【温馨提示】 购买原稿文件请充值后自助下载。

以下预览截图到的都有源文件,图纸是CAD,文档是WORD,下载后即可获得。

预览截图请勿抄袭,原稿文件完整清晰,无水印,可编辑。

有疑问可以咨询QQ:414951605或1304139763

摘要: 随着社会信息化及经济全球化的迅猛发展,人们的审美观念不断的进步与更新,人们对于产品的包装的要求越来越高,对产品的外观提出更高的要求,所以,企业对于包装设备的要求也越来越高。

全自动曲面印刷机是一种专用于曲面状包装规则印刷机器。由程控器协调上下料和各部件的同步联动。

本课题是对曲面印刷机叠杯转鼓机构的设计。叠杯转鼓机构是曲面印刷机中重要组成部分,它是印刷以后将油墨干燥好的杯子摞成卷的自动装置,是高速情况下实现曲面印刷机自动化的关键部分。设计中充分利用了Pro/E软件对设计内容进行三维实体建模、装配、仿真,并通过Pro/E导出2维装配图。设计说明书通过图片与文字相结合的方法,形象的介绍了曲面印刷机叠杯转鼓机构的各个组成部分,并对组成叠杯转鼓机构的关键零件进行了制造工艺分析与设计。

关键词:曲面印刷机;Pro/E;三维;叠杯转鼓机构

The Design of Stacking Institutions Equipment for Curved Surface Printing Machine

Abstarct: As the social informatization and economic globalization are rapidly developing, people's aesthetic ideas are continuously progressing and updating. More and more strict requirements are proposed to improve packing of products, as well as appearance of products. Consequently, it is more and more difficult for enterprises to meet their requirements of packaging equipment.

Automatic surface presses is a dedicated to cylindrical arc-shaped or truncated cone-shaped items, packaging printing machines, including rotary printing agency, reel institutions, the upper and lower feeding mechanism and drive mechanism. Rotary printing organizations patterned chromatic large rubber roller circumference, with reel-mode contact roller printing on the outer surface of the printed material. The machine up to overprint the six-color, maximum speed of 300 per minute, overlay accuracy, pattern reproducibility, high degree of automation. Applicable to high-volume, high-efficiency printing of plastic, metal, paper molding of packaging containers, and letterpress and die easy to replace, but also for the many varieties of small quantities of high-speed color printing.

This topic aims to design the stacking institutions equipment of curved surface printing machine. It is an important part of the transmission system of curved surface printing machine. And it is an automatic device to put up the ink dried cup accumulation and is a key part that can realize the automation of curved surface printing machine when running up. In the design, pro/e software is made full use of to perform 3D modeling, assembly, simulation to content of the design, and 2D diagram of assembly is laid down through SolidWorks. By combining words with pictures, the instructions of the design vividly introduce all parts of stacking institutions for curved surface printing machine, And composition of the cup stacking drum key parts of the manufacturing process analysis and design.

Keywords:curvedsurface printing machine ; pro/E ;data3d; tacking institutionsequipment

