资源目录

压缩包内文档预览:(预览前8页/共34页)

编号:6820254

类型:共享资源

大小:1.50MB

格式:RAR

上传时间:2017-12-30

上传人:优***

认证信息

个人认证

罗**(实名认证)

广西

IP属地:广西

45

积分

- 关 键 词:

-

td

玻璃

烟气

脱硫

回热器

设计

- 资源描述:

-

- 内容简介:

-

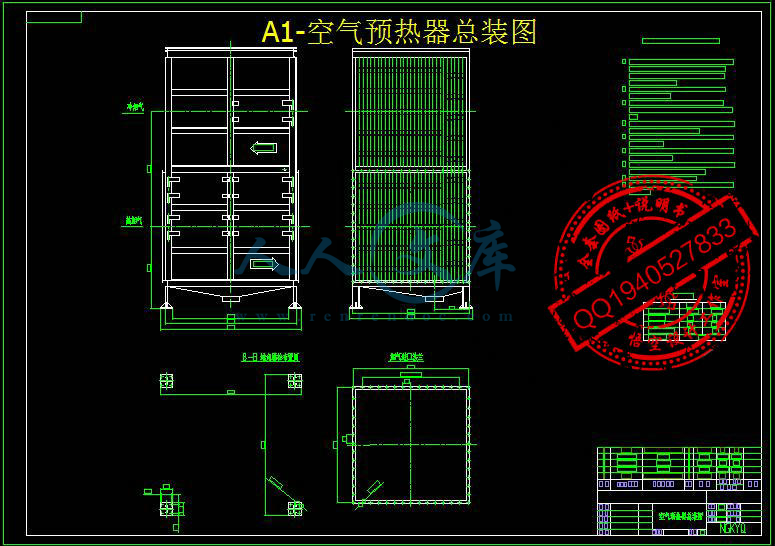

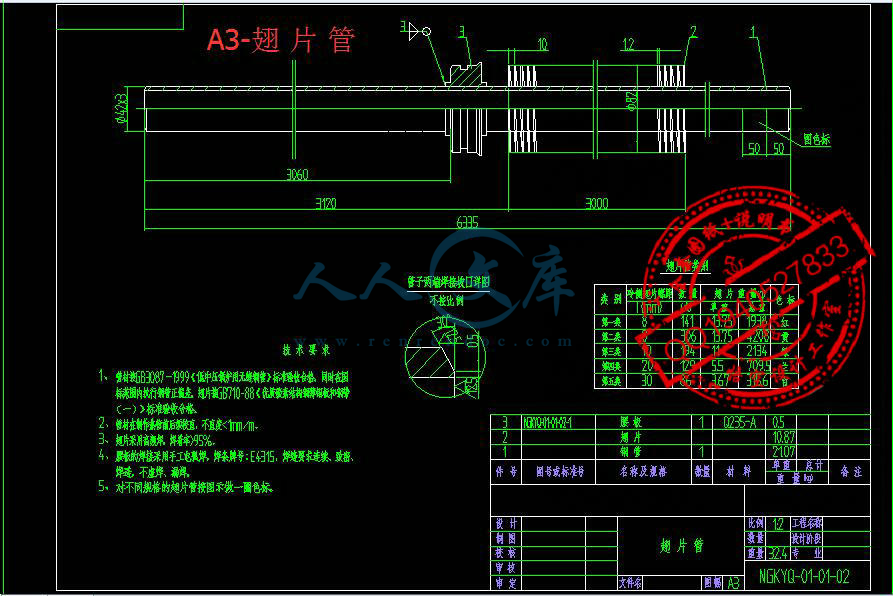

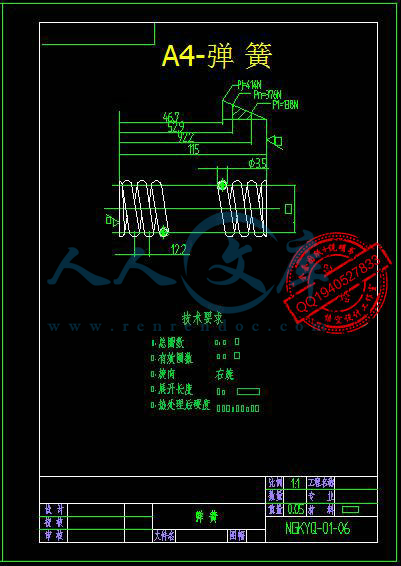

开题报告学生姓名:学号:所在学院:专业:设计(论文)题目:400T/D玻璃窑烟气脱硫回热器的设计指导教师:开题报告填写要求1开题报告(含“文献综述”)作为毕业设计(论文)答辩委员会对学生答辩资格审查的依据材料之一。此报告应在指导教师指导下,由学生在毕业设计(论文)工作前期内完成,经指导教师签署意见及所在专业审查后生效;2开题报告内容必须用黑墨水笔工整书写或按教务处统一设计的电子文档标准格式(可从教务处网页上下载)打印,禁止打印在其它纸上后剪贴,完成后应及时交给指导教师签署意见;3“文献综述”应按论文的格式成文,并直接书写(或打印)在本开题报告第一栏目内,学生写文献综述的参考文献应不少于15篇(不包括辞典、手册);4有关年月日等日期的填写,应当按照国标GB/T740894数据元和交换格式、信息交换、日期和时间表示法规定的要求,一律用阿拉伯数字书写。如“2004年4月26日”或“2004-04-26”。毕业设计(论文)开题报告1结合毕业设计(论文)课题情况,根据所查阅的文献资料,每人撰写2000字左右的文献综述:文献综述1玻璃行业现状及废气污染1.1玻璃行业耗能现状我国玻璃工业经过建国以来近50年的发展,特别是改革开放以来的迅速发展,我国的玻璃工业取得了长足的进步1。2007年中国国内玻璃纤维生产总量达到160万t,比2006年提高38%,其中池窑拉丝产量达到116万吨,比2006年提高30%,现已远远超过老牌世界第一的美国,成为名副其实的世界玻纤第一生产大国2。该行业同时又是耗能和污染大户,玻璃纤维池窑产生的废气,不仅需要脱硫除尘至达标排放,而且余热的回收利用也是重要的内容,既是节约能源的需要,也是保证工程安全可行的需要3。1.2玻璃行业排放污染废气是气体和烟尘的混合物,烟气的成分很复杂,气体中包括水蒸汽、碳氢化合物以及氮氧化合物等,烟尘包括燃料的灰分、煤SO22O2OO2粒、油滴以及高温裂解产物等4。在玻璃窑炉产业中,烧的是重油,排放的废气中含有大量的污染物,主要污染成分是,考虑到对环境的保护,必须添加脱硫的工艺5。SO22.烟气脱硫工艺2.1.烟气脱硫的概述烟气脱硫是指运用物理或者化学的方式除去废气中的硫化物。烟气脱硫技术常用干法、半干法、湿法三种方式6,虽然干法脱硫成本低,但是效率也低。湿法脱硫效虽需要重加热,但是原烟气温度高,因此并不需要额外的燃烧,而且效率高,因此湿法是目前应用最广效果最好的脱硫方法。7在这里运用湿法脱硫的工艺。因此我们将涉及到回热器的添加。2.2湿法烟气脱硫湿法脱硫,又称湿法FGD工艺。世界各国的湿法烟气脱硫工艺流程、形式和机理大同小异,主要是使用石灰石、石灰或碳酸钠等浆液作洗涤剂,在反应塔中对烟气进行洗涤,从而除去烟气中的。烟气进入脱硫装置的湿式吸收塔,与自上而下喷淋的SO2碱性石灰石浆液雾滴逆流接触,其中的酸性氧化物以及其他污染物HCL、HF等被吸SO2收,烟气得以充分净化;吸收后的浆液反应生成,通过就地强制氧化、结晶SO23生成2,经脱水后得到商品级脱硫副产品石膏,最终实现含硫烟气的综合42治理8。由于经过湿法脱硫,脱硫后的废气湿度大,温度较低,可能会导致设备的腐蚀和排放的困难,因此,在窑炉末端加烟气脱硫回热器9。3热管式气体换热器3.1回热器的种类烟气的回热器,及气气换热器,主要有板式、套管式、回转式、热管式等几种类型10。下面简单的介绍下几种换热器类型(1)套管式换热器套管式换热器是由直径不同的直管制成的同心套管,并由U形弯头连接而成。在这种换热器中,一种流体走管内,另一种流体走环隙,两者皆可得到较高的流速,故传热系数较大。另外,在套管换热器中,两种流体可为纯逆流,对数平均推动力较大。套管换热器结构简单,能承受高压,应用亦方便(可根据需要增减管段数目)。特别是由于套管换热器同时具备传热系数大,传热推动力大及能够承受高压强的优点,在超高压生产过程(例如操作压力为3000大气压的高压聚乙烯生产过程)中所用的换热器几乎全部是套管式11。(2)板式换热器最典型的间壁式换热器,它在工业上的应用有着悠久的历史,而且至今仍在所有换热器中占据主导地位。主体结构由换热板片以及板间的胶条组成。(3)管壳式换热器管壳式(又称列管式)换热器是管壳式换热器主要有壳体、管束、管板和封头等部分组成,壳体多呈圆形,内部装有平行管束或者螺旋管,管束两端固定于管板上12。(4)热管式换热器热管是一种具有高导热性能的传热元件,它通过在全封闭真空管壳内工质的蒸发与凝结来传递热量,具有极高的导热性、良好的等温性、冷热两侧的传热面积可任意改变、可远距离传热、可控制温度等一系列优点。以热管为传热元件的换热器具有传热效率高、结构紧凑、流体阻损小、有利于控制露点腐蚀等优点13。在这里我们选用热管换热器。3.2热管换热器3.2.1热管的简介图1热管先介绍下热管的基本结构。如图1所示,热管的基本结构主要包括冷凝段,蒸发段组成。具有高导热性能的传热元件,它通过在全封闭真空管壳内工质的蒸发与凝结来传递热量,具有极高的导热性、良好的等温性、冷热两侧的传热面积可任意改变、可远距离传热、可控制温度等一系列优点14。3.2.2热管换热器的结构图2热管换热器图2是热管换热器的基本结构。在这里上方“冷风”为脱硫后的烟气,经过热管换热器的加热,变为“热风”排入大气。下放的烟气为脱硫前的烟气15。3.2.2热管换热器主要特点(1)热管换热器可以通过换热器的中隔板使冷热流体完全分开,在运行过程中单根热管因为磨损、腐蚀、超温等原因发生破坏时基本不影响换热器运行。热管换热器用于易然、易爆、腐蚀性强的流体换热场合具有很高的可靠性16。(2)热管换热器的冷、热流体完全分开流动,可以比较容易的实现冷、热流体的逆流换热。冷热流体均在管外流动,由于管外流动的换热系数远高于管内流动的换热系数,用于品位较低的热能回收场合非常经济17。(3)对于含尘量较高的流体,热管换热器可以通过结构的变化、扩展受热面等形式解决换热器的磨损和堵灰问题18。(4)热管换热器用于带有腐蚀性的烟气余热回收时,可以通过调整蒸发段、冷凝段的传热面积来调整热管管壁温度,使热管尽可能避开最大的腐蚀区域19。3.3热管式换热器的优点(1)效率高,体积小,通风阻力小,能节约鼓风机和引风机的电能消耗20。(2)热管两端由端盖密封,当一根热管的一侧管壁有穿孔时只有管内少量公职外泄,但热流体不会串通,因此也大大减少了漏风的可能性21。(3)热管的等温传热特性可保证管壁温度保持在烟气露点温度以上,这样就保证管壁温度始终在烟气露点温度以上,在管壁的烟灰基本都是干灰,不会出现灰堵22。(4)能够调节管壁温度,从而能减少烟气中硫酸的腐蚀23。4.总结综上所述,针对玻璃行业的现状及其废气的成分,我们选用湿法脱硫的工艺进行脱硫。