资源目录

压缩包内文档预览:

编号:6050102

类型:共享资源

大小:7.35MB

格式:RAR

上传时间:2017-11-02

上传人:闰***

认证信息

个人认证

冯**(实名认证)

河南

IP属地:河南

50

积分

- 关 键 词:

-

燃气

透平

压缩机

结构设计

- 资源描述:

-

- 内容简介:

-

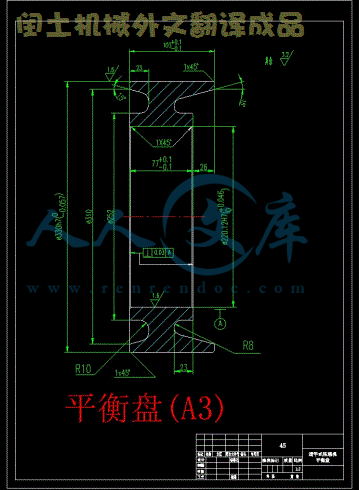

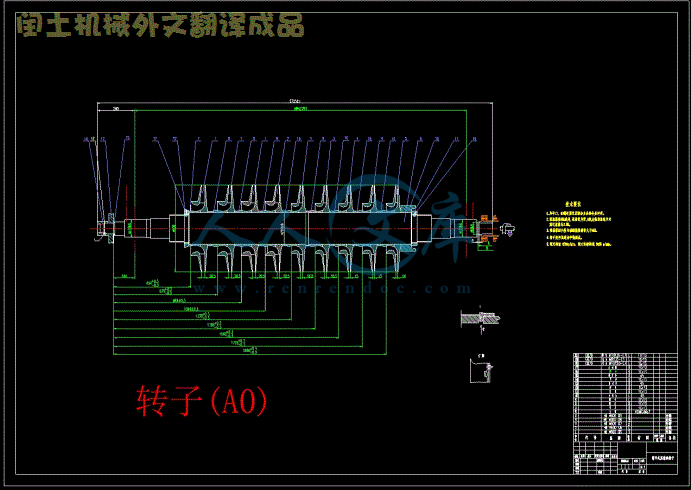

毕业设计(论文)中期报告题目:燃气透平式压缩机的机构设计系 别 专 业 班 级 姓 名 学 号 导 师 (居中,四号,宋体,行距 30 磅)年 月 日(居中,四号,宋体)1.设计(论文)进展状况本设计已经完成以下内容:(1)对于在开题答辩中,老师对我开题报告中提出的相关问题进行了修改,并通过了指导老师的检查。(2)明确了透平式压缩机具体设计思路、设计方案与框架,并完成了外文资料的翻译。本设计设计的是透平式压缩机中的离心式,离心式压缩机的基本原理是通过原动机带动转子部分的旋转,使进入压缩机的气体通过叶轮、扩圧器、弯道、回流器,反复地得到旋转加速加压的效果,并通过逐级的加速加压,最后达到设计所需的气体速度和压力要求,如图 1.1 所示。图 1.1 压缩机工作原理示意图 图 1.2 压缩机级内截面划分(3)对燃气透平式压缩机的主要结构进行了参数设计和计算,包括压缩机缸体的气动计算,压缩机强度轴向推力的设计计算与效验以及密封的设计。为了计算气体流过叶轮时,叶轮对气体所作的功,需先分析气体的运动情况。气体在一级里所作的运动划分如图 1.2 所示:考察常规叶轮的截面 11 及截面 22(图 1.2) ,11 截面是气体刚进入叶片的截面,22 截面是气体即将离开叶片的截面,设截面上气流的绝对速度,牵连速度与相对速度分别以 c、 u 及 w 表示,,则当气流以 进入 11 截面时,其相对速度:c11 截面是气体刚进入叶片的截面,22 截面是气体即将离开叶片的截面,设截面上气流的绝对速度,牵连速度与相对速度分别以 c、u 及 w 表示,,则当气流以进入 11 截面时,其相对速度: c 11uc而当气流以 离开 22 截面时,其绝对速度: w 22式中的 指截面上的圆周速度,其大小: usmDn/60图 1.3 表示出了 c、w 及 u 三个速度矢量的关系,它们组成的三角形表示出了三者之间的数量关系,称为速度三角形。图 1.3 叶轮进出口截面气流速度分析a)进口速度三角形 b)出口速度三角形在图 1.3 中,a )的正值指 c 与 u 之间的夹角,而 的正值指 w 与 u 的反向之间的夹角。今后常需把速度分解为圆周方向(即 u 方向)及垂直于 u 方向(在常规叶轮中即为半径 r 方向)的分量,由图 1.3,对出口速度三角形作几何分析可得:212sincoru221sincoru而且从速度三角形可得下述关系: rwu对于进口速度三角形,同样有如下关系式: 11sincoru11sincoru及 1rwcwucu 有时被称为旋绕,而 cu1 被称为预旋,在大多数设计工况时, cu10(或) ,此时称为 “无预旋 ”情况。901a轴向推力计算示意图,如图(1.4)所示:图 1.4 压缩机轴向推力计算示意图(4)绘制总装配图,如图 1.5 所示。离心式压缩机的本体结构分为两大部分:转子,定子。转子由主轴、叶轮、平衡盘、定距套、推力盘、半联轴节等部分组成。定子由气缸、隔板、支撑轴承、推力轴承、轴端密封等零部件组成。图 1.5 透平式压缩机总装配图2.存在问题及解决措施存在的问题:本设计虽然已经完成重要设计参数的计算,但燃气压缩机对设备的密封性和防暴阻燃要求很高,在设备的密封和防暴阻燃性能存在很大的疑虑。此外本设计涉及到了许多非标准件的选用,综合考虑结构和经济性人不是很合理。解决措施:认真查阅参考资料,向老师请教,与同学交流,继续完善设计,以设计图纸为突破口优化结构,以求更加合理准确。3.后期工作安排对压缩机零件进行优化改进,进而促使压缩机结构更加优化。改进中期设计中存在的缺点,比如压缩机装配时可能出现的互相干涉无法组装、设计时没有考虑加工难度从而导致制造成本高等等缺陷。第 12 周(2015 年 3 月 23 日2015 年 3 月 29 日):对中期答辩提出的问题进行修改,完善中期报告的内容和格式并提交;第 13-14 周(2015 年 3 月 30 日2015 年 4 月 19 日):绘制零件图,开始毕业论注:1)正文:宋体小四号字,行距 20 磅,单面打印;其他格式要求与毕业论文相同。文撰写;第 15-16 周(2015 年 4 月 20 日2015 年 4 月 26 日):完善零件图,完成毕业论文撰写;第 17 周(2015 年 4 月 27 日2015 年 5 月 3 日):修改论文格式并准备毕业答辩。指导教师签字:年 月 日2)中期报告由各系集中归档保存,不装订入册。附录 A 英文原文The entire machine bucket centrifugal compressor gas seal positioning the Boss WeldingLiu Dongju Hafu the Indian Ocean Tong Ming-chen / Shenyang Blower (Group) Co., Ltd. Abstract: The cylinder-type centrifugal compressor gas seal Boss caused due to operational deficiencies, so as to the Welding Technology. Welding on the choice of methods were compared, specifying the use of hand-TIG welding method of Welding Technology Practice has proved that good results. Key words: centrifugal compressor seal Boss Welding CLC: TH452 code: BRep air Welding of Allocating Convex for Dry Ga sSeal in Barrel Typ e Centrifugal Compre ssorAbstract:Repair welding technology of allocatingconvex for dry gas seal in barrel type cent rif ugalCompressor caused by operation fault is int ro2duced.The selections of repair welding technolo2gy are compared,and t he repair welding technol2ogy using handwork gas t ungsten arc welding isdetailed.The result wit h good effect is got.Key words:Cent rif ugal Compressor Seal convexRepair welding1.IntroductionTaiwan assembly in a tube-type gas compressor seal, found in the left and right end cancelled with the installation of dry gas seal, by drilling a vent drilling dry gas seal positioning Boss, Boss to seal damage, destruction of Up to 25 mm 10mm 7mm (see Figure 1 in the F), resulting in dry gas seal targeting local plastic ring seal bad. Left and right to cover their own water pressure test, the pressure for the 30 M Pa, after passing the cover and chassis pressure test done at the same time, pressure to 20 MPa, medium for helium. The product of the media for circulating hydrogen gas, under pressure 16 MPa; if not sealed Boss Welding not only affects the appearance quality is more important to the functioning unit will be sealed leak caused a serious, but will also affect gas The use of sealed, leading to paralysis and crew shutdown process, the consequences would be unthinkable. Left