资源目录

压缩包内文档预览:(预览前20页/共37页)

编号:6782200

类型:共享资源

大小:2.48MB

格式:ZIP

上传时间:2017-12-29

上传人:机****料

认证信息

个人认证

高**(实名认证)

河南

IP属地:河南

50

积分

- 关 键 词:

-

电器

旋钮

注塑

模具设计

全套

cad

图纸

- 资源描述:

-

- 内容简介:

-

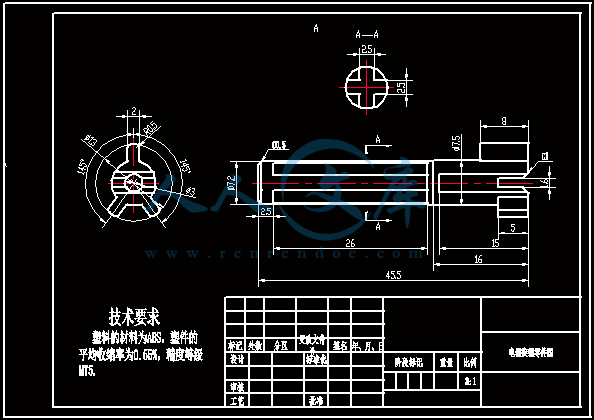

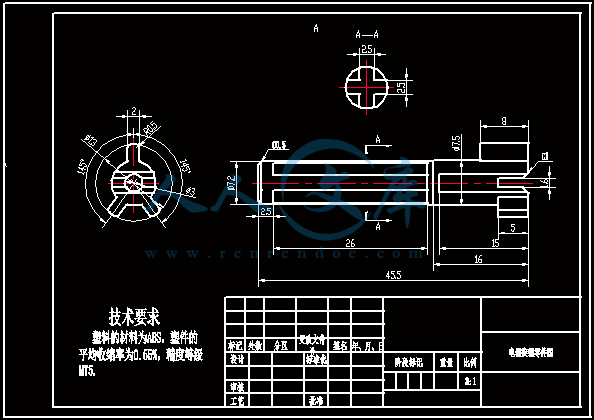

课题任务书系:机械工程系 专业:材料成型及控制工程 指导教师李良喜学生姓名何楚星课题名称电器旋钮CAD注射模设计内容及任务 根据所给定的注塑零件产品(如下图所示),设计出注塑模具。主要内容如下:一、产品基本要求分析二、根据CAD二维图纸对设计模型进行Pro/E三维造型三、塑件材料选择四、成型方法及其工艺的选择五、注射机的选择六、模具相关结构的设计七、成型零件的制造工艺分析设计八、模具材料的选择九、模具工作过程分析十、绘制相关图纸十一、编写设计说明书拟达到的要求或技术指标按照“湖南工学院毕业设计(论文)工作管理规定”,本课题设计要求及技术指标如下:(一)模具1、保证规定的生产率和高质量产品的同时,力求成本低、寿命长。2、模具结构设计合理,工艺性好,具有一定的创新性。3、操作安全、方便,易于维修,便于管理。4、在保证模具强度前提下,注意外形美观,各部分比例协调。(二)设计图纸1、模具绘图布局合理,视图完整、清晰,各项内容符合标准要求。2、设计图纸应符合学校的要求,不少于3张零号图纸的结构设计图、装配图和零件图,其中应包含一张以上用计算机绘制的具有中等难度的1号图纸,同时至少有折合1号图幅以上的图纸用手工绘制。(三)设计说明书1、资料数据充分,并标明数据出处。2、计算过程详细、完全。3、公式的字母含义应标明,有时还应标注公式的出处。4、内容条理清楚,按步骤书写。5、说明书按照学校的有关规定,编写不少于12000字的设计说明书,同时上交电子文档。(四)其他要求1、查阅到10篇以上与题目相关的文献2、翻译一篇本专业外文文献(10000个以上印刷符号),并附译文。进度安排起止日期工作内容备注3月1日3月2日 4月1日4月2日 5月4日5月5日 5月7日5月7日 5月20日5月21日 5月23日5月24日 5月25日5月26日 5月29日6月1日 6月10日选取课题及编写开题报告;英文论文翻译;查询相关资料,产品基本要求分析。根据CAD二维图纸对设计模型进行Pro/E三维造型;塑件材料选择、注射机的选择、成型方法及其工艺的选择;模具相关结构的设计;成型零件的制造工艺分析设计;整理设计说明书,按照学院得规范要求排版打印设计说明书;上交毕业设计资料,评阅;准备答辩。主要参考资料1 高军,李熹平,高玉田,褚兴荣. 注塑成型工艺分析及模具设计M. 北京:化学工业出版社. 2009.2 叶久新,王群. 塑料成型工艺及模具设计M. 北京:机械工业出版社. 2007.3 伍先明,张蓉. 塑料模具设计指导M. 北京:国防工业出版社. 2006.4 石富安,龚云表. 工程塑料手册M. 上海:上海科学技术出版社. 2003.5 塑料模具设计手册编写组. 塑料模设计手册M. 第二版. 北京:机械工业出版社. 1999.6 唐志玉,李德群,徐佩弦. 塑料模具设计师指南M. 北京:国防工业出版社.1999.7 陈锡栋,周小玉. 实用模具技术手册M. 北京:机械工业出版社. 2003.8 詹友刚. ProE/ENGINEER 中文野火版5.0模具设计教程M. 第二版. 北京:机械工业出版社. 2010.9 冯炳虎,韩泰荣,殷振海,蒋文森.模具设计与制造简明手册M. 上海:上海科学技术出版社.1991.10 王卫卫. 材料成型设备M. 北京:机械工业出版社. 2010.教研室意见年 月 日系主管领导意见年 月 日Die history1 Die position in industrial productionMold is a high-volume products with the shape tool, is the main process of industrial production equipment. 采用模具生产零部件,具有生产效率高、质量好、成本低、节约能源和原材料等一系列优点,用模具生产制件所具备的高精度、高复杂程度、高一致性、高生产率和低消耗,是其他加工制造方法所不能比 With mold components, with high efficiency, good quality, low cost, saving energy and raw materials and a series of advantages, with the mold workpieces possess high accuracy, high complexity, high consistency, high productivity and low consumption , other manufacturing methods can not match. 已成为当代工业生产的重要手段和工艺发展方向。 Have already become an important means of industrial production and technological development. 现代经济的基础工The basis of the modern industrial economy. 现代工业品的发展和技术水平的提高,很大程度上取决于模具工业的发展水平,因此模具工业对国民经济和社会发展将起越来越大的作用。The development of modern industrial and technological level depends largely on the level of industrial development die, so die industry to national economic and social development will play an increasing role. 1989 年 3 月国务院颁布的关于当前产业政策要点的决定中,把模具列为机械工业技术改造序列的第一位、生产和基本建设序列的第二位 ( 仅次于大型发电设备及相应的输变电设备 ) ,确立模具工业在国民经济中的重要地位。 March 1989 the State Council promulgated on the current industrial policy decision points in the mold as the machinery industry transformation sequence of the first, production and capital construction of the second sequence (after the large-scale power generation equipment and the corresponding power transmission equipment), establish tooling industry in an important position in the national economy. 1997 年以来,又相继把模具及其加工技术和设备列入了当前国家重点鼓励发展的产业、产品和技术目录和鼓励外商投资产业目录。 Since 1997, they have to mold and its processing technology and equipment included in the current national focus on encouraging the development of industries, products and technologies catalog and to encourage foreign investment industry directory. 经国务院批准,从 1997 年到 2000 年,对 80 多家国有专业模具厂实行增值税返还 70% 的优惠政策,以扶植模具工业的发展。 Approved by the State Council, from 1997 to 2000, more than 80 professional mold factory owned 70% VAT refund of preferential policies to support mold industry. 所有这些,都充分体现了国务院和国家有关部门对发展模具工业的重视和支持。 All these have fully demonstrated the development of the State Council and state departments tooling industry attention and support. 