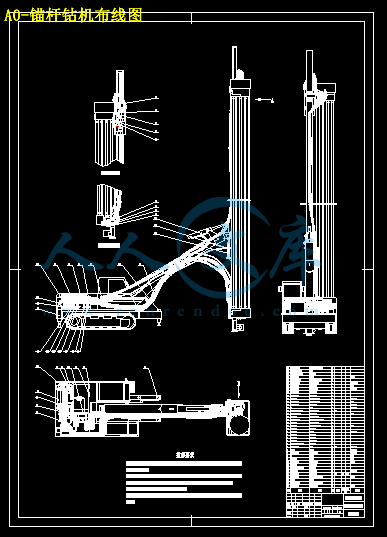

MG100型锚杆钻机液压系统设计【石油】【9张CAD图纸和说明书】

收藏

资源目录

压缩包内文档预览:(预览前20页/共46页)

编号:6050698

类型:共享资源

大小:17.12MB

格式:ZIP

上传时间:2017-11-02

上传人:俊****计

认证信息

个人认证

束**(实名认证)

江苏

IP属地:江苏

40

积分

- 关 键 词:

-

mg100

型锚杆

钻机

液压

系统

设计

石油

cad

图纸

以及

说明书

仿单

- 资源描述:

-

- 内容简介:

-

大庆石油学院本科生毕业设计(论文)1Anchor drilling Document Type and Number:United States Patent 4201270 Abstract:An operator controlled roof bolter with a flexible shaft drill and a roof bolt inserter for drilling and inserting a roof bolt into an unsupported roof of a mine while the operator is positioned at an outby station under a supported roof. The flexible shaft roof drill is constrained to a frame of the roof bolter for pivoting movement between a rest position and a working position. The roof bolt inserter is mounted on a slide for linear movement and limited rotational movement between a retracted position and an extended position for positioning a roof bolt held by the inserter into registration with a hole drilled by the roof drill. Inventors:Ribich, William A. (Lexington, MA, US)Hug, Hans A. (Weston, MA, US)Bellows, Alfred H. (Belmont, MA, US)Application Number:906237 Filing Date:05/15/1978 Publication Date:05/06/1980 Primary Class:173/193Other Classes:81/57.25, 81/57.41, 173/46, 173/52, 405/259.1, 405/303.BACKGROUND OF THE INVENTION 1. Field of the Invention The present invention relates to the supporting of underground mine roofs and, more particularly, is directed towards an apparatus for drilling holes in the roof of a mine and for inserting roof bolts into such holes.2. Description of the Prior Art In underground mines, the roof is supported by roof bolts which are inserted into holes drilled into the roof strata. An apparatus for drilling holes having a depth substantially greater than the height of the mine passageway in which the apparatus is located is described in U.S. Pat. No. 4,057,115. An apparatus for inserting roof bolts into the drilled holes is described in U.S. Pat. No. 4,003,233. Although progress has been made in roof bolting apparatus, roof bolting remains one of the most hazardous mining occupations for several reasons. The operator inserting the roof bolt is stationed inby at an area in which the roof is unsupported. It is the operators task to drill and to insert roof bolts in this unsupported area. Consequently, the operator is exposed to the hazard of having sections of the unsupported roof fall on him. Mine personnel have been injured by flying objects from the exposed rotating drill steel and tools employed to tighten the roof bolts. Workers are also exposed to the risk of being caught on and pulled into the rotating portions of the mining apparatus. 大庆石油学院本科生毕业设计(论文)2Attempts to develop roof bolters which are capable of remotely installing bolts have been met with limited success even for the simplest case when the bolts are shorter than the height of the mine passageway. Such attempts have resulted in complex and costly systems which suffer from low reliability due to many moving parts and continual readjustment. A need has arisen for an improved roof bolting system which does not suffer from the heretofore mentioned disadvantages.What is claimed is: 1. An operator controlled roof bolting system for drilling holes in the roof strata of a mine and for inserting roof bolts into the drilled holes while the operator is in a safe area, said system comprising:(a) a frame with an outby operators station; (b) roof drill means for drilling a hole in the roof strata, said roof drill means mounted to said frame for pivotal movement about an axis between a rest position and a working position; (c) first means operatively connected to said roof drill means and said frame for pivotally moving said roof drill means about said axis between said rest position and said working position: (d) roof bolt inserter means for inserting a roof bolt into a hole drilled in the roof strata by said roof drill means, said roof bolt inserter means mounted to said frame for movement between a retracted position and an extended position, said roof bolt inserter means including slide means mounted to said frame for pivoting movement about said axis; and(e) second means operatively connected to said roof bolt inserter means and said frame for moving said roof bolt inserter means between said retracted position and said extended position, said roof bolt inserter means proximate to said operators station when in said retracted position, whereby the operator can place a roof bolt in said roof bolt inserter means while remaining at said operators station. 2. The system as claimed in claim 1 wherein said roof drill means is a flexible shaft roof drill. 3. The system as claimed in claim 1, wherein said roof drill means is a longer-than-seam height drill. 4. The system as claimed in claim 1 wherein said roof bolt inserter means includes a working head mounted to said slide means, said slide means pivotally mounted to said frame, third means operatively connected to said slide means and said frame for pivotally moving said slide means about said axis. 5. The system as claimed in claim 1, including a plate for pushing a roof bolt inserted into the drilled hole and plate means for moving said plate into engagement with the roof bolt, said plate means connected to said frame and said plate. 