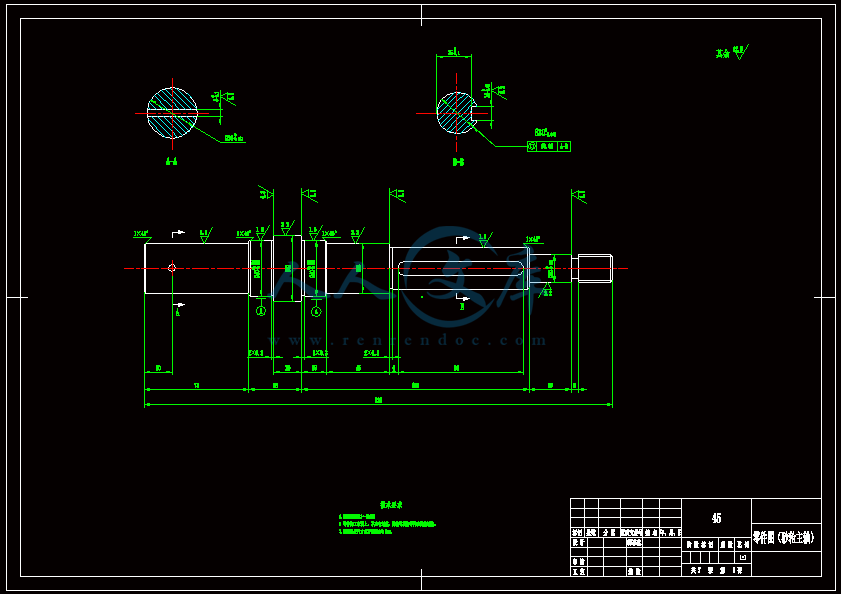

数控平面磨床设计【全套设计含7张CAD图纸】

收藏

资源目录

压缩包内文档预览:

编号:6512067

类型:共享资源

大小:3.07MB

格式:ZIP

上传时间:2017-12-18

上传人:机****料

认证信息

个人认证

高**(实名认证)

河南

IP属地:河南

50

积分

- 关 键 词:

-

数控

平面磨床

设计

全套

cad

图纸

- 资源描述:

-

- 内容简介:

-

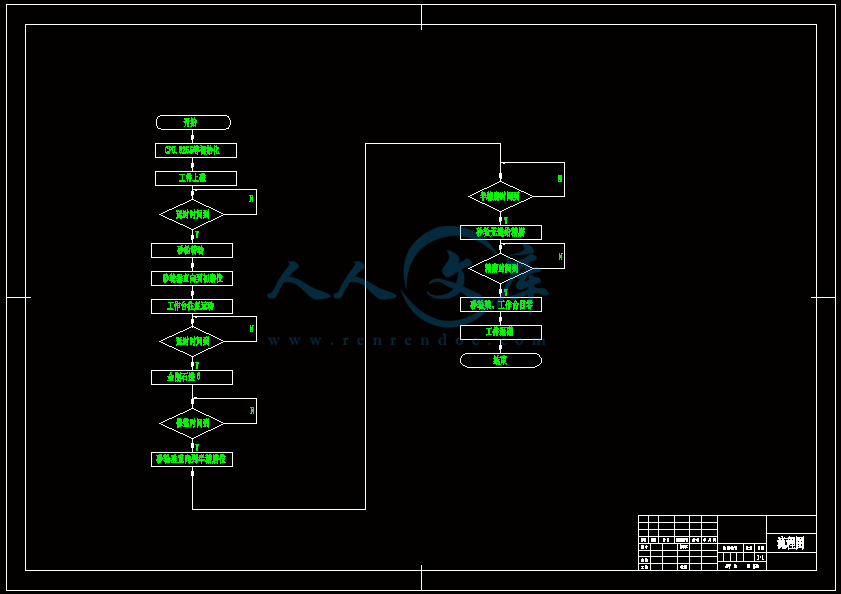

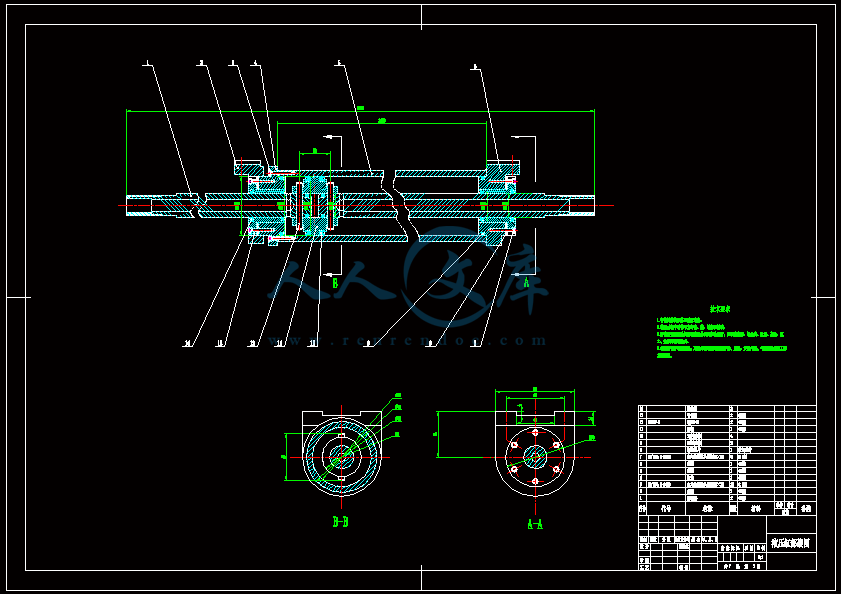

0数控磨削加工中砂轮磨损量的检测方法数控磨床在工件磨削过程中,不可避免的会产生砂轮的磨损现象,为了保证加工精度,需要及时地对砂轮的直径变化或磨损量进行检测。由于磨削加工是一种高精度的加工方法,限于较高测量精度的要求,目前还难以直接对砂轮的直径进行精密的在线测量。同样,由于砂轮表面砂粒的影响,对于砂轮磨损量的高精度检测也是一件困难的事情。因此,目前在数控磨床上还难以实现砂轮磨损的自动补偿。针对这种情况,本文结合数控曲轴磨削加工的研究,提出了一种基于声发射检测技术的砂轮磨损测量及误差补偿的方法。即利用安装在砂轮架上的声发射传感器,测量砂轮相对于机床某一基准的相对位置,通过测量该相对位置的变化,间接地检测砂轮的磨损量,并将测量结果反馈至数控系统,从而实现砂轮磨损的自动补偿。1砂轮磨损量的检测方法考虑到砂轮表面砂粒的影响以及加工环境的影响,采用激光测量等方法均难以实现砂轮磨损量的在线检测。近几年在磨削状态监控中,声发射技术已成为广泛采用的一种方法1 。切削过程中的声发射是重要的切削现象之一,所谓声发射现象是固体材料由于结构变化引起应变能的快速释放而产生的弹性波,简称AE(Acoustic Emission)。在磨削加工中,当磨削加工处于一种稳定状态时,AE 信号并不发生变化。只有当磨削状态发生变化时,声发射信号才随之发生变化。当砂轮与工件相靠近时,砂轮会有高频声发射信号产生,安装在砂轮架上的声发射传感器信号会明显增强,通过试验研究可以确定一个阈值,根据该阈值可以确定砂轮与工件的相对位置。基于该原理,考虑将声发射传感器安装在砂轮架上,用于测量砂轮磨削过程中的声发射信号。金刚石笔作为砂轮定位的基准,安装在磨床床身的某一位置,当需要测量砂轮的磨损量时,数控系统控制砂轮靠近金刚石笔,当砂轮接近金刚石笔时,声发射信号增强,通过试验研究,可以确定一个判定砂轮与金刚石笔相对位置的阈值。当声发射信号超过预先设置的阈值时,由声发射信号处理装置向数控系统的 PLC 发出开关量信号,机床数控系统则记录下当前砂轮的位置,并将砂轮的当前位置与以前的位置相比较,计算出砂轮磨损量的补偿值。进一步通过数控软件在数控系统中实现砂轮磨损的自动补偿。上述方法是否可行,主要取决于能否找到一个能够准确判断金刚石笔与砂轮相对位置的阈值,当砂轮没有磨损时,利用该阈值判断的金刚石笔与砂轮相对位置不应发生变化或具有很小的位置测量误差。为了说明这一问题,对砂轮磨损量对加工误差的影响b(以此确定位置测量的允许误差)以及所提出方法的位置测量精度进行了试验研究。12试验研究为了确定声发射技术应用于砂轮磨损量测量的测量精度,我们在瑞士 Studer精密万能外圆磨床上进行了试验研究。试验时,将金刚石修整笔固定在磨床尾架上,砂轮的最小进给量 1m,砂轮粒度为 80、中软、红刚玉、直径 300mm,砂轮线速度为 45m/s,头架转速为 50r/min。声发射信号监测系统选用美国许密特工业公司的 L42004 型声发射控制机,其声发射信号工作频率范围为50kHz950kHz,响应时间小于 1ms。试验时,首先控制砂轮的进给运动,使其靠近金刚石修整笔,并在声发射控制机上设置一个阈值。然后将砂轮分别以5m 、10 m、15m、20m 作为砂轮退刀量退回砂轮,再重新控制砂轮缓慢进给,靠近金刚石修整笔,直到声发射控制机监控屏幕上显示达到阈值,立即停止砂轮的进给,记录各次的进给量。以上试验过程不断重复,从而测量出声发射传感器测量金刚石修整笔与砂轮相对位置的重复测量精度。表 1 给出了试验结果。由表 1 可知,误差值在-5+5m 之间,其值小于允许的理论计算误差值 6m 。因此,本文所提出的方法可以用于砂轮磨损量的检测。表 1金刚石修整笔与砂轮相对位置的测量误差试验次数 1 2 3 4 5 6 7 8 9 10 11 12 13 14退刀量(m) 5 5 5 5 5 5 5 10 10 10 10 10 10 10进刀量(m) 5 6 7 8 5 5 5 10 11 12 10 10 11 10误差(m) 0 1 2 3 0 0 0 0 1 2 0 0 1 0试验次数 15 16 17 18 19 20 21 22 23 24 25 26 27 28退刀量(m) 15 15 15 15 15 15 15 20 20 20 20 20 20 20进刀量(m) 13 15 14 14 15 13 14 20 19 18 16 16 17 17误差(m) -2 0 -1 -1 0 -2 -1 0 -1 -2 -4 -4 -3 -33结论本文基于声发射检测技术,给出了数控曲轴磨削砂轮磨损的间接检测方法,该方法同样适于平面磨削、外圆磨削等情况,其区别仅在于要求的检测精度不同。实际试验表明,所提出的方法检测误差在-5+5m 之间,可以满足高精度磨削加工的需要。2Test Method of Grinding Wheel Wear in CNC GrindingCNC grinding machine in grinding process of workpiece, which is caused by abrasion wheel, in order to ensure the precision needed in a timely manner the diameter of the wheel to detect changes or wear. Since grinding is a precision machining method, limited to the requirements of high precision, it is hard to direct the diameter of the wheel-line measurement precision. Similarly, the impact of sand surface grinding