目前全世界模具年产值约为 600 亿美元,日、美等工业发达国家的模具工业产值已超过机床工业,从 1997 年开始,我国模具工业产值也超过了机床工业产值。 Mold around the world about the current annual output of 60 billion U.S. dollars, Japan, the United States and other industrialized countries die of industrial output value of more than machine tool industry, beginning in 1997, Chinas industrial output value has exceeded the mold machine tool industry output.2 Chinas mold industry and its development trend模具工业现状 Die & Mould Industry Status由于历史原因形成的封闭式、“ 大 而全” 的 企业特征,我国大部分企业均设有模具车间,处于本厂的配套地位,自 70 年代末才有了模具工业化和生产专业化这个概念。 Due to historical reasons for the formation of closed, big and complete enterprise features, most enterprises in China are equipped with mold workshop, in factory matching status since the late 70s have a mold the concept of industrialization and specialization of production. 生产效率不高,经济效益较差。 Production efficiency is not high, poor economic returns. 模具行业的生产小而散乱,跨行业、投资密集,专业化、商品化和技术管理水平都比较低。 Mold production industry is small and scattered, cross-industry, capital-intensive, professional, commercial and technical management level are relatively low.据不完全统计,全国现有模具专业生产厂、产品厂配套的模具车间(分厂)近17000家,约60万从业人员,年模具总产值达200亿元人民币。 According to incomplete statistics, there are now specialized in manufacturing mold, the product supporting mold factory workshop (factory) near 17 000, about 600 000 employees, annual output value reached 20 billion yuan mold. 但是,我国模具工业现有能力只能满足需求量的60左右,还不能适应国民经济发展的需要。 However, the existing capacity of the mold and die industry can only meet the demand of 60%, still can not meet the needs of national economic development. 目前,国内需要的大型、精密、复杂和长寿命的模具还主要依靠进口。 At present, the domestic needs of large, sophisticated, complex and long life of the mold also rely mainly on imports. 据海关统计,1997年进口模具价值6.3亿美元,这还不包括随设备一起进口的模具;1997年出口模具仅为7800万美元。 According to customs statistics, in 1997 630 million U.S. dollars worth of imports mold, not including the import of mold together with the equipment; in 1997 only 78 million U.S. dollars export mold. 目前我国模具工业的技术水平和制造能力,是我国国民经济建设中的薄弱环节和制约经济持续发展的瓶颈。 At present the technological level of China Die & Mould Industry and manufacturing capacity, Chinas national economy in the weak links and bottlenecks constraining sustainable economic development.1、模具工业产品结构的现状 2.1 Research on the Structure of industrial products mold按照中国模具工业协会的划分,我国模具基本分为10大类,其中,冲压模和塑料成型模两大类占主要部分。 In accordance with the division of China Mould Industry Association, China mold is divided into 10 basic categories, which, stamping die and plastic molding two categories accounted for the main part. 按产值计算,目前我国冲压模占50左右,塑料成形模约占20,拉丝模(工具)约占10,而世界上发达工业国家和地区的塑料成形模比例一般占全部模具产值的40以上。 Calculated by output, present, China accounts for about 50% die stamping, plastic molding die about 20%, Wire Drawing Die (Tool) about 10% of the worlds advanced industrial countries and regions, the proportion of plastic forming die die general of the total output value 40%.我国冲压模大多为简单模、单工序模和符合模等,精冲模,精密多工位级进模还为数不多,模具平均寿命不足100万次,模具最高寿命达到1亿次以上,精度达到35um,有50个以上的级进工位,与国际上最高模具寿命6亿次,平均模具寿命5000万次相比,处于80年代中期国际先进水平。 Most of our stamping die mold for the simple, single-process mode and meet the molds, precision die, precision multi-position progressive die is also one of the few, die less than 100 million times the average life of the mold reached 100 million times the maximum life of more than accuracy 3 5um, more than 50 progressive station, and the international life of the die 600 million times the highest average life of the die 50 million times compared to the mid 80s at the international advanced level.我国的塑料成形模具设计,制作技术起步较晚,整体水平还较低。 Chinas plastic molding mold design, production technology started relatively late, the overall level of low. 目前单型腔,简单型腔的模具达70以上,仍占主导地位。 Currently a single cavity, a simple mold cavity 70%, and still dominant. 一模多腔精密复杂的塑料注射模,多色塑料注射模已经能初步设计和制造。