6. An operator controlled roof bolting system for drilling holes in the roof strata of a mine and for installing roof bolts into the drilled holes while the operator is in a safe or supported area, said system comprising: (a) a frame; (b) roof drill means for drilling a hole in the roof strata, said roof drill means configured to drill a hole having a depth which is greater than the height of the mine, said roof drill 大庆石油学院本科生毕业设计(论文)3means mounted to said frame for pivoting movement about an axis between a rest position and a working position; (c) first actuator means operatively connected to said roof drill means and said frame for pivotally moving said roof drill means about said axis; (d) roof bolt inserter means for inserting a roof bolt into a hole drilled in the roof strata by said roof drill means, said roof bolt inserter means including slide means and a working head, said slide means mounted to said frame for pivoting movement about said axis, said slide means linearly movable between a retracted position and an extended position, said working head carried by said slide means and linearly movable between said retracted position and said extended position, said working head configured to insert a roof bolt having a length which is no longer than the height of the mine into a hole drilled by said roof drill means, said drill means and said roof bolt inserter means independently movable about said axis; (e) second actuator means operatively connected to said slide means for linearly moving said slide means between said retracted position and said extended position; (f) third actuator means operatively connected to said slide means and said frame for pivotally moving said working head about said axis; (g) said roof bolt inserter proximate to said operators station when in said retracted position, whereby the operator can place a roof bolt in said roof bolt inserter while remaining at said operators station. 7. The system as claimed in claim 6 wherein said roof drill means includes a drill and an arm, said drill carried by said arm, fourth actuator means operatively connected to said drill and said arm for moving said drill relative to said arm, said drill constrained for substantially vertical movement relative to said arm, said arm pivotally mounted to said frame for movement about said axis. 8. The system as claimed in claim 7 including torquer means mounted to said working head, said torquer means configured to engage the inserted roof bolt and to tighten the roof bolt to a perdetermined torque. 9. An operator controlled roof bolting system for drilling holes in the roof strata of a mine and for inserting roof bolts into the drilled holes while the operator is in a safe area, said system comprising: (a) a frame with an outby operators station; (b) roof drill means for drilling a hole in the roof strata, said roof drill means pivotally mounted to said frame for pivotal movement about a first axis between a rest position and a working position; (c) first means operatively connected to said roof drill means and said frame for pivotally moving said roof drill means about said first axis between said rest position and said working position; (d) roof bolt inserter means for inserting a roof bolt into a hole drilled in the roof strata by said roof drill means, said roof bolt inserter means slidably mounted to said frame for slidable movement between a retracted position and an extended position; said roof bolt inserter means including a working head and slide means, said slide means pivotally mounted to said frame; 大庆石油学院本科生毕业设计(论文)4(e) second means operatively connected to said roof bolt inserter means and said frame for slidably moving said roof bolt inserter means between said retracted position and said extended position; and (f) third means operatively connected to said slide means and said frame for pivotally moving said slide means about said first axis; (g) said roof bolt inserter means proximate to said operators station when in said retracted position, whereby the operator can place a roof bolt in said roof bolt inserter means while remaining at said operators station. 10. An operator controlled roof bolting system for drilling holes in the roof strata of a mine and for inserting roof bolts into the drilled holes while the operator is in a safe area, said system comprising: (a) a frame with an outby operatorstation; (b) a flexible shaft roof drill for drilling a hole in the roof strata, said roof drill mounted to said frame for movement between a rest position and a working position; (c) first means operatively connected to said roof drill and said frame for moving said roof drill between said rest position and said working position; (d) roof bolt inserter means for inserting a roof bolt into a hole drilled in the roof strata by said roof drill, said roof bolt inserter means mounted to said frame for movement between a retracted position and an extended position; (e) second means operatively connected to said roof bolt inserter means and said frame for moving said roof bolt inserter means between said retracted position and said extended position, said roof bolt inserter means proximate to said operators station when in said retracted position, whereby the operator can place a roof bolt in said roof bolt inserter means while remaining at said operators station; (f) third means mounted to said frame; and (g) a plate mounted to said third means, said plate configured to push a roof bolt inserted