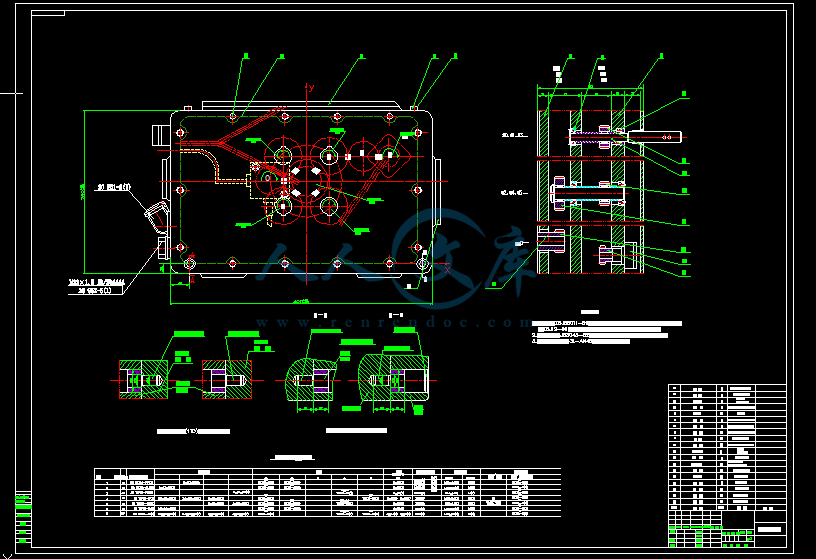

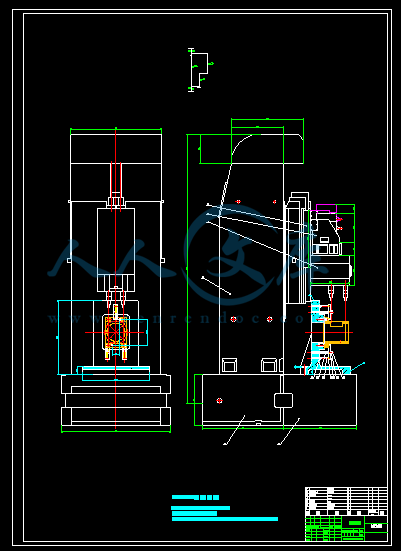

联轴器箱体钻顶面4XM4螺纹底孔组合机床设计(全套含CAD图纸)

收藏

资源目录

压缩包内文档预览:

编号:6706612

类型:共享资源

大小:6.93MB

格式:ZIP

上传时间:2017-12-20

上传人:机****料

认证信息

个人认证

高**(实名认证)

河南

IP属地:河南

100

积分

- 关 键 词:

-

联轴器

箱体

钻顶面

xm4

螺纹

罗纹

底孔

组合

机床

设计

全套

cad

图纸

- 资源描述:

-

- 内容简介:

-

G.Seligeretal.(eds.),AdvancesinSustainableManufacturing:Proceedingsofthe8thGlobalConference149onSustainableManufacturing,DOI10.1007/978-3-642-20183-7_22,Springer-VerlagBerlinHeidelberg2011MethodologyforHighAccuracyInstallationofSustainableJigsandFixturesJ.Jamshidi,P.G.MaropoulosDepartmentofMechanicalEngineering,UniversityofBath,UKAbstractTheabilitytoaccuratelymeasurethecomponentsofjigsandfixturesduringtheirinstallationdeterminesthestateoftheirprecision,especiallyforlargesizeproductsandapplications.Thismatteriscrucialinmasscustomisationwheresmallbatchesofproductsandcomponentswithhighvarietyindesignaremanufactured.Productqualityshouldbeinharmonywithrapidchangeoverphilosophyascompromisingqualityforspeedisnotforgivableforsensitivecomponentsandassembliessuchasthoseseenintheaerospaceindustry.Itisnecessaryfortheinstallationofthejigsandfixturestobehighlyaccurateinordertominimisetheuseoftolerancebudgetduetovariationsinjigsandfixturepositioning.Majoroverheadcostsforjigsandfixturesparticularlyintheaerospaceindustryledtothedevelopmentoftheconceptofflexibleandreconfigurablejigsandfixtures.Reusabilityofreconfigurablejigsandfixturesmakesthemattractiveforsustainablesolutionsastheircomponentscanbereusedforseveralvariantofaproductorassembly.Themaindrawbacksofthistypeofjigsandfixtureshavebeentheirpooraccuracyandreliability.Inthispaperaccuratepositioningofthekeycomponentsofsustainablejigsandfixturesisinvestigated.Thefactorsaffectingtheperformanceofthejigsandfixturesarereviewedfromtheinstallationstage.Thepaperintroducesamethodologyforminimisinguncertaintiesinpositioningoftheholdsandclampsforflexiblejigsandfixtures.Keywords:SustainableJig,Jiginstallation,CalibrationUncertainty,JigMonitoring,Metrology,ReusableJig1INTRODUCTIONFactorssuchasqualityandreliabilityhavelongconvertedtoimplicitcharacteristicsofthenewproducts.Recentmarkettrendshaveforcedmanufacturingindustriestomovetowardsmasscustomisationintheirproductsandservicerange.Increasedvariationinthedesignofnewproductsisfollowedbyasecondwaveofvariationwithhigheramplitudeatsubassembliesandcomponentlevel.Stateoftheartmanufacturingsystemsandtechnologieshaveprovidedmoreflexibility,enablingdesignerstothinkmorefreely.Forinstancenewlargevolumemeasurementsystems,developedinthepastfewyears,arecapableofmeasuringseveraldecametredistances.Suchtechnologiesfacilitatetheverificationoflargesizecomponentsthatusedtobemanufacturedfromseveralassembledcomponents.Themanufacturingoflargesizeproductsrequiresspecialistjigsandfixturesinorderfortheircomponentstobeheldinthedesiredorientationduringbuildandassembly.Thisrequiresmajoroverheadcostthatcanonlybejustifiedbymassproductioninsomecasesorotherwisethecostoffinishedproductscanbeveryhigh.Thisissuecontradictswiththemarkettrendswherecustomersareconstantlylookingforhighervaluefortheirmoney.Inatypicalproductthevariationintheproductcreatesamoresustainablebusinessasitcanfulfiltheneedsofarelativelylargermarket.Flexibleandreconfigurablejigsandfixturethatcanbeformedindifferentshapestosupportdifferentvariationofproductsisakeysolutionfortheabovechallenges.Theconceptofflexiblejigexistedforseveralyearsintheresearchdomain1.However,theyarenotfullyutilisedtoagreatextentinrealproductionfacilitiesespeciallyforlargesizeproductmanufacturers,suchasaerospace.Thisisduetothechallengesrelatedtotheirinitialinstallation,poorcalibration,andrepeatabilitythatoftenexceedthetolerancerequirement.Themanufacturingofthesejigsandfixturesfromhighqualitykeycomponentsaswellastheirintegrationwithlargevolumemetrologysystemscanreducetheabovelimitations.Thispapercoversmetrologyissuesrelatedtotheinstallationandcalibrationofflexiblejigsandfixturesaswellastheirmonitoringduringservice.2RELATEDWORK2.1ManufacturingandassemblyoflargescalepartsTypicallypriortoprecisionmanufacturingofmechanicalpartsitisessentialtomovetherawmaterialtothemachinebench,proceedwithroughcuttingthenfinealignmentandclamping.Atthisstagethepartisreadyformachiningofitshighprecisionkeyfeatures.However,thisisnotalwayspossibleforlargesizeand/orheavycomponents.Largescaleproductsrefertothosewithcomponentsthatarenoteconomicallypossibletohandleormovearoundinthefactoryforfabricationandassemblypurposes2.Themanufacturingandassemblyprocessesofthesepartsencompassmovementofthemachinesandsystemstothedesiredlocationandorientationwithrespecttotheseparts.Suchpartsarenormallyheldintheirpositionsusinglargesizejigsandfixtures.Ifthesepartsareproducedinsmallbatchsizesthatisthecaseforaerospaceindustries,highoverheadcostperproductwilloccur.Therehavebeenmanyattemptstodesignandmanufacturejigsandfixturessothattheycanholdanumberofvariantsofcomponents3,4.However,thisapproachisnotfeasibleforpartswithsensitiveorkeyfeaturesduetotheirhighaccuracyrequirements.J.Jamshidi,P.G.Maropoulos150Adjustable,reconfigurablejigsandfixturesproducelowerrepeatabilityovertimecomparedtofixedones.Fixedjigshavepermanenttopologyachievedthroughtheirpermanentjointsthatareweldedorriveted.Mechanicalfailureofthesejigsandfixturesforexampleduetofatigueandplasticdeformationisamaincauseofterminatingtheirserviceandsendingthemforrecycling.Withsmallbatchmanufacturingrequirementsitisnowcommontoretireaconformingjigastheirservicelifedependsonthelifeofproducts.Inotherwordssoonaftertheceaseofmanufacturingapartsvariant,theassociatedjigsandfixturesbecomeredundant.Evenifthejigsarestillinworkingorder,theyhavetobescrappedandsentforrecycling.Thismethodbringstheburdenofhighenergyconsumptionforrecycling.Evenforthefixedjigsandfixturesthedriftinthelargesizepartsandjigcanaffecttheaccuracyofalargesizeassembly5.Severalmethodsforanalysingjigrigidityhavebeendeveloped6toevaluatetheimpactofvibrationonlargesizejigs.Inanycaseamoresustainablemanufacturingcanonlybeachievedbyalternativesolutions.Figure1:Typicalcomponentsoflargescalejig(imagecourtesyofElectroimpact/G150TFIX/gallery.asp)Extensiveleadtimetomanufactureisanothermajordrawbackforfixedjigsandfixtures.Thesejigsshouldbeorderedwellinadvanceofanymanufacturingprocesses.Thiscancreateadditionalcomplexityinproductionplanningandproducttimetomarket.Regardlessoftheirtype,largescalejigshaveanumberofcommonelementsincludingonemainframe,oneoranumberofinnerframes,potentiallyoneoranumberofmovingmechanisms,andsmallercomponentssuchasclamps,bushings,pickupsandadjustablescrews(Figure1).2.2FlexiblejigsandfixturesTheconceptofflexiblejigsandfixturesisdevelopedforincreasedsustainability,rapidchangeoveraswellaslowcost.Itisnowpossibletouseofftheshelfmodulesandclampsforjigsandfixturesdesignandassembly.Dependingontherequirementonlyahandfulofspecialisedcomponentsforthejigsandfixturesmightbeneededtobecustomdesignedandmanufactured.Inthisconceptthemajorityofbulkcomponents,jointsattheattachmentsareusedinforaspecificapplication.Oncetheproductdesignvariantisfullymanufactureditisthenpossibletodisassembletheabovecomponentsandreassembletheminanewtopologytosuitethenextdesignvariant.Thiscyclecanberepeatedoveralargenumberoftimesresultinginreducedoverheadcostforjigsandfixtures.Needlesstomentiontheotherfactorssuchasdisassemblytime,resettingtime,operatorstimeshouldbeconsideredforevaluatingtherealcostbenefitofusingthistypeofjigsandfixtures.Thisapproachbestreducesthecostofjigsandfixturesfortheassemblyandcomponentrangesthatarefairlycloseindesign.Dependingonthelevelofvariationsinthecomponentsandthetypeofworkrequiredoneachadifferentpercentageoftheflexiblejigsneedtoberearranged.Thismatteriscrucialtobeconsideredatdesignstageinordertoincreasethebenefitofusingthistypeofjigsandfixtures.Forexample,whenpossible,thelocationand3Dpositioningofpickupsandclampsondifferentvariantsofthecomponentoreventotallydifferentpartsshouldbeincloseproximitytoincreasecompatibilityandinter-changeabilityofsub-systemsofjigsandfixtures.Havingacollectionofthekeycomponentsofthejigscanguaranteetheavailabilityofthedesiredjigsinashorttime.Inadditiontothisthestorageofthejigsrequiredlessspaceasitispossibletodismantleallthemodulesthataretypicallyintheformofscaffoldingandplacethemnexttoeachother.Flexiblejigsarecurrentlyutilisedinsomeoftheautomotivecompanies(Figure2)astheiraccuracylevelissufficientforthissector.DespitetheabovebenefitsthereareClampMainframeInnerframeComponentAdjustableholdsMovingmechanismsMethodologyforHighAccuracyInstallationofSustainableJigsandFixtures151notmanyflexiblejigsinoperationinlargesizemanufacturingfacilitiessuchasaerospacefactories.Accuracyanduncertaintyofpositioningpins,repeatabilityoftheclampsanddriftofthejigstructureareallcontributingtothefactthatthesejigscannotmeetthetolerancerequirementsofthepowergenerationandaerospaceindustries.Thesejigshavehighpotentialsforutilisationintheaboveindustriesoncetheiraccuracyproblemsareresolved.Figure2:Fixturewithreconfigurablecomponentsforautomotiveindustry(imagecourtesyofWittehttp:/www.horst-witte.de/en/)Therehasbeenanumberofnewdevelopmentsinlargevolumemetrologysystemsandtechnologies.Modernlaserbasedmetrologysystemsandtechnologiesarenowcapableofmeasuringlargesizeproductsuptoseveraldecametreswithacceptableaccuracy.Thesesystemscanbeusedtoaccuratelypositionmountingsofthekeycomponentsofthejigduringitsinstallationandinitialsetup.Theinstallationofjigsandfixturestypicallystartsformitsbaseormainframethenlargecomponentsandgraduallytothesmallercomponentssuchaspickupsandclamps.Metrologysystemscanbeusedfortheinstallationofflexiblejigmainframeanditsinnerframestoguaranteethecorrectpositioningofeachandeverycomponent.Table1showsafewoftheselargescalemeasurementsystems.Fortechnologicalreviewofthesesystemssee7.Lasertrackersystemscapableofmeasuringreferencepoints,areamongthemostsuitablemeasurementsystemsforthispurpose.TheinstrumenttracksaSphericallyMountedRetroreflector(SMR)targetthepositionofwhichcanberegisteredinthreedimensionalspace.SMRcanbecontacteddirectlywiththetargetobjecttoprovidegeometricalpositionalinformationorcanbeusedwithinamechanicallyrepeatableSMRnestknownasLasertrackertargetorinshorttargetfromthispointon.Lasertrackerslikeanyothermeasurementinstrumenthavealevelofuncertaintythatneedtobeaccountedforduringthejiginstallationprocess.Alsothelineofsightissuesbetweenthelasertrackeranditstargetpointshouldbeconsideredandifnecessarymultipletrackerpositionsshouldbeused.Inrealmeasurementactivitytheresultmustbeaccompaniedwithastatementofuncertainty.Suchstatementcharacterisesthedispersionofthevaluesthatarereasonablyattributedtothemeasurand8.Thisissueisthesamefortheinstallationandlaterverificationofanyjigorfixture.Thisknowledgeclarifiesthejigcapabilityofagivenpositioningandassemblytask.Inotherworditindicatesifajigcanmeetthetolerancerequirementsforitsrelatedprocesses.2.3ComparisonofjigphilosophiesTherearealargenumberofdifferentshapeanddesignjigsandfixturesindifferentcompaniesforvariousmanufacturingandassemblyapplications.Someofthesejigsandfixturesarereadilyavailableinstandardforms,whilesomearedesignedandmanufacturedspecifictoparticularpartsandtasks.Thelattercanbeveryexpensivebasedonthecomplexityandscaleoftheproducts9.Regardlessofcostandpurposeamanufacturingorassemblyprocesscanbeperformedusingwithnojig,withfixedframejigs,orwithreconfigurableorflexiblejigs.Table2providesacomparisonofthesemethodswiththeirtypicalapplications.Fixedframejigsaretypicallyforheavydutyapplications.Theyaremoresuitableforapplicationswithalargenumberofproductsthatcanrelaxtheoverheadcostofthejig.Thereareseveraladvantagesintheapplicationofflexiblejigsandfixturesforthemanufacturingandassemblyoflargeandcomplexproducts.Inparticularforresearchanddevelopmentwork,aswellasforcaseswherelowvolumeproductsaremanufacturedflexiblejigandfixturecanbeverybeneficial.Inadditiontotimeandmoneysavingbenefitsthepossibilityofhavingaflexiblejiggivesmorefreedomtothedesign,manufacturingandassemblyprocessesduetothelowdirectandrecurrentcostofchangingtheoveralltopologyofthejig.ReconfigurabilityandreusabilityofflexiblejigisamainClampMainframeInnerframeComponentJ.Jamshidi,P.G.Maropoulos152advantageforthistypeofjigcomparedtoconventionaljigs.Thisisparticularlyimportantasitisinlinewiththeindustrydirectionintermsofgreenmanufacturingbyrecyclingcomponentsfromausedsystem,reducingprojectcostswithregardstoexpensesfortoolingofassociateditems.Table1:Examplesoflargevolume/portablemeasurementinstrumentsforjigverificationMeasurementtypeInstrumentAuxiliarycomponentsContactNon-contactImageSMRprobe9LaserTrackerT-probe9LaserRadarSphericaltargets9Targets9PhotogrammetryLightprojection9Laserbasedscanninghead9ArticulatedArmCMMContactprobe93FLEXIBLEJIGINSTALLATIONTheissuesandconcernsthatneedtobeconsideredinthejiginstallationprocedurearedescribedinthissection.Theinstallationofthejigcomponentsintherightpositioncanbeachallengingespeciallywhenthepositioningtolerancesaretights.Flexiblejigsshouldalsobemonitoredinordertoexploitandcomparetheirrigiditywiththatoftheconventionalones.Stagebystagemeasurementinstructionforthejiginstallationbasedontheresultsofaninitialjigsetupinthesimulationsoftwareenvironmentandpracticalexperimentofalargesizejigwithdimensionsof5mx4mx3misgiveninagenericdescription.Thisisregardlessofwhetherthejigisinfirsttimeinstallationoritisachangeofanexistingjigtopologyintoanewshape,forholdingadifferentcomponent.Dependingonthecomplexityatypicallargesizejighasbetweenthreetofivelevelsofframes.Apartfromthebaselevelwithnormallyonemainframe,ateachleveltherecanbeoneorseveralframes.Theseframesareinterrelatedwithreferencetothejigdatuminordertofacilitatethepositioningandfunctionalityrequired.Inanautomated,fixedplatform,roboticsystemscarryoutseveraltaskssuchaspartpositioning,machiningandassembly.Therobotworkingdatumthereforeislinkedwiththeworkingframeofthejig.Carefulconsiderationofjigdatumingstrategyanditssubsequentinstallationcansecureachievingthedesiredtolerance.3.1MeasurementassistedflexiblejiginstallationThereareseveralstagesfortheinstallationofflexiblejigsthatcanbecarriedoutinfirstsimulationandthenrealworld.Theuseofsimulationexercisecanreducethenumberofpotentialerrorsandreworkduringthisprocess.Theprocessofmeasurementassistedinstallationissimilartotrackingobjectstopositionthatiscommonforlargesizeassemblies.Inthisapproachthecomponentsofthejigareroughlypositioned,within1mmtolerancefromthetargetposition,atfirst.Thenwhenallofthejigcomponentsareattachedintotheirdesignatedpositions,within0.1mmto0.15mmtolerance,theyaretightenedusingtheappropriatetorque.Thetypicalstagesofmetrologyassistedflexiblejiginstallationaregivenbelow:1.settinginitialreferenceframesinthefactory2.measurementofinitialreferenceframe3.installationofbaseormainframeinitsposition4.installationofinnerframesoffline5.installationofholdingandpositioningbrackets6.installationofclamps,bushingsandpickupsintheirroughpositiononinnerframesandmainframe7.installationofinnerframeonthebaseframe8.fineadjustmentandfasteningofkeylocatingcomponents9.verificationofreferenceframesandclamps10.inservicemonitoringofkeypositionsonthejigThesestagesarerelatedtothecompleteinstallationofthejigfromthescratch.NeedlesstomentionthatincaseofslightMethodologyforHighAccuracyInstallationofSustainableJigsandFixtures153changeindesignvariationsomeofthefollowingoperationswillbeomitted.Table2:AbriefcomparisonbetweendifferentjigphilosophiesTypicalcharacteristicFixedframeFlexiblejigJig-lessApplicationLargevolumeproductionLowvolumeproductionPrototypingUniquenessRepeatableReconfigurableCosteffectivenessDurabilityVeryhighHighLowProsRigidityVeryhighUncertaintyrigidityLowWeightHeavyMediumLowPortabilityNon-portableDifficultcomponentpositioningineachsetupDifficulttoprogramCostVeryhighMediumLowConsManufacturingtimeLongMediumShort3.2AlgorithmforflexiblejiginstallationTheinstallationprocessesforflexiblejigstakethefollowingmainstages:1.theinstallationofmainframeofthejig2.theassemblyofmovingunitsandsub-systems3.theinstallationofthejiginnerframesonthejigassembly4.theassemblyofpickupsandclampsonthejig.Themainframeisthebackboneofthejigthatistypicallyfixedforalargenumberofjigtopologyanddesignvariations.Thereforeitdoesnotchangeinshapeasregularlyastheinnerframeorthesmallerelementsofthejigsuchasbushings,pickupsandclamps.Carefulconsiderationofthemanufacturingprocesscanreducethenecessityofrearranginglargerelementsofthejigcomponentsresultinginfurthertimeandmoneysaving.Figure3inthreeseparategroupsofactivitiesshowstheprocessesofflexiblejiginstallation.Inthisprocessitisassumedthatthestandardpartsofthejigareselectedfromtheavailable,offtheshelfsectionsandcomponents.Theninadvanceofthephysicalinstallationanumberoftestsandtrialsarecarriedouttoplanthejiginstallationinsuchawaythattheuncertaintyofmeasurementisreduced.Oncetheacceptablelevelofuncertaintyisachievedthephysicalinstallationcantakeplace.Figure3:MeasurementassistedinstallationprocedureforflexiblejigJ.Jamshidi,P.G.Maropoulos154Injiginstallationprocessitmightberequiredtousemultiplemeasurementsystemorameasurementsystemfromseverallocationstocoverthecompletesetofkeypointsforjiginstallation.Thisshouldincludetheauxiliarytargetreferencepointsthatareplacedonthefactoryfloorandwallforstabilityanddriftcheckduringthejigservice.Duringthelocalisationofthekeypointsonthejigtheuncertaintyofthemeasurementinstrumentshouldbetakenintoaccount.Asaruleofthumbtheaccuracyofthejigpositioningforeachkeylocationshouldbeinanorder10timesbetterthantherequiredtolerance.Inotherwordifthetoleranceonthecomponentisspecifiedas0.1mmtheaccuracyofthejigpositioningshouldbeatleast0.01mm.Thebestpracticeapproachesfortheflexiblejiginstallationaregivenbelow:1.Aplannedpositionfortheinitialreferencepointsonthefactorywallandfloorispreferredinordertominimiseuncertaintyofthemeasurement.2.Theinstrumentpositionshouldbeverifiedonregularbasesusingtheinitialreferencepoints.3.OneachlargesectionofthejigseveralSMRnestscanbeattachedforbettertrackingandrepeatability.4.Wherethelargecomponentsofthejighavebendortwistthelevelmeasurementshouldbefocussedonthecentralsectionofthebeamstoreduceangularpositioningerror.5.Thereferencepointsontheinnerframesshouldbeselectedasdistantaspossibleforcreatingframecoordinatesystems.Thiscanresultinsmalleruncertaintywhenintheinnerframecoordinatesystem.4UNCERTAINTYUncertaintyifdefinedbyGUM8astheresultoftheevaluationaimedatcharacterisingtherangewithinwhichthetrueval

- 温馨提示:

1: 本站所有资源如无特殊说明,都需要本地电脑安装OFFICE2007和PDF阅读器。图纸软件为CAD,CAXA,PROE,UG,SolidWorks等.压缩文件请下载最新的WinRAR软件解压。

2: 本站的文档不包含任何第三方提供的附件图纸等,如果需要附件,请联系上传者。文件的所有权益归上传用户所有。

3.本站RAR压缩包中若带图纸,网页内容里面会有图纸预览,若没有图纸预览就没有图纸。

4. 未经权益所有人同意不得将文件中的内容挪作商业或盈利用途。

5. 人人文库网仅提供信息存储空间,仅对用户上传内容的表现方式做保护处理,对用户上传分享的文档内容本身不做任何修改或编辑,并不能对任何下载内容负责。

6. 下载文件中如有侵权或不适当内容,请与我们联系,我们立即纠正。

7. 本站不保证下载资源的准确性、安全性和完整性, 同时也不承担用户因使用这些下载资源对自己和他人造成任何形式的伤害或损失。

人人文库网所有资源均是用户自行上传分享,仅供网友学习交流,未经上传用户书面授权,请勿作他用。

川公网安备: 51019002004831号

川公网安备: 51019002004831号