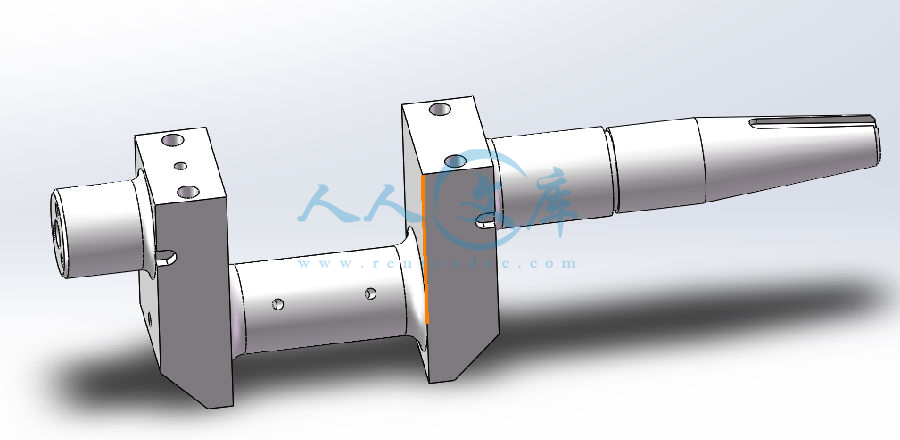

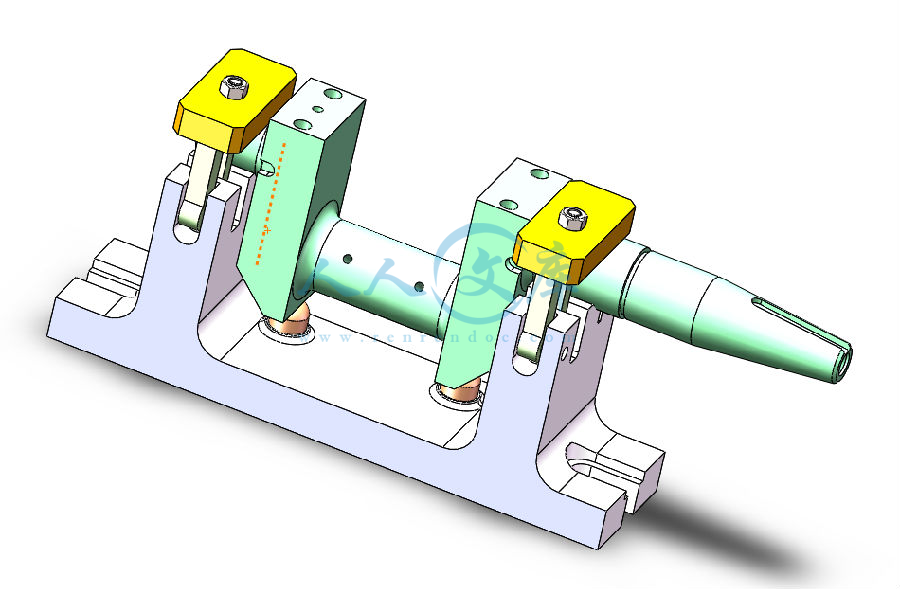

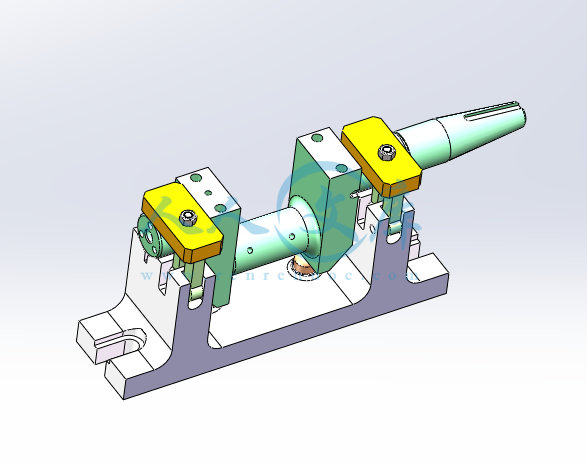

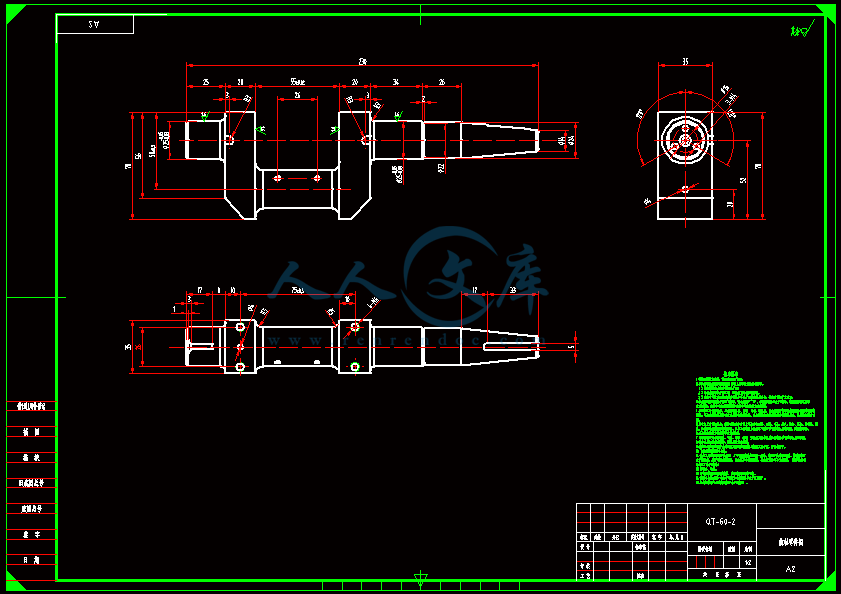

