φ3200×3100格子型球磨机设计【7张CAD图纸和说明书】

收藏

资源目录

压缩包内文档预览:(预览前20页/共52页)

编号:6050831

类型:共享资源

大小:2.09MB

格式:ZIP

上传时间:2017-11-02

上传人:俊****计

认证信息

个人认证

束**(实名认证)

江苏

IP属地:江苏

40

积分

- 关 键 词:

-

格子

球磨机

设计

cad

图纸

以及

说明书

仿单

- 资源描述:

-

- 内容简介:

-

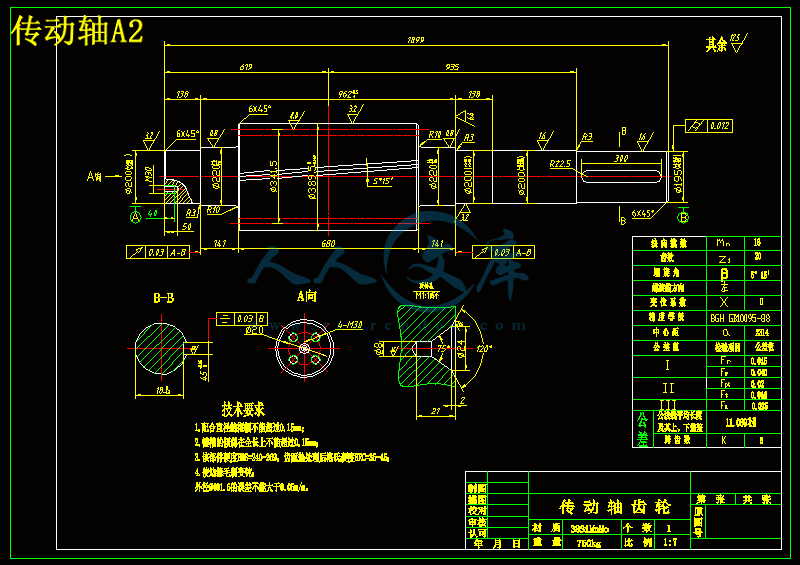

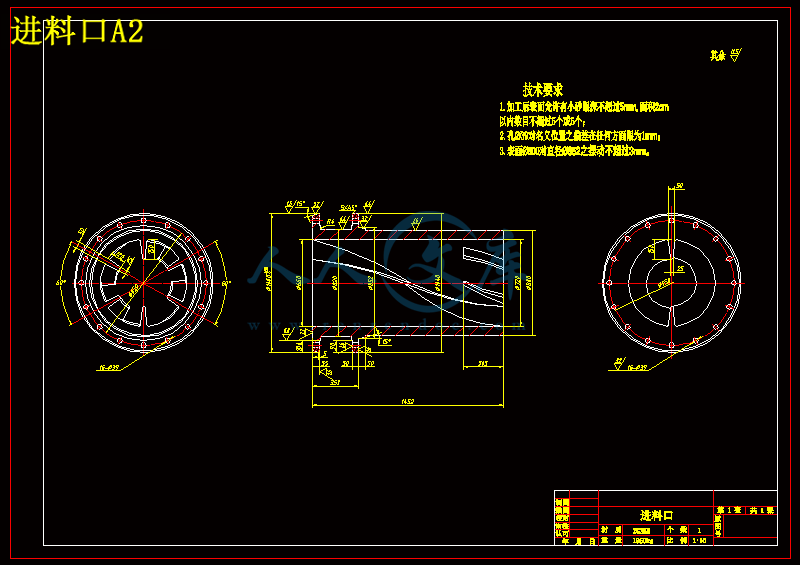

第 I 页32003100 格子型球磨机设计摘要球磨机是选矿厂生产的关键设备之一。在矿山生产中,球磨机作为主要的生产设备,其运转率和效率常常决定了全厂的生产效率和指标,成为全厂生产的“ 咽喉”环节。球磨机是继破碎机之后,对矿石或其它物料继续进行粉碎,旨在获得工艺所要求的更细颗粒产品的机械设备。本文介绍了球磨机的基本理论,包括球磨机的工作原理、构造以及未来的发展趋势等。简单介绍了球磨机设计的一般过程。并以减少能耗为基础, 详细的阐述了 32003100 格子型球磨机传动系统中各个零部件的设计和计算。球磨机的传动部由大齿轮装置、小齿轮装置、齿轮罩,同步 电动机等部分 组成。在本次设计中除了继承传统的方案设计以外,还采用了一些当前世界上比较先进的设计方案,增强了传动性能,增加了磨机的寿命,使球磨机更加具有市场竞争力。关键词:球磨机;传动系统;设计 第 II 页32003100 Check ball mill designAbstractThe ball mill is one of ore dressing plant production essential equipment. In the mine production, the ball mill took the main production equipment, its service factor and the efficiency had decided frequently the entire factory production efficiency and the target, become the entire factory production “the pharynx and larynx” the link. Ball mill is the machine that continues to crush and grind the ore and other materials, after the crusher working procedure ,in order to get finer products that correspond the technology prescribed.IN this thesis ,I introduced the basic theories of ball mill ,including the theory of its work ,structure and the trend of it is design in brief .In order to improve the skills of production ,in this thesis ,I expatiate the design and calculation of every work and part of32003100 stick in wet pattern ,belonging to drive system . the drive system concludes gearwheel part ,pinion part ,gear covers part ,synchronous electric motor and so on .During this design ,we not only inherit the traditional methods ,but use the advanced methods now days ,that develop the capability of the machine and prolong ,its service life to make the ball mill has the competition ability in market .Key words: ball mill; drive system; design 第 III 页目 录1 绪论.11.1 选题背景及目的.11.2 国内外球磨机的发展状况及研究成果.11.3 课题的研究内容及方法.72 总体方案设计.82.1 磨矿机的主要类型.82.1.1 圆筒式磨矿机的类型.82.1.2 旋转筒式磨矿机的工作原理.102.2 总体思路的选择.112.3 主要部件概述.112.3.1 筒体部.112.3.2 给矿部.112.3.3 排矿部.122.3.4 轴承部.122.3.5 传动部.122.3.6 润滑系统.132.4 球磨机内粉磨介质的运动状态.133 球磨机主要参数的分析计算.153.1 球磨机筒体的一般尺寸.153.2 球磨机转速的计算.153.2.1 球磨机的临界转速153.2.2 球磨机的实际工作转速153.3 球磨机内球的脱离点轨迹计算.163.4 球的落点轨迹的计算.17 第 IV 页3.5 球的循环次数的计算.183.6 球磨机中介质充填率的计算.193.7 球磨机中装球量的计算.213.8 球磨机功率的计算.213.9 球磨机生产率的计算.233.10 球磨机工作时筒体的受力分析.233.11 筒体的强度计算.264 传动系统设计计算.294.1 主电机的选择及传动比的分配.294.1.1 电动机的选择294.1.2 传动比的分配294.2 