钢锥锥轮式的无级变速器的传动与设计【6张CAD图纸和说明书】

收藏

资源目录

压缩包内文档预览:

编号:6066178

类型:共享资源

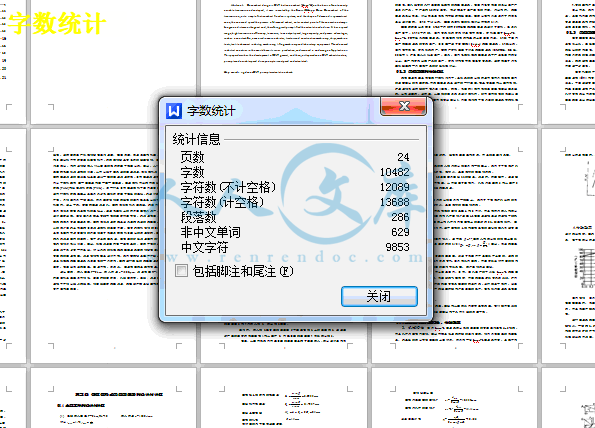

大小:1.41MB

格式:ZIP

上传时间:2017-11-04

上传人:俊****计

认证信息

个人认证

束**(实名认证)

江苏

IP属地:江苏

40

积分

- 关 键 词:

-

钢锥锥

轮式

无级

变速器

传动

设计

cad

图纸

以及

说明书

仿单

- 资源描述:

-

- 内容简介:

-

On the design of slider-crank mechanisms. Part I:method is twofold. First, multiple phases of prescribed rigid body positions are achievable using a mech-*Corresponding author. Tel.: +1 973 596 3362; fax: +1 973 642 4282.E-mail address: sodhi (R.S. Sodhi)./locate/mechmtMechanism and Machine Theory 40 (2005) 285299MechanismandMachine Theory0094-114X/$ - see front matter C211 2004 Elsevier Ltd. All rights reserved.anism with fewer moving parts than the planar four-bar mechanism. Second, the slider-crank motion gen-erator can achieve phases of prescribed rigid body positions without any physical or automatedadjustments of its moving pivots between phases. A slider path that enables the slider-crank motion gen-erator to achieve two phases of prescribed rigid body positions is designed by using 7th order polynomialsto connect the moving pivot paths of the follower link of the adjustable planar four-bar motion generator.This polynomial generates smooth radial displacement, velocity, acceleration and jerk proles with bound-ary conditions that can be prescribed. The example problem in this work considers a two-phase movingpivot adjustment of a planar four-bar mechanism.C211 2004 Elsevier Ltd. All rights reserved.multi-phase motion generationKevin Russella, Raj S. Sodhib,*aArmaments Engineering and Technology Center, US Army Research, Development and Engineering Center,Picatinny Arsenal, NJ 07806-5000, USAbDepartment of Mechanical Engineering, New Jersey Institute of Technology, Newark, NJ 07102-1982, USAReceived 24 February 2003; received in revised form 12 July 2004; accepted 12 July 2004Available online 28 September 2004AbstractA method for designing slider-crank mechanisms to achieve multi-phase motion generation applicationstypically accomplished by adjustable planar four-bar motion generators is presented. The benet of thisdoi:10.1016/j.mechmachtheory.2004.07.0091. IntroductionPlanarfour-barmechanismsarewidelyusedinmechanicalsystemsanddevices.Duetothepla-nar kinematics, joint type and joint axis orientations of the planar four-bar mechanism, it can bepractical to design and implement these mechanisms (compared to most four-bar spatial mecha-nisms). In addition, an extensive array of graphical and analytical design and analysis methodsexists for planar four-bar mechanisms.Motion generation problems in mechanism synthesis require that a rigid body be guidedthrough a series of prescribed positions. The four-bar linkage shown in Fig. 1 can be used to pro-duce this motion by making the rigid body as a part of its coupler link. Fig. 2 shows motion gen-erationforthethreepositionsinanassemblymachine.Anidealmotionofthecouplercanonlybeapproximated by several discrete precision positions. Since a linkage has only a nite number ofsignicant dimensions, the designer may only prescribe a nite number of precision points. Afour-bar linkage can satisfy up to ve prescribed positions for the motion generation problem.However, an adjustable four-bar linkage can satisfy more than ve given positions with the sameCoupler286 K. Russell, R.S. Sodhi / Mechanism and Machine Theory 40 (2005) 285299Fig. 1. Planar four-bar mechanism.Fig. 2. Planar four-bar loading mechanism.K. Russell, R.S. Sodhi / Mechanism and Machine Theory 40 (2005) 285299 287hardware. The moving pivots of a four-bar linkage can beadjusted in two dierent ways: withadjustable crank/follower lengths (Fig. 3) and with xed crank/follower link adjustments (Fig. 4).The adjustable linkages can provide solution for two phases of general plane motion (Fig. 5). Ifa four-bar linkage is designed to reach positions 1, 2 and 3 in phase 1, after the adjustments, theFig. 3. Adjustable crank length.Fig. 4. Fixed crank length.PHASE ONEPHASE TWO412356Fig. 5. Two phases of prescribed rigid body positions.same linkage can reach three new positions 4, 5 and 6 in the second phase 2. Both phases of mo-tioncanbeaccomplishedusingthesamehardwarebyadjustingoneormoreofthelinkageparam-eters. The linkage can create the motion precisely at these positions and will approximate themotion at other positions. The more precision positions are used, the closer to the ideal motionis the actual motion of the coupler.In the area of adjustable linkages for motion generation, published work is somewhat limited119. Previous work includes the work of Ahmad and Waldron 1 who developed a techniquefor synthesizing a four-bar linkage with adjustable driven xed pivot. They solved two-phaseproblemswith a maximumtotal numberofvepositions. Tao