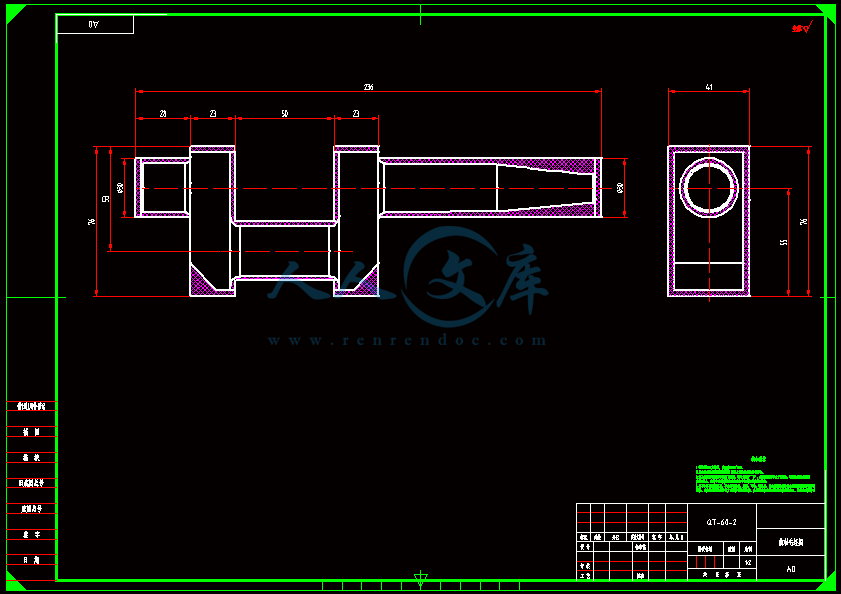

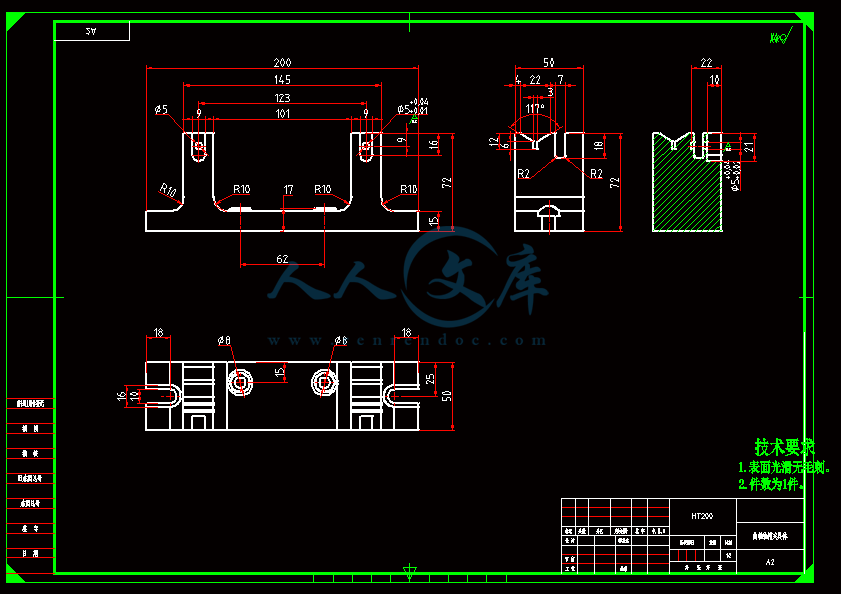

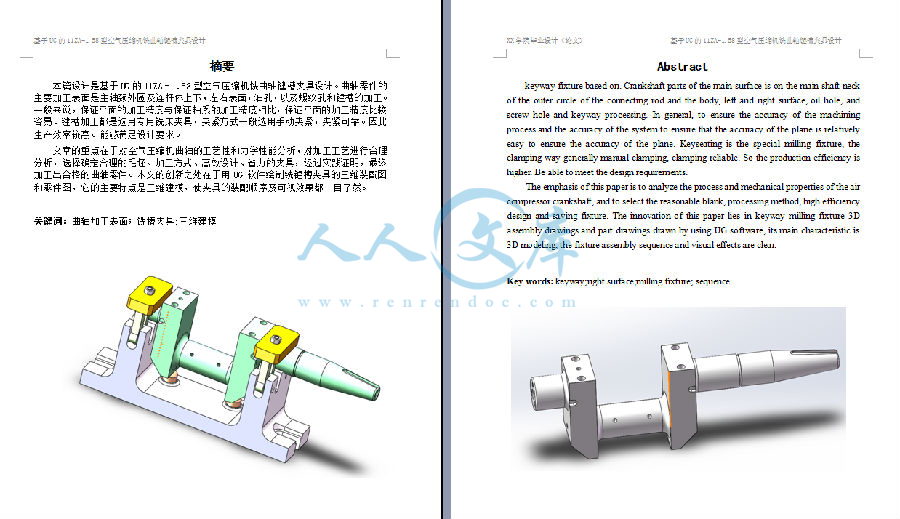

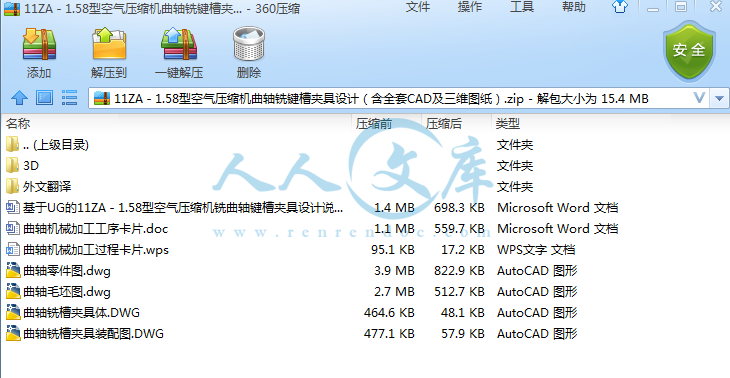