传动装置的运动和动力参数的选择和计算.294.3 传动零件的设计计算.304.3.1 齿轮减速器的设计计算304.3.2 齿轮轴的设计计算354.3.3 滚动轴承的选择和寿命验算394.3.4 键联接的选择和验算404.3.5 两大齿圈处的螺栓的联接的选择404.3.6 齿轮减速器的润滑和密封424.4 齿轮罩的总体布局设计.425 球磨机的安装与试车.435.1 球磨机的安装简介.435.1.1 球磨机总体安装顺序概述435.1.2 大齿轮的安装43 第 V 页5.1.3 小齿轮装置的安装435.1.4 联轴器、气动离合器、主电机和慢速装置的安装445.1.5 齿轮罩的安装445.2 球磨机的试车.445.2.1 无负荷试车.445.2.2 负荷试车456 球磨机的环保和经济性分析.47结束语.48致谢.49参考文献.50 第 1 页球磨机磨损的推断模型摘要:球磨机,典型矿物加工业,被用于将大小分布的矿石磨成别的。磨损与影响研磨性能的钢球电荷方面的细碎机械学的建立联系在一起。在本研究中,球磨机磨损与研磨工作参数有关,决定使用一种数学磨损模型。这种磨损模型联合在压碎过程中能量的消散和填装层的磨损区段同粘着力和磨损描述。这种模型已经被加到钢球装填层运动模型,球磨机磨损率的模拟实验以及球磨机的元件磨损和它的对研磨性能的影响。现有模拟结果显示了在磨损和研磨性能之间的交互作用。更深入的研究是用工业日期确认装填层和磨损模型的答案。1997 年,加拿大采矿和冶金学会。由 Elsevier Science Ltd 出版。引言粉碎,磨碎到微粒,磨成粉都是用于该矿产加工工业的水磨程序的同义名词。与这些过程有关联的是金属磨损,加拿大和美国的年度消耗钢铁量达 300 000 吨。磨损也影响着研磨性能和品质。在这一篇论文中,磨损的推断模型的预测对减少工序磨损、保持研磨性能和品质最理想的磨损状况的决定是必需的。磨损和它与磨损有关机械学原理已经被广泛的应用在2-4期实验数据上,有用的模型对磨损现象的理解在5-9期实验数据上,理论研究在10-12期实验数据上。这篇论文的目的是根据球磨机水磨工序理论的发展而做出的磨损模型的推测。背景球磨机(图 1 所示)是由许多相互联系和相互作用的零件组合成的一个体系,这些零件组合起来是为了磨碎矿石。这种机械粉碎法的工序是由一些特殊的钢球组成的球磨机的零件用来磨碎矿石的过程。同时,这些球在球磨机工作期间能够很好地建成球磨机的填装层的轮廓,如图 2 所示。填装层的轮廓标志描绘为三个有典型破碎特性的区域。研磨区段是由彼此滑动球层数描述,磨碎它们之间的矿石;翻滚的区域是在低能量的冲击下对钢球相互的滚动和磨碎矿石的描述。击碎的区域是在高能量的冲击下对钢球的飞行和击碎矿石的描述。 第 2 页填装层的轮廓的形成是直接地依靠存在填装层和球磨机滚筒壁之间的摩擦力。通过用不同的衬板轮廓,摩擦力也可改变由此而生的影响球磨机轮廓的形式。轮廓运动模型如上述所提。球磨机磨损是能量转移的作用在衬板和球轮廓之间以及在二个碰撞的球之间。因此,塑造轮廓运动模型是预测球磨机磨损和对研磨的影响的作用第一步。模型的发展开始以单个的球的运动为对象(如图 4)。如所描述由 Mclvor 和Powell 15、16,在球磨机中单个球飞行的问题是由转动速度,滚筒半径,静摩擦 第 3 页因子和轮廓的角度决定:(1)cosarsin0g无论如何,Hukki 17 提及球轮廓的运动不是全部依靠一个的单点飞行如假设上述等式。它也是依靠描述球轮廓和衬板类型相互联系的有效的摩擦因子是否和我的差不多。 第 4 页所以,如果我们描述动力传递损耗在二球层数之间作为静态和运动摩擦因子17之间的 一个关系;(2)skV10.62旋转的动力传递损耗速度为:(3)Rsin1使用这个结果,我们可以区分球飞行和点稳定的动力传递损耗之间如下:1. 飞行的问题 (1.0)(4) sos garctnsarcsinarctn22. 稳定的动力传递损耗问题(1.0)(5) kok gRarctnosarcsinarctn2有效的摩擦因子被定义为;(6)2arctnt s用这些关系与被描述的那些一起18-20和应用于他们描述离散的球填充层的质点 第 5 页系,它变得可能模仿球填充运动(如图 5 所示)。因而被定义为填充层运动,我们在各种各样的粉碎区域在填充外形可以通过确定被消耗的运动和分布能量(如图 2),使用下式18-21:(7)efinci iiconsumedmrE1os 第 6 页(8)ngi ciikgrind rNE1(9)tvmEgdmtv ibtumblingbi ibcrushingbiib 222 1:1在球磨机中这种能量轮廓(如图 6)现在被确定为 Hardinge 磨机( 如图 1)。这个轮廓运动模型确定显示能量怎么在研磨,击碎和翻滚时被消耗后分布作为磨机转动速度、滚筒直径、填充层和衬板表示法功能。磨损率的估计如前面所提到,在球磨机的球轮廓的运动外形有三个粉碎区域。虽然有别的磨损机械学的存在,只有胶粘剂和磨蚀是与这些粉碎区域有联系。同翻筋斗和击碎区域联系在一起,当球在这些区域碰撞,当黏着性磨损联系到研磨区域时,球滑过另一个球或越过另一个球。这些机制可以被表达,根据在23-24磨损的能量率而做黏着性磨损(10)EHPmrst3腐蚀磨损(11)grrst)an(运用这些磨损模型于球磨机的情况,我们可以得出:(12)grrststjhEHm)an(13)rumcrgrcrstjh EHpP33)(14)stjwsbjstjom比较最初和最后的衬板磨损外形,衬板磨损率可以被估计使用:(15)TnALmmststjw我们可以通过比较公式(15)和公式(12)确定磨蚀因素,因而得到: 第 7 页(16)grmwEHTnALP1tan进一步,使用公式(13)和公式(14)以及(16)的结果,我们可以尽可能地确定黏着力的大小:(17)grcsttiwatjotumcr EHEHP)an(3以磨蚀因素并且为特定球磨机操作的上下文确定的黏附力可能性,现在我们从这个上下文可以确定球磨机的磨损率的影响是怎么改变的。保持 和 P 为常数,变化的参量例如磨房转动速度和轮廓边界,我们可以推出对球磨机磨损率24 的有关的变动。