andKrishnamoorthy 2 developedgraphical synthesis procedures to generate variable coupler curves with cusps. McGovern andSandor 3,4 presented methods to synthesize adjustable mechanisms for function and path gen-eration using complex variables. Funabashi et al. 5 presented general methods to design planar,sphericalandspatialmechanismswhichcanadjustinputoutputrelationships.Shoup6designedadjustable spatial slider-crank mechanism to be used as a variable displacement pump. Cheun-chom and Kota 7 have presented general methods for the synthesis of adjustable mechanismsusing adjustable dyads. Wilhelm 8 developed synthesis techniques for two-phase motion gener-ation problems of adjustable four-bar linkages. Wang and Sodhi 9 developed solutions for thetwo-phase adjustable moving pivot problems with three positions in each of the two phases. Rus-sell and Sodhi 10,11 recently presented methods for synthesizing adjustable three-dimensionalmechanisms for multi-phase motion generation with tolerances. Using these methods, spatialRRSS mechanisms can be synthesized to achieve phases of prescribed precise rigid body positionsand rigid body positions with tolerances. Recently Chang 12 presented synthesis of adjustablefour-bar mechanisms generating circular arcs with specied tangential velocities.If there is any performance-related limitation to the adjustable planar four-bar mechanism, it isthat manual or automated adjustments are required to achieve all of the prescribed phases inmulti-phase applications. Manual adjustments can be time consumingespecially if the adjust-mentprocedureis involvedandthemechanismadjustmentsmustbeperformedfrequently.Imple-mentingautomatedadjustmentcapabilitiesmaymakethemechanismimpracticalfromanancialstandpointespecially when operations and maintenance expenditures are considered.For an adjustable planar four-bar motion generator that incorporates both moving pivot andlink length adjustments for the follower link and only moving pivot adjustments for the cranklink, an equivalent slider-crank motion generator can be designed to achieve multiple phases ofprescribed rigid body positions. The benets of the method are that multiple phases of prescribedrigid body positions are achievable using a mechanism with fewer moving parts than the planarfour-bar mechanism and the slider-crank motion generator can achieve phases of prescribed rigidbody positions without any physical or automated adjustments of its moving pivots betweenphases.In this work, a method to design slider-crank motion generators to achieve multi-phase motiongenerationapplicationstypicallyaccomplishedbyadjustableplanarfour-barmotiongeneratorsispresented. A slider path that enables the slider-crank motion generator to achieve two phases ofrigidbodypositionsisdesignedbyusing7thorderpolynomialstoconnectthemovingpivotpathsof the follower link of the adjustable planar four-bar motion generator. The radial displacement,velocity, acceleration and jerk parameters of the moving pivot of the follower link are also pre-288 K. Russell, R.S. Sodhi / Mechanism and Machine Theory 40 (2005) 285299scribed using the boundary conditions of these polynomials.2. Rigid body guidance and multi-phase motion generationThe slider-crank motion generator design method presented in this work is adaptable to virtu-ally any multi-phase motion generation method available that incorporates moving pivot adjust-ments with xed and adjustable crank and follower lengths respectively. The authors 10,11developed the multi-phase motion generation method utilized in this work.The planar four-bar motion generator is illustrated in Fig. 6. In this work, linka0a1is the des-ignated crank link and linkb0b1is the designated follower link. Links a0a1andb0b1of the pla-narfour-barmechanismmustsatisfytheconstantlengthconditiononlysinceitsxedandmovingpivot joint axes remain parallel. Given a xed pivot b0and a moving pivot b1the constant lengthcondition in Eq. (1) 20,21 must be satised whensynthesizing the crank and follower links of theplanar four-bar mechanism.bjC0b0TbjC0b0b1C0b0Tb1C0b0 j 2;3; .; n 1whereb0b0x; b0y;1 b1b1x; b1y;1 bjDijC138b1Eq. (1)followerK. Russell, R.S. Sodhi / Mechanism and Machine Theory 40 (2005) 285299 289jajjpYbpXrjji01a0a1bbqrqiiOne objective of this work is to design an equivalent slider-crank motion generator for anadjustable planar four-bar motion generator. Although the moving pivots of both the crank111 111can be rewritten as Eq. (3). In Eq. (3), the variable R represents the length of the crank orlink.andDijC138pjxqjxrjxpjyqjyrjy264375pixqixrixpiyqiyriy264375C012Fig. 6. The planar four-bar motion generator with rigid body points p, q and r.and follower link of the planar four-bar mechanism are adjustable, only the length of the followerlink will be adjusted (not the crank link). By doing this, the equivalent slider-crank motion gen-erator to be designed will have a xed crank link length and a slider path that accounts for theadjustment of the follower link.bjC0b0TbjC0b0R2j 2;3; .n 3Eq.