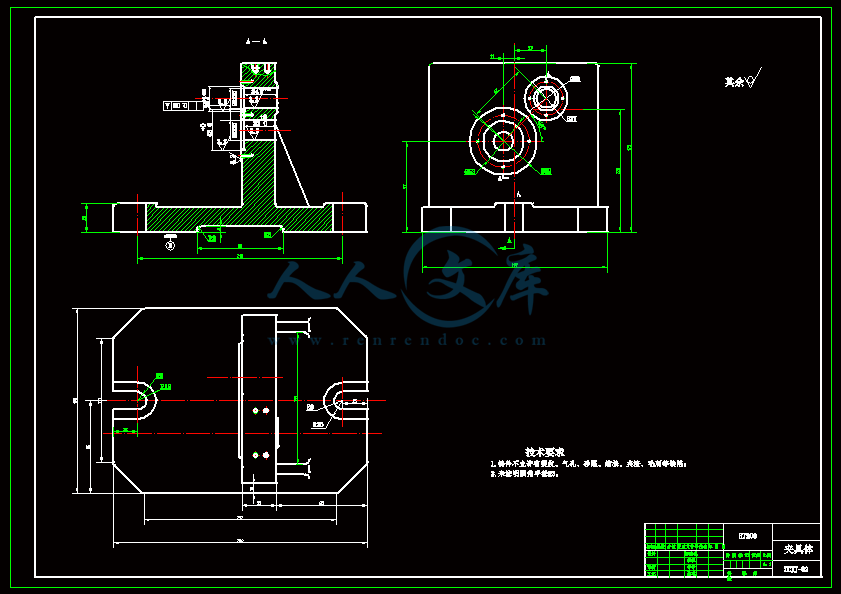

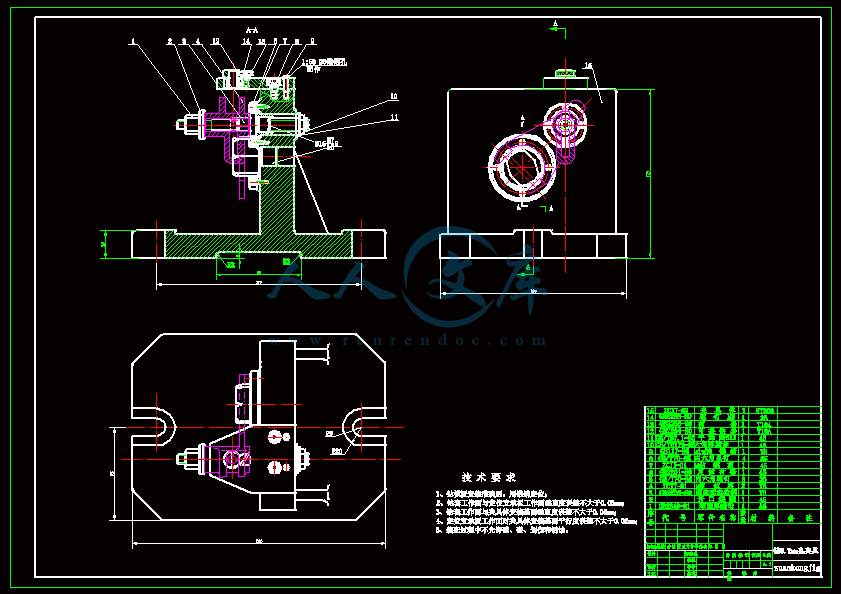

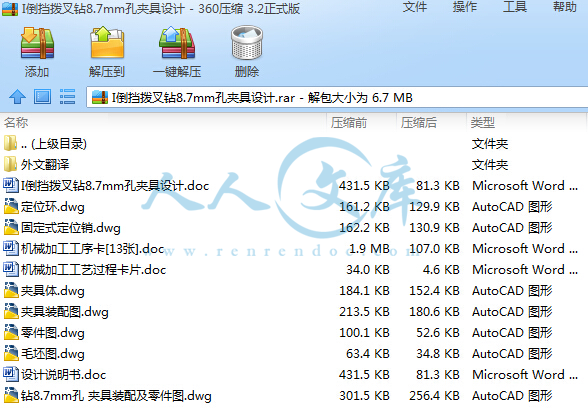

I倒挡拨叉钻8.7mm孔夹具设计(全套含CAD图纸)

收藏

资源目录

压缩包内文档预览:

编号:7023184

类型:共享资源

大小:3.37MB

格式:ZIP

上传时间:2018-01-07

上传人:机****料

认证信息

个人认证

高**(实名认证)

河南

IP属地:河南

50

积分

- 关 键 词:

-

倒挡拨叉钻

mm

妹妹

夹具

设计

全套

cad

图纸

- 资源描述:

-

- 内容简介:

-

INTJADVMANUFTECHNOL2001171041132001SPRINGERVERLAGLONDONLIMITEDFIXTURECLAMPINGFORCEOPTIMISATIONANDITSIMPACTONWORKPIECELOCATIONACCURACYBLIANDSNMELKOTEGEORGEWWOODRUFFSCHOOLOFMECHANICALENGINEERING,GEORGIAINSTITUTEOFTECHNOLOGY,GEORGIA,USAWORKPIECEMOTIONARISINGFROMLOCALISEDELASTICDEFORMATIONATFIXTUREWORKPIECECONTACTSOWINGTOCLAMPINGANDMACHININGFORCESISKNOWNTOAFFECTSIGNIFICANTLYTHEWORKPIECELOCATIONACCURACYAND,HENCE,THEFINALPARTQUALITYTHISEFFECTCANBEMINIMISEDTHROUGHFIXTUREDESIGNOPTIMISATIONTHECLAMPINGFORCEISACRITICALDESIGNVARIABLETHATCANBEOPTIMISEDTOREDUCETHEWORKPIECEMOTIONTHISPAPERPRESENTSANEWMETHODFORDETERMININGTHEOPTIMUMCLAMPINGFORCESFORAMULTIPLECLAMPFIXTURESUBJECTEDTOQUASISTATICMACHININGFORCESTHEMETHODUSESELASTICCONTACTMECHANICSMODELSTOREPRESENTTHEFIXTUREWORKPIECECONTACTANDINVOLVESTHEFORMULATIONANDSOLUTIONOFAMULTIOBJECTIVECONSTRAINEDOPTIMISATIONMODELTHEIMPACTOFCLAMPINGFORCEOPTIMISATIONONWORKPIECELOCATIONACCURACYISANALYSEDTHROUGHEXAMPLESINVOLVINGA321TYPEMILLINGFIXTUREKEYWORDSELASTICCONTACTMODELLINGFIXTURECLAMPINGFORCEOPTIMISATION1INTRODUCTIONTHELOCATIONANDIMMOBILISATIONOFTHEWORKPIECEARETWOCRITICALFACTORSINMACHININGAMACHININGFIXTUREACHIEVESTHESEFUNCTIONSBYLOCATINGTHEWORKPIECEWITHRESPECTTOASUITABLEDATUM,ANDCLAMPINGTHEWORKPIECEAGAINSTITTHECLAMPINGFORCEAPPLIEDMUSTBELARGEENOUGHTORESTRAINTHEWORKPIECEMOTIONCOMPLETELYDURINGMACHININGHOWEVER,EXCESSIVECLAMPINGFORCECANINDUCEUNACCEPTABLELEVELOFWORKPIECEELASTICDISTORTION,WHICHWILLADVERSELYAFFECTITSLOCATIONAND,INTURN,THEPARTQUALITYHENCE,ITISNECESSARYTODETERMINETHEOPTIMUMCLAMPINGFORCESTHATMINIMISETHEWORKPIECELOCATIONERRORDUETOELASTICDEFORMATIONWHILESATISFYINGTHETOTALRESTRAINTREQUIREMENTPREVIOUSRESEARCHERSINTHEFIXTUREANALYSISANDSYNTHESISAREAHAVEUSEDTHEFINITEELEMENTFEMODELLINGAPPROACHORCORRESPONDENCEANDOFFPRINTREQUESTSTODRSNMELKOTE,GEORGEWWOODRUFFSCHOOLOFMECHANICALENGINEERING,GEORGIAINSTITUTEOFTECHNOLOGY,ATLANTA,GEORGIA303320405,USAEMAILSHREYESMELKOTEMEGATECHEDUTHERIGIDBODYMODELLINGAPPROACHEXTENSIVEWORKBASEDONTHEFEAPPROACHHASBEENREPORTED18WITHTHEEXCEPTIONOFDEMETER8,ACOMMONLIMITATIONOFTHISAPPROACHISTHELARGEMODELSIZEANDCOMPUTATIONCOSTALSO,MOSTOFTHEFEBASEDRESEARCHHASFOCUSEDONFIXTURELAYOUTOPTIMISATION,ANDCLAMPINGFORCEOPTIMISATIONHASNOTBEENADDRESSEDADEQUATELYSEVERALRESEARCHERSHAVEADDRESSEDFIXTURECLAMPINGFORCEOPTIMISATIONBASEDONTHERIGIDBODYMODEL911THERIGIDBODYMODELLINGAPPROACHTREATSTHEFIXTUREELEMENTANDWORKPIECEASPERFECTLYRIGIDSOLIDSDEMETER12,13USEDSCREWTHEORYTOSOLVEFORTHEMINIMUMCLAMPINGFORCETHEOVERALLPROBLEMWASFORMULATEDASALINEARPROGRAMWHOSEOBJECTIVEWASTOMINIMISETHENORMALCONTACTFORCEATEACHLOCATINGPOINTBYADJUSTINGTHECLAMPINGFORCEINTENSITYTHEEFFECTOFTHECONTACTFRICTIONFORCEWASNEGLECTEDBECAUSEOFITSRELATIVELYSMALLMAGNITUDECOMPAREDWITHTHENORMALCONTACTFORCESINCETHISAPPROACHISBASEDONTHERIGIDBODYASSUMPTION,ITCANUNIQUELYONLYHANDLE3DFIXTURINGSCHEMESTHATINVOLVENOMORETHAN6UNKNOWNSFUHANDNEE14ALSOPRESENTEDANITERATIVESEARCHBASEDMETHODTHATCOMPUTESTHEMINIMUMCLAMPINGFORCEBYASSUMINGTHATTHEFRICTIONFORCEDIRECTIONSAREKNOWNAPRIORITHEPRIMARYLIMITATIONOFTHERIGIDBODYANALYSISISTHATITISSTATICALLYINDETERMINATEWHENMORETHANSIXCONTACTFORCESAREUNKNOWNASARESULT,WORKPIECEDISPLACEMENTSCANNOTBEDETERMINEDUNIQUELYBYTHISMETHODTHISLIMITATIONMAYBEOVERCOMEBYACCOUNTINGFORTHEELASTICITYOFTHEFIXTUREWORKPIECESYSTEM15FORARELATIVELYRIGIDWORKPIECE,THELOCATIONOFTHEWORKPIECEINTHEMACHININGFIXTUREISSTRONGLYINFLUENCEDBYTHELOCALISEDELASTICDEFORMATIONATTHEFIXTURINGPOINTSHOCKENBERGERANDDEMETER16USEDEMPIRICALCONTACTFORCEDEFORMATIONRELATIONSCALLEDMETAFUNCTIONSTOSOLVEFORTHEWORKPIECERIGIDBODYDISPLACEMENTSDUETOCLAMPINGANDQUASISTATICMACHININGFORCESTHESAMEAUTHORSALSOINVESTIGATEDTHEEFFECTOFMACHININGFIXTUREDESIGNPARAMETERSONWORKPIECEDISPLACEMENT17GUIETAL18REPORTEDANELASTICCONTACTMODELFORIMPROVINGWORKPIECELOCATIONACCURACYTHROUGHOPTIMISATIONOFTHECLAMPINGFORCEHOWEVER,THEYDIDNOTADDRESSMETHODSFORCALCULATINGTHEFIXTUREWORKPIECECONTACTSTIFFNESSINADDITION,THEAPPLICATIONOFTHEIRALGORITHMFORASEQUENCEOFMACHININGLOADSREPRESENTINGAFINITETOOLPATHWASNOTDISCUSSEDLIANDMELKOTE19ANDHURTADOANDMELKOTE20USEDCONTACTMECHANICSTOFIXTURECLAMPINGFORCEOPTIMISATION105SOLVEFORTHECONTACTFORCESANDWORKPIECEDISPLACEMENTPRODUCEDBYTHEELASTICDEFORMATIONATTHEFIXTURINGPOINTSOWINGTOCLAMPINGLOADSTHEYALSODEVELOPEDMETHODSFOROPTIMISINGTHEFIXTURELAYOUT21ANDCLAMPINGFORCEUSINGTHISMETHOD22HOWEVER,CLAMPINGFORCEOPTIMISATIONFORAMULTICLAMPSYSTEMANDITSIMPACTONWORKPIECEACCURACYWERENOTCOVEREDINTHESEPAPERSTHISPAPERPRESENTSANEWALGORITHMBASEDONTHECONTACTELASTICITYMETHODFORDETERMININGTHEOPTIMUMCLAMPINGFORCESFORAMULTICLAMPFIXTUREWORKPIECESYSTEMSUBJECTEDTOQUASISTATICLOADSTHEMETHODSEEKSTOMINIMISETHEIMPACTOFWORKPIECEMOTIONDUETOCLAMPINGANDMACHININGLOADSONTHEPARTLOCATIONACCURACYBYSYSTEMATICALLYOPTIMISINGTHECLAMPINGFORCESACONTACTMECHANICSMODELISUSEDTODETERMINEASETOFCONTACTFORCESANDDISPLACEMENTS,WHICHARETHENUSEDFORTHECLAMPINGFORCEOPTIMISATIONTHECOMPLETEPROBLEMISFORMULATEDANDSOLVEDASAMULTIOBJECTIVECONSTRAINEDOPTIMISATIONPROBLEMTHEIMPACTOFCLAMPINGFORCEOPTIMISATIONONWORKPIECELOCATIONACCURACYISANALYSEDVIATWOEXAMPLESINVOLVINGA321FIXTURELAYOUTFORAMILLINGOPERATION2FIXTUREWORKPIECECONTACTMODELLING21MODELLINGASSUMPTIONSTHEMACHININGFIXTURECONSISTSOFLLOCATORSANDCCLAMPSWITHSPHERICALTIPSTHEWORKPIECEANDFIXTUREMATERIALSARELINEARLYELASTICINTHECONTACTREGION,ANDPERFECTLYRIGIDELSEWHERETHEWORKPIECEFIXTURESYSTEMISSUBJECTEDTOQUASISTATICLOADSDUETOCLAMPINGANDMACHININGTHECLAMPINGFORCEISASSUMEDTOBECONSTANTDURINGMACHININGTHISASSUMPTIONISVALIDWHENHYDRAULICORPNEUMATICCLAMPSAREUSEDINREALITY,THEELASTICITYOFTHEFIXTUREWORKPIECECONTACTREGIONISDISTRIBUTEDHOWEVER,INTHISMODELDEVELOPMENT,LUMPEDCONTACTSTIFFNESSISASSUMEDSEEFIG1THEREFORE,THECONTACTFORCEANDLOCALISEDDEFORMATIONATTHEITHFIXTURINGPOINTCANBERELATEDASFOLLOWSFIJKIJDIJ1WHEREKIJJX,Y,ZDENOTESTHECONTACTSTIFFNESSINTHETANGENTIALANDNORMALDIRECTIONSOFTHELOCALXI,YI,ZICOORDINATEFRAME,DIJFIG1ALUMPEDSPRINGFIXTUREWORKPIECECONTACTMODELXI,YI,ZI,DENOTETHELOCALCOORDINATEFRAMEATTHEITHCONTACTJX,Y,ZARETHECORRESPONDINGLOCALISEDELASTICDEFORMATIONSALONGTHEXI,YI,ANDZIAXES,RESPECTIVELY,FIJJX,J,ZREPRESENTSTHELOCALCONTACTFORCECOMPONENTSWITHFIXANDFIYBEINGTHELOCALXIANDYICOMPONENTSOFTHETANGENTIALFORCE,ANDFIZTHENORMALFORCE22WORKPIECEFIXTURECONTACTSTIFFNESSMODELTHELUMPEDCOMPLIANCEATASPHERICALTIPLOCATOR/CLAMPANDWORKPIECECONTACTISNOTLINEARBECAUSETHECONTACTRADIUSVARIESNONLINEARLYWITHTHENORMALFORCE23THECONTACTDEFORMATIONDUETOTHENORMALFORCEPIACTINGBETWEENASPHERICALTIPPEDFIXTUREELEMENTOFRADIUSRIANDAPLANARWORKPIECESURFACECANBEOBTAINEDFROMTHECLOSEDFORMHERTZIANSOLUTIONTOTHEPROBLEMOFASPHEREINDENTINGANELASTICHALFSPACEFORTHISPROBLEM,THENORMALDEFORMATIONDINISGIVENAS23,P93DINS9PI216RIE2D1/32WHERE1E1N2WEW1N2FEFEWANDEFAREYOUNGSMODULIFORTHEWORKPIECEANDFIXTUREMATERIALS,RESPECTIVELY,ANDNWANDNFAREPOISSONRATIOSFORTHEWORKPIECEANDFIXTUREMATERIALS,RESPECTIVELYTHETANGENTIALDEFORMATIONDITDITXORDITYINTHELOCALXIANDYITANGENTIALDIRECTIONS,RESPECTIVELYDUETOATANGENTIALFORCEQIQIXORQIYHASTHEFOLLOWINGFORM23,P217DTITQI8AIS2NFGF2NWGWD3WHEREAIS3PIRI4S1NFEF1NWEWDD1/3ANDGWANDGFARESHEARMODULIFORTHEWORKPIECEANDFIXTUREMATERIALS,RESPECTIVELYAREASONABLELINEARAPPROXIMATIONOFTHECONTACTSTIFFNESSCANBEOBTAINEDFROMALEASTSQUARESFITTOEQ2THISYIELDSTHEFOLLOWINGLINEARISEDCONTACTSTIFFNESSVALUESKIZ882S16RIE29D1/34KIXKIY4ES2NJGF2NWGWD1KIZ5INDERIVINGTHEABOVELINEARAPPROXIMATION,THENORMALFORCEPIWASASSUMEDTOVARYFROM0TO1000N,ANDTHECORRESPONDINGR2VALUEOFTHELEASTSQUARESFITWASFOUNDTOBE0943CLAMPINGFORCEOPTIMISATIONTHEGOALISTODETERMINETHESETOFOPTIMALCLAMPINGFORCESTHATWILLMINIMISETHEWORKPIECERIGIDBODYMOTIONDUETO106BLIANDSNMELKOTELOCALISEDELASTICDEFORMATIONINDUCEDBYTHECLAMPINGANDMACHININGLOADS,WHILEMAINTAININGTHEFIXTUREWORKPIECESYSTEMINQUASISTATICEQUILIBRIUMDURINGMACHININGMINIMISATIONOFTHEWORKPIECEMOTIONWILL,INTURN,REDUCETHELOCATIONERRORTHISGOALISACHIEVEDBYFORMULATINGTHEPROBLEMASAMULTIOBJECTIVECONSTRAINEDOPTIMISATIONPROBLEM,ASDESCRIBEDNEXT31OBJECTIVEFUNCTIONFORMULATIONSINCETHEWORKPIECEROTATIONDUETOFIXTURINGFORCESISOFTENQUITESMALL17THEWORKPIECELOCATIONERRORISASSUMEDTOBEDETERMINEDLARGELYBYITSRIGIDBODYTRANSLATIONDDWDXWDYWDZWT,WHEREDXW,DYW,ANDDZWARETHETHREEORTHOGONALCOMPONENTSOFDDWALONGTHEXG,YG,ANDZGAXESSEEFIG2THEWORKPIECELOCATIONERRORDUETOTHEFIXTURINGFORCESCANTHENBECALCULATEDINTERMSOFTHEL2NORMOFTHERIGIDBODYDISPLACEMENTASFOLLOWSIDDWIDXW2DYW2DZW26WHEREIIDENOTESTHEL2NORMOFAVECTORINPARTICULAR,THERESULTANTCLAMPINGFORCEACTINGONTHEWORKPIECEWILLADVERSELYAFFECTTHELOCATIONERRORWHENMULTIPLECLAMPINGFORCESAREAPPLIEDTOTHEWORKPIECE,THERESULTANTCLAMPINGFORCE,PRCPRXPRYPRZT,HASTHEFORMPRCRCPC7WHEREPCPL1PLCTISTHECLAMPINGFORCEVECTOR,RCNL1NLCTISTHECLAMPINGFORCEDIRECTIONMATRIX,NLICOSALICOSBLICOSGLITISTHECLAMPINGFORCEDIRECTIONCOSINEVECTOR,ANDALI,BLI,ANDGLIAREANGLESMADEBYTHECLAMPINGFORCEVECTORATTHEITHCLAMPINGPOINTWITHRESPECTTOTHEXG,YG,ZGCOORDINATEAXESI1,2,CINTHISPAPER,THEWORKPIECELOCATIONERRORDUETOCONTACTREGIONDEFORMATIONISASSUMEDTOBEINFLUENCEDONLYBYTHENORMALFORCEACTINGATTHELOCATORWORKPIECECONTACTSTHEFRICTIONALFORCEATTHECONTACTSISRELATIVELYSMALLANDISNEGLECTEDWHENANALYSINGTHEIMPACTOFTHECLAMPINGFORCEONTHEWORKPIECELOCATIONERRORDENOTINGTHERATIOOFTHENORMALCONTACTSTIFFNESS,KIZ,TOTHESMALLESTNORMALSTIFFNESSAMONGALLLOCATORS,KSZ,BYJII1,L,ANDASSUMINGTHATTHEWORKPIECERESTSONNX,NY,ANDNZNUMBEROFLOCATORSORIENTEDINTHEXG,FIG2WORKPIECERIGIDBODYTRANSLATIONANDROTATIONYG,ANDZGDIRECTIONS,THEEQUIVALENTCONTACTSTIFFNESSINTHEXG,YG,ANDZGDIRECTIONSCANBECALCULATEDASKSZSONXI1JID,KSZSONYI1JID,ANDKSZSONZI1JIDRESPECTIVELYSEEFIG3THEWORKPIECERIGIDBODYMOTION,DDW,DUETOCLAMPINGACTIONCANNOWBEWRITTENASDDW3PRXKSZSONXI1JIDPRYKSZSONYI1JIDPRZKSZSONZI1JID4T8THEWORKPIECEMOTION,ANDHENCETHELOCATIONERRORCANBEREDUCEDBYMINIMISINGTHEWEIGHTEDL2NORMOFTHERESULTANTCLAMPINGFORCEVECTORTHEREFORE,THEFIRSTOBJECTIVEFUNCTIONCANBEWRITTENASMINIMIZEIPRCIW11PRXONXI1JI221PRYONYI1JI221PRZONZI1JI2229NOTETHATTHEWEIGHTINGFACTORSAREPROPORTIONALTOTHEEQUIVALENTCONTACTSTIFFNESSESINTHEXG,YG,ANDZGDIRECTIONSTHECOMPONENTSOFPRCAREUNIQUELYDETERMINEDBYSOLVINGTHECONTACTELASTICITYPROBLEMUSINGTHEPRINCIPLEOFMINIMUMTOTALCOMPLEMENTARYENERGY15,23THISENSURESTHATTHECLAMPINGFORCESANDTHECORRESPONDINGLOCATORREACTIONSARE“TRUE”SOLUTIONSTOTHECONTACTPROBLEMANDYIELD“TRUE”RIGIDBODYDISPLACEMENTS,ANDTHATTHEWORKPIECEISKEPTINSTATICEQUILIBRIUMBYTHECLAMPINGFORCESATALLTIMESTHEREFORE,THEMINIMISATIONOFTHETOTALCOMPLEMENTARYENERGYFORMSTHESECONDOBJECTIVEFUNCTIONFORTHECLAMPINGFORCEOPTIMISATIONANDISGIVENBYMINIMISEUW12FOLCI1FIX2KIXOLCI1FIY2KIYOLCI1FIZ2KIZG10LTQLFIG3THEBASISFORTHEDETERMINATIONOFTHEWEIGHTINGFACTORFORTHEL2NORMCALCULATIONFIXTURECLAMPINGFORCEOPTIMISATION107WHEREUREPRESENTSTHECOMPLEMENTARYSTRAINENERGYOFTHEELASTICALLYDEFORMEDBODIES,WREPRESENTSTHECOMPLEMENTARYWORKDONEBYTHEEXTERNALFORCEANDMOMENTS,QDIAGC1XC1YC1ZCLCXCLCYCLCZISTHEDIAGONALCONTACTCOMPLIANCEMATRIX,CIJKIJ1,ANDLF1XF1YF1ZFLCXFLCYFLCZTISTHEVECTOROFALLCONTACTFORCES32FRICTIONANDSTATICEQUILIBRIUMCONSTRAINTSTHEOPTIMISATIONOBJECTIVEINEQ10ISSUBJECTTOCERTAINCONSTRAINTSANDBOUNDSFOREMOSTAMONGTHEMISTHESTATICFRICTIONCONSTRAINTATEACHCONTACTCOULOMBSFRICTIONLAWSTATESTHATFIX2FIY2MISFIZMISISTHESTATICFRICTIONCOEFFICIENTACONSERVATIVEANDLINEARISEDVERSIONOFTHISNONLINEARCONSTRAINTCANBEUSEDANDISGIVENBY19UFIXUUFIYUMISFIZ11SINCEQUASISTATICLOADSAREASSUMED,THESTATICEQUILIBRIUMOFTHEWORKPIECEISENSUREDBYINCLUDINGTHEFOLLOWINGFORCEANDMOMENTEQUILIBRIUMEQUATIONSINVECTORFORMOF012OM0WHERETHEFORCESANDMOMENTSCONSISTOFTHEMACHININGFORCES,WORKPIECEWEIGHTANDTHECONTACTFORCESINTHENORMALANDTANGENTIALDIRECTIONS33BOUNDSSINCETHEFIXTUREWORKPIECECONTACTISSTRICTLYUNILATERAL,THENORMALCONTACTFORCE,PI,CANONLYBECOMPRESSIVETHISISEXPRESSEDBYTHEFOLLOWINGBOUNDONPIPI0I1,LC13WHEREITISASSUMEDTHATNORMALFORCESDIRECTEDINTOTHEWORKPIECEAREPOSITIVEINADDITION,THENORMALCOMPRESSIVESTRESSATACONTACTCANNOTEXCEEDTHECOMPRESSIVEYIELDSTRENGTHSYOFTHEWORKPIECEMATERIALTHISUPPERBOUNDISWRITTENASPISYAII1,LC14WHEREAIISTHECONTACTAREAATTHEITHWORKPIECEFIXTURECONTACTTHECOMPLETECLAMPINGFORCEOPTIMISATIONMODELCANNOWBEWRITTENASMINIMIZEFHF1F2JHLTQLIPRCIWJ15SUBJECTTO11144ALGORITHMFORMODELSOLUTIONTHEMULTIOBJECTIVEOPTIMISATIONPROBLEMINEQ15CANBESOLVEDBYTHEECONSTRAINTMETHOD24THISMETHODIDENTIFIESONEOFTHEOBJECTIVEFUNCTIONSASPRIMARY,ANDCONVERTSTHEOTHERINTOACONSTRAINTINTHISWORK,THEMINIMISATIONOFTHECOMPLEMENTARYENERGYF1ISTREATEDASTHEPRIMARYOBJECTIVEFUNCTION,ANDTHEWEIGHTEDL2NORMOFTHERESULTANTCLAMPINGFORCEF2ISTREATEDASACONSTRAINTTHECHOICEOFF1ASTHEPRIMARYOBJECTIVEENSURESTHATAUNIQUESETOFFEASIBLECLAMPINGFORCESISSELECTEDASARESULT,THEWORKPIECEFIXTURESYSTEMISDRIVENTOASTABLESTATEIETHEMINIMUMENERGYSTATETHATALSOHASTHESMALLESTWEIGHTEDL2NORMFORTHERESULTANTCLAMPINGFORCETHECONVERSIONOFF2INTOACONSTRAINTINVOLVESSPECIFYINGTHEWEIGHTEDL2NORMTOBELESSTHANOREQUALTOE,WHEREEISANUPPERBOUNDONF2TODETERMINEASUITABLEE,ITISINITIALLYASSUMEDTHATALLCLAMPINGFORCESAREUNKNOWNTHECONTACTFORCESATTHELOCATINGANDCLAMPINGPOINTSARECOMPUTEDBYCONSIDERINGONLYTHEFIRSTOBJECTIVEFUNCTIONIEF1WHILETHISSETOFCONTACTFORCESDOESNOTNECESSARILYYIELDTHELOWESTCLAMPINGFORCES,ITISA“TRUE”FEASIBLESOLUTIONTOTHECONTACTELASTICITYPROBLEMTHATCANCOMPLETELYRESTRAINTHEWORKPIECEINTHEFIXTURETHEWEIGHTEDL2NORMOFTHESECLAMPINGFORCESISCOMPUTEDANDTAKENASTHEINITIALVALUEOFETHEREFORE,THECLAMPINGFORCEOPTIMISATIONPROBLEMINEQ15CANBEREWRITTENASMINIMIZEF1LTQL16SUBJECTTOIPRCIWE,1114ANALGORITHMSIMILARTOTHEBISECTIONMETHODFORFINDINGROOTSOFANEQUATIONISUSEDTODETERMINETHELOWESTUPPERBOUNDFORIPRCIWBYDECREASINGTHEUPPERBOUNDEASMUCHASPOSSIBLE,THEMINIMUMWEIGHTEDL2NORMOFTHERESULTANTCLAMPINGFORCEISOBTAINEDTHENUMBEROFITERATIONS,K,NEEDEDTOTERMINATETHESEARCHDEPENDSONTHEREQUIREDPREDICTIONACCURACYDANDUEU,ANDISGIVENBY25KFLOG2SUEUDDG17WHEREIDENOTESTHECEILINGFUNCTIONTHECOMPLETEALGORITHMISGIVENINFIG45DETERMINATIONOFOPTIMUMCLAMPINGFORCESDURINGMACHININGTHEALGORITHMPRESENTEDINTHEPREVIOUSSECTIONCANBEUSEDTODETERMINETHEOPTIMUMCLAMPINGFORCEFORASINGLELOADVECTORAPPLIEDTOTHEWORKPIECEHOWEVER,DURINGMILLINGTHEMAGNITUDEANDPOINTOFCUTTINGFORCEAPPLICATIONCHANGESCONTINUOUSLYALONGTHETOOLPATHTHEREFORE,ANINFINITESETOFOPTIMUMCLAMPINGFORCESCORRESPONDINGTOTHEINFINITESETOFMACHININGLOADSWILLBEOBTAINEDWITHTHEALGORITHMOFFIG4THISSUBSTANTIALLYINCREASESTHECOMPUTATIONALBURDENANDCALLSFORACRITERION/PROCEDUREFORSELECTINGASINGLESETOFCLAMPINGFORCESTHATWILLBESATISFACTORYANDOPTIMUMFORTHEENTIRETOOLPATHACONSERVATIVEAPPROACHTOADDRESSINGTHESEISSUESISDISCUSSEDNEXTCONSIDERAFINITENUMBERSAYMOFSAMPLEPOINTSALONGTHETOOLPATHYIELDINGMCORRESPONDINGSETSOFOPTIMUMCLAMPINGFORCESDENOTEDASP1OPT,P2OPT,PMOPTATEACHSAMPLING108BLIANDSNMELKOTEFIG4CLAMPINGFORCEOPTIMISATIONALGORITHMUSEDINEXAMPLE1POINT,THEFOLLOWINGFOURWORSTCASEMACHININGLOADVECTORSARECONSIDEREDFXMAXFMAXXF1YF1ZTFYMAXF2XFMAXYF2ZTFZMAXF3XF3YFMAXZT18FRMAXF4XF4YF4ZTWHEREFMAXX,FMAXY,ANDFMAXZARETHEMAXIMUMXG,YG,ANDZGCOMPONENTSOFTHEMACHININGFORCE,THESUPERSCRIPTS1,2,3OFFX,FY,ANDFZSTANDFORTHEOTHERTWOORTHOGONALMACHININGFORCECOMPONENTSCORRESPONDINGTOFMAXX,FMAXY,ANDFMAXZ,RESPECTIVELY,ANDIFRMAXIMAXFX2FY2FZ2ALTHOUGHTHEFOURWORSTCASEMACHININGLOADVECTORSWILLNOTACTONTHEWORKPIECEATTHESAMEINSTANT,THEYWILLOCCURONCEPERCUTTERREVOLUTIONATCONVENTIONALFEEDRATES,THEERRORINTRODUCEDBYAPPLYINGTHELOADVECTORSATTHESAMEPOINTWOULDBENEGLIGIBLETHEREFORE,INTHISWORK,THEFOURLOADVECTORSAREAPPLIEDATTHESAMELOCATIONBUTNOTSIMULTANEOUSLYONTHEWORKPIECECORRESPONDINGTOTHESAMPLINGINSTANTTHECLAMPINGFORCEOPTIMISATIONALGORITHMOFFIG4ISTHENUSEDTOCALCULATETHEOPTIMUMCLAMPINGFORCESCORRESPONDINGTOEACHSAMPLINGPOINTTHEOPTIMUMCLAMPINGFORCESHAVETHEFORMPIJMAXCI1JCI2JCICJTI1,MJX,Y,Z,R19WHEREPIJMAXISTHEVECTOROFOPTIMUMCLAMPINGFORCESFORTHEFOURWORSTCASEMACHININGLOADVECTORS,ANDCIKJK1,CISTHEFORCEMAGNITUDEATEACHCLAMPCORRESPONDINGTOTHEITHSAMPLEPOINTANDTHEJTHLOADSCENARIOAFTERPIJMAXISCOMPUTEDFOREACHLOADAPPLICATIONPOINT,ASINGLESETOF“OPTIMUM”CLAMPINGFORCESMUSTBESELECTEDFROMALLOFTHEOPTIMUMCLAMPINGFORCESFOUNDFOREACHCLAMPFROMALLTHESAMPLEPOINTSANDLOADINGCONDITIONSTHISISDONEBYSORTINGTHEOPTIMUMCLAMPINGFORCEMAGNITUDESATACLAMPINGPOINTFORALLLOADSCENARIOSANDSAMPLEPOINTSANDSELECTINGTHEMAXIMUMVALUE,CMAXK,ASGIVENINEQ20CMAXKCIKJK1,C20ONCETHISISCOMPLETE,ASETOFOPTIMISEDCLAMPINGFORCESPOPTCMAX1CMAX2CMAXCTISOBTAINEDTHESEFORCESMUSTBEVERIFIEDFORTHEIRABILITYTOENSURESTATICEQUILIBRIUMOFTHEWORKPIECEFIXTURESYSTEMOTHERWISE,MORESAMPLINGPOINTSARESELECTEDANDTHEAFOREMENTIONEDPROCEDUREREPEATEDINTHISFASHION,THE“OPTIMUM”CLAMPINGFORCE,POPT,CANBEDETERMINEDFORTHEENTIRETOOLPATHFIGURE5SUMMARISESTHEALGORITHMJUSTDESCRIBEDNOTETHATALTHOUGHTHISAPPROACHISCONSERVATIVE,ITPROVIDESASYSTEMATICWAYOFDETERMININGASETOFCLAMPINGFORCESTHATMINIMISETHEWORKPIECELOCATIONERROR6IMPACTONWORKPIECELOCATIONACCURACYITISOFINTERESTTOEVALUATETHEIMPACTOFTHECLAMPINGFORCEALGORITHMPRESENTEDEARLIERONTHEWORKPIECELOCATIONACCURACYTHEWORKPIECEISFIRSTPLACEDONTHEFIXTUREBASEPLATEINCONTACTWITHTHELOCATORSCLAMPINGFORCESARETHENAPPLIEDTOPUSHTHEWORKPIECEAGAINSTTHELOCATORSCONSEQUENTLY,LOCALISEDDEFORMATIONSOCCURATEACHWORKPIECEFIXTURECONTACT,CAUSINGTHEWORKPIECETOTRANSLATEANDROTATEINTHEFIXTURESUBSEQUENTLY,THEQUASISTATICMACHININGLOADISAPPLIEDCAUSINGADDITIONALMOTIONOFTHEWORKPIECEINTHEFIXTURETHEWORKPIECERIGIDBODYMOTIONISDEFINEDBYITSTRANSLATIONDDWDXWDYWDZWTANDROTATIONDUWDUWXDUWYDUWZTABOUTTHEXG,YG,ANDZGAXESSEEFIG2ASNOTEDEARLIER,THEWORKPIECERIGIDBODYMOTIONARISESFROMTHELOCALISEDDEFORMATION,DIDIXDIYDIZT,ATEACHFIXTURINGPOINTASSUMINGTHATRIXIYIZITDESCRIBESTHEPOSITIONVECTOROFTHEITHLOCATINGPOINTRELATIVETOTHEWORKPIECECENTREOFMASS,THECOORDINATETRANSFORMATIONTHEOREMCANBEUSEDTOEXPRESSDIINTERMSOFTHEWORKPIECETRANSLATION,DDWDXWDYWDZW,ANDWORKPIECEROTATION,DUWDUWXDUWYDUWZT,ASFOLLOWSDIR1ITRDUWRIDDWRI21WHERER1IDENOTESTHEROTATIONMATRIXDESCRIBINGTHEORIENTATIONOFTHELOCALXI,YI,ZICOORDINATEFRAMEATTHEITHCONTACTRELATIVETOTHEGLOBALCOORDINATEFRAMEANDRDUWCISAROTATIONMATRIXFIXTURECLAMPINGFORCEOPTIMISATION109FIG5THEALGORITHMUSEDINEXAMPLE2FIG6THEWORKPIECELOCATIONERRORDRMDUETOCLAMPINGANDMACHININGDEFININGTHEORIENTATIONOFTHEWORKPIECEFIXEDCOORDINATEFRAMERELATIVETOTHEGLOBALCOORDINATEFRAMEASSUMINGTHATWORKPIECEROTATIONWITHINTHEFIXTUREDUETOCLAMPING,DUW,ISSMALL,RDUWCANBEAPPROXIMATEDASRDUWF1DUWZDUWYDUWZ1DUWXDUWYDUWX1G22EQUATION21CANNOWBEREWRITTENASDIR1ITBIQ23WHEREBI31000ZIYI010ZI0XI001YIXI04ISTHETRANSFORMATIONMATRIXOBTAINEDAFTERREARRANGINGEQ21,ANDQDXWDYWDZWDUWXDUWYDUWZTISTHEWORKPIECERIGIDBODYMOTIONVECTORDUETOCLAMPINGA

- 温馨提示:

1: 本站所有资源如无特殊说明,都需要本地电脑安装OFFICE2007和PDF阅读器。图纸软件为CAD,CAXA,PROE,UG,SolidWorks等.压缩文件请下载最新的WinRAR软件解压。

2: 本站的文档不包含任何第三方提供的附件图纸等,如果需要附件,请联系上传者。文件的所有权益归上传用户所有。

3.本站RAR压缩包中若带图纸,网页内容里面会有图纸预览,若没有图纸预览就没有图纸。

4. 未经权益所有人同意不得将文件中的内容挪作商业或盈利用途。

5. 人人文库网仅提供信息存储空间,仅对用户上传内容的表现方式做保护处理,对用户上传分享的文档内容本身不做任何修改或编辑,并不能对任何下载内容负责。

6. 下载文件中如有侵权或不适当内容,请与我们联系,我们立即纠正。

7. 本站不保证下载资源的准确性、安全性和完整性, 同时也不承担用户因使用这些下载资源对自己和他人造成任何形式的伤害或损失。

人人文库网所有资源均是用户自行上传分享,仅供网友学习交流,未经上传用户书面授权,请勿作他用。

川公网安备: 51019002004831号

川公网安备: 51019002004831号