然而,推测球磨机磨损率是有限的,在球磨机研磨时,考虑到我们的确定球的磨损的影响的目标时的表现。衬板磨损在球磨机研磨的表现取决于主要能量怎样被分布在球轮廓外形的各种各样的粉碎区域。如被提及,轮廓外形的形式,和每个粉碎区域的重要特性,是直接地依靠存在球轮廓和球磨机桶壁之间的摩擦力。不同的衬板轮廓类型(图 3) 在球轮廓和球磨机筒壁以及研磨的表现之间影响这中摩擦力。由于有特定的上下文,所以使用被认为优选的衬板类型的轮廓是可能的。然而,以时间,球磨机磨损将修改最初的衬板轮廓外形和随后碾碎研磨。在球磨机轮廓的力量下塑造运动形式成为推断球磨机磨损和它对研磨性能的影响的下一个步骤。在球磨机运转期间,整个轮廓大厅由重心和离心力然后施加力场组成衬板轮廓(图 7)23-25。 第 8 页用这种描述,平均的组成力可以被确定作为展示在图 8 中;(i)平均组成的离心力(18)cos(pcpFN(ii)平均组成的重力(19)s(21gqgq进一步,在球磨机衬板上面作为球磨机轮廓,球磨机轮廓的衬板部分的位移会产生一个压缩力(图 9) 。 这力量被定义如下: 第 9 页(20).CKFcom这里 xystV.通常表示为:(21)cos(mcoFN在衬板表面总的平均作用力可以成为:(22)comgqcpt N衬板磨损,作为球磨机球轮廓创造的力场的位置和强度功能以及磨蚀因素,成为:(23)surftrst VNHm)an(那里(24)cos(lsurfV指出在衬板的滑动速度由早先的公式(2)重新整理。 第 10 页在衬板离散化到 的区别,定时乘 ,这种仿真算法可以被开发之后成为23-25,包括衬板齿廓磨损的模拟实验。举例来说,图 10 中图解的一种波形衬板的轮廓磨损的模拟实验和在图 11 中现实的衬板的轮廓磨损差不多。球磨机磨损和研磨性能虽然工业上的研究需要更多这样的磨损模型,但是想象出一种弹性衬板的进化磨损的推断模型是有可能的。当然,这将计算怎样的磨损影响对研磨性能的决定,这里解释为在颗粒测定的生产能力的变化。由图 1.的 Hardinge 情况得,消逝在倾斜的衬板的现象由这里转化为模拟如图 12 所示。进一步,该图 6 的能量率曲线是怎么随这种衬板磨损而变化的,推断球磨机的输出同输入的变化一样,是有可能的。从表格 1 可以看出,使用一种已经被开发的破碎模型,可以解释衬板的寿命期限是有可能的。这里,球磨机生产能力将提高而衬板磨损下降。与这种现象相联系,球磨机能源消耗的减少如所显示。这两种现象说明最佳化球磨机的性能作为一种推断磨损影响的函数是可能的。表 1.球磨机的输出量作为衬板曲线的一个函数。颗粒大小(m)最初通过量%1/2 通过量 %最后通过量%741001503008301170165058.0868.2578.5492.1299.4599.96100.0058.2568.4478.6892.1599.4599.96100.0060.1370.3880.2593.9699.6199.97100.00 第 11 页讨论在结束这篇论文之前应该对球磨机填装层运动、衬板磨损和球磨机输出的产品做几点评论。如所示,球磨机的填装层运动依靠许多物理和操作因素;它也依靠矿浆的流变特性。当然这些矿浆的流变特性是百分比固体的作用并且矿石的性质。在填装层运动的模型中,这些因素的影响被包括在(2)滑动速度的关系中,如所描述的静态和动摩擦因素。摩擦因素的变化,如矿浆的流变特性的一个可能的变化造成的,可以增加或减少在钢球层之间和衬板磨损之间的相当数量的动力传递损耗。 第 12 页在球磨机的磨损模型和两种磨损机械学中,它只是一种假设,球磨机不是空转的或者运转状况不直接地把钢球放到球磨机衬板里。在这样的情况下,衬板磨损同磨损机械学一样(表面,破裂,磨损) ,都增加了衬板的磨损率。球磨机产品的变化的重要性与衬板的磨损有关,是从属与一种特殊的矿石的破碎特性。同样地,检验使用的工业数据为了确定这个模型精确度是必要的。然而,假设,整体模型的一个充分检验是可能的,这里被提出的初步结果表示,考虑使用这个模型 第 13 页为球磨机优化作为能源消耗和球磨机衬板磨损功能变得可能。结论这篇论文根据球磨机的一个理论描述提出了一个有预测性的衬板磨损模型。当包括一个简单的胶粘剂和磨损模型的应用对一个复杂的钢球填装层模型时,不仅能确定必要的磨损参数,而且推断衬板和研磨性能是可能的。无论如何,进一步的研究对模型的检验和参数确定是必要的。尽管这是必要的,但在将来,球磨机在设计和操作方面的优化也有了可能性。鸣谢-本文的出版物由加拿大研究经费自然和工程研究委员会使成为可能。 第 1 页PREDICTIVE MODEL FOR BALL MILL WEARAbstract-ball mills, characteristic of the mineral processing industry, are used to reduce ore from one size distribution to another. Wear is associated with comminution mechanisms found in the ball charge which in turn affects grinding performance. In this work, ball mill wear, as a function of mill operating variables, is determined using a mathematical wear model. The wear model incorporates the energy dissipated in crushing, tumbling and grinding zones of the charge profile with adhesive and abrasive wear descriptions. This model has been added to a ball charge motion model allowing the simulation