而考虑到烟气的排放和防止设备的腐蚀,在玻璃窑炉后加回热器。24由于热管式换热器呈现出预热温度高、节省燃料、寿命较长等优势,特别是热管式换热器能够良好的解决传统换热器的漏风问题、腐蚀问题等,经济效益提升效果极为明显,这里选用热管式换热器最为合理25。6.参考文献1黄福娟.用回收的废热预热碎玻璃J.玻璃,1990,5.2张司桥,葛林,钱培金.范军玻璃纤维池窑废气余热回收及脱硫除尘J.煤炭科学研究总院杭州环境保护研究所.2009:,2.3DeRondom1,P.OANALYSISOFELEMENTARYPROCESSSTEPSININDUSTRIALGLASSMELTINGTANKS-SOMEIDEASONINNOVATIONSININDUSTRIALGLASSMELTING.2008,9.4胡秀丽湿法烟气脱硫经济运行研究J电力设备,2006,7(8):12-155胡帆,史庆玺,任冬,吴晓光,杜长澎.玻璃窑余热利用关键技术问题的探讨.2011,31(5):381-3866傅文玲,胡秀丽.烟气膨硫系统回转再生式烟气携热器清浇装置使用效果探讨.2006:37薛润.脱硫方式的选择M.2008,9.8杨杰,宋晓红湿法烟气脱硫系统烟囱防腐措施J河北电力技术,2006,25(1):33-379李辉,尹华强,刘勇军,彭宏,梁锦平.烟气脱硫与循环经济J.2005,6.10KonstantinTourkova,LauraSchaeferb.Effectofregeneratorpositioningonthermoacousticeffectinaloopedtubetravelingwavethermoacousticengine.2015:94-100.11邹昌校,韩跃.套管式换热器J.2006,6:16-25.12王秋旺.螺旋折流板管壳式换热器壳程传热强化研究进展.西安交通大学学报,2004,38(9):881-886.13赵斌,王子兵热管及其换热器在钢铁工业余热回收中的应用J冶金动力,2005,3:34-3614张杰,梁慧敏,任艳,李佩涛.热管换热器与回转式换热器在湿法脱硫系统中的应用比较.2010-215HeimoWalter,WladimirLinzerFlowStabilityofHeatRecoverySteamGeneratorsJTransactionsoftheASME,2006,128:840-84916董其伍,王丹,刘敏珊余热回收用热管及热管式换热器的研究J工业加热,2007,20(4):33-3717蒋章焰,马同泽.气-气热管换热器设计中的一些问题.1985-03.18AlessandroFranco,NicolaGianniniAgeneralmethodfortheoptimumdesignofheatrecoverysteamgeneratorsJEnergy,2006,31:3342-336119FaghriHeatPipeScienceandTechnologyMTaylor&FrancisPress,199520钱伯章.热管换热器的发展和应用.1996(5):47-54.21李菊香,杨峻,徐通明热管换热器的设计原则与应用J化工设备设计,1997,34(3):46-5022沈玉英,陈保东,方国文气-气热管换热器的优化选型设计J抚顺石油学院学报,2000,20(2):52-5423仲华,洪亮.一种热管式冷热回收器:,CN103256842AP.2013.24苏俊林,王震坤,矫振伟.热管式高效型煤锅炉研究J.节能技术,2007,25(5):413-415.25卢作基,孙克勤.热管式GGH在湿法烟气脱硫中的应用J.电力科技与环保,2005,21(4):22-23.毕业设计(论文)开题报告本课题要研究或解决的问题和拟采用的研究手段(途径):研究内容本课题是400T/D玻璃窑烟气脱硫回热器的设计,本课题来源于工程实践,玻璃工业不但是高耗能行业而且是高污染行业,对于玻璃窑通过余热锅炉排放的烟气必需进行脱硫处理,湿法脱硫运行成本低,脱硫效果好,是玻璃行业经常应用的脱硫工艺,而烟气回热器是是湿法脱硫工艺中的重要设备,对于脱硫后的湿烟气回热处理具有现实意义。研究手段要求熟练掌握热能工程专业的有关课程以及热管技术和工程应用等有关知识,查阅大量有关中外文献资料,了解玻璃窑炉烟气脱硫工艺的特点和发展趋势,熟悉玻璃窑炉热管式烟气脱硫回热器的结构型式和性能特点,与管式回热器和回转式回热器进行比较。了解烟气脱硫回热器在脱硫工艺中的重要性。学生应完成3000字以上的英文资料翻译,2000字以上的文献综述以及开题报告。进行热管式烟气脱硫回热器的热力计算、烟气冷热两侧阻力计算等。在完成计算书后确定热管式烟气脱硫回热器的外形结构,完成工程制图6张以上A1图。毕业设计(论文)开题报告指导教师意见:1对“文献综述”的评语:2对本课题的深度、广度及工作量的意见和对设计(论文)结果的预测:指导教师:年月日所在专业审查意见:负责人:年月日热力计算1原始数据设计参数:热侧烟气进口温度:210冷侧烟气进口温度:70冷侧烟气出口温度:110热侧烟气流量:52000Nm3/h冷侧烟气流量:52000Nm3/h燃料种类:重油结构型式:热管式2冷侧烟气热物性参数及放热量冷侧烟气进口温度c170t冷侧烟气出口温度c2t冷侧烟气定性温度ccf12()90tt冷侧烟气流量c350Nm/hG冷侧烟气定压比热容cp1.6kJ/(g)C冷侧烟气密度c30.98/冷侧烟气导热系数c2f.451W/(m)冷侧烟气黏度c6f9.0kg/s冷侧烟气普朗特数c.3Pr冷侧烟气实际传热量cc21fp()79.16kWQtGC热管传出热量cc8.k(3%)热侧烟气放出热量ch47.23(1)Q3热侧烟气热物性参数及放热量热侧烟气进口温度h120t热侧烟气流量h3520Nm/hG热侧烟气出口温度hh21p167.23QtC热侧烟气定压比热容hp.0kJ/(g)热侧烟气密度h3.87/m热侧烟气导热系数h2f.10W/()热侧烟气黏度h6f9.8kg/s热侧烟气普朗特数h0.Pr对数平均温差12m98.6ln()t4确定迎风面积及迎风面管排数4.1迎风速度标准迎风速度取N2.5m/s热侧烟气迎风面积h2exN.78GA冷侧烟气迎风面积ch2ex5.4.2迎风面宽度E已采用5m长热管,并取热侧长与冷侧长相等hex2.3mAEl则热侧迎风管排数BT28.5ES根取9B根实际迎风宽度为EhcT2.35mS实际迎风速度hhNex.46/s0GA则冷侧实际迎风速度c2.m/s实际迎风面积hcex5.87A5求总换热系数HU5.1管末最小流通截面积NFA热侧hh2Tof()1.5mNFASdl冷侧c2ofc3.9lB5.2流体最大质量流速maxG热侧h2fmax5497.1kg/(h)NFA冷侧cc2fmax20458.76kg/(mh)GNFA5.3雷诺数fRe热侧hmaxoff2468Gd冷侧caxoff910Re5.4流体换热系数fh热侧hh0.638h1/32ffffo0.137()().6W/(m)RePrd冷侧cc0.638c1/32ffffo.