资源目录

压缩包内文档预览:(预览前20页/共23页)

编号:6139964

类型:共享资源

大小:571.47KB

格式:RAR

上传时间:2017-11-27

上传人:机****料

认证信息

个人认证

高**(实名认证)

河南

IP属地:河南

50

积分

- 关 键 词:

-

电动汽车

充电

控制系统

设计

cad

图纸

- 资源描述:

-

- 内容简介:

-

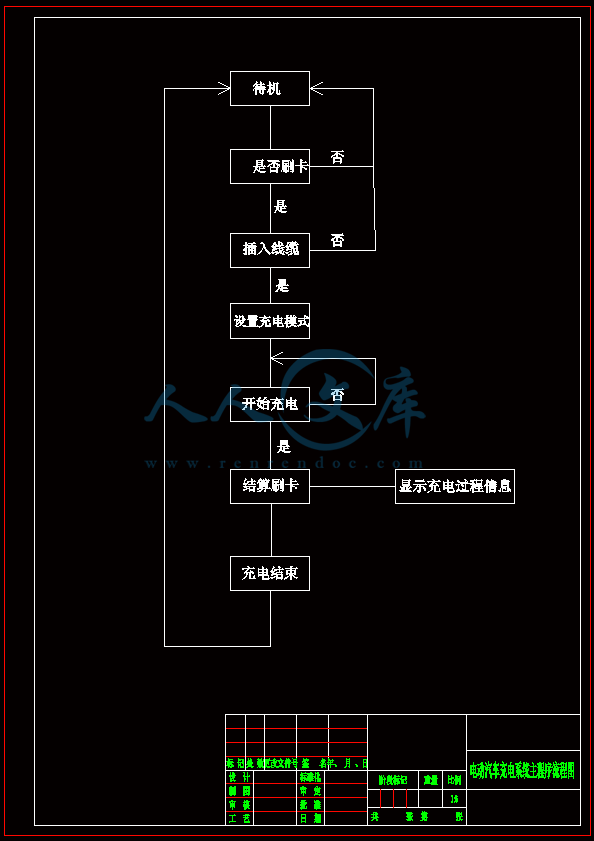

电动汽车充电控制系统的设计随 着 全 球 能 源 危 机 的 不 断 加 深 , 石 油 资 源 的 日 趋 枯 渴 以 及 大 气 污 染 、全 球 气 温 上 升 的 危 害 加 剧 , 各 国 政 府 及 汽 车 企 业 普 遍 认 识 到 节 能 和 减 排 是 未来 汽 车 技 术 发 展 方 向 , 发 展 电 动 汽 车 将 是 解 决 这 两 个 难 题 的 最 佳 途 径 。 电 动 汽 车 具 有 环 保 特 性 , 代 表 着 汽 车 产 业 未 来 的 发 展 方 向 。 目 前 动 力 电 池 作为 电 动 汽 车 的 动 力 源 为 汽 车 提 供 动 力 , 使 电 动 汽 车 一 次 充 电 最 大 行 驶 里 程 为200km, 但 当 动 力 电 池 电 力 耗 尽 时 必 须 补 充 电 能 量 。 目 前 国 内 就 充 电 模 式 提出 了 多 种 方 式 , 例 如 : 电 池 组 快 速 更 换 、 快 速 充 电 以 及 常 规 充 电 等 。 根 据 现实 情 况 , 动 力 电 池 体 积 大 、 重 量 重 , 不 便 于 随 意 更 换 , 同 时 大 功 率 直 流 充 电柜 作 为 应 急 充 电 装 置 能 为 电 动 汽 车 提 供 快 速 续 航 电 力 , 但 对 电 池 伤 害 很 大 。因 此 , 交 流 充 电 桩 解 决 了 电 动 汽 车 随 时 随 地 电 能 量 补 给 问 题 , 无 须 装 卸 电 池 ,整 车 通 过 充 电 电 缆 直 接 与 充 电 桩 连 接 即 可 实 现 充 电 , 同 时 以 交 流 电 的 形 式供 给 电 能 , 对 电 池 无 伤 害 , 既 提 高 了 电 动 汽 车 动 力 电 池 寿 命 , 也 是 电 动 汽 车最 佳 的 日 常 充 电 方 式 。 流 充 电 桩 体 积 小 、 重 量 轻 , 与 电 网 供 电 系 统 连 接方 便 , 可 布 置 于 小 区 、 办 公 楼 宇 、 超 市 停 车 场 以 及 电 动 汽 车 专 用 充 电 站 内 ,并 同 时 能 为 两 辆 电 动 汽 车 充 电 。 自从上世纪的六、七十年代以来,电子技术领域得到了飞速的发展,可谓是日新月异,不仅在理论上,而且越来越多地运用到我们的日常生活中,致使工业、农业、科技和国防等领域以及人们的社会生活都发生着令人瞩目的变革。小到可以随身携带的电子产品,如 MP3,USB 存储器,大到电瓶车、电视、巨型计算机,在我们日常生活中越来越方便了我们的生活,在 21 世纪,电子技术在以更快的速度前进,新一代的电子产品更广泛地应用在我们生活的各个方面。电子产业的发展,也极大的推进了电力的利用。各种各样的充电式产品诞生并得到极大的发展,其高效、环保、便捷等优点正逐步渗入我们的生活。根据电动自行车铅酸蓄电池的特点,当其为 36V/12AH 时,采用限压恒流充电方式,初始充电电流最大不宜超过 3A。也就是说,充电器输出最大达到 44V/3A/130W,已经可满足。在充电过程中,充电电流还将逐渐降低。充电器常见的几种充电模式1)限流恒压充电模式12)两阶段恒流充电模式3)恒流脉冲充电模式此三种充电模式均为业界推荐采用,其各阶段充电电流间的转换,都分别受有温度补偿的转换电压 Vmin(快充最低允许电压)、Vbik 快充终止电压)和Vflt(浮充电压)控制。本次设计的内容是将 220V 市电通过一系列的转换与控制输出稳定的电压44V 对电动车进行充电。本文通过四部分电路的设计来实现充电器的功能,即电源电路、振荡电路、保护电路和充电状态指示电路。该电路能够实现电压的自动转换、充电过程的自动保护及充电状态的指示,克服了种种充电时的隐患。设计中主要以模拟器件为核心设计并制作了充电电路。该电路能实现充电过程的自动控制,设计中用桥式整流、滤波将 220V 交流电转换成 311V 直流电,经变压器反馈振荡得到 44V 充电电压,充电过程中有保护电路控制电压的输出,同时指示电路反应充电的状态。其间用到了精密基准稳压源及四运放集成电路等重要元件。在设计过程方面,从总体方案、单元电路、元器件选择和设计到调试等同样进行了细致的介绍。本设计是利用普通常用的元器件实现电动车的充电功能。其性能可达到:可以产生 44V 电压充电,充电过程以指示灯为状态显示。采用整流稳压电路, 以实现安全充电,其常用的器件在实现快速充电的同时又加以保护电路,以保证元器件的性能。采用 LM324 四运放器进行电压比较,可实现电路比较功能。电动汽车是全部或部分由电能驱动电机作为动力系统的汽车,按照目前技术的发展方向或者车辆驱动原理,可划分为纯电动汽车、混合动力汽车和燃料电池电动汽车三种类型。近年来,我国电动汽车行业取得了快速发展,攻克了一系列关键技术难题, 在部分领域已实现了与日美欧等国同步发展。目前我国发展电动汽车已具有消费市场规模大、制造成本低、技术取得局部突破、资源保障2能力强的四大优势。在技术突破和政策扶持的双重刺激下,我国电动汽车已处于市场引爆的临界点,预计未来两年电动汽车的市场规模和生产规模将迅速扩大,电动汽车将进入快速成长期。电动汽车充电设施是电动汽车产业链的重要组成部分,在电动汽车产业发展的同时还应该充分考虑充电设施的发展。The design of control system of charging electric carAs soon as of Aviation Technology Liu xin Yaintroduced a concurrent engineering, agile manufacturing and sophistif cated production, and other advanced manufacturing technology and the characteristics of the development omachine tools in the portfolio of applications, how to deepen and extend the application of specific measures.In the machine tool industry, with the social demands of the continuous improvement of products, along with the growing competition in the market to meet user requirements, including the improvement of product quality, shorten production cycles, reduce costs, improve service and win market has become a breakthrough. In order to achieve this goal and win market, it should be the introduction of modern and advanced manufacturing technology: concurrent engineering, agile manufacturing and sophisticated production, in order to promote the development of combination machine.Concurrent Engineering is also known as concurrent engineering, integrated, parallel to optimize product design and its related processes (including manufacturing and support) system approach, which guide the product development staff began to consider a product from concept to design to the demise