and right cover material for KMN materials, the special material, very difficult Welding, the left and right cover has been finished, if Welding improper measures will cause cracks, after welding deformation, the most serious is the result of the components scrapped.Figure 1 Cover Welding regional plans2 KMN briefing materials KMN material is my company centrifugal compressor impeller welding, end caps, and other special materials. The material for chromium molybdenum alloy, solder needed before preheating, after welding need to heat treatment, in the use of state-quality, complex welding process, welding materials used KMN dedicated electrode. 3 Welding Methods Laser 3.1 cold welding As left and right cover has been finished, dry gas seal targeting Taiwan has finished processing, welding heat input will lead solder after deformation. To prevent deformation after welding, welding is the preferred method of cold welding. In order to ensure the quality of Welding, the author and the Chinese Academy of Sciences Institute of metal surface laser fusion of professional and technical personnel, the quality of the scene, can be used to confirm whether the cold welding method Welding. Laser fusion welding surface of the technical staff to cover KMN of performance, welding, etc., are familiar, Welding position in the middle of the cover, to confirm the repair welding electrodes when contact is very difficult, even if exposure to welding electrodes Efficiency is very low, quality is difficult to ensure that, in the face of this situation, it is not appropriate to confirm the laser cold welding. 3.2 manual arc welding Using manual arc welding to repair welding, flexible. As KMN material is material for the company, has dedicated KMN electrode, welding materials and welding no problems after the performance. Welding is to be the key to the left and right end caps are in place after finishing the dry gas seal region, Welding before preheating required welding, heat treatment after welding, manual arc welding of the great heat input will increase Welding The regional heat input, heat input of the constantly increasing, and will lead solder after deformation. If a deformation, which means that the left and right cover will be scrapped, we should not use this method. 3.3 manual TIG welding Welding is the use of argon gas for the protection of a welding method. Welding, argon arc in the formation of the protection of the surrounding gas, molten metal, tungsten wire and extremism is not the first contact with air. Argon is an inert gas, it does not react chemically with the metal, very stable. Therefore, in the process of being welded metal and welding wire in the alloying elements not burning. In addition, Argon do not dissolve in metal, it can not be formed in the metal in the stomata. With these characteristics, can be used welding quality of the weld. The use of welding parts to repair welding, more fully the reasons are: (1) As the argon arc by the compression and cooling, allowing more concentrated arc energy, small heat-affected zone, the deformation is small; (2) Weld Central slag, welder in operation can clearly see the pool and the formation of the weld, easy to operate; (3) operation from space location restrictions, suitable for all-position welding; (4) suitable for welding and non-ferrous metal alloy steel, stainless steel, high-temperature alloy steel, special steel and refractory metals such as the activity. Based on the characteristics of welding, using welding on the left and right cover to seal the Welding most appropriate. 