of mill wear rates as well as ball mill element wear and its affect on grinding performance. Simulation results presented show the interaction between wear and grinding performance. Further work is necessary to validate charge and wear model results using industrial date. 1997 Canadian Institute of Mining and Metallurgy. Published by Elsevier Science Ltd.INTRODUCTIONTo comminute, to reduce to minute particles, to pulverize, are all synonyms of grinding processes used in the mineral processing industry. Associated with these processes is metal wear which in Canada and the United States represents an annual consumption of some 300 000 tons of iron and steel 1. Wear also affects grinding performance and quality. In such a context, predictive wear models become a necessity to determine optimal grinding conditions that reduce process wear while maintaining grinding performance and quality.Wear and its mechanisms related to grinding has been studied extensively using experimental data 2-4, models useful to understanding of wear phenomena 5-9 and theoretical studies 10-12.The goal of this paper is the presentation of a predictive wear model based on a theoretical development for one such grinding process, the ball mill.BACKGROUNDThe ball mill (Fig.1) is a system composed of a number of interrelated and interactive elements that work together in order to grind a given ore. This comminution process is achieved by the individual balls which constitute the actual ball mill element that brings about 第 2 页ore breakage. Together, these balls form the mill ball charge which, during ball mill operation, typically has a charge profile as found in Fig.2.Note that the charge profile shows three zones that are characterized by the type of breakage occurring there. The grinding zone is described by ball layers sliding over one another, breaking the material trapped between them; the tumbling zone is described by balls rolling over one another and breaking the material in low-energy impact; the crushing zone is described by balls in flight re-entering the ball charge and crushing the material in high-energy impact.The form of the charge profile is directly dependant on the friction force existing between 第 3 页the charge and the ball mill wall. By the use of different liner profile (Fig.3), the friction force can be changed subsequently affecting the form of the mill charge as well.Charge motion modelAs mentioned. Mill wear is a function of the energy transferred between liner and ball charge as well as between two colliding balls. Therefore, modelling charge motion