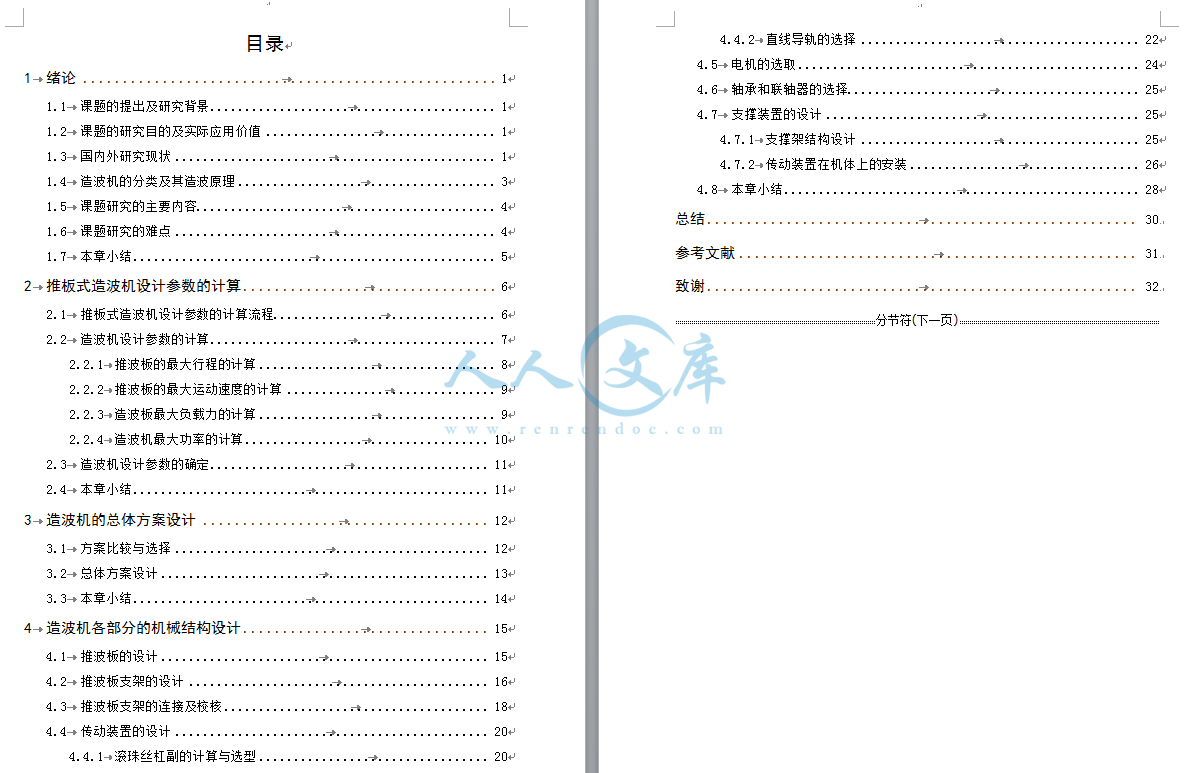

推板式造波机的机械结构设计(全套含CAD图纸)

收藏

资源目录

压缩包内文档预览:

编号:7069017

类型:共享资源

大小:9.88MB

格式:ZIP

上传时间:2018-01-08

上传人:机****料

认证信息

个人认证

高**(实名认证)

河南

IP属地:河南

30

积分

- 关 键 词:

-

板式

造波机

机械

结构设计

全套

cad

图纸

- 资源描述:

-

- 内容简介:

-

PREPRINTSERIESISSUENO200919STUTTGARTRESEARCHCENTREFORSIMULATIONTECHNOLOGYSRCSIMTECHSIMTECHCLUSTEROFEXCELLENCEPFAFFENWALDRING7A70569STUTTGARTPUBLICATIONSSIMTECHUNISTUTTGARTDEWWWSIMTECHUNISTUTTGARTDESFREYAADADALAUAAVERLAEXPEDIENTMODELINGOFBALLSCREWFEEDDRIVESSTUTTGART,FEBRUARY2011AINSTITUTEFORCONTROLENGINEERINGOFMACHINETOOLSANDMANUFACTURINGUNITSISW,UNIVERSITYOFSTUTTGART,SEIDENSTRAE36,70174STUTTGART/GERMANYALEXANDRUDADALAUISWUNISTUTTGARTDEWWWISWUNISTUTTGARTDEABSTRACTBALLSCREWFEEDDRIVESARETHEMOSTCOMMONLYUSEDMECHANISMTOPROVIDELINEARMOTIONINHIGHSPEEDMACHINETOOLSPOSITIONACCURACYANDTHEACHIEVABLECLOSEDLOOPBANDWIDTHOFSUCHDRIVESYSTEMSAREUSUALLYLIMITEDBYTHESTRUCTURALVIBRATIONMODESOFTHEMECHANICALCOMPONENTSHIGHERORDERPLANTMODELSALLOWFORABETTERUNDERSTANDINGOFTHESYSTEMDYNAMICS,IMPROVETHEDESIGNPROCESSOFFEEDDRIVESANDAREESSENTIALFORTHEDEVELOPMENTOFSOPHISTICATEDCONTROLSTRATEGIESTHISWORKPRESENTSACLEARLYARRANGEDANDVERSATILEMODEL,CAPABLEOFEXPRESSINGTHERELEVANTDYNAMICSOFBALLSCREWFEEDDRIVESKEYWORDSMACHINETOOLSIMULATIONBALLSCREWPLASTICITYINTRODUCTIONDYNAMICALFEEDDRIVESCOMMONLYUSEDINMACHINETOOLSANDPRODUCTIONUNITSREPRESENTCOMPLEXMECHANICALSTRUCTURESWITHMULTIPLEDEGREESOFFREEDOMDOFANDVARIOUSEIGENMODESNUMEROUSSCIENTIFICWORKSHAVEDEALTWITHTHESIMULATIONOFSUCHDRIVESYSTEMS,USINGFINITEELEMENTMETHODSFEMANDCOMPLEXMODELINGTECHNIQUESINORDERREPRESENTTHEDYNAMICALBEHAVIORASDETAILEDASPOSSIBLE13INCONTRARYTHEAPPROACHPRESENTEDINTHISPAPERAIMSATFINDINGANINTUITIVEANDEASYTOUSEMODEL,CAPABLEOFEXPRESSINGTHEMOSTRELEVANTCHARACTERISTICSOFABALLSCREWFEEDDRIVEWITHRESPECTTOTHEIRAPPLICATIONINMACHINETOOLSGENERALLYSPOKENABALLSCREWDRIVECANBECHARACTERIZEDASASYSTEMWITHTHREEDIFFERENTTYPESOFEIGENMODESAXIAL,ROTATIONALANDFLEXURALMODES4TYPICALLYTHEFIRSTAXIALANDROTATIONALMODEOFTHEBALLSCREWSHOWADOMINANTINFLUENCEONTHEOVERALLDYNAMICSWHILETHERELEVANCEOFHIGHERORDERMODESFORMOSTTECHNICALAPPLICATIONSISRATHERSMALLTHEEXCITATIONOFTHEFLEXURALMODESANDTHEIREFFECTONTHEFEEDMOTIONGREATLYDEPENDONFABRICATIONANDMOUNTINGTOLERANCESASWELLASONTHEOPERATINGCONDITIONSOFTHEDRIVESYSTEMPRESUMINGPROPERMOUNTINGANDOPERATINGCONDITIONS,THEEXCITATIONOFTHEFLEXURALMODESARECONSIDERABLYSMALLANDTHEREFOREWILLBENEGLECTEDINTHECOURSEOFTHISPAPERTHETWODOMINANTVIBRATIONALDEGREESOFFREEDOM,