摘要

此次课题主要研究盖塑料注塑模具的设计,圆盖的应用材料为聚丙烯(pp)是一种半结晶的热塑性塑料。具有较好的耐冲击性,机械性质较为强韧,具有抗多种有机溶剂和酸碱腐蚀。在工业界具有广泛的应用,是我们现如今常见的高分子材料之一。

现在模具已成为产业发展的基础,然而,对塑料模具占模具总量的比例37%,可见塑料成型没模具在生活应用领域中占有很重要的部分,随着我国经济发展,塑料制品生产越来越广泛,塑料何曾性工业在工业中地位日益提高。

本次毕业的设计通过对塑件进行工艺性的分析和比较从而了解盖塑料模具的生产过程以及工作原理。此次课题从多个方面介绍了注射成型的基本原理,完整零件的尺寸计算到模具动作过程、从注射机的选用、浇注系统的组成,并对模具强度要求做了说明,较为详细的研究了盖塑料注塑模具的设计。通过本次设计,使我对塑料注射模有了一个初步的认识和见解,从中也注意到了生产过程中的细节问题,研究注塑模具来生产塑件产品,也让我了解其生产过程和实现自动化提高产量有很大的生活意义。

关键词: 注塑模;圆盖

Abstract

This topic mainly studies cover plastic injection mold design, the application of the dome material for polypropylene (pp) is a semicrystalline thermoplastic plastics. Has good resistance to impact, mechanical properties is relatively strong, with a variety of organic solvent and acid and alkali corrosion resistance. Has wide application in industry, is one of our nowadays common polymer materials.

Now the mold has become the foundation for the development of the industry, however, the plastic mold accounted for 37% of the total mould, plastic molding didn't die in life occupies a very important part of the application field, along with our country economic development, the plastic products production is more and more widely, plastic ever sex industry growing status in the industry.

The graduation design through the analysis of plastic parts for manufacturability and comparison to understand what the cover plastic mold production process and working principle. The subject, the basic principle of the injection molding are introduced from several aspects, the size of the complete parts calculation to mold action process, including the selection of

injection machine, the composition of gating system, and has proved to mold strength requirement, more detailed study of the cover of plastic injection mould design. Through the design, make me to plastic injection mould has a preliminary understanding and insights, which also noticed the details in the process of production, plastic injection mold to produce a product, also let me know the production process and automation to increase production has a lot of life meaning.

Key words: Injection mold; round cap

目 录

第一章产品的说明 1

第二章塑件的分析 2

2.1 PP的主要特点 2

第三章注射机的型号和规格选择及校核 4

3.1 注射机的选用 4

3.2 注射压力的校核 4

3.3 锁模力的校核 5

3.4 开模行程与推出机构的校核 5

第四章分型面的选择 7

4.1 分型面的形式 7

4.2 分型面的选择原则 7

4.3 我们这里选择水平分型面 8

第五章型腔数目的决定及排布 9

5.1 型腔数目的确定 9

5.2 多型腔的排列 9

第六章浇注系统的设计 11

6.1 浇注系统的组成 11

6.2 浇注系统各部件设计 11

6.2.1 主流道设计 11

6.2.2 冷料穴的设计 12

6.2.3 分流道的设计 13

6.2.4 浇口的设计 14

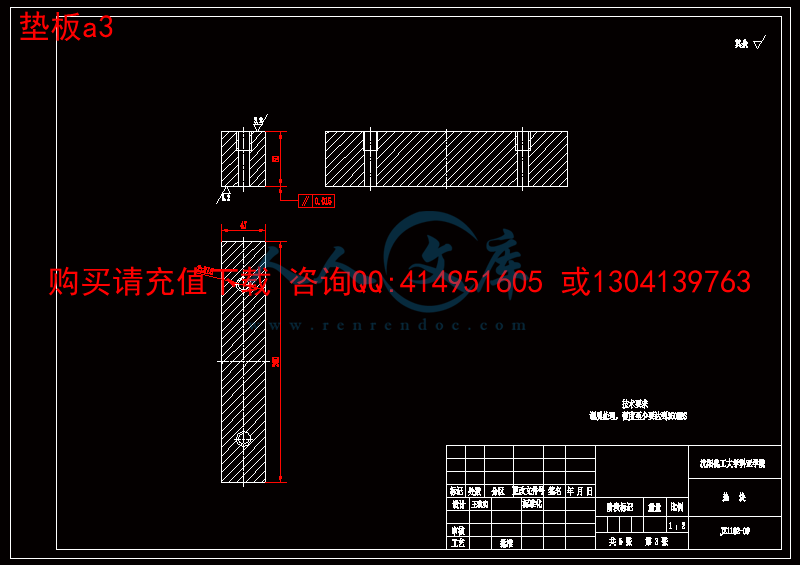

第七章成型零件的工作尺寸计算 16

7.1 凹模的结构形式 16

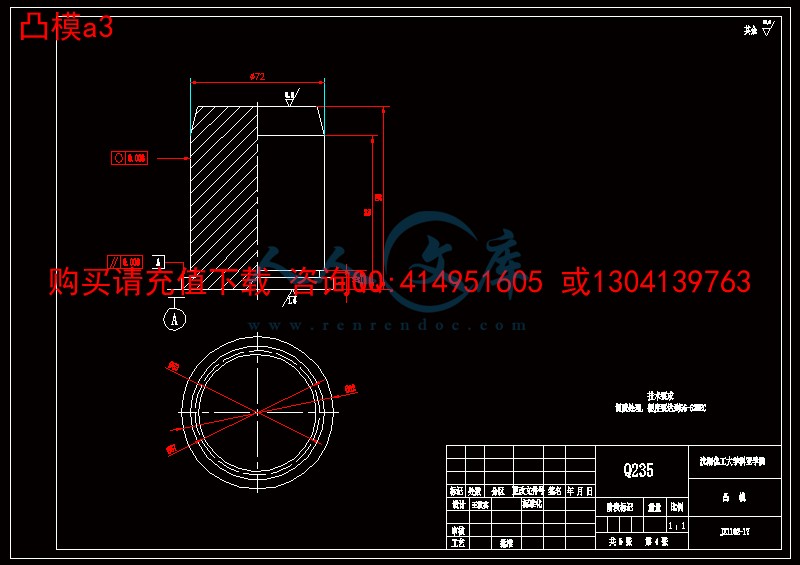

7.2 凸模的结构设计 16

7.3 成型零件的工作尺寸计算 17

7.3.1 凹模径向尺寸计算 17

7.3.2 凹模型腔高度尺寸的计算 17

7.3.3 型芯径向尺寸的计算 18

7.3.4 型芯高度尺寸的计算 19

7.3.5 型腔壁厚和底板厚度计算 19

第八章导柱导向机构的设计 20

第九章脱模机构的设计 22

9.1 何为脱模机构 22

9.2 脱模机构的分类及选用 22

9.3 脱模机构的设计原则 22

9.4 推杆的结构形式及形状 22

9.5 推杆的固定方式 23

第十章温度调节系统的设计 24

10.1 冷却系统设计 24

10.2 冷却时间的确定 24

10.3 冷却系统设计原则 25

10.4 冷却系统的结构形式 25

10.5 冷却系统的计算 26

结论 27

参考文献 28

致谢 29

川公网安备: 51019002004831号

川公网安备: 51019002004831号