is a first step to predicting mill wear and its effect on grinding.Model development starts with defining single ball motion (Fig.4). As described by Mclvor and Powell 15、16, the point of flight of a single ball in a ball mill can be determined as a function of rotation speed, mill radius, static friction factor and the liner lifer angle:(1)cosrsin0gHowever, Hukki 17 mentions that ball charge motion is not entirely dependant on a single point of flight as assumed with the above equation. It is also dependant on whether the effective friction factor describing the interrelationship between ball charge and type of liner used is greater or less than I. 第 4 页Therefore, if we describe slippage between two ball layers as a relationship between static and kinetic friction factors 17;(2)skV10.62Rotational slippage speed becomes:(3)Rsin1Using this result, we can differentiate between ball flight and the point of stable slippage as:1. point of flight (1.0) (4) sosgRarctnsarcsinarctn22. point of stable slippage (1.0)(5) kokgarctnsarcsinarctn2Where the effective friction factor is defined as;(6)2rtt sUsing these relationships along with those described in 18-20 and applying them to a system of particles that describe a discretized ball charge, it becomes possible to simulate ball charge motion (Fig. 5). 第 5 页Having thus defined charge motion, we can further this development by determining energy consumed and distributed in the various comminution zones on the charge profile (Fig, 2) using the following equations 18, 21:(7)efinci iiconsumed mrE1os(8)ngi ciikgrind rN1 第 6 页(9)tvmEgdmtv ibtumblingbi ibcrushingbiib 222 1:1The energy profile (Fig. 6) in a ball mill can now be determined as for the Hardinge mill of Fig. 1. Note that this charge motion model determines how energy is consumed and then distributed in grinding, crushing and tumbling as a function of mill rotation speed, mill diameter, ball charge and liner representation.Wear rate estimationAs mentioned earlier, there are three comminution zones in the ball charge motion profile. Although other wear mechanisms exist, only adhesive and abrasive wear are associated here with these comminution zones. Adhesive wear is associated with the tumbling and crushing zone as balls in these zones collide while abrasive wear is associated to the grinding zone where balls slide pass one another or over the null liner. These mechanisms can be expressed in terms of energy rate used in wear as 23-24:adhesive wear(10)EHPmrst3abrasive wear(11)grst)an(Applying these wear models to the ball mill case, we