NAMELYTHEAXIALANDROTATIONALMODE,AREPRIMARILYINFLUENCEDBYTHEGEOMETRICALDIMENSIONSANDTHEPITCHOFTHEBALLSCREWSHAFTDEPENDINGONTHETRANSMISSIONRATIOASWELLASONTHEOPERATINGCONDITIONSTHESYSTEMCANBEHAVEQUALITATIVELYANDQUANTITATIVELYVERYDIFFERENTINMOSTCASESHOWEVER,THECONFIGURATIONOFAFEEDDRIVEALLOWSFORASIMPLEAPPROXIMATIONOFTHESYSTEMSCHARACTERISTICSINTHEFOLLOWINGAPRACTICALANDAPPLICATIONORIENTEDMODELINGTECHNIQUEFORBALLSCREWFEEDDRIVESWILLBEDERIVEDANDVERIFIEDBYMEASUREMENTRESULTSBALLSCREWFEEDDRIVESFORMACHINETOOLSFIGURE1SHOWSATYPICALBALLSCREWASSEMBLYWITHITSRELEVANTCOMPONENTSINTHISCASESERVOMOTORANDBEARINGSAREFIXEDTOTHEMACHINEBASEANDTHETORQUEOFTHESERVOMOTORISTRANSMITTEDTHROUGHANELASTICCOUPLINGONTOTHEBALLSCREWSHAFTNOTDEPICTEDINFIGURE1ARETHELINEARGUIDEWAYSCONSTRAININGTHEMOVEMENTOFTHEMACHINETABLEINAXIALDIRECTIONTHETRANSFORMATIONFROMTHEROTATIONALINTOTHELINEARMOTIONISREALIZEDBYTHEBALLSCREWSYSTEMWITHITSTRANSMISSIONRATIOI,DEFINEDASTHEDISTANCEOFTRAVELHDURINGONEREVOLUTIONOFTHESHAFT1MANUFACTURERSPROVIDEAGREATVARIETYOFBALLSCREWSYSTEMSWITHDIFFERENTCONSTRUCTIVEDESIGNS,DIMENSIONSANDTRANSMISSIONRATIOSTHEAVAILABLEPITCHESNOWADAYSLIEBETWEEN005AND3TIMESTHEBALLSCREWDIAMETER,WHILEFORMOSTAPPLICATIONSINMACHINETOOLSVALUESBETWEEN025AND1AREBEINGUSEDFIG1SCHEMATICCONFIGURATIONOFABALLSCREWFEEDDRIVETHEDYNAMICALBEHAVIOROFSUCHADRIVESYSTEMISGREATLYINFLUENCEDBYTHEPHYSICALDIMENSIONSOFTHEBALLSCREWSHAFTDIAMETERANDLENGTHOFTHESHAFTHAVEADECISIVEIMPACTONTHEOVERALLRIGIDITYANDTHEREFOREONTHEDYNAMICALBEHAVIOROFTHEDRIVESYSTEMFIGURE2SHOWSAMEASUREDFREQUENCYRESPONSEOFABALLSCREWDRIVE,DERIVEDFROMTHECOMPARISONOFMOTORANDMACHINETABLEVELOCITYFIG2MEASUREDFREQUENCYRESPONSEOFABALLSCREWFEEDDRIVECLEARLYNOTICEABLEARETHETWODOMINANTEIGENFREQUENCIESF1ANDF2,CHARACTERISTICALFORBALLSCREWFEEDDRIVESTHEFIRSTEIGENFREQUENCYINFIGURE2REPRESENTSANAXIALOSCILLATIONOFTHEMACHINETABLEWHILETHESECONDEIGENFREQUENCYCANBEPRIMARILYASCRIBEDTOANANGULARDEFLECTIONOFTHEROTATIONALSYSTEMALTHOUGHEACHMODEISARESULTOFAXIALANDANGULARDEFORMATIONS,ITISCONVENIENTTOCLASSIFYANAXIALANDAROTATIONALMODEDEPENDINGONTHEPREDOMINANTDEFORMATIONINBOTHCASESTHEFLEXIBILITYOFTHEBALLSCREWSHAFTHASAMAJORINFLUENCEONTHEABSOLUTEVALUEOFTHEEIGENFREQUENCIESTHISISDUETOTHEFACTTHATTHESHAFTREPRESENTSTHECOMPONENTWITHTHELEASTRIGIDITYWITHINTHEDRIVESYSTEM5FURTHERMORETHEPROPERTIESOFTHEBALLSCREWSHAFTARENOTCONSTANTBUTCHANGEOVERTHETRAVELRANGEOFTHEMACHINETABLEATTHISPOINTITSHOULDBENOTEDTHATFORMOSTTECHNICALAPPLICATIONSTHEEIGENFREQUENCYOFTHEAXIALMODEISARTICULATELYSMALLERTHANTHATOFTHEROTATIONALMODEONTHISACCOUNTTHEAXIALMODEISOFTENREFERREDTOASTHEFIRSTEIGENFREQUENCYOFABALLSCREWFEEDDRIVETHESTRUCTURALVIBRATIONMODESOFTHEMECHANICALSYSTEMAREOFPARTICULARIMPORTANCEWHENCONSIDERINGTHEDYNAMICALBEHAVIOROFAPOSITIONCONTROLLEDFEEDDRIVEESPECIALLYINHIGHSPEEDAPPLICATIONS,HIGHACCELERATIONANDJERKVALUESCANEXCITETHEMECHANICALSTRUCTUREANDTHEREFOREHAVETOBECONSIDEREDWHENTUNINGTHECONTROLLERWHENUSINGCASCADEDPPOSITIONPIVELOCITYCONTROLLER,THECLOSEDLOOPBANDWIDTHANDTRACKINGACCURACYOFTHEFEEDDRIVEISDIRECTLYLIMITEDBYTHEFIRSTEIGENFREQUENCYOFTHEMECHANICALSYSTEM6,7INSIMILARMATTEREXTERNALEXCITATIONSEGCUTTINGFORCESCANCAUSEUNWANTEDOSCILLATIONSANDSTABILITYPROBLEMSMORESOPHISTICATEDCONTROLSTRATEGIESUSINGPLANTMODELSINTENDTOCOMPENSATETHESENEGATIVEEFFECTS,REQUIRINGDETAILEDINFORMATIONANDAGOODUNDERSTANDINGOFTHEMECHANICALSYSTEM8,9THEDEMANDFOREVENHIGHERDYNAMICSANDBETTERTRACKINGACCURACYINMACHINETOOLSTHEREFOREGOESALONGWITHHIGHLYEFFICIENTANDACCURATEFEEDDRIVEMODELSCOMPARISONOFTWODIFFERENTMODELINGTECHNIQUESINORDERTOEXAMINETHEINFLUENCEOFTHESHAFTONTHEOVERALLDYNAMICALBEHAVIOROFABALLSCREWDRIVE,TWOSIMPLIFIEDMODELSWITHDIFFERENTDEGREESOFCOMPLEXITYAREBEINGINTRODUCEDANDCOMPAREDTOONEOTHERTHEFIRSTMODELISBUILTUPINFEMUSINGACOMBINATIONOFSPRINGS,DAMPERS,MASSELEMENTSANDTIMOSHENKOBEAMELEMENTSWECALLTHISMODELAHYBRIDMODELSINCEWEAREUSINGDISCRETEANDCONTINUOUSFORMULATIONELEMENTSTHERELEVANTAXIALANDROTATIONALFLEXIBILITIESOFTHESYSTEM,NAMELYTHEAXIALRIGIDITYOFTHEFIXEDBEARINGINCLUDINGTHEMOUNTINGKBEARING,THERIGIDITYOFTHEBALLSCREWNUTKNUTANDTHETORSIONALRIGIDITYOFTHECOUPLINGKCOUPLINGAREBEINGEXPRESSEDASLINEARSPRINGSTHEINDIVIDUALDAMPINGVALUESARETREATEDINEQUALMEASURETHESHAFTINCLUDINGBOTH,RELEVANTAXIALANDTORSIONALCHARACTERISTICS,ISMODELEDWITHTIMOSHENKOBEAMELEMENTSANDCOUPLEDWITHTHESURROUNDINGSPRINGSANDDAMPERSTHISPROVIDESTHEPOSSIBILITYOFANEXACTEXAMINATIONOFTHESTRUCTURALBEHAVIOROFTHESHAFTANDITSINFLUENCEONTHEOVERALLDYNAMICALBEHAVIORINCONCORDANCETOTHEREALMECHANICALSYSTEM,ROTATIONALANDAXIALMOTIONARECOUPLEDBYTHETRANSMISSIONRATIOI,WHICHISMODELEDUSINGCONSTRAINTEQUATIONSONTHEINVOLVEDDOFFIGURE3DEPICTSTHECOMPOSITIONOFTHISHYBRIDMODELX2KROTCROT1KAXCAXMTKNUTCNUTX1X32JMIH/2TIMOSHENKOBEAMELEMENTTABLEPOSITIONX2FIG3HYBRIDMODELOFABALLSCREWDRIVETHESECONDMODEL,ENTIRELYUSINGLUMPEDPHYSICALFEATURES,ISREFERREDTOASADISCRETEMODELDUETOITSSIMPLICITYITCANBEDIRECTLYMODELEDWITHCACETOOLSCOMPUTERAIDEDCONTROLENGINEERINGTOOLS,USINGAVAILABLESTANDARDBLOCKSLIKEGAINS,INTEGRATORSANDBASICMATHEMATICALOPERATIONSINTHISCASETHECHARACTERISTICSOFTHESHAFTARESEPARATEDINTOTWODIFFERENTBRANCHES,ANAXIALANDAROTATIONALBRANCHSINCEALLCOMPONENTSAREEXPRESSEDBYDISCRETESPRINGSANDDAMPERS,THERIGIDITYVALUESOFSHAFT,COUPLINGANDBEARINGARECOMBINEDTOANOVERALLAXIALKAXANDROTATIONALVALUEKROT23FIGURE4SHOWSTHEPRINCIPLESETUPOFTHEDISCRETEMODELTHEINDIVIDUALPARAMETERSINEACHMODELSUCHASTHEMASSOFTHEMACHINETABLE,THEMASSOFTHEBALLSCREWSHAFT,THEROTARYINERTIAOFSHAFTANDMOTOR,ASWELLASTHERIGIDITYANDDAMPINGFACTORSCORRESPONDTOTHEIRPHYSICALVALUESJSX2KROTCROT1MSKAXCAXMTKNUTCNUTX1X32JMIH/2FIG4DISCRETEMODELOFABALLSCREWFEEDDRIVEPRECONDITIONFORTHISAPPROACHISTHEDEFINITIONOFADEQUATE,ALTERNATIVEVALUESFORTHEAXIALANDROTATIONALRIGIDITYOFTHESHAFTFORTHISPURPOSETHESHAFTISCONSIDEREDASASOLIDSTEELRODYOUNGMODULUS,SHEARMODULUS,DENSITYWITHTHEDIMENSIONSOFTHEBALLSCREW,NAMELYEQUIVALENTDIAMETER,LENGTHANDEFFECTIVELENGTH,THEAXIALANDROTATIONALRIGIDITYVALUESOFTHESHAFTANDCANBEAPPROXIMATEDUSINGEQUATIONS4THROUGH6456NOTICETHATTHEALTERNATIVEROTATIONALRIGIDITYOFTHESHAFTHASBEENAPPROXIMATEDUSINGTHEEIGENFREQUENCYOFASOLID,ONONESIDEFIXEDRODWHICHCANACCORDINGTO10BECALCULATEDUSINGEQUATION6WITHTHISAPPROACHTHEAXIALRIGIDITYOFTHESHAFTDEPENDSONTHEEFFECTIVELENGTHLEFFWHILETHEROTATIONALRIGIDITYISCONSIDEREDCONSTANTTHROUGHOUTTHETRAVELRANGEOFTHEMACHINETABLEINTHEFOLLOWINGBOTHMODELSHAVEBEENEXAMINEDWITHANIDENTICALSETOFPARAMETERSACCORDINGTOTABLE1TABLE1PARAMETERVALUESUSEDFORTHESIMULATIONSROTARYINERTIAMOTOR640E03KGM2ROTARYINERTIACOUPLING650E04KGM2AXIALRIGIDITYNUT50000N/MTORSIONALRIGIDITYCOUPLING14100NM/MRADBALLSCREWDIAMETER3800MMLENGTHSHAFT200000MMAXIALRIGIDITYBEARING250N/MFURTHERISSHOULDBENOTICEDTHATTHEEXACTEQUIVALENTDIAMETERDEPENDSONALLGEOMETRICPARAMETERSOFTHEBALLSCREW,INCLUDINGSCREWPITCHIN11ITISSHOWN,THATSPINDLEPITCHCANAFFECTTHEAXIALANDTORSIONALSTIFFNESSOFBALLSCREWSUPTO15FORREASONSOFSIMPLICITYINTHISWORKTHEBALLSCREWDIAMETERISCHOOSENTOBECONSTANTTHESIMULATIONRESULTS,NAMELYTHEFIRSTTWOEIGENFREQUENCIESOFTHEFEEDDRIVE,AREPRESENTEDINTABLE2TABLEMASSSCREWPITCHTABLEPOSITION1STEIGENFREQUENCYHZ2NDEIGENFREQUENCYHZKGMMMMHYBRIDMODELDISCRETEMODELPERCENTALDIFFERENCEHYBRIDMODELDISCRETEMODELPERCENTALDIFFERENCE3001050010121008043754345081300101000907904033757344284300101500831827043759343886300205009979861137663491733002010008888890037793463843002015008108150637873445903004050094491135380936324630040100082483411385335348330040150074277342387634681056001050072171903375434498160010100064764601375734428460010150059259100375934388660020500711704103765349073600201000633635023779346384600201500577583103786344490600405006736503438083629476004010005875951438523533836004015005285524638763468105TABLE2FIRSTTWOEIGENFREQUENCIESOFTHEBALLSCREWDRIVEMODELSFORDIFFERENTMASS,SCREWPITCHANDTABLEPOSITIONSASEXPECTEDTHEVALUEOFTHEFIRSTEIGENFREQUENCYGREATLYDEPENDSONTHEMASSANDTHEPOSITIONOFTHEMACHINETABLETHEHIGHERTHEMASSANDTHEGREATERTHEDISTANCEBETWEENMACHINETABLEANDFIXEDBEARINGTHESMALLERTHEVALUEOFTHEFIRSTEIGENFREQUENCYINCOMPARISONTOTHATTHESECONDEIGENFREQUENCYSEEMSTOCHANGERATHERINSIGNIFICANTLYWITHDIFFERENTOPERATINGCONDITIONSBOTHMODELSSHOWTHATTHEROTATIONALMODEREMAINSALMOSTCONSTANTFORAGREATRANGEOFPARAMETERSTHEDIFFERENCEBETWEENHYBRIDANDDISCRETEMODELEXPRESSEDINFIGURE5CANBEASCRIBEDTOTHESIMPLIFIEDREPRESENTATIONOFTHESHAFTINTHEDISCRETEMODELFIG5PERCENTALDIFFERENCEBETWEENHYBRIDANDDISCRETEMODELOFTHEBALLSCREWDRIVEFROMFIGURE5ITCANBESEENTHATTHEABSOLUTEDIFFERENCEASWELLASTHEPARAMETERSENSITIVITYOFTHEEIGENFREQUENCYGREATLYDEPENDSONTHEINTERACTIONBETWEENAXIALANDROTATIONALMODE,DETERMINEDBYTHETRANSMISSIONRATIOOFTHEBALLSCREWWITHINCREASINGTRANSMISSIONRATIOTHEINFLUENCEOFTHEROTATIONALRIGIDITYOFTHESHAFTONTHEOVERALLAXIALRIGIDITYINCREASESTHEPOSITIONDEPENDENT,EFFECTIVEAXIALRIGIDITYCANBEEXPRESSEDASFOLLOWS7INMANYCASESHOWEVER,THEINFLUENCEOFTHEROTATIONALRIGIDITYONTHEAXIALMODECANBENEGLECTEDDUETOTHETRANSMISSIONRATIOOFTHEBALLSCREWWITHTHEEFFECTIVEAXIALRIGIDITYANDTHEKNOWLEDGEOFTHECONSISTENCYOFTHEROTATIONALMODE,THETWOCHARACTERISTICEIGENFREQUENCIESOFABALLDRIVECANBEAPPROXIMATEDUSINGEQUATIONS8AND989DESPITETHECHOSENSIMPLIFICATIONSTHEDISCRETEMODELSHOWSGOODRESULTSFORTHEFIRSTTWOEIGENFREQUENCIESOFABALLSCREWSYSTEMTHISALLOWSFORANINTUITIVEANDCLEARLYARRANGEDSIMULATIONOFTHEDYNAMICALBEHAVIOR,VALIDFORAGREATRANGEOFPARAMETERSANDWELLSUITABLEFORMOSTPRACTICALAPPLICATIONSINTHEFOLLOWINGCHAPTERTHESIMULATIONRESULTSOFTHEDISCRETEMODELDEPICTEDINFIGURE4WILLBECOMPAREDTOMEASUREMENTSONANACTUALMACHINETOOLFEEDDRIVEEXPERIMENTALVERIFICATIONOFTHEMODELATTHEINSTITUTEFORCONTROLENGINEERINGOFMACHINETOOLSANDMANUFACTURINGUNITSISWATTHEUNIVERSITYOFSTUTTGARTEXISTSAGREATVARIETYOFTESTBENCHESWITHDIFFERENTSIZEBALLSCREWSANDNUMEROUSTRANSMISSIONRATIOSWHILETHERESEARCHONTHISTOPICISBASEDONEXPERIMENTSWITHDIFFERENTBALLSCREWTYPES,THEFOLLOWINGMEASUREMENTSFOCUSONATYPICALBALLSCREWSETUPFORMACHINETOOLSACCORDINGTOTHESPECIFICATIONSINTABLE3THEPARAMETERSUSEDFORTHESIMULATIONCOMPLYWITHTHOSEOFTHEEXPERIMENTALSETUPTHEVALUESFORRIGIDITYANDMASSAREBASEDONMANUFACTURERSDATAWHILETHEDAMPINGFACTORSCORRESPONDTOEMPIRICALVALUESTABLE3SPECIFICATIONSOFTHETESTBENCHWITHTHEGIVENFEEDDRIVEVARIOUSMEASUREMENTSHAVEBEENCONDUCTEDANDCOMPAREDTOTHESIMULATIONRESULTSFROMTHEDISCRETEMODELFIGURES6AND7EXEMPLARILYSHOWSIMULATEDANDMEASUREDFREQUENCYRESPONSESFORTHEGIVENFEEDDRIVEATDIFFERENTOPERATINGCONDITIONSFIG6SIMULATEDANDMEASUREDFREQUENCYRESPONSEFORTHEFEEDDRIVEATDIFFERENTMACHINETABLEPOSITIONSNOMINALDIAMETERBALLSCREWD040MMBALLSCREWLEADPH20MMDYNAMICALLOADVALUECN54600NNOMINALBALLDIAMETERDW6MMNUMBEROFBALLTRACKTURNS5TRAVELRANGE700MMMASSMACHINETABLE300600KGFIG7SIMULATEDANDMEASUREDFREQUENCYRESPONSEFORDIFFERENTMACHINETABLEMASSESTHEDISCRETEMODELUSEDTODESCRIBETHEMECHANICALSYSTEMSHOWSGOODCONCORDANCEWITHTHEBEHAVIOROFTHEACTUALFEEDDRIVEDESPITEOFTHECHOSENSIMPLIFICATIONSANDTHEIMPRECISENESSOFTHEMANUFACTURERSDATA,AGOODPREDICTABILITYCOULDBEACHIEVEDFURTHERMORETHEPREDICTEDPARAMETERDEPENDENCYOFTHEEIGENFREQUENCIESISCONFIRMEDBYTHEMEASUREMENTRESULTSTHEFREQUENCYOFTHEAXIALMODECHANGESDEPENDINGONMACHINETABLEMASSANDPOSITIONWHILETHEROTATIONALMODEOFTHEBALLSCREWDRIVEREMAINSALMOSTCONSTANTTHEINVARIANCEOFTHEROTATIONALMODETOWARDSOPERATINGCONDITIONS,ASALREADYDETECTEDINTHEFOREGOINGSIMULATIONS,CANBEEXPLAINEDBYTHELOWPASSCHARACTERISTICOFTHEMECHANICALSYSTEMAFTERTHEFIRSTEIGENFREQUENCYTHESYSTEMEXPERIENCESANAMPLITUDEDROPOFFOF20DB/DECADEHENCETHEENERGYIMPOSEDBYTHESERVODRIVEATHIGHERFREQUENCIESISMERELYTRANSFORMEDONTOTHEMACHINETABLETHEAXIALMOTIONOFTHETABLEATTHESECONDEIGENFREQUENCYISTHEREFOREQUITESMALLDUETOTHEKINEMATICCOUPLING,THEANGULARDEFLECTIONOFTHESHAFTWILLSTILLLEADTOANAXIALDISPLACEMENTWHICHINTHISCASEISPREDOMINANTLYEXECUTEDBYTHEDEFLECTIONOFTHESHAFT,BEARINGANDMOUNTINGCONSIDERINGTHEMINORCHANGESINTABLEPOSITIONATTHEROTATIONALMODEOFTHEBALLSCREWSYSTEM,ITISINTELLIGIBLETHATTHENEITHERTHEMASSNORTHEEFFECTIVEPOSITIONOFTHETABLEHAVEARELEVANTINFLUENCEONTHESECONDEIGENFREQUENCYOFTHEOSCILLATINGSYSTEMTHEPREDICTABILITYANDSIMULATIONOFTHEDOMINANTEIGENFREQUENCIESOFABALLSCREWDRIVEANDTHEIRDEPENDENCYTODIFFERENTOPERATINGCONDITIONSPROVIDESABETTERUNDERSTANDINGOFTHESYSTEMDYNAMICSANDISBENEFICIALFORTHEDESIGNPROCESSOFTHEMECHANICALCOMPONENTSASWELLASFORTHEIMPLEMENTATIONOFADEQUATEFEEDBACKCONTROLLERSINPARTICULARTHECONSISTENCYOFTHEROTATIONALEIGENMODEISQUITEFAVORABLEFORTHEDESIGNOFVIBRATIONREJECTIONANDCONTROLALGORITHMSSUCHASNOTCHFILTERSCONCLUSIONINTHISPAPERTWOWELLSTRUCTUREDANDCLEARLYARRANGEDMODELSFORBALLSCREWFEEDDRIVESHAVEBEENPRESENTEDADISCRETEANDAHYBRIDDISCRETECONTINUUMMODELBYSEPARATINGTHEPHYSICALCHARACTERISTICSOFTHESHAFTINTOANAXIALANDAROTATIONALSYSTEM,THEBALLSCREWDRIVECOULDBEMODELLEDEXCLUSIVELYUSINGDISCRETEBLOCKSINMATLAB/SIMULINKTHROUGHCOMPARISONWITHTHEMORECOMPLEXHYBRIDMODELITCOULDBESHOWNTHATTHESIMPLIFIEDDISCRETEMODELISWELLSUITABLEFORPREDICTINGTHEMOSTRELEVANTEIGENFREQUENCIESOFAFEEDDRIVEOVERAGREATRANGEOFPARAMETERSSIMULATIONRESULTSSHOWTHATTHEBALLSCREWSHAFTHASADECISIVEIMPACTONTHEOVERALLDYNAMICSOFSUCHADRIVESYSTEMFURTHERMORETHESECONDRELEVANTEIGENFREQUENCYPROVESTOBELESSSENSITIVEWITHRESPEC

- 温馨提示:

1: 本站所有资源如无特殊说明,都需要本地电脑安装OFFICE2007和PDF阅读器。图纸软件为CAD,CAXA,PROE,UG,SolidWorks等.压缩文件请下载最新的WinRAR软件解压。

2: 本站的文档不包含任何第三方提供的附件图纸等,如果需要附件,请联系上传者。文件的所有权益归上传用户所有。

3.本站RAR压缩包中若带图纸,网页内容里面会有图纸预览,若没有图纸预览就没有图纸。

4. 未经权益所有人同意不得将文件中的内容挪作商业或盈利用途。

5. 人人文库网仅提供信息存储空间,仅对用户上传内容的表现方式做保护处理,对用户上传分享的文档内容本身不做任何修改或编辑,并不能对任何下载内容负责。

6. 下载文件中如有侵权或不适当内容,请与我们联系,我们立即纠正。

7. 本站不保证下载资源的准确性、安全性和完整性, 同时也不承担用户因使用这些下载资源对自己和他人造成任何形式的伤害或损失。

人人文库网所有资源均是用户自行上传分享,仅供网友学习交流,未经上传用户书面授权,请勿作他用。

川公网安备: 51019002004831号

川公网安备: 51019002004831号