of throughout the life cycle of all the factors, including quality, cost, programming and user needs.Concurrent Engineering is the first to shorten product development cycles as a means to develop. Products will be characterized by the development, production engineering involved in the acts broken down into a series of tasks, such as market analysis, design, process design, production plans and equipment purchases, processing, quality assurance, testing and after sales 3service. These sub-tasks as far as possible and consider synchronous parallel to achieve improved design to shorten the cycle and improve quality, reduce costs, optimize the design purpose. It stressed that integrated, coordinated and parallel, namely: (1) management, design, production, and service of all project-related personnel and product information integration as a whole, and stressed that all relevant departments and the interests of the overall goal line (2) to the establishment of a competent and reasonable charge of the project personnel structure of the working group coordinated management model, by the Working Group in the ministries responsible for project elements, and the promotion of the coordination of tasks, (3) parallel processing stages of the work. According to the project in the different tasks of the linkages between the different ministries mandate of the elements of the work process can be completely overlap or duplication. In accordance with these principles, formulate a reasonable, and optimize the work plan, and the location in which the necessary settings assessment, the Working Group by the project implementation so that all sub-tasks in parallel, to move forward in an orderly manner, so as to ensure the smooth implementation of the whole project .According to the traditional methods of work, the work of the various stages in a row serial. In such a product development approach, divorced from each other at various stages, are not related, resulting in increased design error, and difficult to discover such a design rework, to lengthen the development cycle, adding to the costs.Parallel working methods used, the process will be integrated with parallel consideration, the work can be carried out duplication. Problems can be promptly coordinate the changes so that the follow-up stage left to increase the difficulty of correction And costs. Thus, the application of concurrent engineering can significantly shorten the product development cycle, reduce costs, it is suitable for the development of professional portfolio machine.Concurrent engineering methods will be applied to product development, the effect was very significant. March 1997, Beijing Institute of Aviation Technology with a motorcycle design and manufacturing plants to sign the 6-crank machine project contract for delivery end of the 4year, and the requirements of machine tools in the past quite different. In the project using a concurrent engineering approach, in parallel, cross-operation , greatly reducing the design, manufacture period, the successful completion of the tasks.Parallel development of the combination of machine specific methods are:(1) the establishment of a multi-composed of professionals to develop working groups. By the Working Group of the specific part of the implementation of the project, members of the Working Group in collaboration division of duties, timely and coordinated in order to achieve optimization of the design. Such as a machine tool demand in the clamping fixture parts to the process of floating, if separate consideration from the mechanical structure to meet this requirement more difficult, complex structure of the fixture. Later, with the hydraulic design of electrical control and coordinate, control procedures proposed amendments to change the order clamping action, adjusting the hydraulic pressure of solutions to meet the requirements of the clamping.