematic analysis. The narration movement analysis duty contains the organization between the main dimension, the component links mutually with the input movement technical characteristic or the actuation method. The goal is must discover the displacement, the speed, the acceleration, the impact or the beat (two step accelerations), with various components higher order acceleration which possibly occurs as well as describes the diameter mark and the movement which realizes by certain components. The definition second part of available following two aspect explained :1. research produces with the aid of the organization assigns the movement the method.2. research construction to be able to produce assigns the motion the method, but in two plans, the movement is assigns the organization is the foundation. This is the movement synthesis essence. Such movement synthesis involves to for assigns the performance the organization system design. The movement synthesis aspect may sum up as following two kinds: 1. types are comprehensive. The stipulation requests the performance, how is one kind of type organization appropriate? (Tooth gear train, link motion gear? Cam gear?)How many components but should the organization have? How many degrees of freedom needs? How outline structure is hoped? . About the member number and the degree of freedom consideration was usually considered is in the type synthesis is been called as for a quantity synthesis branch domain. 2. sizes are comprehensive. The movement synthesis second predominant type is the best method which determined through the goal law. The size synthesis attempts to determine the organization the important size and the starting position, this organization is conceives beforehand for the realization stipulation duty and the anticipated performance. Of the so-called important size meanings are refer about two poles, three poles and so on between the length or the pole are away from, angle between number of articles and spool thread, cam contour size, cam follower diameter, eccentricity, gear quota and so on. Expected the organization type possibly is the crank slide organiz

- 温馨提示:

1: 本站所有资源如无特殊说明,都需要本地电脑安装OFFICE2007和PDF阅读器。图纸软件为CAD,CAXA,PROE,UG,SolidWorks等.压缩文件请下载最新的WinRAR软件解压。

2: 本站的文档不包含任何第三方提供的附件图纸等,如果需要附件,请联系上传者。文件的所有权益归上传用户所有。

3.本站RAR压缩包中若带图纸,网页内容里面会有图纸预览,若没有图纸预览就没有图纸。

4. 未经权益所有人同意不得将文件中的内容挪作商业或盈利用途。

5. 人人文库网仅提供信息存储空间,仅对用户上传内容的表现方式做保护处理,对用户上传分享的文档内容本身不做任何修改或编辑,并不能对任何下载内容负责。

6. 下载文件中如有侵权或不适当内容,请与我们联系,我们立即纠正。

7. 本站不保证下载资源的准确性、安全性和完整性, 同时也不承担用户因使用这些下载资源对自己和他人造成任何形式的伤害或损失。

人人文库网所有资源均是用户自行上传分享,仅供网友学习交流,未经上传用户书面授权,请勿作他用。

川公网安备: 51019002004831号

川公网安备: 51019002004831号