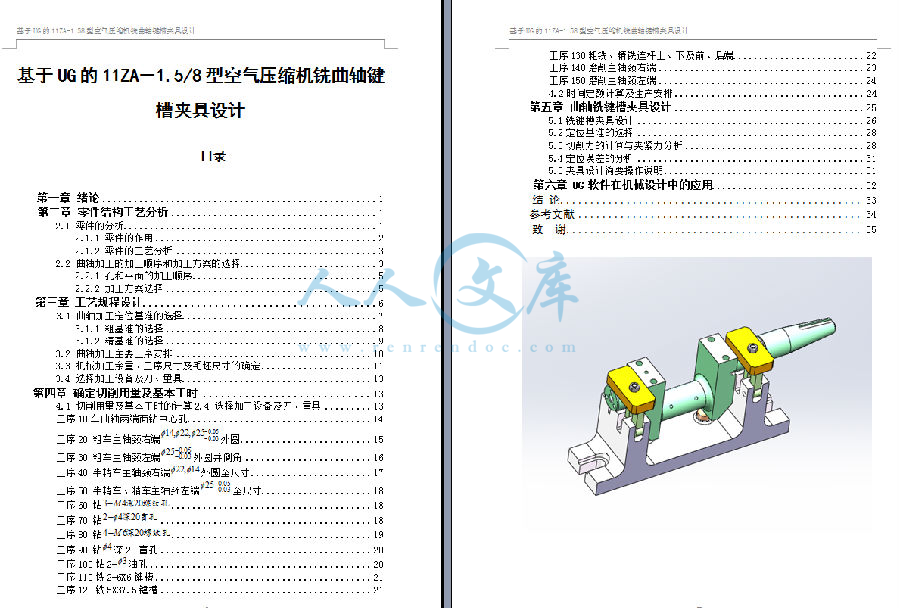

11ZA-1.58型空气压缩机曲轴铣键槽夹具设计(含全套CAD及三维图纸)

收藏

资源目录

压缩包内文档预览:

编号:6121352

类型:共享资源

大小:6.59MB

格式:ZIP

上传时间:2017-11-23

上传人:机****料

认证信息

个人认证

高**(实名认证)

河南

IP属地:河南

50

积分

- 关 键 词:

-

11

十一

za

空气压缩机

曲轴

键槽

夹具

设计

全套

cad

三维

图纸

- 资源描述:

-

- 内容简介:

-

G. Seliger et al. (eds.), Advances in Sustainable Manufacturing: Proceedings of the 8th Global Conference 149on Sustainable Manufacturing, DOI 10.1007/978-3-642-20183-7_22, Springer-Verlag Berlin Heidelberg 2011Methodology for High Accuracy Installation of Sustainable Jigs and FixturesJ. Jamshidi, P.G. MaropoulosDepartment of Mechanical Engineering, University of Bath, UKAbstractThe ability to accurately measure the components of jigs and fixtures during their installation determines thestate of their precision, especially for large size products and applications. This matter is crucial in masscustomisation where small batches of products and components with high variety in design are manufactured.Product quality should be in harmony with rapid changeover philosophy as compromising quality for speed isnot forgivable for sensitive components and assemblies such as those seen in the aerospace industry. It isnecessary for the installation of the jigs and fixtures to be highly accurate in order to minimise the use oftolerance budget due to variations in jigs and fixture positioning. Major overhead costs for jigs and fixturesparticularly in the aerospace industry led to the development of the concept of flexible and reconfigurable jigsand fixtures. Reusability of reconfigurable jigs and fixtures makes them attractive for sustainable solutions astheir components can be reused for several variant of a product or assembly. The main drawbacks of this typeof jigs and fixtures have been their poor accuracy and reliability. In this paper accurate positioning of the keycomponents of sustainable jigs and fixtures is investigated. The factors affecting the performance of the jigsand fixtures are reviewed from the installation stage. The paper introduces a methodology for minimisinguncertainties in positioning of the holds and clamps for flexible jigs and fixtures.Keywords:Sustainable Jig, Jig installation, Calibration Uncertainty, Jig Monitoring, Metrology, Reusable Jig1 INTRODUCTIONFactors such as quality and reliability have long converted toimplicit characteristics of the new products. Recent markettrends have forced manufacturing industries to move towardsmass customisation in their products and service range.Increased variation in the design of new products is followedby a second wave of variation with higher amplitude atsubassemblies and component level.State of the art manufacturing systems and technologieshave provided more flexibility, enabling designers to thinkmore freely. For instance new large volume measurementsystems, developed in the past few years, are capable ofmeasuring several decametre distances. Such technologiesfacilitate the verification of large size components that used tobe manufactured from several assembled components.The manufacturing of large size products requires specialistjigs and fixtures in order for their components to be held in thedesired orientation during build and assembly. This requiresmajor overhead cost that can only be justified by massproduction in some cases or otherwise the cost of finishedproducts can be very high. This issue contradicts with themarket trends where customers are constantly looking forhigher value for their money. In a typical product the variationin the product creates a more sustainable business as it canfulfil the needs of a relatively larger market.Flexible and reconfigurable jigs and fixture that can be formedin different shapes to support different variation of products isa key solution for the above challenges. The concept offlexible jig existed for several years in the research domain1. However, they are not fully utilised to a great extent inreal production facilities especially for large size productmanufacturers, such as aerospace. This is due to thechallenges related to their initial installation, poor calibration,and repeatability that often exceed the tolerance requirement.The manufacturing of these jigs and fixtures from high qualitykey components as well as their integration with large volumemetrology systems can reduce the above limitations.This paper covers metrology issues related to the installationand calibration of flexible jigs and fixtures as well as theirmonitoring during service.2 RELATED WORK2.1 Manufacturing and assembly of large scale partsTypically prior to precision manufacturing of mechanical partsit is essential to move the raw material to the machine bench,proceed with rough cutting then fine alignment and clamping.At this stage the part is ready for machining of its highprecision key features. However, this is not always possiblefor large size and/or heavy components. Large scale productsrefer to those with components that are not economicallypossible to handle or move around in the factory forfabrication and assembly purposes 2. The manufacturingand assembly processes of these parts encompassmovement of the machines and systems to the desiredlocation and orientation with respect to these parts. Suchparts are normally held in their positions using large size jigsand fixtures. If these parts are produced in small batch sizesthat is the case for aerospace industries, high overhead costper p

- 温馨提示:

1: 本站所有资源如无特殊说明,都需要本地电脑安装OFFICE2007和PDF阅读器。图纸软件为CAD,CAXA,PROE,UG,SolidWorks等.压缩文件请下载最新的WinRAR软件解压。

2: 本站的文档不包含任何第三方提供的附件图纸等,如果需要附件,请联系上传者。文件的所有权益归上传用户所有。

3.本站RAR压缩包中若带图纸,网页内容里面会有图纸预览,若没有图纸预览就没有图纸。

4. 未经权益所有人同意不得将文件中的内容挪作商业或盈利用途。

5. 人人文库网仅提供信息存储空间,仅对用户上传内容的表现方式做保护处理,对用户上传分享的文档内容本身不做任何修改或编辑,并不能对任何下载内容负责。

6. 下载文件中如有侵权或不适当内容,请与我们联系,我们立即纠正。

7. 本站不保证下载资源的准确性、安全性和完整性, 同时也不承担用户因使用这些下载资源对自己和他人造成任何形式的伤害或损失。

人人文库网所有资源均是用户自行上传分享,仅供网友学习交流,未经上传用户书面授权,请勿作他用。

川公网安备: 51019002004831号

川公网安备: 51019002004831号