wheel, grinding wheel wear for high-precision detection is a difficult task. Therefore, it is still difficult in the CNC grinding machine to achieve automatic compensation for wheel wear. In response, this paper studies CNC Crankshaft Grinding, a technique based on acoustic emission measurement of grinding wheel wear and error compensation method. That is installed on the wheel rack using acoustic emission sensors, measuring wheel with a benchmark for the relative position of machine tools by measuring changes in the relative position of the indirect detection of grinding wheel wear, and measuring the results fed back to the control system, which achieve automatic compensation for wheel wear.1. A grinding wheel wear detection methods.Taking into account the impact of grinding wheel surface grit and processing environment, using laser measurement methods are difficult to achieve on-line detection of grinding wheel wear. In recent years, the grinding condition monitoring, acoustic emission technology has become a widely used method 1. Cutting process of cutting acoustic emission is an important phenomenon of the so-called acoustic emission phenomenon is caused by structural changes of solid materials due to the rapid release of strain caused by elastic waves, referred to as AE (Acoustic Emission). In the grinding process, when the grinding process in a steady state, AE signal does not change. Only when the grinding conditions change, the acoustic emission signal was changed with it. When the grinding wheel and workpiece with close, the wheel will produce high-frequency acoustic emission signals, install the shelves in the wheel acoustic emission sensor signals will be significantly enhanced through the pilot study determine a threshold, according to the threshold value can determine the grinding wheel and workpiece relative position. Based on this principle, consider the acoustic emission sensors installed in the wheel rack, used to measure the grinding wheel in the process of acoustic emission signals. Diamond grinding wheel orientation as a benchmark document, installed in the bed of a grinding position, when 3the need to measure wheel wear, the CNC control wheel near the diamond pen, when the wheel close to the diamond pen, acoustic emission signal enhancement, the experimental study , a judge can determine the relative position of grinding wheel with diamond document threshold. When the acoustic emission signal exceeds a pre-set threshold, the acoustic emission signal processing device to send digital control system, PLC