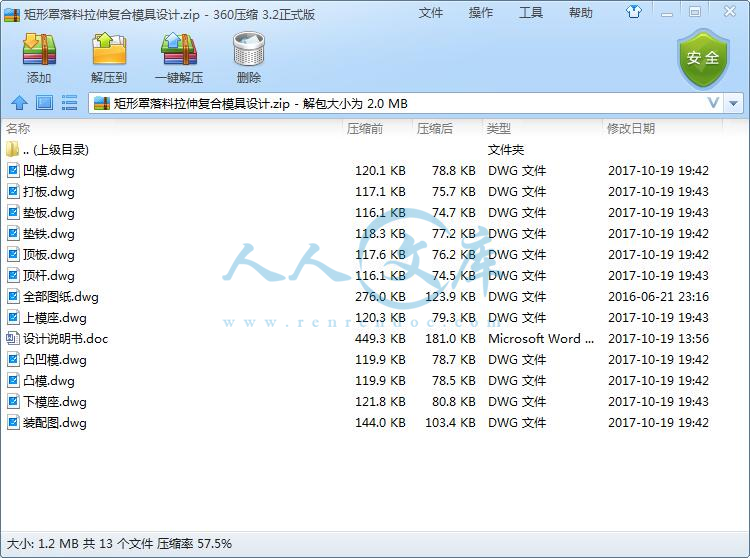

!【包含文件如下】【冲压模具设计类】CAD图纸+word设计说明书.doc【需要咨询购买全套设计请企鹅97666224】.bat

上模座.dwg

下模座.dwg

全部图纸.dwg

凸凹模.dwg

凸模.dwg

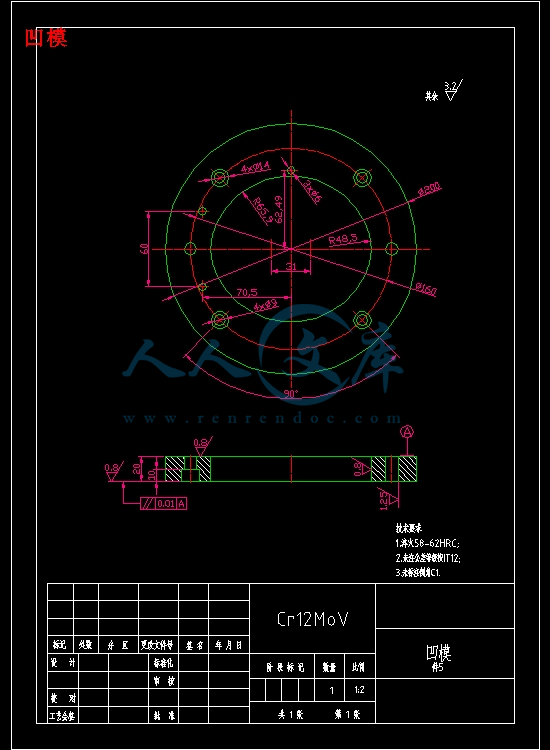

凹模.dwg

垫板.dwg

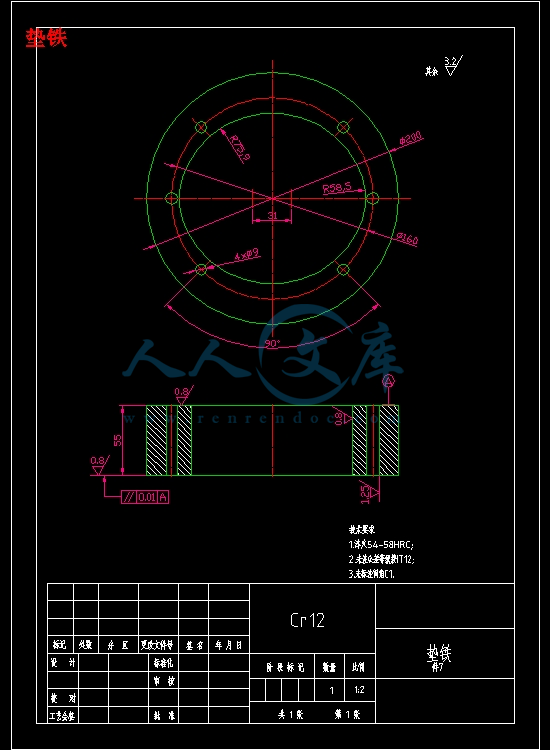

垫铁.dwg

打板.dwg

装配图.dwg

设计说明书.doc

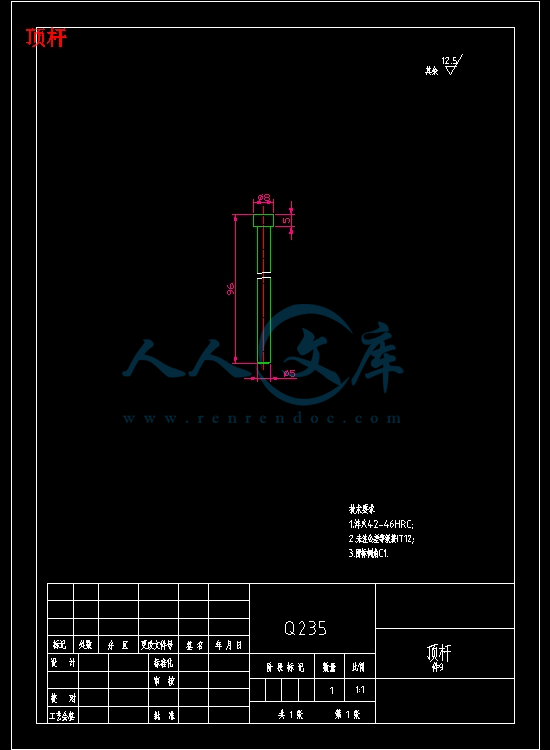

顶杆.dwg

顶板.dwg

摘 要

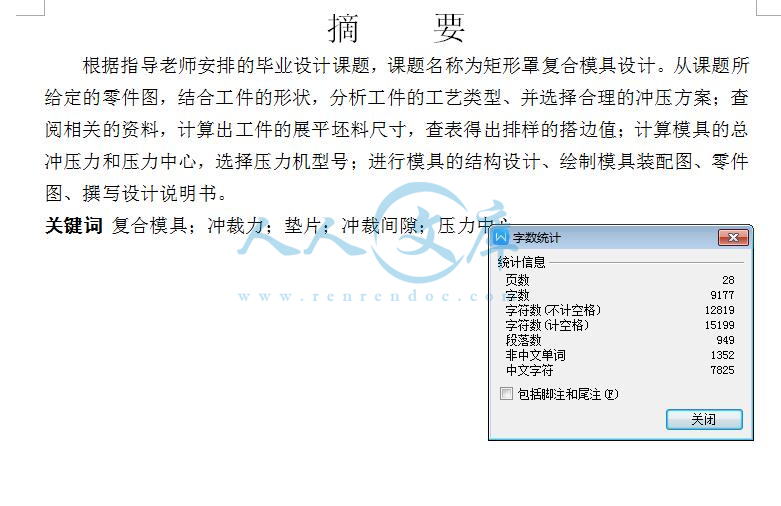

根据指导老师安排的毕业设计课题,课题名称为矩形罩复合模具设计。从课题所给定的零件图,结合工件的形状,分析工件的工艺类型、并选择合理的冲压方案;查阅相关的资料,计算出工件的展平坯料尺寸,查表得出排样的搭边值;计算模具的总冲压力和压力中心,选择压力机型号;进行模具的结构设计、绘制模具装配图、零件图、撰写设计说明书。

关键词 复合模具;冲裁力;垫片;冲裁间隙;压力中心

ABSTRACT

According to the graduation project guidance teacher arrangement, subject name for the cover design of rectangular composite mold. From the topic given by the parts of the map, combined with the structure and the shape size. Firstly, it analyzes the process of workpiece type, according to the size of the workpiece, analysis and selection of suitable design; secondly, die arrangement of sample design, access to relevant data, calculation of blank size of workpiece, reasonable choice of nesting take the boundary value; finally, the calculation of the die pressure center and flushing pressure, corresponding to the press; finally choose between mold standard, drawing mold assembly drawings and part drawings and prepare design specification. In addition, combining the workpiece structure, from the point of view of the production of in order to save the mold manufacturing costs, improve production efficiency, ensure the production precision of the workpiece, the workpiece punching blanking die design of the compound die of blanking. In the mold design mainly find the workpiece drawings unlabeled tolerances of tolerance, according to the dimensional tolerances to determine precision mold manufacturing, after multiple layout analysis to design of mold structure.

Keywords composite die; blanking force; gasket; blanking clearance; pressure center

目 录

第1章 绪言 1

1.1冷冲压模具的发展及概述 1

第2章 冲压件工艺分析 2

2.1材料力学性能分析 2

2.2 工件结构形状分析 3

2.3 尺寸精度 3

第3章 冲压工艺方案确定 4

3.1 冲裁工艺方案的确定 4

3.2 冲裁工艺方法的选择 4

第4章 模具总体结构 5

4.1 定位方式的选择 5

4.2 出件方式的确定 5

4.5模架结构和导向装置的选择 5

第5章 工艺参数计算 6

5.1 坯料尺寸计算 6

5.2 排样方式的选择 6

5.2 冲压力的计算 9

第6章 刃口尺寸的计算 13

6.1 冲裁间隙的确定 13

6.2 刃口尺寸的计算及依据与法则 14

第7章 主要零部件设计 18

7.1 凹模设计 18

7.2 凸模的设计 20

7.3 卸料装置的设计 21

7.4 凸模固定板的设计 21

7.5 导向零件及模架的选用的设计 22

7.6 模柄的选用 22

第8章 冲压设备的校核与选定 26

8.1 冲压设备的校核 26

8.2 冲压设备的选用 26

8.3压力机的选择 26

结 论 28

参考文献 29

致 谢 30

川公网安备: 51019002004831号

川公网安备: 51019002004831号