A sophisticated multi-cavity mold plastic injection mold, plastic injection mold has been able to multi-color preliminary design and manufacturing. 模具平均寿命约为80万次左右,主要差距是模具零件变形大、溢边毛刺大、表面质量差、模具型腔冲蚀和腐蚀严重、模具排气不畅和型腔易损等,注射模精度已达到5um以下,最高寿命已突破2000万次,型腔数量已超过100腔,达到了80年代中期至90年代初期的国际先进水平。 Mould is about 80 million times the average life span is about, the main difference is the large deformation of mold components, excess burr side of a large, poor surface quality, erosion and corrosion serious mold cavity, the mold cavity exhaust poor and vulnerable such as, injection mold 5um accuracy has reached below the highest life expectancy has exceeded 20 million times, the number has more than 100 chamber cavity, reaching the mid 80s to early 90s the international advanced level.2、模具工业技术结构现状 2.2 mold Present Status of Technology我国模具工业目前技术水平参差不齐,悬殊较大。 Technical level of Chinas mold industry currently uneven, with wide disparities. 从总体上来讲,与发达工业国家及港台地区先进水平相比,还有较大的差距。 Generally speaking, with the developed industrial countries, Hong Kong and Taiwan advanced level, there is a large gap. 在采用CAD/CAM/CAE/CAPP等技术设计与制造模具方面,无论是应用的广泛性,还是技术水平上都存在很大的差距。 The use of CAD / CAM / CAE / CAPP and other technical design and manufacture molds, both wide application, or technical level, there is a big gap between both. 在应用CAD技术设计模具方面,仅有约10%的模具在设计中采用了CAD,距抛开绘图板还有漫长的一段路要走;在应用CAE进行模具方案设计和分析计算方面,也才刚刚起步,大多还处于试用和动画游戏阶段;在应用CAM技术制造模具方面,一是缺乏先进适用的制造装备,二是现有的工艺设备(包括近10多年来引进的先进设备)或因计算机制式(IBM微机及其兼容机、HP工作站等)不同,或因字节差异、运算速度差异、抗电磁干扰能力差异等,联网率较低,只有5%左右的模具制造设备近年来才开展这项工作;在应用CAPP技术进行工艺规划方面,基本上处于空白状态,需要进行大量的标准化基础工作;在模具共性工艺技术,如模具快速成型技术、抛光技术、电铸成型技术、表面处理技术等方面的CAD/CAM技术应用在我国才刚起步。 In the application of CAD technology design molds, only about 10% of the mold used in the design of CAD, aside from drawing board still has a long way to go; in the application of CAE design and analysis of mold calculation, it was just started, most of the game is still in trial stages and animation; in the application of CAM technology manufacturing molds, first, the lack of advanced manufacturing equipment, and second, the existing process equipment (including the last 10 years the introduction of advanced equipment) or computer standard (IBM PC and compatibles, HP workstations, etc.) different, or because of differences in bytes, processing speed differences, differences in resistance to electromagnetic interference, networking is low, only about 5% of the mold manufacturing equipment of recent work in this task; in the application process planning CAPP technology, basically a blank state, based on the need for a lot of standardization work; in the mold common technology, such as mold rapid prototyping technology, polishing, electroforming technologies, surface treatment technology aspects of CAD / CAM technology in China has just started. 计算机辅助技术的软件开发,尚处于较低水平,需要知识和经验的积累。 Computer-aided technology, software development, is still at low level, the accumulation of knowledge and experience required. 我国大部分模具厂、车间的模具加工设备陈旧,在役期长、精度差、效率低,至今仍在使用普通的锻、车、铣、刨、钻、磨设备加工模具,热处理加工仍在使用盐浴、箱式炉,操作凭工人的经验,设备简陋,能耗高。 Most of our mold factory, mold processing equipment shop old, long in the length of civilian service, accuracy, low efficiency, still use the ordinary forging, turning, milling, planing, drilling, grinding and processing equipment, mold, heat treatment is still in use salt bath, box-type furnace, operating with the experience of workers, poorly equipped, high energy consumption. 设备更新速度缓慢,技术改造,技术进步力度不大。 Renewal of equipment is slow, technological innovation, technological progress is not much intensity. 虽然近年来也引进了不少先进的模具加工设备,但过于分散,或不配套,利用率一般仅有25%左右,设备的一些先进功能也未能得到充分发挥。 Although in recent years introduced many advanced mold processing equipment, but are too scattered, or not complete, only about 25% utilization, equipment, some of the advanced functions are not given full play.缺乏技术素质较高的模具设计、制造工艺技术人员和技术工人,尤其缺乏知识面宽、知识结构层次高的复合型人才。 