4 .manual TIG welding Welding Technology 4.1 welding technical parameters Equipment Model: Osaka, Japan OTC companys AC2CU TI G 300 P pulse welding machine; Power Polarity: DC is received; Tungsten: Ce tungsten; diameter: 3.2 mm; Extended Length: 7 mm; Argon purity: 99.99%; argon gas flow rate: 8 L / min; Nozzle diameter: 10 mm; tungsten extreme workpiece distance: 4 mm; Arc: by high frequency arc-arc; Welding current: 110 120 A; Welding voltage: 20 22 V. 4.2 welding pre(1) Welding with the oil-alcohol, acetone thoroughly cleaned. (2) check the power, water, gas, such as whether or not the normal way. (3) KMN 3.2 mm electrode-skin cleared, sandpaper after finishing with acetone clean, do Welding filled with wire. 4.3 points (1) arc advance of 5 10 s transmission argon, in order to rule out the possibility of Welding and welding pieces by the air-conditioning argon gas flow. (2) Welding the first layer using the left-welding method, the second layer by the right-welding, and from then to Welding. After a weld seam equivalent to a pre-tempered, eliminate stress the role played by the left-welding, the right-welding, turn to each other Welding of meat, until the end of the welding. (3) Welding short arc welding used to enhance the protection, but will reduce the width of the heat-affected areas and to prevent deformation of Welding. (4) filled wire to uniform, in the pool in front of a metal-joining, do not disturb argon flow and not with the tungsten Xiangpeng. (5) Welding dying, we should add more wire, and then slowly started to prevent the generation of arc pit. (6) Welding finished, cut off power, must be within 3 5 s to send the protection of gas, tungsten and pool until slightly cooled the region, the unaspirated stop and avoid areas of Welding. After testing five Welding Welding colored surface after their inspection, the surface without any deficiencies. Welding after passing inspection Department for manual grinding, grinding to meet the requirements, then Kim Sang fine sandpaper to throw. Welding the fine after throwing the metal color, luster, with the full - Metal color, luster consistent, it can not see signs of Welding. Conclusion (1) using manual TIG welding, the left and right have Cover Finishing the dry gas seal positioning Boss Department Welding, is the most Welding the ideal method. (2) the use of hand-TIG welding left and right to welding, And from each other alternately to repair welding, welding without preheating, after welding No heat treatment, Welding good effect, no deformation of the workpiece. (3) high-pressure centrifugal compressor in the bucket in the case, in On the left and right end of the dry gas seal with a convex targeting Taiwan into the Welding Gong, ensuring product quality and delivery scheduleCentrifugal domestic refrigeration compressors that idea Abstract: centrifugal refrigeration compressor characteristics, application conditions and trends; development of the difficulty of centrifugal compressor, the focus and countermeasures; development of the centrifugal compressor roughly steps. Keyword: Centrifugal domestic refrigeration compressors 1. centrifugal refrigeration compressor characteristics. Centrifugal refrigeration compressor as a speed-type compressors, has the following advantages: (1) Cold in the same circumstances, particularly in the large-capacity, compared with the screw compressors, eliminating a huge oil installations, units of smaller size and weight, small footprint; (2) Centrifugal compressor compact simple structure, movement of small, reliable, durable, low operating costs; (3) Easy to implement multi-level compression and a variety of evaporation temperature, cooling easy to implement the middle, making lower power consumption; (4) Centrifuges group mixes the oil is extremely small, the heat exchanger on the effect of smaller units with high efficiency. Has the following shortcomings: (1) Rotor speed higher, in order to guarantee a certain width impeller, must be used for large and medium-sized flow of occasions, not suitable for small flow occasions; (2) Pressure than the low single-stage, in order to get a higher pressure than required to adopt the multi-stage impeller, but also with the general growth rate of gear; (3) Surge is a centrifugal compressor inherent shortcomings of units required to add anti-surge systems; (4) The same unit working conditions can not be a major change in the scope is narrow. 