into the drilled hole, said third means moving said plate into engagement with the roof bolt. SUMMARY OF THE INVENTION It is an object of the present invention to provide a roof bolting system which does not suffer from the heretofore mentioned disadvantages and limitations. A further object of the invention is to provide a simple and reliable roof bolting system for remote drilling and insertion of roof bolts, particularly bolts that are longer than the height of the mine passage. Another object of the invention is to provide a simple and reliable roof bolting system with an outby operators station for remote drilling and insertion of roof bolts in which an inserter is moved rearwardly towards an operator for reception of the bolt rather than having the bolt fed forwardly to the inserter from the operator. Such a system includes a rugged mechanism for moving the inserter which is simpler and more reliable than bolt feed systems. Yet another object of the invention is to provide an operator controlled roof bolter with a flexible shaft roof drill or other longer than seam height drill and a roof bolt inserter for drilling and inserting a roof bolt into an unsupported roof of a mine while the 大庆石油学院本科生毕业设计(论文)5operator is outby and is positioned under a supported roof. The flexible shaft roof drill is mounted to a frame of the roof bolter and is constrained for pivoted movement between a rest position and a working position. The roof bolt inserter is configured to bend and feed roof bolts having a length that is greater than the height of the mine passageway. A head of the roof bolt inserter is mounted on a slide for linear movement and limited rotational movement between a retracted position and an extended position in order to align the advancing roof bolt with a hole drilled in the roof strata of the mine by the flexible shaft roof drill. In the retracted position, the inserter is in place to receive a roof bolt from an operator without requiring the operator to leave a supported or safe area. The hole is drilled when the roof drill is in its working position. Upon completion of the drilling step, the roof drill is pivoted to its rest position and the roof bolter inserter is moved to its extended position. A controller is provided for aligning the roof bolt and the drilled hole. A hydraulically actuated plate pushes the inserted roof bolt further into the drilled hole. A torquer engages the inserted roof bolt and tightens the roof bolt to effect the roof support.大庆石油学院本科生毕业设计(论文)1锚杆钻机文件类型和号码:美国专利权 4201270 摘要:操作者控制锚杆钻机通过一个揉性轴带动钻头和一个为实现钻进的锚杆钻机桅杆的相互移动插入一根锚杆在无支护的矿井顶部,这时操作者站在被支护的巷道下面的车体旁边。因为揉性轴转动同时在一个静止位置和一个工作位置之间的运动,锚杆钻机的桅杆被固定在巷道顶部,锚杆钻机钻头安装在可作线性移动的滑道上并且在收缩位置和扩展位置之间转动,用以通过锚杆钻机在巷道顶部钻孔,并且通过螺栓将锚杆紧固在所钻的孔处。 发明家:瑞比斯,威廉一. (勒克星敦、文学硕士, 美国)哈戈,汉斯一. (费斯顿标准电池、文学硕士, 美国)布鲁斯,艾佛烈 H. (贝尔蒙、文学硕士, 美国)申请编号: 906237 文件日期: 05/15/1978 出版日期: 05/06/1980 主要种类: 173/193其他种类: 81/57.25, 81/57.41, 173/46, 173/52, 405/259.1, 405/303 发明的背景:1、发明的领域现在的发明领域涉及到地下的矿井巷道顶部的支护,并且更特别是,这种趋势正向着依靠机械装置在矿井顶部钻孔并将锚杆插入孔中的方向发展。2、之前的技术描述在地下矿井中,巷道顶部支护是通过插入户顶土层钻孔中的锚杆来实现的。机械装置能够钻孔的足够深度,要比机械装置所在的矿井出口处的高度大,这时有美国的一项专利所描述的,专利号. 4,057,115。在美国专利号为 4,003,233的专利中描述到机械装置能够将锚杆插入钻孔中。虽然进步已经在锚杆钻机装置中表现, 但是仍然有一些理由被认为锚杆支护采矿职业中最危险的。插入户顶锚杆的操作者站在没有护顶支护的区有附近。它是操作者在这钻孔而且插入锚杆不支护的区域.。结果, 操作者有遭受被不支护的护顶砸在身上甚至送命的危险.。我本人就受过伤,是由飞来的钻钢和用于紧固锚杆的工具所造成的,工人也遭受过危险而且滑进了采矿装置的旋转部分。大庆石油学院本科生毕业设计(论文)2发展很有前景且具有安装功能的锚杆钻机的尝试已经在简单的情形下取得了有限制的成功,这是当锚杆的长度短于矿井出口的高度的时候。这些尝试已经导致那些昂贵并且复杂的系统可靠性低,这些系统的可靠性低大多是由于移动部分和联系的再次调整。需要有为改进锚杆钻机系统不受前面所提到的不利因素的影响的兴起。设计要求:1、操作者控制锚杆钻机系统在矿井的护顶土层处进行钻孔并且将锚杆插入所钻的孔,这时操作者站在安全区域,上述系统包含;(1)具有远距离操作位置的结构;(2)锚杆钻机要实现在护顶土层钻孔,上述钻机意味着要有固定的结构来实现静止位置和工作位置之间关于轴向的枢轴运动;(3)首先要实现锚杆钻头和上述结构的有效的连接来实现钻机静止位置和工作位置之间沿轴线方向的枢轴运动;(4)锚杆钻机插锚作业就是要实现在护顶土层中通过锚杆钻机所钻的孔中插入锚杆,上述锚杆的插入过程是通过该结构在收缩位置和扩展位置之间的运动来实现的,锚杆插入过程也包括上述机构的滑动和沿轴线方向的枢轴运动;(5)其次要实现收缩位置和扩展位置之间的锚杆钻机的隔板和锚杆插入机构运送的有效连接,当在缩回位置时锚杆钻机的隔板离操作者的工作位置最近,这就是当时操作者为何能够将锚杆插入其所要插入的孔中。2、锚杆钻机系统在上述的要求 1 的基础上还要有柔性轴驱动钻头的钻进。3、锚杆钻机系统在上述的要求 1 的基础上也要有长接合高度钻杆的钻进。4、锚杆钻机系统在上述要求 1 的基础上要求锚杆钻机隔板计划包括一个能够达到上述滑动要求的动力头,上述滑动要求达到枢轴性的设计,再次要求运转的连接到滑槽和该设计,这因为枢轴性的运动是沿滑槽作轴线运动。5、锚杆钻机在系统中要求,包括一个隔板为了推进锚杆插入钻孔中并且滑板按指定的轨迹移动并与顶板锚杆接合,上述隔板要求连接到上述结构和滑板上。6、操作者控制锚杆钻机是现在矿井顶部土层钻孔并且将锚杆插入到钻孔中,这时操作者处于一个安全区域或是一支护区域,上述系统包括:(1)一个结构框架;(2)钻机钻头在矿井顶部土层的指定位置钻孔,上述钻机钻头计划对具有一定深度钻孔进行组态,该深度大于矿井出口的高度,上述钻机钻头应达到隔板在静止位置和工作位置之间的关于轴线方向的枢轴运动;(3)首先执行机构按照要求有效的连接到锚杆钻机钻头和钻机钻头计划关于轴线方向的枢轴运动的机构上;(4)锚杆钻机隔板按指定的要求将一根锚杆插入在矿井顶部土层由锚杆钻机钻头工具所钻的孔中,上述锚杆钻机隔板工具包括滑道工具和一个动力头,上述滑大庆石油学院本科生毕业设计(论文)3道工具要达到按照关于轴线方向的枢轴性运动的机架上,该滑道的线性运动是在收缩位置和扩展位置之间进行的,上述动力头是经过滑道工具和在收缩位置和扩展位置之间的线性运动被运送的,该动力头对一组具有一定长度的锚杆进行组态,该长度是不再比进入并在其内由上述锚杆钻机钻头钻孔的矿井出口的高度长的长度,上述的钻头工具和锚杆钻机隔板工具是关于轴线方向独立运动的;(5)其次钻机执行机构有效的连接到具有指定的线性运动的滑道上,该滑道是在上述的收缩位置和扩展位置之间;(6)第三执行机构有效的连接到上述滑道工具和上述动力头关于轴线方向的枢轴运动的机架上;(7)当在收缩位置是上述锚杆钻机隔板距离上述操作位置最近,凭此操作者站在上述的操作位置就可以控制锚杆钻机隔板将锚杆装入。7、锚杆钻机系统在要求的基础上要求上述钻机

- 温馨提示:

1: 本站所有资源如无特殊说明,都需要本地电脑安装OFFICE2007和PDF阅读器。图纸软件为CAD,CAXA,PROE,UG,SolidWorks等.压缩文件请下载最新的WinRAR软件解压。

2: 本站的文档不包含任何第三方提供的附件图纸等,如果需要附件,请联系上传者。文件的所有权益归上传用户所有。

3.本站RAR压缩包中若带图纸,网页内容里面会有图纸预览,若没有图纸预览就没有图纸。

4. 未经权益所有人同意不得将文件中的内容挪作商业或盈利用途。

5. 人人文库网仅提供信息存储空间,仅对用户上传内容的表现方式做保护处理,对用户上传分享的文档内容本身不做任何修改或编辑,并不能对任何下载内容负责。

6. 下载文件中如有侵权或不适当内容,请与我们联系,我们立即纠正。

7. 本站不保证下载资源的准确性、安全性和完整性, 同时也不承担用户因使用这些下载资源对自己和他人造成任何形式的伤害或损失。

人人文库网所有资源均是用户自行上传分享,仅供网友学习交流,未经上传用户书面授权,请勿作他用。

川公网安备: 51019002004831号

川公网安备: 51019002004831号