Lack of technology of high-quality mold design, manufacturing technology and skilled workers, especially the lack of knowledge and breadth, knowledge structure, high levels of compound talents. 中国模具行业中的技术人员,只占从业人员的8%12%左右,且技术人员和技术工人的总体技术水平也较低。 Chinas mold industry and technical personnel, only 8% of employees 12%, and the technical personnel and skilled workers and lower the overall skill level. 1980年以前从业的技术人员和技术工人知识老化,知识结构不能适应现在的需要;而80年代以后从业的人员,专业知识、经验匮乏,动手能力差,不安心,不愿学技术。 Before 1980, practitioners of technical personnel and skilled workers, the aging of knowledge, knowledge structure can not meet the current needs; and staff employed after 80 years, expertise, experience lack of hands-on ability, not ease, do not want to learn technology. 近年来人才外流不仅造成人才数量与素质水平下降,而且人才结构也出现了新的断层,青黄不接,使得模具设计、制造的技术水平难以提高。 In recent years, the brain drain caused by personnel not only decrease the quantity and quality levels, and personnel structure of the emergence of new faults, lean, make mold design, manufacturing difficult to raise the technical level.3、模具工业配套材料,标准件结构现状 2.3 mold industry supporting materials, standard parts of present condition近10多年来,特别是“八五”以来,国家有关部委已多次组织有关材料研究所、大专院校和钢铁企业,研究和开发模具专用系列钢种、模具专用硬质合金及其他模具加工的专用工具、辅助材料等,并有所推广。 Over the past 10 years, especially the Eighth Five-Year, the State organization of the ministries have repeatedly Material Research Institute, universities and steel enterprises, research and development of special series of die steel, molds and other mold-specific carbide special tools, auxiliary materials, and some promotion. 但因材料的质量不够稳定,缺乏必要的试验条件和试验数据,规格品种较少,大型模具和特种模具所需的钢材及规格还有缺口。 However, due to the quality is not stable enough, the lack of the necessary test conditions and test data, specifications and varieties less, large molds and special mold steel and specifications are required for the gap. 在钢材供应上,解决用户的零星用量与钢厂的批量生产的供需矛盾,尚未得到有效的解决。 In the steel supply, settlement amount and sporadic users of mass-produced steel supply and demand contradiction, yet to be effectively addressed. 另外,国外模具钢材近年来相继在国内建立了销售网点,但因渠道不畅、技术服务支撑薄弱及价格偏高、外汇结算制度等因素的影响,目前推广应用不多。 In addition, in recent years have foreign steel mold set up sales outlets in China, but poor channels, technical services support the weak and prices are high, foreign exchange settlement system and other factors, promote the use of much current.模具加工的辅助材料和专用技术近年来虽有所推广应用,但未形成成熟的生产技术,大多仍还处于试验摸索阶段,如模具表面涂层技术、模具表面热处理技术、模具导向副润滑技术、模具型腔传感技术及润滑技术、模具去应力技术、模具抗疲劳及防腐技术等尚未完全形成生产力,走向商品化。 Mold supporting materials and special techniques in recent years despite the popularization and application, but failed to mature production technology, most still also in the exploratory stage tests, such as die coating technology, surface treatment technology mold, mold guide lubrication technology Die sensing technology and lubrication technology, mold to stress technology, mold and other anti-fatigue and anti-corrosion technology productivity has not yet fully formed, towards commercialization. 一些关键、重要的技术也还缺少知识产权的保护。 Some key, important technologies also lack the protection of intellectual property.我国的模具标准件生产,80年代初才形成小规模生产,模具标准化程度及标准件的使用覆盖面约占20%,从市场上能配到的也只有约30个品种,且仅限于中小规格。 Chinas mold standard parts production, the formation of the early 80s only small-scale production, standardization and standard mold parts using the coverage of about 20%, from the market can be assigned to, is just about 30 varieties, and limited to small and medium size. 标准凸凹模、热流道元件等刚刚开始供应,模架及零件生产供应渠道不畅,精度和质量也较差。 Standard punch, hot runner components and other supplies just the beginning, mold and parts production and supply channels for poor, poor accuracy and quality.模具的发展趋势 3 Die trend1、模具CAD/CAE/CAM正向集成化、三维化、智能化和网络化方向发展 3.1 mold CAD / CAE / CAM being integrated, three-dimensional, intelligent and network direction(1)模具软件功能集成化 (1) mold software features integrated模具软件功能的集成化要求软件的功能模块比较齐全,同时各功能模块采用同一数据模型,以实现信息的综合管理与共享,从而支持模具设计、制造、装配、检验、测试及生产管理的全过程,达到实现最佳效益的目的。 Die software features of integrated software modules required relatively complete, while the function module using the same data model, in order to achieve Syndicated news management and sharing of information to support the mold design, manufacture, assembly, inspection, testing and production management of the entire process to achieve optimal benefits. 如英国Delcam公司的系列化软件就包括了曲面/实体几何造型、复杂形体工程制图、工业设计高级渲染、塑料模设计专家系统、复杂形体CAM、艺术造型及雕刻自动编程系统、逆向工程系统及复杂形体在线测量系统等。 Series such as the UK Delcams software will include a surface / solid geometric modeling, engineering drawing complex geometry, advanced rendering industrial design, plastic mold design expert system, complex physical CAM, artistic design and sculpture automatic programming system, reverse engineering and complex systems physical line measurement systems. 集成化程度较高的软件还包括:Pro/ENGINEER、UG和CATIA等。 A higher degree of integration of the software includes: Pro / ENGINEER, UG and CATIA, etc. 国内有上海交通大学金属塑性成型有限元分析系统和冲裁模CAD/CAM系统;北京北航海尔软件有限公司的CAXA系列软件;吉林金网格模具工程研究中心的冲压模CAD/CAE/CAM系统等。 Shanghai Jiaotong University, China with finite element analysis of metal plastic forming systems and Die CAD / CAM systems; Beijing Beihang Haier Software Ltd. CAXA Series software; Jilin Gold Grid Engineering Research Center of the stamping die mold CAD / CAE / CAM systems .(2)模具设计、分析及制造的三维化 (2) mold design, analysis and manufacture of three-dimensional传统的二维模具结构设计已越来越不适应现代化生产和集成化技术要求。 Two-dimensional mold of traditional structural design can no longer meet modern technical requirements of production and integration. 模具设计、分析、制造的三维化、无纸化要求新一代模具软件以立体的、直观的感觉来设计模具,所采用的三维数字化模型能方便地用于产品结构的CAE分析、模具可制造性评价和数控加工、成形过程模拟及信息的管理与共享。 Mold design, analysis, manufacturing three-dimensional technology, paperless software required to mold a new generation of three-dimensional, intuitive sense to design the mold, using three-dimensional digital model can be easily used in the product structure of CAE analysis, tooling manufacturability evaluation and CNC machining, forming process simulation and information management and sharing. 如Pro/ENGINEER、UG和CATIA等软件具备参数化、基于特征、全相关等特点,从而使模具并行工程成为可能。 Such as Pro / ENGINEER, UG and CATIA software such as with parametric, feature-based, all relevant characteristics, so that mold concurrent engineering possible. 另外,Cimatran公司的Moldexpert,Delcam公司的Ps-mold及日立造船的Space-E/mold均是3D专业注塑模设计软件,可进行交互式3D型腔、型芯设计、模架配置及典型结构设计。 In addition, Cimatran company Moldexpert, Delcams Ps-mold and Hitachi Shipbuilding of Space-E/mold are professional injection mold 3D design software, interactive 3D cavity, core design, mold base design configuration and typical structure . 澳大利亚Moldflow公司的三维真实感流动模拟软件MoldflowAdvisers已经受到用户广泛的好评和应用。 Australian company Moldflow realistic three-dimensional flow simulation software MoldflowAdvisers been widely praised by users and applications. 国内有华中理工大学研制的同类软件HSC3D4.5F及郑州工业大学的Z-mold软件。 China Huazhong University of Science have developed similar software HSC3D4.5F and Zhengzhou University, Z-mold software. 面向制造、基于知识的智能化功能是衡量模具软件先进性和实用性的重要标志之一。 For manufacturing, knowledge-based intelligent software function is a measure of die important sign of advanced and practical one. 如Cimatron公司的注塑模专家软件能根据脱模方向自动产生分型线和分型面,生成与制品相对应的型芯和型腔,实现模架零件的全相关,自动产生材料明细表和供NC加工的钻孔表格,并能进行智能化加工参数设定、加工结果校验等。 Such as injection molding experts Cimatrons software can automatically generate parting direction based parting line and parting surface, generate products corresponding to the core and cavity, implementation of all relevant parts mold, and for automatically generated BOM Form NC drilling process, and can intelligently process parameter setting, calibration and other processing results.(3)模具软件应用的网络化趋势 (3) mold software applications, networking trend随着模具在企业竞争、合作、生产和管理等方面的全球化、国际化,以及计算机软硬件技术的迅速发展,网络使得在模具行业应用虚拟设计、敏捷制造技术既有必要,也有可能。 