2. the centrifugal refrigeration compressor application conditions and trends. The current domestic centrifugal chiller in most of Europe from Japan and the United States occupied by some refrigeration business. Well-known enterprises such as Trane, Kai-li, York, Maikeweier, AXIMA (original Sool Shou), EBARA original, Mitsubishi And so rely on advanced technology and good technology-led centrifugal chiller market. Domestic enterprises in Chongqing mainly generic, early introduction of the technology to develop NREC centrifugal chillers. With the development of society, users need more and more of the cold high, and because of Energy-saving requirements of the Group of centrifuges makes the market more widely. Number of domestic air-conditioning manufacturers such as Haier, Australia Kema, Geli and the United States (and Chongqing Universal Merger) have launched their own centrifugal chiller. AXIMA the cold and cooperative development Chu Lixin chiller and regional heating centrifugal heat pump units. Most of these centrifuges group of the use of environmentally friendly R134a. With the growing tension in the form of energy, energy saving products development is a major trend. In addition the level of urbanization in China because of the continuous improvement, building energy consumption is increasing. With the highest coefficient of performance of the centrifugal chiller will no doubt be a hot market, In recent years centrifugal chiller sales continues to increase. Most of the development of domestic enterprises centrifugal chiller compressor only buy imports, basically no profit. Centrifuges foreign manufacturers will not easily transfer their core technologies, to develop centrifugal refrigeration compressors, only walk the path of independent development. With Design and manufacturing technology continues to mature, making China the centrifugal refrigeration compressor developed possible. 3. developed and the difficulty of centrifugal compressor, the focus and countermeasures. Development of a centrifugal compressor, including many of the elements: air heat, the intensity and vibration, structural design, materials selection, manufacturing process design, control and regulate the design and pattern-driven choice. Which The main emphasis of the difficulty in the following areas: (1) Impeller Design Centrifugal compressor rotor as the moving parts, the core part of the impeller. Centrifuges are the major domestic and foreign manufacturers have adopted methods of ternary flow impeller design. Ternary flow approach requires designers to have the numerical simulation, computational fluid dynamics, fluid Machinery, such as the internal flow of very specialized knowledge. Domestic companies do not have the technical staff most of these professional expertise, to design efficient ternary impeller, the only college and research institutions. Centrifugal compressor in the College of experts mainly in Shanghai National Chiao Tung Universitys Professor Gu-Gang, Xian Jiaotong University Professor Wang Shangjin. Professor Gu has long been engaged in the research centrifuges, has presided over six to complete the National Natural Science Foundation project, in ternary flow centrifuge design, compressor unit testing, monitoring and Control, anti-surge systems, such as in-depth study of all aspects, he presided over the completion of the multi-stage centrifugal compressor aerodynamic design and application of technology projects for 2004 national scientific and technological progress second prize. Leadership of Professor Wang Xian Jiaotong University Purcell Pump research group to a unique controllable vortex impeller design theory, in the fields of petrochemical unit in the transformation of a good application. (2) Impeller manufacture Ternary flow to the design of the impeller blade shape for the general space surface, the impeller blade and the forming process is to create the focus is difficult. Impeller for three yuan, the processing methods commonly used mainly two kinds: 1) welding of three forms: That is roulette, leaves, round covered were processed. This method of processing equipment is relatively simple request, roulette, wheel covers only vehicles to form enough. Leaf processing it will take some work, The first to use 3-D milling machine to leaf mold, and then under the leaves of good material for heat treatment, the necessary pressure-leaf shape. Finally, the leaves of welding to the wheel, then covered welding good round. So in need of Equipment is probably the 3-D milling machine, heat treatment furnace, hydraulic machines and other equipment required for the conventional, the investment required is relatively low, more suited to start. 