binary signals, machine tool numerical control system is to record the current wheel position and wheel position of the current position compared with the previous comparison, calculate the value of grinding wheel wear compensation. Further through the digital software in the CNC system to achieve automatic compensation for wheel wear. The feasibility of this method depends largely on the ability to find a can accurately determine the relative position of grinding wheel diamond pen and the threshold, when the wheel is not worn, the use of the threshold to judge the relative position of grinding wheel diamond pen and should not change or have a very the location of a small measurement error. To illustrate this problem, on the grinding wheel wear on the machining error of b (position measurement in order to determine the allowable error), and the location of the proposed method accuracy were studied.2. StudyTo determine the acoustic emission technology for grinding wheel wear measurement accuracy, we in Switzerland Precision Universal Cylindrical Grinding Machine Studer were studied. Tests will be fixed in the grinding diamond dressing document the end of the shelf, the smallest wheel feed 1m, wheel size is 80, in the soft, red corundum, diameter 300mm, wheel speed is 45m / s, the first frame speed 50r / min. AE signal monitoring system used the United States Xu Schmitt Industries, Inc., L-4200-4-type acoustic emission control machine, the acoustic emission signal frequency range of 50kHz 950kHz, response time of less than 1ms. Test, the first feed control wheel movement, so close to the diamond dressing pen, and acoustic emission control plane to set a threshold value. Then the wheel respectively 5m, 10m, 15m, 20m, as the amount refunded back the knife wheel grinding wheel, and then slowly regained control of the feed wheel, near the diamond dressing pens, launch control until the sound of the monitoring and controlling the screen to reach the threshold value, stop wheel feed, record the times of the feed. Repeat the abo

- 温馨提示:

1: 本站所有资源如无特殊说明,都需要本地电脑安装OFFICE2007和PDF阅读器。图纸软件为CAD,CAXA,PROE,UG,SolidWorks等.压缩文件请下载最新的WinRAR软件解压。

2: 本站的文档不包含任何第三方提供的附件图纸等,如果需要附件,请联系上传者。文件的所有权益归上传用户所有。

3.本站RAR压缩包中若带图纸,网页内容里面会有图纸预览,若没有图纸预览就没有图纸。

4. 未经权益所有人同意不得将文件中的内容挪作商业或盈利用途。

5. 人人文库网仅提供信息存储空间,仅对用户上传内容的表现方式做保护处理,对用户上传分享的文档内容本身不做任何修改或编辑,并不能对任何下载内容负责。

6. 下载文件中如有侵权或不适当内容,请与我们联系,我们立即纠正。

7. 本站不保证下载资源的准确性、安全性和完整性, 同时也不承担用户因使用这些下载资源对自己和他人造成任何形式的伤害或损失。

人人文库网所有资源均是用户自行上传分享,仅供网友学习交流,未经上传用户书面授权,请勿作他用。

川公网安备: 51019002004831号

川公网安备: 51019002004831号