With the mold in the enterprise competition, cooperation, production and management, globalization, internationalization, and the rapid development of computer hardware and software technology, the Internet has made in the mold industry, virtual design, agile manufacturing technology both necessary and possible. 美国在其21世纪制造企业战略中指出,到2006年要实现汽车工业敏捷生产/虚拟工程方案,使汽车开发周期从40个月缩短到4个月。 The United States in its 21st Century Manufacturing Enterprise Strategy that the auto industry by 2006 to achieve agile manufacturing / virtual engineering solutions to automotive development cycle shortened from 40 months to 4 months.2、模具检测、加工设备向精密、高效和多功能方向发展 3.2 mold testing, processing equipment to the precise, efficient, and multi-direction(1)模具检测设备的日益精密、高效 (1) mold testing equipment more sophisticated, efficient精密、复杂、大型模具的发展,对检测设备的要求越来越高。 Sophisticated, complex, large-scale mold development, testing equipment have become increasingly demanding. 现在精密模具的精度已达23m,目前国内厂家使用较多的有意大利、美国、日本等国的高精度三坐标测量机,并具有数字化扫描功能。 Precision Mould precision now reached 2 3m, more domestic manufacturers have to use Italy, the United States, Japan and other countries in the high-precision coordinate measuring machine, and with digital scanning. 如东风汽车模具厂不仅拥有意大利产3250mm3250mm三坐标测量机,还拥有数码摄影光学扫描仪,率先在国内采用数码摄影、光学扫描作为空间三维信息的获得手段,从而实现了从测量实物建立数学模型输出工程图纸模具制造全过程,成功实现了逆向工程技术的开发和应用。 Such as Dongfeng Motor Mould Factory not only has the capacity 3250mm 3250mm Italian coordinate measuring machine, also has a digital photography optical scanner, the first in the domestic use of digital photography, optical scanning as a means of spatial three-dimensional access to information, enabling the establishment from the measurement of physical model output of engineering drawings the whole process of mold making, reverse engineering a successful technology development and applications. 这方面的设备还包括:英国雷尼绍公司第二代高速扫描仪(CYCLON SERIES2)可实现激光测头和接触式测头优势互补,激光扫描精度为0.05mm,接触式测头扫描精度达0.02mm。 This equipment include: second-generation British Renishaw high-speed scanners (CYCLON SERIES2) can be realized and contact laser probe complementary probe, laser scanner accuracy of 0.05mm, scanning probe contact accuracy of 0.02 mm. 另外德国GOM公司的ATOS便携式扫描仪,日本罗兰公司的PIX-30、PIX-4台式扫描仪和英国泰勒霍普森公司的TALYSCAN150多传感三维扫描仪分别具有高速化、廉价化和功能复合化等特点。 Another German company GOM ATOS portable scanners, Japan Rolands PIX-30, PIX-4 desktop scanner and the United Kingdom Taylor Hopsons TALYSCAN150 multi-sensor, respectively Three-dimensional scanner with high speed, low-cost and functional composite and so on.(2)数控电火花加工机床 (2) CNC EDM日本沙迪克公司采用直线电机伺服驱动的AQ325L、AQ550LLS-WEDM具有驱动反应快、传动及定位精度高、热变形小等优点。 Japan Sodick linear motor servo drive using the companys AQ325L, AQ550LLS-WEDM have driven fast response, transmission and high positioning accuracy, the advantages of small thermal deformation. 瑞士夏米尔公司的NCEDM具有P-E3自适应控制、PCE能量控制及自动编程专家系统。Switzerland Chanmier company NCEDM with P-E3 adaptive control, PCE energy control and automatic programming expert systems. 另外有些EDM还采用了混粉加工工艺、微精加工脉冲电源及模糊控制(FC)等技术。 Others also used the powder mixed EDM machining technology, micro-finishing pulse power and fuzzy control (FC) technologies.(3)高速铣削机床(HSM) (3) high-speed milling machine (HSM)铣削加工是型腔模具加工的重要手段。 Milling is an important means of cavity mold. 而高速铣削具有工件温升低、切削力小、加工平稳、加工质量好、加工效率高(为普通铣削加工的510倍)及可加工硬材料(60HRC)等诸多优点。 The low-temperature high-speed milling with the workpiece, cutting force is small, smooth processing, processing quality, processing efficiency (for the general milling process 5 to 10 times) and can process hard materials (60HRC) and many other advantages. 因而在模具加工中日益受到重视。 Thus in the mold processing more and more attention. 瑞士克朗公司UCP710型五轴联动加工中心,其机床定位精度可达8m,自制的具有矢量闭环控制电主轴,最大转速为42000r/min。 Ruishikelang company UCP710-type five-axis machining center, machine tool positioning accuracy up to 8m, home-made closed-loop vector control spindle with a maximum speed 42000r/min. 意大利RAMBAUDI公司的高速铣床,其加工范围达2500mm5000mm1800mm,转速达20500r/min,切削进给速度达20m/min。 