(2)isarigidbodydisplacementmatrix.Itisaderivativeofthespatialrigidbodydisplacementmatrix 20,21. Given the coordinates for a rigid body in position i and the subsequent j, ma-trixDijis the transformationmatrixrequiredtotransformcoordinatesfrom positioni toposi-tionspace.singlepointandadisplacementangle(pand h forexample),theauthorschosetodescribetherigidPrescribedNumber290 K. Russell, R.S. Sodhi / Mechanism and Machine Theory 40 (2005) 285299Number of unknowns Number of free choices15 4 028 6311 8mrigid body position and phase variations for the adjustable planar four-bar mechanismof phases Maximum number of rigid body positions Crank or follower linksbody using three points for computational purposes. If the user prefers to describe the rigid bodyusing conventional notation, the displacement matrix in Eq. (2) will be replaced with the conven-tional plane rigid body displacement matrix 20,21. Since there are four variables (b0x,b0y,b1xand b1y), a maximum of ve rigid body positions can be prescribed, with no arbitrary choiceof parameter for one phase (see Table 1).Points p, q and r should not all lie on the same line in each rigid body position. Taking thisprecaution prevents the rows in the rigid body displacement matrix (Eq. (2) from becoming pro-portional. With proportional rows, this matrix cannot be inverted.In Table 1, the maximum numbers of prescribed rigid body positions for the adjustable planarfour-bar motion generator for several phases are given. The number of xed and moving pivotcoordinates for the crank and follower links determine the maximum number of rigid body posi-tions. In the example problem in this work, an equivalent slider crank is designed to achieve atwo-phase moving pivot adjustment application for an adjustable planar four-bar motiongenerator.In the two-phase, adjustable moving pivot example problem in this work, the required un-knowns are a0, a1, a1n, b0, b1and b1n. The unknowns a0and b0represent the xed pivots of theplanar four-bar mechanism. The unknowns a1, a1n, b1and b1nrepresent the moving pivots inphase 1 and phase 2 of the planar four-bar mechanism. Since each of these unknowns has twocomponents, there are a total of 12 variables to determine.a0a0x; a0y a1a1x; a1y a1na1nx; a1nyb0b0x; b0y b1b1x; b1y b1nb1nx; b1nyTable 1j. Variablesp,qandrinEq. (2)representthepositionoftherigidbodyintwo-dimensionalAlthoughthepositionofarigidbodyintwo-dimensionalspaceiscommonlydescribedbya5+3(m C0 1) 2 + 2m 013 1 0 13 1 01D14C138b1C0b0TD14C138b1C0b0C0R2 0 113. TrajectoryAfterwillallowmovingon thewill bethem.Duringpositionsities,pivot,ing pivotK. Russell, R.S. Sodhi / Mechanism and Machine Theory 40 (2005) 285299 291jerks of the moving pivots undergo a transition from the link parameters in the former phase tothe link parameters inthe latter phase. Iftransition curvesare generatedfor the follower link, andthesesmoothdisplacement,velocity,accelerationandjerktransitionsbetweenthedeterminedpivot paths. Abrupt or discontinuous transitions will ultimately result in excessive wearslider-crank mechanism. The slider path of the equivalent slider-crank motion generatorcomprised of the moving pivot paths of the follower link and the trajectories that connectthe operation of an adjustable four-bar mechanism within a particular phase, the radialof the moving pivots of the crank and follower links are constant and the radial veloc-accelerations and jerks of these moving pivots are zero. The same holds true during movingconstant link length adjustments of the adjustable planar four-bar mechanism. When mov-and linklengthadjustments considered,the radialpositions, velocities, accelerations andtion, the user can synthesize a planar four-bar motion generator and determine the paths of itsmoving pivots. The moving pivot paths of the follower link must be connected in a manner that1D56C138b1nC0b0TD56C138b1nC0b0C0R21 0 12D57C138b1nC0b0TD57C138b1nC0b0C0R21 0 13generationincorporating the multi-phase motion generation method described in the previous