write;(12)grststjhEHm)a(13)rumcrgrcstjh EHpP3n(14)stjwsbjstjoComparing initial and final liner wear profiles, liner wear rate can be estimated using:(15)TnALmmststjwWe can determine the abrasion factor by equating eqn (15) with eqn (12), thus getting: 第 7 页(16)grmwEHTnALP1taFurther, using eqn (13) and eqn (14) with the result of eqn(16),we can determine the adhesion probability:(17)grcstiwatjotumcr HEP)tan(3With the abrasion factor and adhesion probability P determined for a given mill operating context, we can now determine how changes from this context affect mill wear rates. Keeping and P constant, and varying parameters such as mill rotation speed and charge column, we can predict the associated changes to mill wear rates 24. However, predicting wear rates is only of limited use when considering our goal of determining the effect of wear on ball mill grinding performance.Liner wearGrinding performance in a ball mill is determined primarily by how energy is distributed into the various comminution zone found in the ball charge profile. As mentioned, the form of the charge profile, and consequently the importance of each comminution zone, is directly dependant on the friction force existing between the ball charge and the mill wall.Different liner types (Fig.3) affect this friction force between the ball charge and the mill wall and the mill grinding performance. For a given grinding context, it is possible to use a liner type that is considered optimal. However, with time, mill wear will modify the initial liner profile and subsequently mill grinding. Modelling the forces acting on the mill liners becomes the next step to predicting mill wear and its effect on grinding.During mill operation, the hall charge exerts a force field composed of gravitational and centrifugal components on the mil liner (Fig.7) 23, 25. 第 8 页Using this description, normal force component can be determined as show in Fig.8, giving: (i) centrifugal normal component (18)cos(pcFN(ii) gravitational normal component(19)(21gqFurther, as the ball charge slip over the mill liner, a compression force is created with the 第 9 页local displacement of the mill charge by the liner (Fig.9). This force is defined as:(20).CKFcomWherexystV.The normal compression component as:(21)cos(mcoFNThe total normal force acting on the liner surface becomes:(22)comgqcpt NLiner wear, as a function of the position and intensity of the force field created by the ball charge as well as the abrasion factor 0, become:(23)surftrstVNHm)an(Where(24)cos(lsurfVNote that slippage speed on the liner is defined previously by