Italy RAMBAUDIs high-speed milling, the processing range of up to 2500mm 5000mm 1800mm, speed up 20500r/min, cutting feed speed of 20m/min. HSM一般主要用于大、中型模具加工,如汽车覆盖件模具、压铸模、大型塑料等曲面加工,其曲面加工精度可达0.01mm。 HSM generally used large, medium-sized mold, such as motor cover mold, die casting mold, large plastic surface machining, the surface precision up to 0.01mm.3.3 mold materials and surface treatment technology developed rapidly模具工业要上水平,材料应用是关键。 Industry to the level of mold, material application is the key. 因选材和用材不当,致使模具过早失效,大约占失效模具的45%以上。 Due to improper selection and use of materials, causing premature die failure, which accounts for more than 45% failure die. 在模具材料方面,常用冷作模具钢有CrWMn、Cr12、Cr12MoV和W6Mo5Cr4V2,火焰淬火钢(如日本的AUX2、SX105V(7CrSiMnMoV)等;常用新型热作模具钢有美国H13、瑞典QRO80M、QRO90SUPREME等;常用塑料模具用钢有预硬钢(如美国P20)、时效硬化型钢(如美国P21、日本NAK55等)、热处理硬化型钢(如美国D2,日本PD613、PD555、瑞典一胜白136等)、粉末模具钢(如日本KAD18和KAS440)等;覆盖件拉延模常用HT300、QT60-2、Mo-Cr、Mo-V铸铁等,大型模架用HT250。多工位精密冲模常采用钢结硬质合金及硬质合金YG20等。在模具表面处理方面,其主要趋势是:由渗入单一元素向多元素共渗、复合渗(如TD法)发展;由一般扩散向CVD、PVD、PCVD、离子渗入、离子注入等方向发展;可采用的镀膜有:TiC、TiN、TiCN、TiAlN、CrN、Cr7C3、W2C等,同时热处理手段由大气热处理向真空热处理发展。另外,目前对激光强化、辉光离子氮化技术及电镀(刷镀)防腐强化等技术也日益受到重视。 In the mold material, commonly used cold work tool steel with CrWMn, Cr12, Cr12MoV and W6Mo5Cr4V2, flame hardened steel (such as Japan, AUX2, SX105V (7CrSiMnMoV), etc.; used a new type of hot work die steel American H13, Sweden QRO80M, QRO90SUPREME, etc.; used a pre-hardened plastic mold steel (such as the U.S. P20), age-hardening steel (such as the U.S. P21, Japan NAK55, etc.), heat treatment hardened steel (such as the United States, D2, Japan, PD613, PD555, Sweden wins the White 136, etc.), powder die steel (such as Japan KAD18 and KAS440), etc.; panel drawing die used HT300, QT60-2, Mo-Cr, Mo-V cast iron, large-scale mold with HT250. more regular use of Precision Die Hard Steel Results YG20 and other alloys and carbide. in the mold surface treatment, the main trends are: the infiltration of a single element to the multi-element penetration, complex permeability (such as TD method) development; by the general diffusion to the CVD, PVD, PCVD, ion penetration , the direction of ion implantation, etc.; can use the coating are: TiC, TiN, TiCN, TiAlN, CrN, Cr7C3, W2C, etc., while heat from the air treatment means to the development of vacuum heat treatment. In addition, the current strengthening of the laser, glow plasma Nitriding and electroplating (plating) enhanced anti-corrosion technologies are also more and more attention.5、模具工业新工艺、新理念和新模式逐步得到了认同 3.4 mold industry new techniques, new ideas and new models have been gradually recognized在成形工艺方面,主要有冲压模具功能复合化、超塑性成形、塑性精密成形技术、塑料模气体辅助注射技术及热流道技术、高压注射成形技术等。 In the forming process, the main function of composite stamping die, superplastic forming, plastic precision molding technology, plastic mold gas-assisted injection technology and hot runner technology, high-pressure injection molding technology. 另一方面,随着先进制造技术的不断发展和模具行业整体水平的提高,在模具行业出现了一些新的设计、生产、管理理念与模式。 On the other hand, with the continuous development of advanced manufacturing technology and raise the level of mold industry as a whole, in the mold industry, there are some new design, production, management ideas and models. 具体主要有:适应模具单件生产特点的柔性制造技术;创造最佳管理和效益的团队精神,精益生产;提高快速应变能力的并行工程、虚拟制造及全球敏捷制造、网络制造等新的生产哲理;广泛采用标准件通用件的分工协作生产模式;适应可持续发展和环保要求的绿色设计与制造等。 Concrete are: to adapt to the characteristics of mold-piece production flexible manufacturing technologies; to create the best management and effective teamwork, lean production; to enhance rapid response capabilities of Concurrent Engineering, Virtual Manufacturing and global agile manufacturing, manufacturing of new production networks philosophy; extensive use of standard parts common parts of the division of work mode of production; meet the environmental requirements of sustainable development and green design and manufacturing.总Summary进入21世纪,在经济全球化的新形势下,随着资本、技术和劳动力市场的重新整合,我国装备制造业在加入WTO以后,将成为世界装备制造业的基地。 