(2) in the formulation of programmes, the signing of the contract stage, on the preliminary identified a number of standard components.(3) Multiple Multi-accreditation programme. Machine Tool Technology in determining the overall programme, key components in the overall design process, many times by the Solidworks committee to review the design plan, and put into production before the user in the design plan joint trials. Thus, from the design to take into account the beginning of a process design, tooling design, manufacturing, assembly and other downstream various stages of debugging problems that may arise, thus greatly reducing the number of design changes Rated meet user requirements, to achieve design best.(4) a design pre-release method. Machine overall plans in a formal drawing ago, has been released in stages set by the main structure and the major components of data, process design, tooling design can be carried out ahead of schedule. In the design of the machine tool to determine some components such as fixtures, tools such as the coordination of size, and at the same time began to design and tool fixture, and, also identified slider, mobile workstations and other components, these 5components have the choice as far as possible Standard components, in the design of its operation will be completed. And the overall design of the various components such as fixtures, and timely coordination between the tool, linked to changes in the size of each other timely coordination so that the size of other relevant drawings are promptly corrected.(5) components in the design of the processing cycle can be long specific parts such as folders, such as casting stereotypes as soon as possible to advancing the process design, production.(6) completion of the various components of a design, process design and ready to enter the production stage. Therefore, the various components of the parts is in the workshop, parallel processing.Adopt this approach, the Working Group 4 were used only four weeks time on the part of generic components such as the slider, mobile platforms and power first went into operation at the same time, the completion of the mechanical design of the machine and outsourcing of orders. Machine tool production process, the various components in the Beijing Institute of Aviation Technology Association, and several manufacturers at the same time. In the machine, installation and debugging, but also several machine at the same time, through these work, and machine tools for the timely delivery of valuable time.Agile manufacturing in the United States of the Caspian Sea, the 21st century manufacturing strategy in the report of a new manufacturing paradigm. After development, the United States lacocca Institute will be defined as: a company that is agile in the market for the unpredictable changes in the competitive environment in the development and prosperity of a capability, that is rapidly changing global market a rapid response capability, with the company computer network and the global production system, the market, competitors to link up in the high-quality, high-performance, low-cost, customer product configuration settings, such as user demand-driven market situation demonstrated a capability. Characterized by the flexible production technology, flexible organization management and professional skills of the staff have integrated into a coordinated, interconnected systems, in order to achieve the strategic 6goal of reunification, the same industry in different enterprises through joint infrastructure links, past life-and-death competition will become friendly and cooperative competition, thereby changing market faster response. Therefore, this technology is suitable for the development of professional portfolio machine.