旋转工作台式真空包装机设计(全套含CAD图纸)

收藏

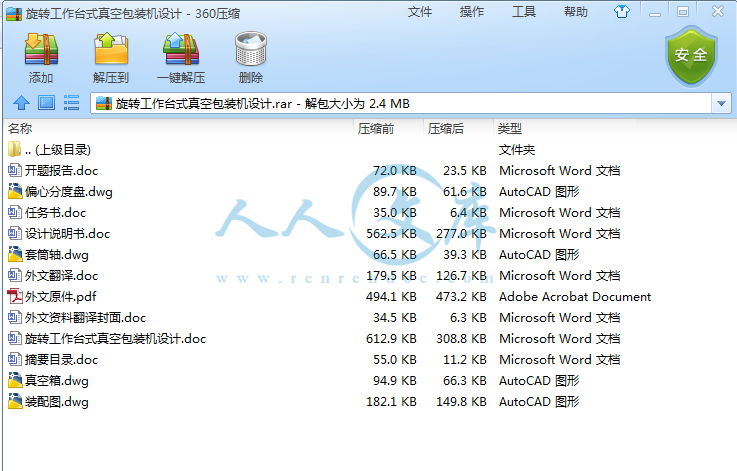

资源目录

压缩包内文档预览:(预览前20页/共25页)

编号:6973330

类型:共享资源

大小:1.56MB

格式:ZIP

上传时间:2018-01-05

上传人:机****料

认证信息

个人认证

高**(实名认证)

河南

IP属地:河南

50

积分

- 关 键 词:

-

旋转

工作

台式

真空

装机

设计

全套

cad

图纸

- 资源描述:

-

- 内容简介:

-

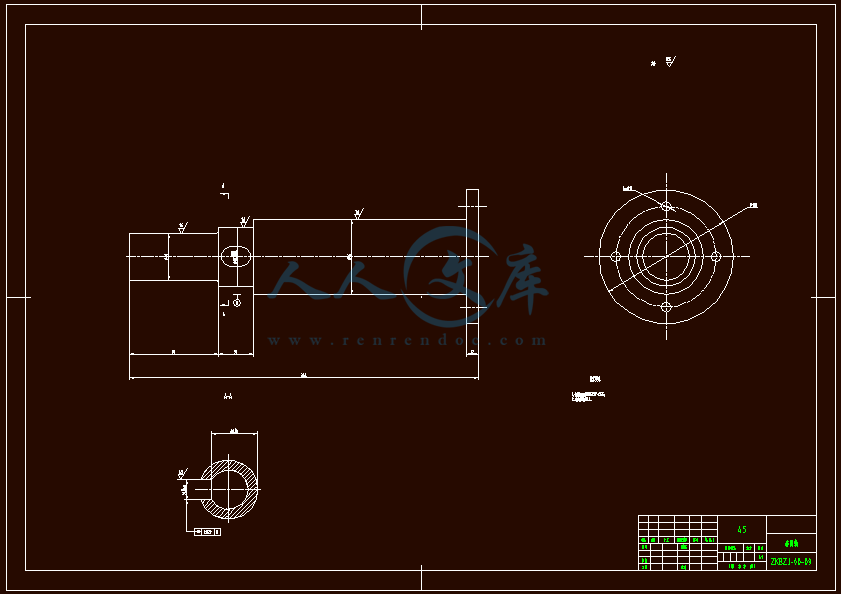

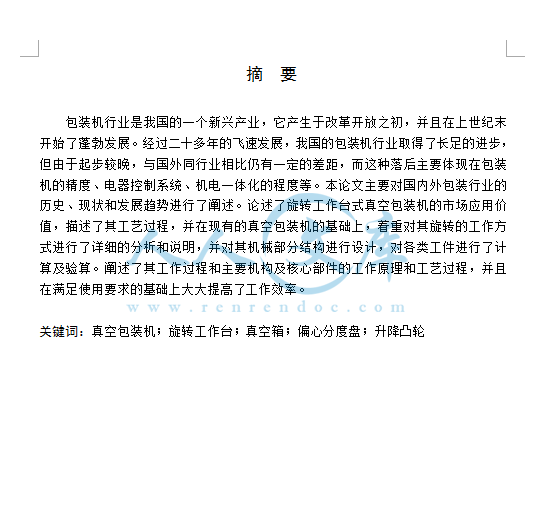

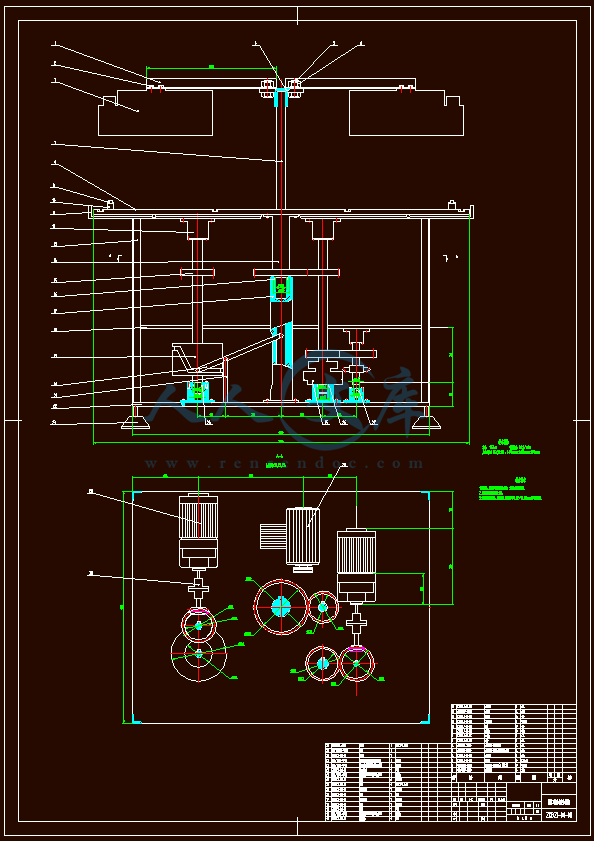

毕业设计(论文)任务书机械工程学院机械设计制造及其自动化(数控技术)专业论文题目旋转工作台式真空包装机设计学生姓名学号起讫日期指导教师姓名(签名)指导教师职称指导教师工作单位院(系)领导签名下发任务书日期题目旋转工作台式真空包装机设计论文时间课题的主要内容及要求含技术要求、图表要求等根据以下参数旋转工作台真空包装机是一种新型高效包装机,它在厚两工俭,联动真空包装机的基础上创新突破,大大提高了生产效率。适合于食品保鲜,包装行业的大批量生产。该设备目前没有厂家生产,有一定的推广价值。设计一种旋转式真空包装机,完成总装图及零件。编写设计说明书;完成专业外文资料翻译1份。课题的实施的方法、步骤及工作量要求设计方法学生在指导教师的指导下,利用所学的课程并自学有关知识,掌握机械设计的特点、方法,借助机械设计手册等技术资料,完成本机设计。设计步骤调研收集设计资料根据所给定的参数制定总体设计方案完成总装图及部装图完成零件图编写设计说明书。工作量要求设计图纸工作量合计3张零号图纸(A02张,A12张,A20张,A30张,A40张,电子手绘若干);毕业设计说明书不少于8000汉字;外文资料原文与课题相关的1万印刷符号左右,外文资料翻译译文(约3000汉字)。指定参考文献1成大先主编机械设计手册(单行本)减(变)速器电机与电器M北京化学工业出版社,20042濮良贵,纪名刚主编机械设计(第七版)M北京高等教育出版社,20013成大先主编机械设计手册(单行本)机构M北京化学工业出版社,20024王世刚,张秀亲,苗淑杰机械设计实践(修订版)M哈尔滨哈尔滨工程大学出版社,20035孙凤兰,马喜川主编包装机械概论M北京印刷工业出版社,20066成大先机械设计手册(第七卷)M北京化学工业出版社,2002毕业设计论文进度计划以周为单位第1周(2012年2月20日2012年2月26日)下达设计任务书,明确任务,熟悉课题,收集资料,上交外文翻译、参考文献和开题报告。第2周第8周(2012年2月27日2012年4月15日)制定总体方案,绘制总装图草图。第9周第14周(2012年4月16日2012年5月27日)修改并完成总装图及部装图,完成有关零件图的设计。第15周(2012年5月28日2012年6月5日)编写设计说明书第16周(2012年6月6日2012年6月8日)准备答辩备注MEMSVACUUMPACKAGINGTECHNOLOGYANDAPPLICATIONSJINYUFENG,ZHANGJIAXUNPEKINGUNIVERSITYSHENZHENGRADUATESCHOOL,SHENZHEN,518055,CHINANATIONALKEYLABOFMICRO/NANOFABRICATIONTECHNOLOGYOFCHINATEL861062752536,FAX861062751789,JINYFIMEPKUEDUCNABSTRACTMANYMEMSMICROELECTROMECHANICSYSTEMSPARTSHAVETOMEETTHEREQUIREMENTSFORVACUUMPACKAGINGINVACUUMPACKAGING,LEAKAGEANDGASPERMEATION,WHICHWILLAFFECTTHENORMALFUNCTIONOFTHECOMPONENTS,AREMAJORPROBLEMSHERMETICSEALINGISONEOFTHEMOSTIMPORTANTTECHNOLOGIESFORRELIABLEVACUUMPACKAGINGINTHISPAPER,SEVERALHERMETICSEALINGTECHNOLOGIESFORVACUUMPACKAGINGWILLBEPRESENTED,INCLUDINGEUTECTICBONDING,ADHESIVEBONDING,GLASSFRITBONDING,ANDSILICONGLASSANODICBONDINGFURTHERFORE,THEAUTHORWILLINTRODUCEDTWOAPPROACHESTODEALWITHSEALINGIMPERFECTSURFACECAUSEDBYELECTRICFEEDTHROUGHS,WHICHLINKTOTHEOUTSIDEOFTHESMALLCAVITYOFMEMSSENSORSTHEGETTERWILLBEDISDUSSEDASITISESSENTIALTOKEEPTHEVACUUMENVIRONMENTINSIDETHECAVITYOFDEVICESINCETHEINNERWALLSMIGHTRELEASEGASAFTERHERMETICSEAL1MATERIALSUSEDINMEMSVACUUMPACKAGING1GASPERMEATIONINVACUUMPACKAGINGHASTOBECONSIDERED,WHENCHOOSINGMATERIALSAPPLIEDINMEMSPACKAGINGFORTHESAMEQUANTITYPERMEATEDGAS,THEPRESSUREDETERIORATIONCAUSEDBYGASPERMEATIONINMEMSISMUCHMORETHANTHATINCONVENTIONALSTRUCTURE,SINCETHEVOLUMEISSMALLERINMEMSCAVITYFURTHERMORE,THINNERSTRUCTURESAREOFTENUSEDINMEMSVACUUMPACKAGINGTHISWILLCAUSEMORESERIOUSPERMEATIONPROBLEMFORTHEMEMSDEVICESFORINSTANCE,THEPERMEATEDGASISHUNDREDTIMESMOREWHENTHETHICKNESSOFAWALLORDIAPHRAGMISREDUCEDFROM1MMTO10MINCASEOFTHEGASPERMEATION,WESHOULDCHOOSETHEPACKAGINGMATERIALSWITHLOWPERMEATIONRATEFIG1COMPARESTHEPERMEATIONRATEOFMOISTUREORWATERMOLECULESTHROUGHSEVERALKINDSOFPACKAGINGMATERIALS,WHICHAREUSEDINMODERNELECTRONICFABRICATIONANDPACKAGINGTHEIRPERMEATIONRATERANGESFROM1018CM3/SECTO1010CM3/SECFIG1PERMEABILITYOFWATERTHROUGHNONHERMETICANDHERMETICMATERIALSFEATURINGLOWERPERMEATIONRATE,GLASSES,CERAMICS,SILICONNITRIDES,METALS,ANDSOMEPURECRYSTALSARESUGGESTEDTOBETHECANDIDATESFORHERMETICPACKAGINGTHOSEWITHHIGHERPERMEATIONRATE,WHICHAREREGARDEDASNONHERMETICMATERIALS,MUSTBEKEPTAWAYFROMTHECATALOGUEFORHERMETICPACKAGINGINOURWORKS,GLASS,CERAMIC,ANDADHESIVEMATERIALSWITHLOWPERMEATIONRATEWERECHOSENASTHEPACKAGINGSTRUCTURES/MATERIALS2HERMETICALSEALINGFORMEMSSTRUCTUREHERMETICPACKAGINGPLAYSANIMPORTANTROLEINMANYMICROSYSTEMSHERMETICSEALING,WHICHPROTECTSTHEMICROSYSTEMSFROMHARMFULENVIRONMENTALINFLUENCES,CANSIGNIFICANTLYINCREASETHERELIABILITYANDLIFETIMEOFTHEMBESIDESANODICBONDING,ANUMBEROFOTHERBONDINGTECHNIQUESHAVEALSOBEENUSEDFORHERMETICPACKAGING,INCLUDINGSILICONTOGOLDEUTECTICBONDING,GLASSFRITBONDING,FUSIONBONDING,ANDBONDINGUSINGEVAPORATEDGLASSTHEHERMETICSEALINGPROCESSESDEVELOPEDINTHISRESEARCHWORKINCLUDEELECTROSTATICBONDINGORANODICSILICONGLASSBONDING,EUTECTICBONDING,GLASSFRITBONDING21SOLDERBONDINGANDEUTECTICBONDINGSOLDERBONDINGFORHERMETICALLYSEALINGWAFERSISBASEDONSOLDERJOININGTWOWAFERTOGETHEROFTHEM,EUTECTICBONDINGISWIDELYAPPLIEDINMEMSPACKAGING,WHICHTAKESTHEADVANTAGEOFTHEEUTECTICALLOYTOREALIZEABONDBETWEENTWOSUBSTRATESATALOWERTEMPERATURESOLDEROFASUITABLEMATERIALSETCANBEFORMEDINTHEBONDINGAREABETWEENSUBSTRATESOFPACKAGEANDDEVICERAISETHETEMPERATUREUNTILTHESOLDERFLOWSANDCREATESABONDTOSEALTWOSUBSTRATESTHEMOSTOBVIOUSMATERIALSTOUSEARETHOSESTANDARDSOLDERSUSEDINMICROELECTRONICAPPLICATIONS,BUTMANYOFSUCHSOLDERMATERIALSCONTAINEITHERFLUXORSUFFICIENTIMPURITIESTHESEFLAWSCAUSESIGNIFICANTOUTGASSINGDURINGTHEREFLOWPROCESSTHISBECOMESAMAJORPROBLEMWHENTRYINGTOUSESUCHSOLDERSFORVACUUMPACKAGINGRECENTDEVELOPMENTRESEARCHONNEWFLUXLESSSOLDERMATERIALSMAYOVERCOMESUCHPROBLEMANDSEVERALGROUPSAREPURSUINGTHIS2COMPARINGWITHSTANDARDSOLDER,ITISALSOPOSSIBLETOUSEALLOYSOFDIFFERENTMATERIALSINTHEFORMOFEUTECTICSOLDERONEOFTHEMOSTCOMMONMATERIALSETSISTHEEUTECTICOFGOLDANDSILICONSILICONGOLDEUTECTICISQUITEATTRACTIVEBECAUSEITISFORMEDATATEMPERATUREOF363CWITHONEPARTSILICONANDFOURPARTSGOLDTHISMATERIALSISCOMMONLYUSEDINMEMSFABRICATION,ANDWHENTHEEUTECTICISFORMED,THEOUTGASSINGPROBLEMISRESOLVEDSINCETHEMIXTUREISSIMPLYFORMEDBYRAISINGTHETEMPERATUREANDTHESTARTINGMATERIALSAREPUREINADDITION,THETEMPERATUREISLOWENOUGHFORMOSTAPPLICATIONS0780394496/05/20002005IEEE20056THINTERNATIONALCONFERENCEONELECTRONICPACKAGINGTECHNOLOGYONONEHAND,FORSILICONGOLDEUTECTICBONDING,ALTHOUGHTHEEUTECTICPOINTIS363OC,THEBONDINGTEMPERATUREMUSTBEHIGHERAHIGHERTEMPERATURECANPROMOTETHEDIFFUSIONOFGOLDANDSILICONINTOEACHOTHER,ANDINCREASETHETHICKNESSOFTHEDIFFUSIONLAYERWHERETHECHEMICALCOMPOSITIONCANMATCHWITHWHATISNEEDEDFOREUTECTICBONDINGTHEREFORE,AHIGHERTEMPERATUREANDALONGERBONDINGTIMEAREBENEFICIALTOAGOODBONDINGONTHEOTHERHAND,IFTHEBONDINGTEMPERATUREISTOOHIGH,ITMAYCAUSESERIOUSDIFFUSIONOFGOLDINTOSILICON,WHICHWILLDEGRADETHEFUNCTIONOFTHESILICONDEVICESFIG2SHOWSTHESCANNINGACOUSTICMICROSCOPESAMMICROGRAPHSOFEUTECTICALLYBONDEDSENSORWAFERANDSILICONCAPWAFERATABONDINGTEMPERATUREOF400450OCDURINGSAMANALYZINGPROCESS,THEBONDEDWAFERSAREIMMERSEDINDEIONIZEDWATERBUBBLEFREEINTERFACESAREOBSERVEDANDNOWATERISSUCKEDINTOTHECAVITIESITINDICATESTHATTHECAVITIESAREWELLSEALEDTHEPULLTESTRESULTSSHOWTHATTHEBONDSTRENGTHISMORETHAN5MPAFIG2SAMMICROGRAPHSOFSEALEDWAFERS22ADHESIVEBONDINGTHEADVANTAGESOFADHESIVEBONDINGAREITSLOWPROCESSTEMPERATUREANDTHEPOSSIBILITYTOJOINDIFFERENTMATERIALS3THISBONDINGTECHNOLOGYMAKESUSEOFANINTERMEDIATEADHESIVELAYERTOJOINTWOSUBSTRATEMATERIALSWITHDIFFERENTPROPERTIESTHEADHESIVEMATERIALSMAYBEEPOXIESORPOLYMERSSOMETIMESEPOXYISACCEPTABLEFORGASFILLEDMEMSDEVICEFORINSTANCE,EPOXYISUSEDINMICROOPTICALSWITCHFORHOLDINGOPTICALCOMPONENTSTOGETHERHOWEVER,EPOXYINTHELIGHTPATHISNOTDESIRABLEASITMAYAGE,DRIFT,ORCRACKATHIGHLASERPOWERLEVELSTHISCAUSESASIGNIFICANTPROBLEMFORTHEPACKAGE,SINCETHEPACKAGEHASTOPROTECTTHEDEVICEANDSIMULTANEOUSLY,PROVIDEACCESSTOTHEENVIRONMENTTHATTHEDEVICEISSUPPOSEDTOCONTACTWITHASARESULT,ALOTOFEFFORTHASBEENEXPENDEDONDEVELOPINGTHEPROPERPROTECTION/ENCAPSULATIONMEDIUMFORMEMSFIG3ISANAPPLICATIONEXAMPLEOFADHESIVEBONDINGFORMICROOPTICALSWITCHTHEPROCESSOFADHESIVEBONDINGSTARTSWITHAPPLYINGTHEADHESIVELAYER,FOLLOWEDBYCONTACTINGTHEWAFERSANDFORMINGBONDBYAHEATCURING,ORULTRAVIOLETUVCURING4OPTICALFIBERSUBSTRATECERAMICPLATE2CERAMICPLATE1GLASSCAPADHESIVEFIG3ADHESIVEPACKAGINGFORMICROOPTICALSWITCHADHESIVESAREWIDELYUSEDINPACKAGINGFORMOEMS,SUCHASTACKING,FILLINGANDSEALINGTHEPRECISIONSTRUCTURE,JOININGTHECERAMICFRAMES,GLASSLIDANDPCBSUBSTRATESTOFORMAHERMETICPACKAGEHOWEVER,ITISDIFFICULTTOOBTAINUNIFORMANDHERMETICBONDINGWITHVACUUMGRADEANDHUMIDITYINSENSITIVEDUETOTHEPERMEATIONOFMOISTUREWECOULDCHOOSEANADHESIVEMATERIALWITHLOWPERMEATIONRATEORCOATANANTIPERMEATIONLAYERSUCHASSIO2TORESOLVESUCHAPROBLEM23GLASSFRITBONDINGTHEADVANTAGEOFGLASSFRITBONDINGISTHECAPABILITYOFPRODUCINGGOODHERMETICSEALSDEVELOPMENTOFAGLASSFRITBONDINGPROCESSISTOUSEANINBETWEENGLASSLAYERATTEMPERATURESBELOW400CBYCOMBININGANODICBONDINGWITHGLASSFRITCOATINGONWAFERSINVARIOUSMATERIALS,SUCHASSILICON,CERAMICANDMETAL,ITISPOSSIBLETOANODICALLYBONDWAFERSEXCEPTGLASSWAFERWITHSILICONWAFERBESIDES,ITCANBEUSEDINHERMETICBONDINGBETWEENCERAMICLAYERSFIG4ISONEEXAMPLEOFITSAPPLICATIONSILICONLIDGLASSFRITSUBSTRATEFIG4SCHEMATICPACKAGINGOFGLASSFRITBONDINGTHEPROCESSCANBEDESCRIBEDASBELOWFIRSTAPPLYTHEFRITPASTEONTOTHESUBSTRATEWITHMEMSCHIPSTHROUGHSCREENPRINTPROCESSAFTERTHATTHEFRITMUSTBETHOROUGHLYDRIEDOVENDRYINGCANBEUSEDTHENRAISETHETEMPERATURETOAROUND400C,THESOFTENINGPOINTOFTHEFRIT,ANDHOLDFOR5TO10MINUTESBEFORECOOLINGDOWNSEALINGCYCLESDEPENDSONTHEGEOMETRYANDSIZEOFSEALINGINTERFACETHEIMPORTANTPARAMETERSOFHEATINGPROCESSARESTARTINGPOINTFOREXPERIMENTATION,SEALINGTEMPERATURE,HOLDINGTEMPERATURE,ANDHEATINGRATEOFEACHSTEP,WHICHSHOULDBEFOLLOWEDTHESPECIFICATIONGIVENBYTHEFRITSUPPLIERITISNECESSARYTOMAINTAINANOXIDIZINGENVIRONMENTATALLTIMESINTHEFURNACE24ANODICBONDINGANODICBONDINGCANBEUSEDTOBONDTWOMATERIALS,SUCHASSILICONANDGLASS,SILICONANDSILICON,CERAMICANDMETAL,ETCINRECENTYEARS,ANODICBONDINGHASBEENWIDELYAPPLIEDTOVACUUMPACKAGINGOFMEMSDEVICESITISARELIABLEANDEFFECTIVEPROCESSFORHERMETICALLYSEALINGSILICONWAFERSTOGLASSWAFERSORQUARTZSUBSTRATESANODICBONDINGISUSUALLYCARRIEDOUTUNDERCONSTANTTEMPERATUREANDVOLTAGETHECATHODEMAKESCONTACTWITHTHEGLASSWAFER,WHILETHEANODECONNECTSTOTHESILICONWAFERBYHEATINGAT200500CANDSUPPLYING2001500VOLTSDCVOLTAGEACROSSASILICONGLASSWAFERSTACK,THEPOSITIVEIONSINTHEGLASS,MAINLYSODIUMIONSWHICHCOMEFROMTHEDISSOCIATIONOFNAO2,MOVETOTHECATHODE,LEAVINGTHENONBRIDGINGOXYGENIONSTHEOXYGENIONSBONDEDTOONLYONESILICONATOMBEHINDCONSEQUENTLY,ANEGATIVELYCHARGEDDEPLETIONLAYERISFORMEDADJACENTTOTHEANODETHEELECTROSTATICFORCEBETWEENTHISNEGATIVELAYERANDTHEPOSITIVECHARGESINDUCEDAROUNDTHEANODEMAKESTHETWOSIDESINTIMATELYCONTACTWITHEACHOTHERTHISFORCE,ALLIEDTOTHESOFTENINGOFTHEGLASS,ALLOWSSOMECONFORMINGOFGLASSTOTHEOPPOSINGSURFACEANDMAKESPOSSIBLEHERMETICALLYBONDINGBETWEENSURFACESTHATAREIMPERFECTALOWTEMPERATUREANODICBONDINGFORHERMETICSEALINGWASDEVELOPEDTHEINTERFACEINTEGRITYWASOBSERVEDUNDERSCANNINGELECTRONMICROSCOPESEMFIG5SHOWSATYPICALCROSSSECTIONOFBONDEDSIANDGLASSITPROVESTHATSILICONANDGLASSWEREDENSELYBONDEDTOGETHERFIG5ATYPICALCROSSSECTIONOFBONDEDSIANDGLASSMEASUREMENTOFTHEDISTRIBUTIONOFTHEELEMENTSSI,OANDNAINTHEINTERFACEBETWEENSIANDGLASSALSOSHOWSTHATSICONTENTDECREASESWHILEOCONTENTINCREASESFROMSIWAFERSIDETOGLASSWAFERSIDENOOBVIOUSCHANGEWASFOUNDFORNAELEMENTTHEREASONISTHATLOWTEMPERATUREWASUSEDINOURBONDINGPROCESSALTHOUGHNAMAYMIGRATETOCATHODE,THEMIGRATIONLEVELISMUCHLOWERTHANTHATATHIGHTEMPERATURE25HERMETICBONDINGWITHIMPERFECTSURFACETHEELECTRICALFEEDTHROUGHS,WHICHLINKTOTHEOUTSIDEOFTHESEALEDSTRUCTURE,MAKETHESURFACEOFTHESUBSTRATEIMPERFECTTHEREFORE,THEHERMETICPACKAGINGWITHELECTRICALFEEDTHROUGHSISANESSENTIALCONSIDERATIONFORMANYMICROSYSTEMS5,6THEELECTRICALFEEDTHROUGHSAREGENERALLYREQUIREDTOCONNECTAMICROSENSINGORACTUATINGELEMENTFROMTHEINSIDEOFTHESEALEDSTRUCTURETOTHEOUTSIDEWORLDFOREXAMPLE,ELECTRICALPOWERNEEDSTOBESUPPLIEDTOTHESEALEDREGIONANDELECTRICALSENSINGSIGNALSNEEDTOBEEXTRACTEDFROMTHESEALEDPACKAGELATERALELECTRICALFEEDTHROUGHSOFMETALCONDUCTORSARECOMMONLYUSEDFORALONGTIMETHESTANDARDFABRICATIONPROCESSINSEMICONDUCTORINDUSTRY,SUCHASELECTRONICPLATING,VAPORDEPOSITIONANDSPUTTERING,MAKESTHELATERALELECTRICALFEEDTHROUGHTECHNIQUEVERYCONVENIENTHOWEVER,THICKMETALCOATINGONTHEINTERFACEOFSILICONWAFERORGLASSWAFERWILLRESULTSINFAILUREINANODICBONDINGBETWEENSILICONANDGLASSDUETOTHEAIRLEAKAGEORDEBONDINGFROMTHEBONDINGINTERFACETHEREARETWOAPPROACHESTOREALIZEHERMETICSEALINGVIAANODICBONDINGOFSILICONTOGLASSWITHTHICKMETALFEEDTHROUGHONTHESURFACES7THEYARETHEPATTERNEDEMBEDEDELECTRODEANDTHEVERTICALVIAELECTRODEMETHODFORINTERCONNECTIONOFMEMSDEVICESFIG6APROCESSFLOWOFTHEEMBEDEDELECTRODEMETHODTHEFABRICATIONPROCESSOFEMBEDEDELECTRODEMETHODISSHOWNINFIG6BOTHGLASSANDSILICONWAFERSAREAVAILABLEINTHEPROCESSFIRSTAPATTERNEDSHALLOWTRENCHWASETCHEDONTHESURFACEOFTHEWAFERSECONDFORSILICONWAFER,ANADDITIONALSIO2FILMWASDEPOSITEDINORDERTOFORMANINSULATIONLAYERAFTERTHAT,METALWASDEPOSITEDONTHEPATTERNEDWAFERTOFORMEMBEDDEDTHICKELECTRODESINSIDETHETRENCHCHEMICALMECHANICALPOLISHINGCMPPROCESSWASTHENCARRIEDOUTTOFORMASMOOTHANDLEVELEDBONDINGSURFACEFINALLY,THESILICONANDGLASSWAFERSWEREBONDEDTOGETHERBYANODICBONDINGTESTRESULTSHOWSTHATAFTERCMPTHEROUGHNESSOFTHEGLASSWAFERPLANARIZATIONISASLOWAS13NM,WHICHISGOODENOUGHFORSILICONTOGLASSANODICBONDINGWITHHERMETICSEALINGTHEEMBEDEDELECTRODESBOTHONGLASSWAFERANDSILICONWAFERHAVEBEENSUCCESSFULLYFABRICATEDTHEWIDTHOFTHEELECTRODESCANBEFABRICATEDFROM20MTO80M,ANDTHETHICKNESSFROM05MTO19MUSINGMEMSPRESSURESENSORTOINVESTIGATETHEHERMETICITY,WEFOUNDTHATTHELEVELEDANDPOLISHEDGLASSWAFERWITHEMBEDEDELECTRODEWASANODICALLYBONDEDWITHSILICONWAFERTHEOTHERAPPROACHISCALLEDTHEVERTICALVIAELECTRODEMETHODMICROSTRUCTUREWASFABRICATEDTHROUGHSTANDARDMEMSPROCESSANDANODICBONDINGAFTERETCHINGOFVIAHOLES,VERTICALELECTRODESWEREFORMEDTHROUGHTHEVIASBYDEPOSITIONANDPATTERNINGOFMETALFILMTHEN,AMETALVIAPROCESSWASAPPLIEDTOFORM3DELECTRICINTERCONNECTIONATTHESAMETIME,ITALSOSERVESASTHEHERMETICSEALINGPROCESSBYFILLINGMETALMATERIALINTOTHEVIASFINALLY,POSTPROCESSES,SUCHASFILLINGPOLYMERINSULATIONPI,DEPOSITINGUBMANDWAFERBUMPING,WEREPERFORMEDANDTHREEDIMENSION3DINTERCONNECTIONBYVIASWASFORMEDFIG7SHOWSAMICROGRAPHOFANELECTRICVIAONSILICONWAFERVERTICALINTERCONNECTIONBOTTOMELECTRODEPIVIATOPELECTRODEFIG7AMICROGRAPHOFANELECTRICVIAONSIWAFER3VACUUMMAINTENANCEFORMEMSPACKAGINGAFTERHERMICSEALING,THEINNERWALLSOFTHESMALLSCALECAVITYMIGHTRELEASEGAS,WHICHAFFECTTHEVACUUMMAINTENANCEWITHTHEADVANTAGEOFHIGHSORBINGCAPABILITY,COMMERCIALNONEVAPORABLEGETTERNEGHASBEENUSEDINVACUUMMAINTENANCEOFELECTRONICPACKAGINGITISPREPAREDBYCOATINGGETTERMATERIALSONSTRIPSORSHEETSANDCUTTHEMINTOTHEDESIRABLESHAPEANDSIZEBYMECHANICALCUTTINGORBYLASERBEAMTHENTHENEGISFASTENEDONTHEINNERSURFACEOFDEVICESSTRUCTUREHOWEVER,ITISDIFFICULTTOAPPLYTHECOMMERCIALNEGTOMAINTAINHIGHERVACUUMENVIRONMENTINMICROSCALECAVITYINORDERTOMATCHWITHTHEMINIATURIZATIONOFMEMSDEVICESTHEMETHODOFDEPOSINGTHINFILMORTHICKFILMOFGETTERMATERIALSONTOINNERSURFACEOFMICROSTRUCTURESBECOMESASOLUTIONTOMAINTAINVACUUMINMICROCAVITY8,9ASCHEMATICOFTHEKEYPROCESSSTEPSISPRESENTEDINFIG8THEPREPROCESSCONSISTSOFMASKDESIGN,MAKINGOFGETTERPASTEBYMIXINGK4SI,GRAPHITEWITHPOWDEROFZRVFEALLOY,ANDTHEFABRICATIONOFMEMSCHIPFIRST,PRINTGETTERPASTEONTHESURFACEOFDOUBLESIDEPOLISHEDPYREX7740GLASSWAFERTOFORMAPATTERNTHENCOATNEGTHICKFILMONTHESURFACEAFTERPREBAKINGAT120CFORHALFANHOUR,THEGLASSWAFERANDSILICONWAFERWITHMEMSSTRUCTUREARECLEANEDTOELIMINATEPARTICLESANDOTHERCONTAMINATIONONTHESURFACESANODICBONDINGWASTHENAPPLIEDTOHERMETICALLYJOINTHEGLASSWAFERTOTHESILICONWAFERTHEBONDINGPROCESSWASCARRIEDOUTWITHEV501BONDERATAPRESSUREOF1103TORRANDDCVOLTAGEOF1000VOLTSFOR60MINUTESTHEBONDINGTEMPERATUREIS450CWETESTEDTHESORPTIONCAPABILITYTOEXAMINETHEPERFORMANCEOFTHEGETTERFILMEXPERIMENTALPRESSUREVARIATIONAGAINSTTIMEISSHOWNINFIG9GOODSORPTIONCAPABILITYOF488106PASCALLITRE/M2HASBEENMEASUREDWITHTHEGETTERINGOF65PALITRE/SFIG8PACKAGINGFLOWFORMEMSWITHTHICKFILMNEGFIG9SORPTIONCAPABILITYTESTPRESSUREVARIATIONVSTIMETHEFLASHINGGETTERMATERIALHASALSOBEENUSEDINTHEMEMSPACKAGINGRESEARCHBECAUSEOFITSATTRACTIVEFEATURES,SUCHASSTEADYPERFORMANCE,CONSISTENTYIELDOFGETTERINGMATERIALSANDMINIMALOUTGASSINGDURINGEVAPORATIONBYEVAPORATIONITCANBEEASILYDEPOSITEDONTOTHEINNERWALLSOFTHEMICROCAVITYINTHEFORMOFTHINFILMTHEGETTERUSEDINOURRESEARCHISCOMMERCIALLYAVAILABLEUNDERTHETRADENAMEOFBI5U1HFG21,WHOSEACTIVEINGREDIENTSAREBA,ALANDNIALLOYSBESIDESITSHIGHEFFICIENTADSORPTIONPERFORMANCE,THEEXPERIMENTALRESULTSALSOSHOWTHATITHASTHEGOODADHESIONOFTHETHINFILMTHETHICKNESSOFGETTERFILMCOATEDONTHEWAFERCANBECONTROLLEDINTHERANGEOFSEVERALTOHUNDREDSMICRONSBYADJUSTINGTHEHEATERTEMPERATUREANDPROCESSTIMEITISALSOFEASIBLETOFORMAPATTERNEDGETTERFILMONTHELIDSURFACEUSINGAPHYSICALMASKBETWEENGETTERSOURCEANDTHETARGET4CONCLUSIONSSILICONGOLDEUTECTICBONDINGFORMSASOFTEUTECTICTOALLOWBONDINGOVERNONPLANARSURFACES,ITCANBEDONEATABOVETHEEUTECTICTEMPERATURE363C,ANDITSELFDOES

- 温馨提示:

1: 本站所有资源如无特殊说明,都需要本地电脑安装OFFICE2007和PDF阅读器。图纸软件为CAD,CAXA,PROE,UG,SolidWorks等.压缩文件请下载最新的WinRAR软件解压。

2: 本站的文档不包含任何第三方提供的附件图纸等,如果需要附件,请联系上传者。文件的所有权益归上传用户所有。

3.本站RAR压缩包中若带图纸,网页内容里面会有图纸预览,若没有图纸预览就没有图纸。

4. 未经权益所有人同意不得将文件中的内容挪作商业或盈利用途。

5. 人人文库网仅提供信息存储空间,仅对用户上传内容的表现方式做保护处理,对用户上传分享的文档内容本身不做任何修改或编辑,并不能对任何下载内容负责。

6. 下载文件中如有侵权或不适当内容,请与我们联系,我们立即纠正。

7. 本站不保证下载资源的准确性、安全性和完整性, 同时也不承担用户因使用这些下载资源对自己和他人造成任何形式的伤害或损失。

人人文库网所有资源均是用户自行上传分享,仅供网友学习交流,未经上传用户书面授权,请勿作他用。

川公网安备: 51019002004831号

川公网安备: 51019002004831号