sec-Eqs. (4)(8), wereused to calculateveof the six unknownsina0,a1anda1n. The variablea0xandthe link length R1are specied.D12C138a1C0a0TD12C138a1C0a0C0R21 0 4D13C138a1C0a0TD13C138a1C0a0C0R21 0 5D14C138a1C0a0TD14C138a1C0a0C0R21 0 6D56C138a1nC0a0TD56C138a1nC0a0C0R21 0 7D57C138a1nC0a0TD57C138a1nC0a0C0R21 0 8Eqs. (9)(13) were used to calculate ve of the six unknowns in b0, b1and b1n. The variable b0xand the link lengths R1and R2are specied.D12C138b1C0b0TD12C138b1C0b0C0R21 0 9D C138b C0b TD C138b C0b C0R2 0 10curves are connected piecewise to the moving pivot curves of the follower corresponding tothephasestransitionAandjerktionTheareInthisis theeight equations with eight unknowns whose solutions are292 K. Russell, R.S. Sodhi / Mechanism and Machine Theory 40 (2005) 285299a2R0225a3Rv026a1_R024a0 R023dh0_R016dR2h0dh20R017dR3h0dh30Rv018RhfRf19dRhfdhf_Rf20dR2hfdh2fRf21dR3hfdh3fRvf22work,thetermR0isthelengthofthefollowerlinkinphaseone(linkb0b1)andthetermRflength of the follower link in phase two (link b0b1n). The constraints specify a linear set ofRh0R015dRh0beforeandafterthistransition,asinglesliderpathisgeneratedthatwillaccountforthebetween phases (or follower link moving pivot adjustment).7th order polynomial 22,23 is required to specify the radial position, velocity, accelerationparametersofthemovingpivotofthefollowerlinkoftheadjustableplanarfour-barmo-generator during the transition between phases.Rha0 a1h a2h2 a3h3 a4h4 a5h5 a6h6 a7h714radial displacement, velocity, acceleration and jerk boundary conditions for this polynomial6a435h4fRfC0 R0C0_R0hfC012R0h2fC016Rv0h3fC18C19C015h3fC0_R0C0R0hfC012Rv0h2fC18C1952h2fC0R0C0Rv0hf16hfRv027a5C084h5fRfC0 R0C0_R0hfC012R0h2fC016Rv0h3fC18C1939h4fC0_R0C0R0hfC012Rv0h2fC18C19C072h3fC0R0C0Rv0hf12h2fRv028a6706RfC0 R0C0_R0hfC01R0h2fC01Rv0h3fC18C19345C0_R0C0R0hfC01Rv0h2fC18C19h7f2f6fh6f2f2v1v4. ExampleTwo-phasexedthe XTablePrescribedPhasePositionPositionPositionPositionPhasePositionPositionPositionK. Russell, R.S. Sodhi / Mechanism and Machine Theory 40 (2005) 285299 293C0h5fC0R0C0R0hf6h4fR030problemmoving pivot adjustments of the adjustable planar four-bar motion generator withcrank and adjustable follower lengths are exemplied in this section. Listed in Table 2 are- and Y-coordinates of p, q and r for seven prescribed rigid body positions.2rigid body positions for the adjustable planar four-bar motion generatorpqr11 C00.5175, 0.9640 C00.2148, 1.5049 0.3551, 1.31032 C00.4502, 1.0207 C00.1413, 1.5581 0.4263, 1.35703 C00.3786, 1.0720 C00.0645, 1.6064 0.5011, 1.39974 C00.3030, 1.1173 0.0152, 1.6492 0.5792, 1.438225 C00.0583, 1.2042 0.4515, 1.6834 0.9782, 1.39146 0.1449, 1.2155 0.5383, 1.6945 1.0648, 1.4023hf2 6hf2132h4fC0R0C0Rv0hf12h3fRv029a7C020RfC0 R0C0_R0hfC01R0h2C01Rv0h3C18C1910C0_R0C0R0hfC01Rv0h2C18C197 0.2319, 1.2195 0.6249, 1.6988 1.1517, 1.4070Eqs. (4)(8) were used to calculate ve of the six unknowns in a0, a1and a1n. The variable a0xand the link length R1were specied (a0x=0 and R1=1). Using the following initial guesses:a0y 0:1 a1C00:5;0:5 a1nC00:5;0:5the planar four-bar mechanism solutions converged toa0y 0:0761 a1C00:7049;0:7859 a1nC00:1739;1:0608:a0b0a1b1b1nXYa1nr1p1p2p3p4p5p6p7q1q2q3q4q5q6 q7r2r3r4r5r6r7Fig. 7. Adjustable planar four-bar motion generator and corresponding prescribed rigid body positions.ab41n571a1bba1n4D 57D 1na1nbY294 K. Russell, R.S. Sodhi / Mechanism and Machine Theory 40 (2005) 285299b0Xa0Fig. 8. Moving pivot paths of the synthesized adjustable planar four-bar motion generator.Eqs. (9)(13) were used to calculate ve of the six unknowns in b0, b1and b1n. The variable b0xand the links length R1and R2were specied (b0x=1.5, R1=1.5 and R2=1.3).Using the following initial guesses:b0y 0:1 b10:6;1:2 b1n0:6;1:2the planar four-bar mechanism solutions converged tob0yC00:1064 b10:6821;1:1505 b1n1:2964;1:1775:Using the calculated xed and moving pivot parameters, the resulting adjustable planar four-bar motion generator is illustrated in Fig. 7. An equivalent slider-crank motion generato

- 温馨提示:

1: 本站所有资源如无特殊说明,都需要本地电脑安装OFFICE2007和PDF阅读器。图纸软件为CAD,CAXA,PROE,UG,SolidWorks等.压缩文件请下载最新的WinRAR软件解压。

2: 本站的文档不包含任何第三方提供的附件图纸等,如果需要附件,请联系上传者。文件的所有权益归上传用户所有。

3.本站RAR压缩包中若带图纸,网页内容里面会有图纸预览,若没有图纸预览就没有图纸。

4. 未经权益所有人同意不得将文件中的内容挪作商业或盈利用途。

5. 人人文库网仅提供信息存储空间,仅对用户上传内容的表现方式做保护处理,对用户上传分享的文档内容本身不做任何修改或编辑,并不能对任何下载内容负责。

6. 下载文件中如有侵权或不适当内容,请与我们联系,我们立即纠正。

7. 本站不保证下载资源的准确性、安全性和完整性, 同时也不承担用户因使用这些下载资源对自己和他人造成任何形式的伤害或损失。

人人文库网所有资源均是用户自行上传分享,仅供网友学习交流,未经上传用户书面授权,请勿作他用。

川公网安备: 51019002004831号

川公网安备: 51019002004831号