()()7./()er5.5冷侧翅片效率cfccffw20.91hl5.6热侧每米热管管外总表面积hAh2o0.1mAd5.7冷侧每米长翅片间管表面积cfAc22ffofof()0.46m4Addn5.8冷侧每米长翅片间管表面积crAc2rof(1)0.8mAdn5.9冷侧每米热管管外总表面积chAcc2hfr0.5A5.10传热面积h热侧h20.5mAl冷侧c2h1.38l5.11有效换热系数fe热侧hh2frffe()13.6W/(m)A冷侧cc2frffeh()4.50/()5.12污垢热阻yr热侧h42y3.10m/W冷侧c52y8.6/r5.13金属管壁热阻wr热侧h52w6.310m/Wr冷侧c52w./r5.14热侧中径传热面积hwAhh2w0.35mAdl5.15热侧内径传热面积hiAhh2ii0.41Adl5.16总传热系数HU2HhhhwyhccfeHPi19.45W/(m)112()AAr6加热侧总传热面积ch2Hm8.5QAUt7所需热管数hH1405Anl根8换热器纵深管排数48.nmB排取32排排列方式595859585958管子总根数59168172n根9热管换热器的压力降换热器的净自由容积223TLofof0.86()4.610m/4NFVSddn热侧容积当量直径h2evh7.3NFVDA冷侧容积当量直径c2evch41.0m热侧雷诺数hevmaxff564DGR冷侧雷诺数cevaxff3792热侧摩擦系数hh0.145f.()fR冷侧摩擦系数cc0.145f.928fe热侧平均管壁温度hhwfe.7QtAn冷侧平均管壁温度ccwfeh90.1t查表可得:热侧壁温下流体粘度h6w19.70kg/(ms)冷侧壁温下流体粘度c62./10第一排热管的工作温度热侧:传热量h126.47kWQm传热面积h21.8AB查表可得:粘度h6f124.870kg/(ms)导热系数h2f1.9W/普朗特数hf10.68Pr雷诺数hmaxof1f94GdRe蒸发段传热系hh0.638h1/32f11ffo0.37()().7W/(m)RePrd有效传热系数hh21rffe()./()A壁温hh1w1fe207.Qtn冷侧:传热量c125.68kWQm传热面积c21h40.AB查表可得:粘度c6f120.8kg/(ms)导热系数c2f13.W/普朗特数cf10.68Pr雷诺数cmaxof1f73GdRe冷凝段传热系cc0.638c1/32f1h1ffo0.()().9W/(m)RePrd有效传热系数hccc21rffe()4./()A壁温cc1w1feh70.Qtn第一排热管工作温度hcw138.52t11末排热管管壁温度热侧:传热量h326.48kWQm传热面积h2327.AB查表可得:粘度h6f32.10kg/(ms)导热系数h2f32.W/普朗特数hf320.679Pr雷诺数hmaxof32f135GdRe蒸发段传热系hh0.638h1/32f3232ff2o0.7()()7.64W/(m)RePrd有效传热系数hh232rffe()./()A末端壁温hh9w32ffe32164.03Qtn末端管壁温度152(露点温度)REGENERATIVEHEATEXCHANGERSWillmott,A.J.DOI:10.1615/AtoZ.r.regenerative_heat_exchangersWhereasinrecuperators,whereheatistransferreddirectlyandimmediatelythroughapartitionwallofsomekind,fromahottoacoldfluid,bothofwhichflowsimultaneouslythroughtheexchanger,theoperationoftheregenerativeheatexchangerinvolvesthetemporarystorageoftheheattransferredinapackingwhichpossessesthenecessarythermalcapacity.Oneconsequenceofthisisthatinregenerativeheatexchangersorthermalregenerators,thehotandcoldfluidspassthroughthesamechannelsinthepacking,alternately,bothfluidswashingthesamesurfacearea.Inrecuperators,thehotandcoldfluidspasssimultaneouslythroughdifferentbutadjacentchannels.Inthermalregeneratoroperationthehotfluidpassesthroughthechannelsofthepackingforalengthoftimecalledthehotperiod,attheendofwhich,thehotfluidisswitchedoff.Areversalnowtakesplacewhenthecoldfluidisadmittedintothechannelsofthepacking,initiallydrivingoutanyhotfluidstillresidentinthesechannels,therebypurgingtheregenerator.Thecoldfluidthenflowsthroughtheregeneratorforalengthoftimecalledthecoldperiod,attheendofwhichthecoldfluidisswitchedoffandanotherreversaloccursinwhich,thistime,thehotfluidpurgesthechannelsofthepackingofanyremainingcoldfluid.Afreshhotperiodthenbegins.Duringthehotperiod,heatistransferredfromthehotfluidandisstoredinthepackingoftheregenerator.Inthesubsequentcoldperiod,thisheatisregeneratedandistransferredtothecoldfluidpassingthroughtheexchanger.Acycleofoperationconsistsofahotfollowedbyacoldperiodofoperationtogetherwiththenecessaryreversals.Aftermanycyclesofidenticaloperation,thetemperatureperformanceofthethermalregeneratorinonecycleisidenticaltothatinthenext.Whenthisconditionisrealized,theheatexchangerissaidtohavereachedcyclicequilibriumorperiodicsteadystate.Shouldastepchangebeintroducedinoneormoreoftheoperatingparameters,inparticular,theflowrateandentrancetemperatureofthefluidforeitherperiodofoperation,orthedurationofthehotandcoldperiods,theregeneratorundergoesanumberoftransientcyclesuntilthenewcyclicequilibriumisreached.Inthemostcommoncounterfloworcontraflowregeneratoroperation,thehotgaspassesthroughtheregeneratorintheoppositedirectionofthecoldfluid.Inlessefficientparallelfloworco-flowthehotandcoldfluidspassthroughthechannelsofthepackinginthesamedirection().