!【包含文件如下】【工艺设计类】CAD图纸+word设计说明书.doc【需要咨询购买全套设计请企鹅97666224】.bat

CAXA仿真

件1工序卡片.doc

件1工艺过程卡片.doc

件2工序卡片.doc

件2工艺过程卡片.doc

任务书.doc

刀具卡片.doc

设计说明书.doc

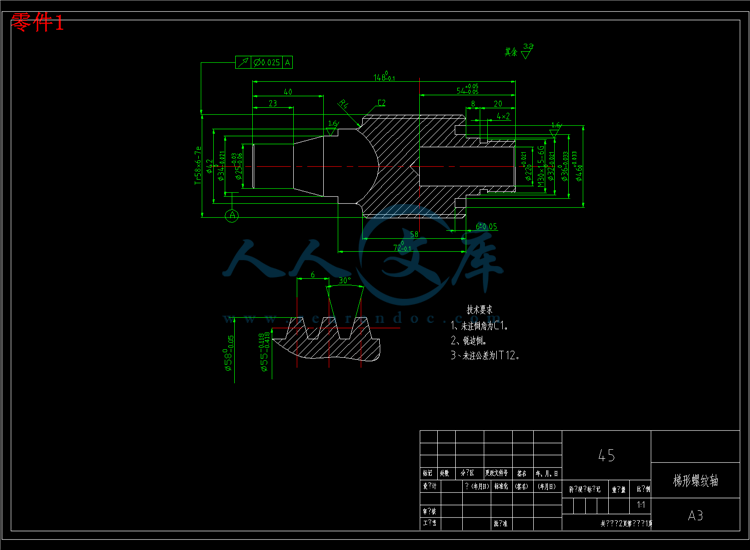

零件1.dwg

零件2.dwg

摘 要

本毕业设计主要研究了梯形螺纹配合件的编程加工与仿真根据任务图两个零件的图纸,进行车削的工艺分析,包括工艺路线:毛坯的选择,定位基准的选择,夹具、刀具的选择,各个切削用量的计算与确定。包括主轴转速,进给速度,背吃刀量等,下面确定加工路线,一轴一套,先粗后精,先内后外。做好这些再手工编程,然后采用CAXA数控车软件模拟加工仿真,并进行后期处理。

本文的主要内容为梯形螺纹配合件的数控加工工艺分析,还有用 CAXA数控车进行仿真加工。零件的编程中用到了外圆车削、内轮廓车削、螺纹车削等。

关键词:工艺分析、夹具、手动编程、CAXA仿真

Abstract

This thesis mainly studies the programming process and Simulation of the trapezoidal thread fitting.

First of all, according to the task graph two parts drawings, turning process analysis, including process route: blank choice, selection of locating datum, fixture, tool selection, calculation of various cutting parameters and determine. Including spindle speed, feed rate, depth of quantity, the following to determine processing route, a set of axis, the first coarse to fine, after the first period. Do these manual programming, and then use the CAXA CNC software simulation processing software, and the late processing.

The main content of this paper is the numerical control processing technology of the trapezoidal thread, and the CAXA numerical control lathe is used to simulate the machining process. Parts of the programming used in the outer circle turning, internal contour turning, screw turning, etc..

Key words: process analysis, assembly, manual programming, CAXA simulation

目录

摘 要 2

前言 5

1、零件的分析 6

1.1、零件图的分析 7

1.2、图样分析 7

2、确定工艺路线 8

3、切削用量的选择 11

3.1、主轴转速的确定 12

3.2、进给速度的确定 13

3.3、背吃刀量的确定 13

4、工艺规程设计 14

4.1、工艺路线 14

5、数控加工程序清单 16

5.1、零件一的程序单 16

5.2、零件二的程序单 20

6、CAXA仿真 24

结束语 38

参考文献 39

致谢 40

川公网安备: 51019002004831号

川公网安备: 51019002004831号