2) milling system as a whole: that is, roulette and leaves with the use of multi-axis milling equipment to the overall system and get a semi-open impeller. In order to avoid interference, the current international impeller on the processing of this large are using 5-axis machining Centre. A 5-axis equipment probably from several million to 10 million more than the cost was very high. Impeller to processing 600 mm for example, domestic bed about 5-axis to 3.5 million yuan, 5-axis bed probably have to import 4.8 million yuan. Through 4 Coordinates of the machine tool rotary table tilted to achieve the four ternary impeller milling coordinates the overall system, if the leaves more consistency, to interfere in the issue on the coordinates of the four is inevitable. Coordinates of the four devices are relatively cheap, probably more than 100 million yuan. (3) Rotor critical speed of calculation Speed is critical when the design of the rotor speed to be considered an important factor, the rotor speed to avoid the critical speed. Critical speed of calculation used Pu Luoer general, the market is critical speed of specialized computing software, can also develop their own calculation software. (4) Antisurge system design By the centrifugal compressor of the work we can see that surge is inherent in the nature of centrifuges, can not be eliminated, but can be an effective way to be avoided. Centrifugal refrigeration compressor surge in the reasons: low flows and high pressure condensate . Surge against the crew of a large, carefully designed to be anti-surge systems. (5) Bearing Design Centrifugal refrigeration compressors the general growth rate of gear, the rotor speed is generally in more than 5000 RPM, use plain bearings, sliding bearing centrifuge development of the design is also a priority. 4. developed and the centrifugal compressor general steps: (1) Collect, study and centrifugal compressor centrifugal chiller and the relevant standards. (2) Organization of the centrifugal compressor learn the basic knowledge to use one yuan-design theory compressor level. (3) Organizing the personnel to the relevant scientific research institutes, manufacturers and professional study tour. (4) In cooperation with research institutes ternary impeller design. (5) The entire machine developed. (6) Prototype test improvement. 5. the idea that In the 1950s, Chinese scientists made Turbomachinery Professor Wu Zhonghua ternary flow theory, laid a ternary the theoretical basis for the design flow. Some foreign companies such as NREC this theory, such as the development of Chu Lixin impeller mechanical design and processing software . Chinas scientists and technology workers have also carried out a large number of fruitful research, the centrifugal compressor design and processing carried out in-depth study and formed a series of research results, compared with foreign countries, no less. Recommendations Refrigeration domestic enterprises hold high the banner

- 温馨提示:

1: 本站所有资源如无特殊说明,都需要本地电脑安装OFFICE2007和PDF阅读器。图纸软件为CAD,CAXA,PROE,UG,SolidWorks等.压缩文件请下载最新的WinRAR软件解压。

2: 本站的文档不包含任何第三方提供的附件图纸等,如果需要附件,请联系上传者。文件的所有权益归上传用户所有。

3.本站RAR压缩包中若带图纸,网页内容里面会有图纸预览,若没有图纸预览就没有图纸。

4. 未经权益所有人同意不得将文件中的内容挪作商业或盈利用途。

5. 人人文库网仅提供信息存储空间,仅对用户上传内容的表现方式做保护处理,对用户上传分享的文档内容本身不做任何修改或编辑,并不能对任何下载内容负责。

6. 下载文件中如有侵权或不适当内容,请与我们联系,我们立即纠正。

7. 本站不保证下载资源的准确性、安全性和完整性, 同时也不承担用户因使用这些下载资源对自己和他人造成任何形式的伤害或损失。

人人文库网所有资源均是用户自行上传分享,仅供网友学习交流,未经上传用户书面授权,请勿作他用。

川公网安备: 51019002004831号

川公网安备: 51019002004831号