()Intheory,itispossibletoimagineacross-flowregeneratorinwhichthehotandcoldfluidsflowindirectionsperpendiculartooneanother.Thisisrarely,ifever,realizedinpracticealthoughcross-flowrecuperatorsarecommon.Theperiodicoperationofregeneratorscanexploittheperiodicoperationofthesystemtowhichtheexchangerisattached.Forexample,inhotclimates,daytimeheatcanbestoredinapackingbypassingthewarmatmosphericairthroughit:thisheatcanthenberecoveredbyblowingcoldnighttimeairthroughthesamepackingduringtheeveningtoprovideatleastsomesupplementarywarmingofthelivingspaceinabuilding.Hausen(1976)suggeststhatthethroatandnasalpassagesactasaregeneratorpackingincoldweather.Whenananimalbreathesincoldair,itiswarmedasitpassesthroughthenoseandthroatbeforetheairreachesthelungs,therebyprotectingthelungsfromtheeffectsofcoldtemperatures.Astheanimalbreathesout,thesamepassagesinthenoseandthroatarewarmedbytheairleavingthelungs.Clearly,thetemperatureofthethroatandnasaltissueisalsoregulatedbytheflowofbloodthroughit.Ingeneral,however,acontinuoussupplyofheatedfluidisrequiredsothatthediscontinuousoperationoftheregenerator,whichisinherentinitsdesign,mustbeconcealedinsomeway.FixedBedRegeneratorsThemostobvioustechniqueforrealizingapparentcontinuousoperation,istousetwoormoreregeneratorsoperatingoutofphasewithrespecttooneanothersothatwhileoneregeneratorissupplyingheatedfluid,theotherregenerator(s)isstoringheatfromtheheatingfluid.Anapparentlyeasywaytodothisisbyenclosingthesetofregeneratorswithinasystemofductsorpipesfittedwithvalvestofacilitatetheswitchingoftheregeneratorsattheendofaperiodofoperation.Asonesetofvalvesclose,atareversal,soanothersetopen:theflowofhotgas,forexample,isdivertedfromoneregeneratortotheotherbytheclosingofsuchasetofvalvesandtheopeningoftheother.Simultaneously,theflowofcoldgasisswitchedfromtheotherregeneratorinasymmetricfashion.(SeeFigure1.)Suchanarrangementiscalledasystemoffixedbedregenerators,incontrasttotherotaryregeneratorwhichwillbedescribedshortly.Thereversalprocesscanbemorecomplicatedthanthis.Thefollowingareimportantconsiderations.Someapplicationsrequirethattheregenerator(s)bepurgedbeforethesupplyofheatedfluid,forexample,isswitchedfromoneregeneratortothenext.Inthiscase,thecoldperiodofoneregeneratorisextendedtomaintainthesupplyofheatedfluidtotheexternalprocesstowhichthesetofregeneratorsisattached.Meanwhile,thehotperiodoftheotherregeneratoristerminatedandthatregeneratoriscompletelypurgedbeforeitscoldperiodbegins.Thisregeneratorthenshoulderstheburdenofsupplyingheatedfluidfromtheotherregeneratorwhoseendofcoldperiodreversalcanbegin.Sucharrangementsnecessarilycomplicatethevalveandductfacilitiesassociatedwiththesetofregenerators:inaddition,asuitableexhaustforfluidspurgedfromtheregenerator,notpermittedtoentertheheatedfluidstream,forexample,mustbeprovided.Figure1.Fixedbedregeneratorarrangement.Wherethefluidsaregases,itisnotuncommonforthepressureofthecoldgasstream,forexample,tobesignificantlyhigherthanthatofthehotgasstrewn.Inthiscase,attheendofacoldperiod,timemustbeallowedduringthereversalfortheregeneratortobedecompressedbeforethehotperiodispermittedtobegin.Similarly,timemustbeallowedatthestartofacoldperiodforthepressureofthecoldgasintheregeneratortobuildupbeforethecoldperiodpropercanbegin.Again,additionalvalvesandpipeworkmustbeprovidedtoaccommodatethesecomplications.Inhightemperatureregenerators,itisdesirablenottohaveanyvalvesatallatthehotendoftheregenerators.Wherethiscannotbeavoided,thevalvesareoftenveryexpensive,perhapsrequiringtobewatercooledtoavoidmalfunctionathightemperatures.Itisoftenthecase,however,thehotendoftheregeneratorisattachedtothefurnaceorboilertowherepre-heatedair,forthecombustionofafuelgas,issupplieddirectly,andfromwhere,afterareversal,thehotgas,frequentlythewasteproductsofcombustionofthefuel,isextracteddirectlytotheregenerator.Inthisway,novalvesarerequiredbetweentheregeneratorandthefurnaceorboiler.Thenecessarysuctionofthehotgasthroughtheregeneratorisachievedbyattachingtheexitductforthisgasatthecoldendoftheregeneratortoachimney,which,iftallenough,willprovidethenecessaryupdraft.Valvesareemployedsafelyatthecoldendoftheregeneratortoswitchtheheatexchangerfromthechimneyexhaustforwastegasestothesupplyofcoldairforthecoldperiodofregeneratoroperation,orvice-versa.Acontinuoussupplyofpreheatedcombustionairisachievedbyattachingseveralregeneratorstoafurnaceorboiler,operatingasnecessary,outofphasewithrespecttooneanother.RotaryRegeneratorsIntheLjungstrmairpreheater,orrotaryregenerator,theporouspackingisrotatedaroundanaxis.Initssimplestform,thepackingisdividedintotwogastightsectionsandthehotandcoldgasesflowsimultaneouslyinadirectionparalleltothisaxis,usuallyincontra-flow,throughthesedifferentsegmentsofthepacking.Asthepackingrotatesthroughthehotgasstream,itstoresheat,asinthehotperiodofafixedbedregenerator.Thisthermalenergyisliterallytransportedintothecoldgasstreamasthepackingisrotated.Onceintheothergasstream,theheatisregeneratedandispassedtothecoldgas,asinthecoldperiodofoperationofafixedbedsystem.Itisimpossibletosecurecompletelygas-tightsealsatthejunctionsbetweentheducts,carryingthehotandcoldfluids,respectively,andthemovingsurfacesoftherotatingheatstoringmassoftheregeneratorpacking.However,ifitisrequiredtopreventpreheatedair,forexample,frombeingcontaminatedbythewastecombustionproductswhichsupplythenecessarythermalenergy,itisarrangedthatthepressureoftheairisdeliberatelyhigherwiththeconsequencethatanyleakageunderthesealsoftherotaryregeneratorisofairintothestreamofhotcombustionproducts.Whentherotorfirstpassesfromthehotgastothecoldgasstream,forexample,abodyofhotgasinthevoidsoftheregeneratorpacking,iscarriedbyrotationintothecoldgasstreamandmustbepurgedfromtheregenerator,asinthefixedbedmodeofoperation.Insomeapplications,itisvitalthatthiscarryovergasshouldnotbepermittedtocontaminatethestreamofcoldgasbeingheatedbytheexchanger.Inthesecircumstances,anadditionalsectorisprovidedinthepackingsothatgasespurgedfromtheregeneratorattheendofthehotperiod,forexample,canbesentofftoaseparateexhaust,possiblyfedbackintothehotgasstream.Anotherversionoftherotaryregeneratorexistsinwhichthepackingremainsstationarybutthehoodsatbothendsofthepacking,throughwhichthehotandcoldfluidspassinseparateducts,rotateinstead.MathematicalModelingofThermalRegeneratorsTherelationshipbetweentheheattransferredbetweenthefluidandthesolidpacking,andtheheatabsorbedbythatpackingisgivenbytheequation(1)Ontheotherhand,therelationshipbetweenthethermalenergytransferredbetweenthesolidpackingandthefluid,andtheheattakenupbythefluidpassingthroughtheregeneratorisgivenbytheequation(2)Theseequationsapplyequallytothehotandcoldperiodsofregeneratoroperation,forwhichtherelevantparametersmaybedifferent.Wethereforedenotethebulkheattransfercoefficientinthehotperiodby,inthecoldperiodby,forexample.Theboundaryequationsrelatefirsttotheentrancegastemperature,Tf,in,whereitisassumedthatTf,in(t)=constantineachperiodofoperation.Next,wespecifythatEquations(1)and(2)considerthegastobemovingfromy=0toy=Linboththehotandthecoldperiodsofregeneratoroperation.Inordertospecifythatthesolidtemperaturedistributionatthestartofaperiodisequaltothatattheendofthepreviousperiod,andtoincorporatethecontraflowoperationoftheregenerator,theboundaryconditionsarewrittenintheform(3)(4)wherePisthedurationofthehotperiodandPthedurationofthecoldperiod.Themostimportantassumptionembodiedinthismodelisthattheresistancetoheattransferatthesurfaceofthesolidandtheresistanceduetothefiniteconductivityofthepacking,inadirectionnormaltofluidflow,canbeincorporatedtogetherinabulkorlumpedheattransfercoefficientwhere,usingadevelopmentofHausenHausen(1942)thedefiningequationisgivenby(5)whereisthethicknessofthepackinganditsthermalconductivity.Thefunctionattemptstoreproducetheeffectoftheveryrapidtemperaturechangeswithinthepacking,immediatelyafterareversal,atthestartofahotorcoldperiod.Itisafunctionofthedimensionlessparametersand,where(6)Inthecasewherethepackingcanbeconsideredtobeasimple,plainwallofthickness(7)for(8)where(9)then(10)Similarexpressionsareavailableforthecasewherethepackingcanberegardedasacollectionofsolidcylindersorasabedofspheres.ReferenceshouldbemadetothelaterworkofHausen(Hausen(1976).ThecaseforhollowcylindersiscoveredinthepaperbyRazelosRazelos(1967)etal.Itisalsoassumedinthismodelthatthethermalconductivityinadirectionparalleltofluidflow,socalledlongitudinalconductivity,canbeneglected.ThisproblemisdiscussedinthepaperbyBahnkeandHowardBahnkeandHoward(1964).Itisfurtheridealizedthattheflowoffluidisuniformthroughthecross-sectionofthepackinginbothperiodsofoperation.Itisgenerallyallowed,however,thattherelevantthermophysicalpropertiesofbothfluidandsolid,includingtheheattransfercoefficients,canvaryspatiallyandtimewise,asafunctionoftemperature.Equally,itispermittedtoconsiderthecasewherethemassflowratesofthefluidsineitherorbothperiodsofregeneratoroperationcanvarywithtime.Themodelisgreatlysimplifiedinthesocalledlinearmodelinwhichitisfurtherassumedthattherelevantthermophysicalpropertiesofbothfluidandsolid,includingtheheattransfercoefficients,donotvaryspatiallyandtimewise,butareconstant.Ontheotherhand,theyarepermittedtobedifferentbetweenthehotandcoldperiods.Similarly,itisassumedthatthegasflowratesareconstant,although