The 21st century, in the new situation of economic globalization, with capital, technology and labor market re-integration of equipment manufacturing in China after joining the WTO will become the worlds equipment manufacturing base. 而在现代制造业中,无论哪一行业的工程装备,都越来越多地采用由模具工业提供的产品。 In the modern manufacturing industry, no matter which industry, engineering equipment, are increasingly used to provide the products from the mold industry. 为了适应用户对模具制造的高精度、短交货期、低成本的迫切要求,模具工业正广泛应用现代先进制造技术来加速模具工业的技术进步,满足各行各业对模具这一基础工艺装备的迫切需求。 In order to meet the users high-precision mold manufacturing, short delivery time, the urgent demand low-cost, mold industry is extensive application of modern advanced manufacturing technology to speed up the mold industry, technological progress, to meet the basic sectors of the mold process equipment urgent needs.模具的发展1模具在工业生产中的地位模具是大批量生产同形产品的工具,是工业生产的主要工艺装备。采用模具生产零部件,具有生产效率高、质量好、成本低、节约能源和原材料等一系列优点,用模具生产制件所具备的高精度、高复杂程度、高一致性、高生产率和低消耗,是其他加工制造方法所不能比拟的。已成为当代工业生产的重要手段和工艺发展方向。现代经济的基础工业。现代工业品的发展和技术水平的提高,很大程度上取决于模具工业的发展水平,因此模具工业对国民经济和社会发展将起越来越大的作用。1989年3月国务院颁布的关于当前产业政策要点的决定中,把模具列为机械工业技术改造序列的第一位、生产和基本建设序列的第二位(仅次于大型发电设备及相应的输变电设备),确立模具工业在国民经济中的重要地位。1997年以来,又相继把模具及其加工技术和设备列入了当前国家重点鼓励发展的产业、产品和技术目录和鼓励外商投资产业目录。经国务院批准,从1997年到2000年,对80多家国有专业模具厂实行增值税返还70%的优惠政策,以扶植模具工业的发展。所有这些,都充分体现了国务院和国家有关部门对发展模具工业的重视和支持。目前全世界模具年产值约为600亿美元,日、美等工业发达国家的模具工业产值已超过机床工业,从1997年开始,我国模具工业产值也超过了机床工业产值。2我国模具工业现状及发展趋势由于历史原因形成的封闭式、“大而全”的企业特征,我国大部分企业均设有模具车间,处于本厂的配套地位,自70年代末才有了模具工业化和生产专业化这个概念。生产效率不高,经济效益较差。模具行业的生产小而散乱,跨行业、投资密集,专业化、商品化和技术管理水平都比较低。据不完全统计,全国现有模具专业生产厂、产品厂配套的模具车间(分厂)近17000家,约60万从业人员,年模具总产值达200亿元人民币。但是,我国模具工业现有能力只能满足需求量的60左右,还不能适应国民经济发展的需要。目前,国内需要的大型、精密、复杂和长寿命的模具还主要依靠进口。据海关统计,1997年进口模具价值6.3亿美元,这还不包括随设备一起进口的模具;1997年出口模具仅为7800万美元。目前我国模具工业的技术水平和制造能力,是我国国民经济建设中的薄弱环节和制约经济持续发展的瓶颈。2.1 模具工业产品结构的现状 按照中国模具工业协会的划分,我国模具基本分为10大类,其中,冲压模和塑料成型模两大类占主要部分。按产值计算,目前我国冲压模占50左右,塑料成形模约占20,拉丝模(工具)约占10,而世界上发达工业国家和地区的塑料成形模比例一般占全部模具产值的40以上。 我国冲压模大多为简单模、单工序模和符合模等,精冲模,精密多工位级进模还为数不多,模具平均寿命不足100万次,模具最高寿命达到1亿次以上,精度达到35um,有50个以上的级进工位,与国际上最高模具寿命6亿次,平均模具寿命5000万次相比,处于80年代中期国际先进水平。 我国的塑料成形模具设计,制作技术起步较晚,整体水平还较低。目前单型腔,简单型腔的模具达70以上,仍占主导地位。一模多腔精密复杂的塑料注射模,多色塑料注射模已经能初步设计和制造。模具平均寿命约为80万次左右,主要差距是模具零件变形大、溢边毛刺大、表面质量差、模具型腔冲蚀和腐蚀严重、模具排气不畅和型腔易损等,注射模精度已达到5um以下,最高寿命已突破2000万次,型腔数量已超过100腔,达到了80年代中期至90年代初期的国际先进水平。2.2 模具工业技术结构现状 我国模具工业目前技术水平参差不齐,悬殊较大。从总体上来讲,与发达工业国家及港台地区先进水平相比,还有较大的差距。 在采用CAD/CAM/CAE/CAPP等技术设计与制造模具方面,无论是应用的广泛性,还是技术水平上都存在很大的差距。在应用CAD技术设计模具方面,仅有约10%的模具在设计中采用了CAD,距抛开绘图板还有漫长的一段路要走;在应用CAE进行模具方案设计和分析计算方面,也才刚刚起步,大多还处于试用和动画游戏阶段;在应用CAM技术制造模具方面,一是缺乏先进适用的制造装备,二是现有的工艺设备(包括近10多年来引进的先进设备)或因计算机制式(IBM微机及其兼容机、HP工作站等)不同,或因字节差异、运算速度差异、抗电磁干扰能力差异等,联网率较低,只有5%左右的模具制造设备近年来才开展这项工作;在应用CAPP技术进行工艺规划方面,基本上处于空白状态,需要进行大量的标准化基础工作;在模具共性工艺技术,如模具快速成型技术、抛光技术、电铸成型技术、表面处理技术等方面的CAD/CAM技术应用在我国才刚起步。计算机辅助技术的软件开发,尚处于较低水平,需要知识和经验的积累。我国大部分模具厂、车间的模具加工设备陈旧,在役期长、精度差、效率低,至今仍在使用普通的锻、车、铣、刨、钻、磨设备加工模具,热处理加工仍在使用盐浴、箱式炉,操作凭工人的经验,设备简陋,能耗高。设备更新速度缓慢,技术改造,技术进步力度不大。虽然近年来也引进了不少先进的模具加工设备,但过于分散,或不配套,利用率一般仅有25%左右,设备的一些先进功能也未能得到充分发挥。缺乏技术素质较高的模具设计、制造工艺技术人员和技术工人,尤其缺乏知识面宽、知识结构层次高的复合型人才。中国模具行业中的技术人员,只占从业人员的8%12%左右,且技术人员和技术工人的总体技术水平也较低。1980年以前从业的技术人员和技术工人知识老化,知识结构不能适应现在的需要;而80年代以后从业的人员,专业知识、经验匮乏,动手能力差,不安心,不愿学技术。近年来人才外流不仅造成人才数量与素质水平下降,而且人才结构也出现了新的断层,青黄不接,使得模具设计、制造的技术水平难以提高。2.3 模具工业配套材料,标准件结构现状 近10多年来,特别是“八五”以来,国家有关部委已多次组织有关材料研究所、大专院校和钢铁企业,研究和开发模具专用系列钢种、模具专用硬质合金及其他模具加工的专用工具、辅助材料等,并有所推广。但因材料的质量不够稳定,缺乏必要的试验条件和试验数据,规格品种较少,大型模具和特种模具所需的钢材及规格还有缺口。在钢材供应上,解决用户的零星用量与钢厂的批量生产的供需

- 温馨提示:

1: 本站所有资源如无特殊说明,都需要本地电脑安装OFFICE2007和PDF阅读器。图纸软件为CAD,CAXA,PROE,UG,SolidWorks等.压缩文件请下载最新的WinRAR软件解压。

2: 本站的文档不包含任何第三方提供的附件图纸等,如果需要附件,请联系上传者。文件的所有权益归上传用户所有。

3.本站RAR压缩包中若带图纸,网页内容里面会有图纸预览,若没有图纸预览就没有图纸。

4. 未经权益所有人同意不得将文件中的内容挪作商业或盈利用途。

5. 人人文库网仅提供信息存储空间,仅对用户上传内容的表现方式做保护处理,对用户上传分享的文档内容本身不做任何修改或编辑,并不能对任何下载内容负责。

6. 下载文件中如有侵权或不适当内容,请与我们联系,我们立即纠正。

7. 本站不保证下载资源的准确性、安全性和完整性, 同时也不承担用户因使用这些下载资源对自己和他人造成任何形式的伤害或损失。

人人文库网所有资源均是用户自行上传分享,仅供网友学习交流,未经上传用户书面授权,请勿作他用。

川公网安备: 51019002004831号

川公网安备: 51019002004831号