目 录

摘要…………………………………………………………………………………………Ⅰ

Abstract ……………………………………………………………………………………Ⅱ目录…………………………………………………………………………………………Ⅲ

1 绪论 1

1.1全自动曲面印刷机简介 1

1.2 设计目的和意义 1

1.3 国内外曲面印刷机的研究开发状况 1

1.4本次设计思路 4

2 研究手段与机构分析 4

2.1 研究手段 5

2.2 叠杯转鼓机构的机构分析 7

2.3 叠杯转鼓机构内部结构图 9

2.4 叠杯转鼓机构装配三维图 10

3 重要零件的选取和设计 10

3.1 重要零件的选取 10

3.2 叠杯转鼓的设计 13

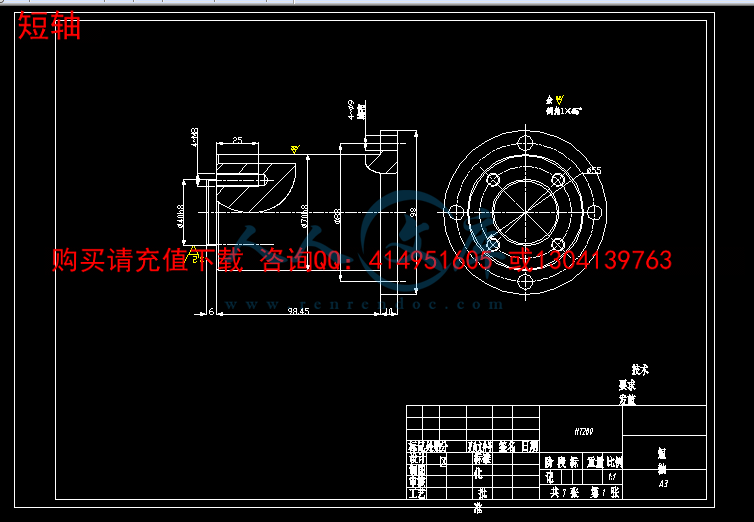

3.3 轴的设计 16

3.4 轴承的选择 20

3.5 螺钉的选择 23

3.6 其他零件结构设计和三维模型 24

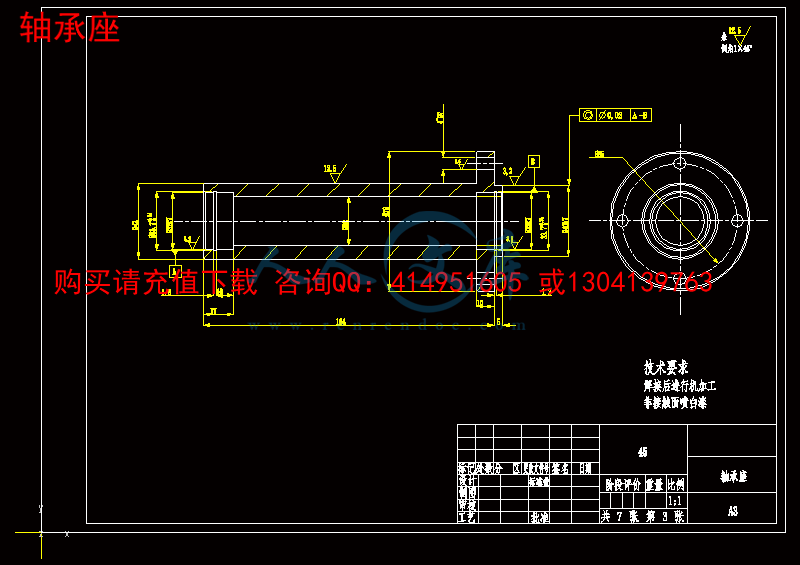

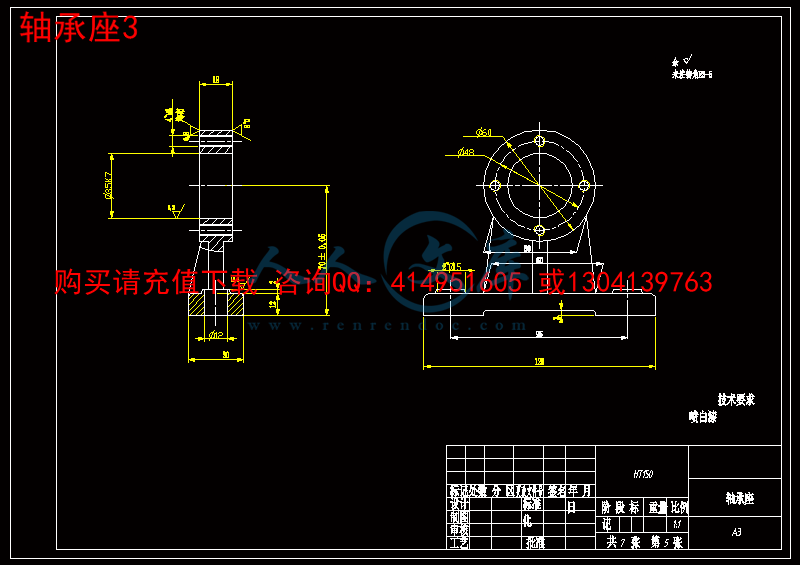

4 轴承座的工艺结构设计和工序 28

4.1 零件的分析 28

4.2 毛坯选择 29

4.3 拟订加工工艺路线 29

4.4 选择加工设备和工艺设备 30

4.5 机械加工工序卡 31

5 结论 33

参考文献 34

致谢 36

1 绪论

1.1 全自动曲面印刷机简介

全自动曲面印刷机是机器可以达到六色套印,MAX300r/min,套印准确,重复性模式高,自动化程度高。

1.2 设计目的和意义

印刷业在国民经济中的工业部门中占有非常重要的地位,在人们生活的各个方面他的产品都渗透,所以它是推动人类文明进步一股力量。因此,在工业化先进国家和地区,印刷业已经成为印刷机械制造业的支柱产业,它是为印刷业提供技术和成套设备[3]。展望未来,在未来很长一段时间,这种技术会占有一定的市场,打印的增长将持续到2040年至2050年五年,然后会逐渐减少,但不会死亡[3]。本研究的目的是为了改进现有的曲面印刷机的缺点。现在印刷机的印刷数量是不够的,有的只能打印四色或单色,有的只能打印一种形状的物品。虽然有些技术水平高,但生产成本也相对较高。然而,所以本研究应在这些区域中进行,必须进行修改,以便它在彩色印刷,对印刷和印刷费用的数量的进一步改进,该技术是更成熟的[1] - [6]。

川公网安备: 51019002004831号

川公网安备: 51019002004831号