,ingeneral.Inthesesimplifyingcircumstances,itispossibletoreduceEquations(1)and(2)intotheforms(11)(12)Here,thedimensionlessparameters,fortimeandforlength,areintroducedwhere(13)Uponsettingt=Pandy=L,eachperiodofregeneratoroperationisdefinedintermsoftwodimensionlessparametersgiventhenamesbyHausenHausen(1929)reducedperiod,andreducedlength,.Equations(14)belowdefinetheseforhotperiodoperation:(14)Forthecoldperiod,thecorrespondingequationsare(15)Inthislinearmodel,itisalsopossibletotreatthehotperiodinlettemperatureTf,in=1.0andthecoldperiodinlettemperatureTf,in=0.0().ThisisequivalenttosettingwherefandsaretherealfluidandsolidtemperaturesandTfandTsarethecorrespondingdimensionlesstemperatures.Itisnotwithintheorbitofthistexttodescribethemanyandvariedmethodsofsolutionofthesedifferentialequationswhichhavebeendevelopedoverseveralyears.Beitsufficienttosaythattherearetwoclassesofmethodofsolution,theopenmethodsandtheclosedmethods.Intheopenmethods,astartingdistributionoftemperature,Ts(,0),ofthesolidatthestartofahotperiodisassumed.ThemodeloftheregeneratoristhencycledthroughmanycyclesbysolvingEquations(11)and(12),forexample,throughsuccessivehotandcoldperiodsofoperation.Thissimulationoftheheatexchangeristhenpermittedtorununtiltheperiodicsteadystateisrealized.Intheclosedmethods,itissimplyassumedthatthesolidtemperaturedistributionTs(,0)(n),atthestartofthenthcycleisequaltothat,Ts(,0)(n+1),atthestartofthefollowingcycle,atcyclicequilibrium.Theequationsarethensolved,ofteninintegralequationform,asaboundary-valueproblem.Notransientcyclespriortoequilibriumbeestablishedaresimulated.Itturnsoutthatclosedmethodsareusefulforsolvingarangeoflinearproblemsbutthattheybecomeextremelycomplicatedwhendealingwithnonlinearproblems,thatiswhenitispermittedthattherelevantthermophysicalpropertiesofbothfluidandsolid,includingtheheattransfercoefficients,canvaryspatiallyandtimewise,asafunctionoftemperatureand/orwhenthemassflowratesofthefluidsineitherorbothperiodsofregeneratoroperationcanvarywithtime.Inthesecases,theopenmethodsaremoreeasilyadoptedConstructionoftheRegeneratorPackingThepackingofaregeneratorvariesconsiderablyfromonetypeofapplicationtoanother.Ontheonehand,theselectionoftheheatstoringmassisdeterminedbytheharsh,orotherwise,operatingconditionsunderwhichtheregeneratorisrequiredtooperate.Ontheother,thepossibleoperatingarrangementswithsuchpackingsisbestunderstoodinthecontextofthedimensionlessparametersand.Foragivenreducedlength,themaximumthermalperformance,itcanbeshown,isachievedbyemployingassmallavalueofreducedperiod,aspossible.Theratiosrepresenttheheatcapacityofthepackingperhotperiodandpercoldperiodrespectively.Theeffectiveinterfacebetweenthefluidflowingthroughtheregeneratoratanyinstantandtheheatstoringpackingaretheproductsandforthehotandcoldperiods.Thelargertheseinterfaces,thegreatermustbetheheatcapacityperperiodtoaccommodatethethermalenergyinvolved.Inotherwords,theratiosmustbematchedbyperiodswhichyieldsmallenoughvaluesofandsothatasgoodathermalperformanceoftheregeneratoraspossiblecanbeobtained.Thiscanbeconsideredinanothermanner:economiesinregeneratorsizecanbeobtainedifthinpackingsareusedwheretheareatomassratio,A/Mforthehotperiod,A/Mforthecoldperiod,islarge.Inthiscase,smallenoughvaluesofandareobtainedbyoperatingtheregeneratorwithshortperiodlengths,thatiswithshortcycletimes.Ontheotherhand,harshoperatingconditionsmightrequirethepackingoftheregeneratortobeconstructedofsuitablematerialsfabricatedwitharobustgeometricalarrangement.Inthiscase,theareatomassratio,A/Mforthehotperiod,A/Mforthecoldperiod,mightwellberelativelysmallinwhichcase,suitablevaluesofandcanbeobtainedusinglongcycletimes,therebyavoidingarapidswitchingoftheregeneratorsinthesystemused.Thematteriscomplicatedstillfurtheriftheprocessofreversingaregeneratorisitselfslow.Forexample,ifitisnecessarytopressurizetheregeneratorvesselatthestartofthecoldperiod,andthendepressurizeitattheendofthecoldperiod,asisthecasewithCowperstovesusedforpreheatingtheblast(ofair)foriron-making,thenthetotalcycletimemustbelongenoughforthetimenecessaryforthesereversalsnottoconstituteanoverlargeproportionofthetotalcycletime.Inthiscase,theareatomassratio,A/Mforthehotperiod,A/Mforthecoldperiod,mustbeforcedtobesmallenoughtogeneratesufficientlysmallvaluesofandwiththelongerhotandcoldperiodsofoperationnecessary.VeryHighTemperatureRegeneratorsFixedbedregeneratorsoperatingwithhotgasinlettemperaturesinexcessof1200Karefittedwithpackingsconstructedoffireproofrefractoriesorceramicmaterialsofspecialquality,capableofwithstandingtheeffectsofanycorrosivematerialsentrainedinthehotgas.Thus,inglassfurnaceregenerators,ithasnotbeenuncommontousehighaluminapackingswhicharecapableofcopingwiththecorrosiveeffectsoflime,potash,silica,sodiumsulfateandvanadiumwhichcanbecarriedoverintotheregeneratorpackingfromtheglassmakingprocess.InCowperstoves,usedtopreheattheblastfortheironmakingandzincsmeltingprocesses,thepackingisfrequentlyzoned:atthetopoftheregenerator,materialscapabletowithstandingtheeffectsofveryhightemperatures,andfurtherdowntheregenerator,ofhighcompressiveloadsareused,forexample,silica.Atthebottomoftheregenerator,itisimperativetoprovidematerialswhichpossessthemechanicalstrengthandvolumestability,abletosupportthegreatweightofpackingabove.Differentsilica-aluminarefractoriesareoftenemployedinthesecircumstances.Notonlymustthematerialsofthepackingsbeabletocopewiththeeffectsofcorrosivematerials,soalsomustthegeometryofthepackingsbesoarrangedthatthesepossiblydirtygasescanhavefreepassagethroughtheregenerator.Theblockingofthechannelsmustbeavoided.Inthesecircumstances,variousgeometricalarrangementsoftherefractorymaterialsmustbeused.Squarechimneyorclosedbasketweavearrangementsarefrequentlyusedinthesecircumstances(Figure2).Itcanbearrangedthatthechannelsarewideenoughtoprovidefreepassagefordirtygasesbutforthe

- 温馨提示:

1: 本站所有资源如无特殊说明,都需要本地电脑安装OFFICE2007和PDF阅读器。图纸软件为CAD,CAXA,PROE,UG,SolidWorks等.压缩文件请下载最新的WinRAR软件解压。

2: 本站的文档不包含任何第三方提供的附件图纸等,如果需要附件,请联系上传者。文件的所有权益归上传用户所有。

3.本站RAR压缩包中若带图纸,网页内容里面会有图纸预览,若没有图纸预览就没有图纸。

4. 未经权益所有人同意不得将文件中的内容挪作商业或盈利用途。

5. 人人文库网仅提供信息存储空间,仅对用户上传内容的表现方式做保护处理,对用户上传分享的文档内容本身不做任何修改或编辑,并不能对任何下载内容负责。

6. 下载文件中如有侵权或不适当内容,请与我们联系,我们立即纠正。

7. 本站不保证下载资源的准确性、安全性和完整性, 同时也不承担用户因使用这些下载资源对自己和他人造成任何形式的伤害或损失。

人人文库网所有资源均是用户自行上传分享,仅供网友学习交流,未经上传用户书面授权,请勿作他用。

川公网安备: 51019002004831号

川公网安备: 51019002004831号