rearrangement of eqn (2).After liner discretization into differences ,and time into , a simulation algorithm can be developed 23, 25 which allows liner profile wear simulation.As an example, Fig. 10 illustrates a wave liner profile wear simulation which is comparable 第 10 页to the real liner profile wear presented in Fig.11.MILL WEAR AND GRINDING PERFORMANCEEven though industrial studies are needed to further validate these wear models, it is possible envisage the prediction of wear evolution of a given liner type. This, of course, wou1d allow the determination of how wear affects grinding performance here defined as variations in output granulometry. For the Hardinge case of Fig.1, this translates into simulating the effect of wear on the bevel liner as shown in Fig.12.Further, simulating how the energy rate profile of Fig.6 changes with this liner wear, it is possible to predict the changes in mill output granulometry for the same input granulometry. Table 1 shows how, using a breakage model developed in 22,23, it is possible to illustrate output variation over the life period of the liner. Here, mill output becomes finer with liner wear.Associated with this phenomenon, mill energy consumption decreases as shown in Fig.13. Both these phenomena illustrate the possibility of optimizing ball mill performance as a function of the predetermined effect of wear.Table 1. Ball mill output granulometries as a function of worn liner profileParticle size(m)Initial %passing1/2 life %passingFinal %passing741001503008301170165058.0868.2578.5492.1299.4599.96100.0058.2568.4478.6892.1599.4599.96100.0060.1370.3880.2593.9699.6199.97100.00 第 11 页DISCUSSIONBefore concluding this work a few remarks should be made concerning charge motion, liner wear and associated mill output product.As shown, ba11 charge motion is dependant on a number of physical and operating factors; it is also dependant on the rheological characteristics of a given slurry. These rheological characteristics are of course a function of percentage solids as well as ore properties. In the mode

- 温馨提示:

1: 本站所有资源如无特殊说明,都需要本地电脑安装OFFICE2007和PDF阅读器。图纸软件为CAD,CAXA,PROE,UG,SolidWorks等.压缩文件请下载最新的WinRAR软件解压。

2: 本站的文档不包含任何第三方提供的附件图纸等,如果需要附件,请联系上传者。文件的所有权益归上传用户所有。

3.本站RAR压缩包中若带图纸,网页内容里面会有图纸预览,若没有图纸预览就没有图纸。

4. 未经权益所有人同意不得将文件中的内容挪作商业或盈利用途。

5. 人人文库网仅提供信息存储空间,仅对用户上传内容的表现方式做保护处理,对用户上传分享的文档内容本身不做任何修改或编辑,并不能对任何下载内容负责。

6. 下载文件中如有侵权或不适当内容,请与我们联系,我们立即纠正。

7. 本站不保证下载资源的准确性、安全性和完整性, 同时也不承担用户因使用这些下载资源对自己和他人造成任何形式的伤害或损失。

人人文库网所有资源均是用户自行上传分享,仅供网友学习交流,未经上传用户书面授权,请勿作他用。

川公网安备: 51019002004831号

川公网安备: 51019002004831号