(1) promote the Agile first modular products, reflected in the composition of the machine is in the machine tool components and the standardization of serialization. Crankshaft Machine Tool in the development and design, can greatly shorten the design cycle, the application of concurrent engineering is a factor, large number of standard components, the application of common components is a key element.(2) In the Agile Manufacturing, must reflect the people and organizations is the most valuable asset. In the production of large quantities, people are always Solidworks solution as manufacture and sale of the crux of the problem, and in Agile Manufacturing, the best use of people is the key to solve the problem, technology is only a method or means. Therefore, the need for the Project Working Group organizational model advocated hard working, give full play to their initiative.Sophisticated production is the United States in the 1990s, Japans Toyota Motor Corporation summed up production management methods on the basis of summing up by the production. It stressed that by improving the production of enterprises in the management of the activities, including the efficiency of various activities and cost accounting, to achieve the fastest speed of response to the market, the lowest cost of production, the optimal product design to design and Manufacturing of products needed by the market. Its features are user-God, a people-centred, as a means to streamline, to zero defect goal.Can be seen from the above analysis, and advanced manufacturing technology in the Beijing Institute of Aviation Technology Portfolio machine has been developed in a number of applications, but still need to further deepen and extend the application. In later work, Should pay attention to the following aspects:(1) Working Group on the further implementation of the project model, a responsibility to the people, by the use of concurrent engineering group responsible for the 7completion of the way from the machine tool technology programme to design, manufacture, testing and delivery of the work of the staff at the same time strengthen the knowledge and skills training, keep track machine tool industry at home and abroad combination of the latest developments.(2) market changes and the development of pre-study plan at the same time maintain close ties with users, users who regularly visit provides its users with quality after-sales service, and equipment operation and understanding of user needs, in order to improve the design.(3) high-quality products to win customers. Machine Tool in the development portfolio, in addition to enhancing the sense of quality, the new technology, the application of new technology in the market is also an important means. Now users generally require machine efficiency, flexibility, and adapt to small quantities and variety of processing. Portfolio Tool to enhance the efficiency of production and increase in the design should be cutting speed, the use of advan

- 温馨提示:

1: 本站所有资源如无特殊说明,都需要本地电脑安装OFFICE2007和PDF阅读器。图纸软件为CAD,CAXA,PROE,UG,SolidWorks等.压缩文件请下载最新的WinRAR软件解压。

2: 本站的文档不包含任何第三方提供的附件图纸等,如果需要附件,请联系上传者。文件的所有权益归上传用户所有。

3.本站RAR压缩包中若带图纸,网页内容里面会有图纸预览,若没有图纸预览就没有图纸。

4. 未经权益所有人同意不得将文件中的内容挪作商业或盈利用途。

5. 人人文库网仅提供信息存储空间,仅对用户上传内容的表现方式做保护处理,对用户上传分享的文档内容本身不做任何修改或编辑,并不能对任何下载内容负责。

6. 下载文件中如有侵权或不适当内容,请与我们联系,我们立即纠正。

7. 本站不保证下载资源的准确性、安全性和完整性, 同时也不承担用户因使用这些下载资源对自己和他人造成任何形式的伤害或损失。

人人文库网所有资源均是用户自行上传分享,仅供网友学习交流,未经上传用户书面授权,请勿作他用。

川公网安备: 51019002004831号

川公网安备: 51019002004831号