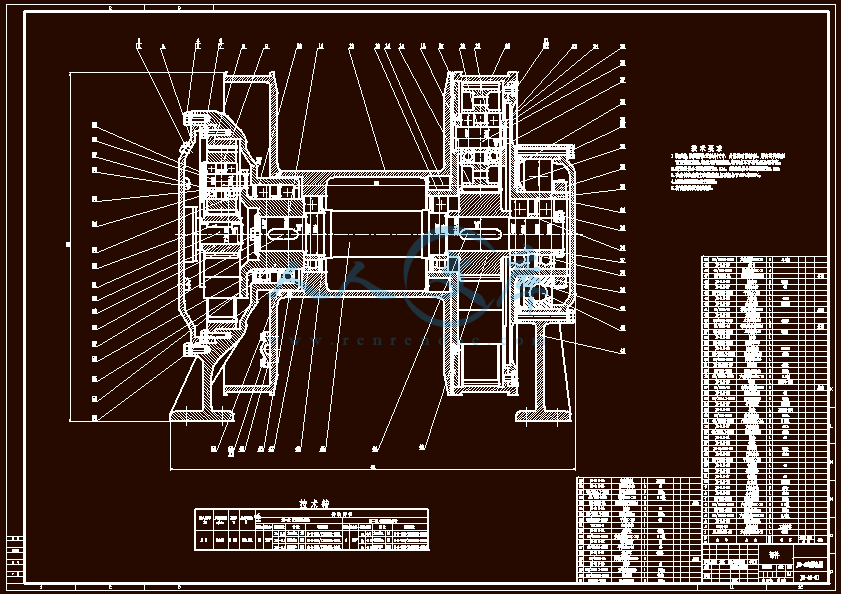

JD-40型调度绞车改进设计(全套含CAD图纸)

收藏

资源目录

压缩包内文档预览:

编号:7130208

类型:共享资源

大小:4.01MB

格式:ZIP

上传时间:2018-01-09

上传人:机****料

认证信息

个人认证

高**(实名认证)

河南

IP属地:河南

50

积分

- 关 键 词:

-

jd

40

调度

绞车

改进

改良

设计

全套

cad

图纸

- 资源描述:

-

- 内容简介:

-

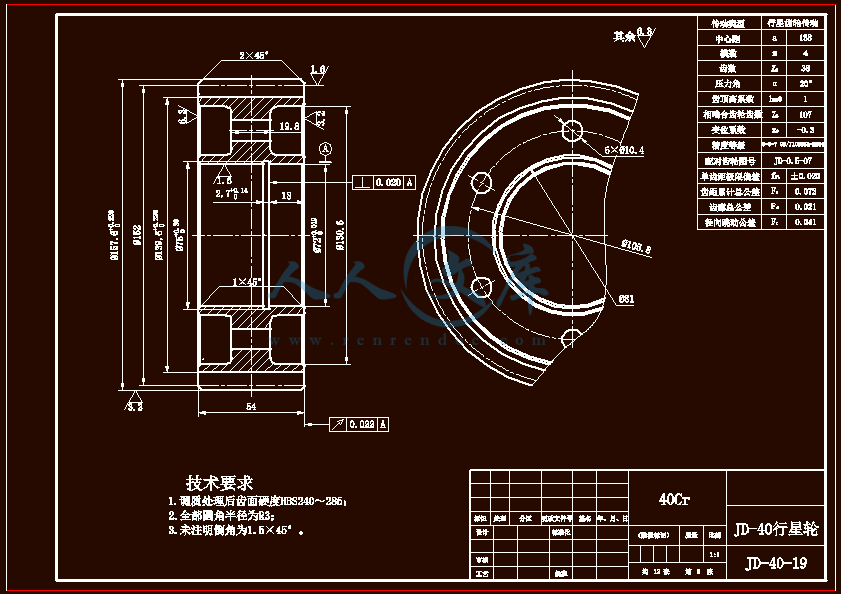

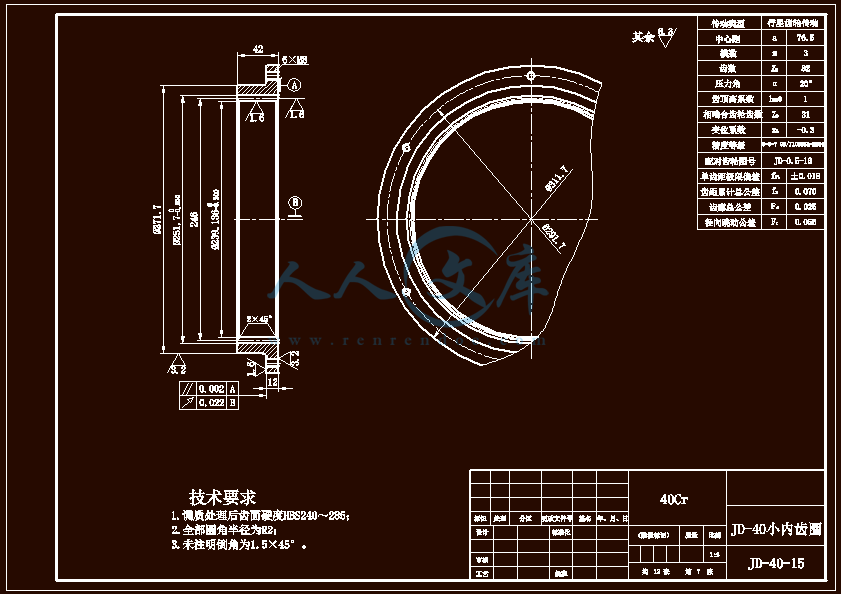

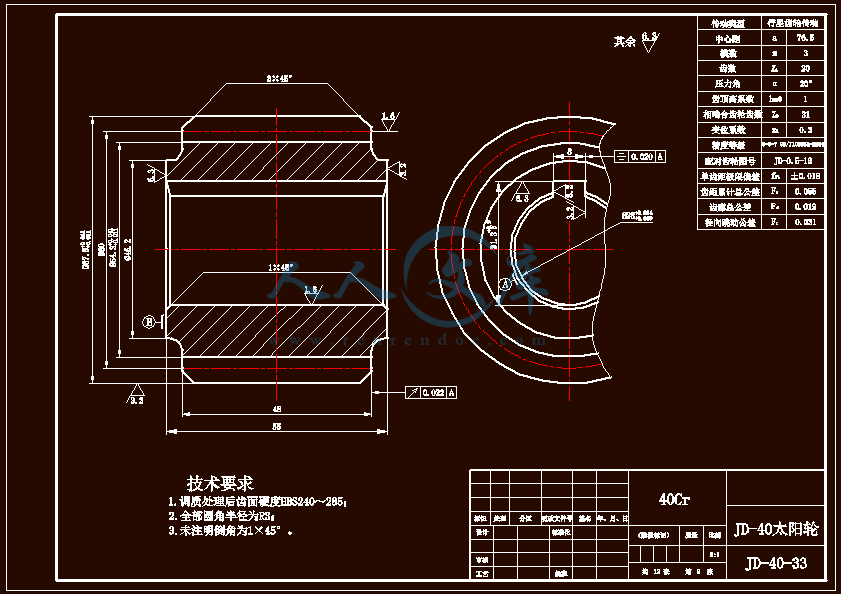

翻译部分英文原文MICROPLANETARYREDUCTIONGEARUSINGSURFACEMICROMACHININGABSTRACTAMICROPLANETARYGEARMECHANISMFEATURINGAHIGHGEARREDUCTIONRATIOWITHCOMPACTNESSINSIZEISPRESENTEDINTHISPAPERSUMMITVISEMPLOYEDFORTHEFABRICATIONMETHODSOTHATTHEREDUNDANCYOFASSEMBLINGPARTSISELIMINATEDTHEDESIGNRULESOFWHICHHASALSOBEENCHECKEDTOMAKEFULLUSEOFTHEBENEFITSOFTHESURFACEMICROMACHINING,THEPLANETARYREDUCTIONGEARISDESIGNEDTOWARDUSINGTHEONCHIPMICROENGINETHEEXPECTEDGEARREDUCTIONRATIOISCALCULATEDANDCOMPAREDWITHTHECONVENTIONALCHAINGEARMECHANISMTHEMICROPLANETARYGEARMECHANISMPRESENTEDINTHISPAPERISEXPECTEDTOHAVE1621REDUCTIONRATIOUTILIZINGLESSSPACECONSUMPTIONTHISISANORDEROFMAGNITUDEHIGHERTHANTHEPREVIOUSLYREPORTEDDESIGNINASINGLEREDUCTIONGEARTRAINKEYWORDSMEMS,PLANETARYGEAR,REDUCTIONGEARSURFACEMICROMACHINING,SUMMITVPROCESSNOMENCLATUREASUNGEARBPLANETGEARSCINTERNALGEARFIXEDDINTERNALGEARROTARYNTHENUMBEROFUNITSOFGEARTRAINDDIAMETEROFTHEPITCHCIRCLENNUMBEROFTEETHPNUMBEROFPLANETSANGULARVELOCITYINTRODUCTIONTHEGEARMECHANISMSINMICROELECTROMECHANICALSYSTEMSMEMSARECOMMONLYEXPECTEDTOGENERATEHIGHTORQUEINTHECONFINEDMICROSIZESYSTEMSHOWEVER,ITISGENERALLYDIFFICULTFORTHEMICROSCALESYSTEMSTOHAVESUCHAHIGHTORQUEWITHOUTHAVINGMULTIPLEREDUCTIONSYSTEMSTHEDESIGNOFTHEREDUCTIONGEARDRIVEBASEDONAPLANETARYPARADOXGEARMECHANISMCANINCREASETHETORQUEWITHINACOMPACTAREA,SINCETHEMICROPLANETARYGEARSYSTEMHASANADVANTAGEOFHIGHREDUCTIONRATIOPERUNITVOLUME1HOWEVERITSMECHANISMISSOCOMPLICATEDTHATRELATIVELYFEWATTEMPTSHAVEBEENMADETOMINIATURIZETHEGEARSYSTEMS23SUZUMORIETAL2USEDTHEMECHANICALPARADOXPLANETARYGEARMECHANISMTODRIVEAROBOTFOR1INPIPESFORWARDORBACKWARDTHEYEMPLOYEDASINGLEMOTORTODRIVETHEGEARMECHANISMSWITHHIGHREDUCTIONRATIOPRECISEGEARFABRICATIONWASENABLEDBYMICROWIREELECTRICALDISCHARGEMACHININGMICROEDMTHESEPARTS,HOWEVER,SHOULDBEASSEMBLEDBEFORETHEDRIVEMOTORISATTACHEDTOTHEGEARBOXTAKEUCHIETAL3ALSOUSEDMICROEDMTOFABRICATETHEMICROPLANETARYGEARSTHEYSUGGESTEDSPECIALCERMETSORHIGHCARBONSTEELFORPOSSIBLEMATERIALSWHILETHEDESIGNCANACHIEVEAREDUCTIONRATIOOF200,THEGEARSSHOULDALSOBEASSEMBLEDANDMOTORDRIVENTOENABLETHEDRIVINGOFTHEPLANETARYGEARBYONCHIPMEANS,SANDIAULTRAPLANARMULTILEVELMEMSTECHNOLOGYSUMMITVPROCESS4FORPLANETARYGEARFABRICATIONISADOPTEDINTHISSTUDYTHESUMMITVPROCESSISTHEONLYFOUNDRYPROCESSAVAILABLEWHICHUTILIZESFOURLAYERSOFRELEASABLEPOLYSILICON,FORATOTALOFFIVELAYERSINCLUDINGAGROUNDPLANE5DUETOTHISFACT,ITISFREQUENTLYUSEDINCOMPLICATEDGEARMECHANISMSBEINGDRIVENBYONCHIPELECTROSTATICACTUATORS5HOWEVER,INMANYCASES,THEMICROENGINESMAYNOTPRODUCEENOUGHTORQUETODRIVETHEDESIREDMECHANICALLOAD,SINCETHEIRELECTROSTATICCOMBDRIVESTYPICALLYONLYGENERATEAFEWTENSOFMICRONEWTONSOFFORCEFORTUNATELY,THESEENGINESCANEASILYBEDRIVENATTENSOFTHOUSANDSOFREVOLUTIONSPERMINUTESTHISMAKESITVERYFEASIBLETOTRADESPEEDFORTORQUE7RODGERSETAL7PROPOSEDTWODUALLEVELGEARSWITHANOVERALLGEARREDUCTIONRATIOOF121THUSSIXOFTHESEMODULARTRANSMISSIONASSEMBLIESCANHAVEA2,985,9841REDUCTIONRATIOATTHECOSTOFTHEHUGESPACEWITHTHEDESIREFORSIZECOMPACTNESSANDATTHESAMETIME,HIGHREDUCTIONRATIOS,THEPLANETARYGEARSYSTEMISPRESENTEDINTHISPAPERITWILLBETHEFIRSTPLANETARYGEARMECHANISMUSINGSURFACEMICROMACHINING,TOTHEAUTHORSKNOWLEDGETHEPRINCIPLESOFOPERATIONSOFTHEPLANETARYGEARMECHANISM,FABRICATION,ANDTHEEXPECTEDPERFORMANCEOFTHEPLANETARYGEARSYSTEMSAREDESCRIBEDINTHISPAPERPRINCIPLESOFOPERATIONANALTERNATIVEWAYOFUSINGGEARSTOTRANSMITTORQUEISTOMAKEONEORMOREGEARS,IE,PLANETARYGEARS,ROTATEOUTSIDEOFONEGEAR,IESUNGEARMOSTPLANETARYREDUCTIONGEARS,ATCONVENTIONALSIZE,AREUSEDASWELLKNOWNCOMPACTMECHANICALPOWERTRANSMISSIONSYSTEMS1THESCHEMATICOFTHEPLANETARYGEARSYSTEMEMPLOYEDISSHOWNINFIGURESINCESUMMITVDESIGNSARELAIDOUTUSINGAUTOCAD2000,THEFIGURE1ISGENERATEDAUTOMATICALLYFROMTHELAYOUTMASKSAPPENDIX1ONEUNITOFTHEPLANETARYGEARSYSTEMISCOMPOSEDOFSIXGEARSONESUNGEAR,A,THREEPLANETARYGEARS,B,ONEFIXEDRINGGEAR,C,ONEROTATINGRINGGEAR,D,ANDONEOUTPUTGEARTHENUMBEROFTEETHFOREACHGEARISDIFFERENTFROMONEANOTHEREXCEPTAMONGTHEPLANETARYGEARSANINPUTGEARISTHESUNGEAR,A,DRIVENBYTHEARMCONNECTEDTOTHEMICROENGINETHEROTATINGRINGGEAR,D,ISSERVEDASANOUTPUTGEARFOREXAMPLE,IFTHEARMDRIVESTHESUNGEARINTHECLOCKWISEDIRECTION,THEPLANETARYGEARS,B,WILLROTATECOUNTERCLOCKWISEATTHEIROWNAXISANDATTHESAMETIME,THOSEWILLROTATEABOUTTHESUNGEARINCLOCKWISEDIRECTIONRESULTINGINPLANETARYMOTIONDUETOTHERELATIVEMOTIONBETWEENTHEPLANETARYGEARS,B,ANDTHEFIXEDRINGGEAR,C,THEROTATINGRINGGEAR,D,WILLROTATECOUNTERCLOCKWISEDIRECTIONTHISISSOCALLEDA3KMECHANICALPARADOXPLANETARYGEAR1FABRICATIONPROCEDUREANDTESTSTRUCTURESTHEFEATURESOFTHESUMMITVPROCESSOFFERFOURLEVELSOFSTRUCTURALPOLYSILICONLAYERSANDANELECTRICALPOLYLEVEL,ANDALSOEMPLOYTRADITIONALINTEGRATEDCIRCUITPROCESSINGTECHNIQUES4THESUMMITVTECHNOLOGYISESPECIALLYSUITABLEFORTHEGEARMECHANISMTHEPLANETARYGEARMECHANISMCANBEDRIVENBYTHEONCHIPENGINEANDTHUSISANOTHERREASONOFUSINGTHESUMMITVPROCESSSINCETHESANDIAPROCESSISSUCHAWELLKNOWNPROCEDURE57,ONLYBRIEFEXPLANATIONISPRESENTEDFIGURE2REPRESENTSTHECROSSSECTIONALVIEWOFFIGURE1,ANDALSOWASGENERATEDFROMTHEAUTOCADLAYOUTMASKSAPPENDIX1THEDISCONTINUITYINTHECROSSSECTIONISFORTHEETCHHOLESTHEPOLY1GRAYISUSEDFORTHEHUBSANDALSOPATTERNEDTOMAKETHEFIXEDRINGGEAR,IE,C,THESUNGEAR,IE,A,THEROTATINGRINGGEAR,IE,C,ANDTHEOUTPUTGEARISPATTERNEDINTHEPOLY2SINCETHEPLANETARYGEARNEEDSTOCONTACTBOTHTHEFIXEDRINGANDROTATINGRINGGEAR,POLY2ISADDEDTOPOLY3,WHERETHEGEARTEETHAREACTUALLYFORMEDTHEPOLY4LAYERISUSEDFORTHEARMTHATDRIVESTHESUNGEARAFTERTHERELEASEETCH,THEPLANETARYGEARSWILLFALLDOWNSOTHATTHOSEWILLENGAGEBOTHTHERINGGEARSTHEFIGURESFORTHETESTSTRUCTURESAREPRESENTEDINAPPENDIX2SINCETHEAIMOFTHISPAPERISTOSUGGESTAGEARREDUCTIONMECHANISM,THEPLANETARYGEARSYSTEMISDECOMPOSEDTOSEVERALGEARUNITSTOVERIFYITSPERFORMANCETHEFIRSTTESTSTRUCTUREISABOUTTHEARM,WHICHROTATESTHESUNGEAR,CONNECTEDTOTHEONCHIPENGINETHEANGULARVELOCITYOFTHEARMDEPENDSONTHEENGINEOUTPUTSPEEDTHESECONDTESTSTRUCTUREDESCRIBESTHEPOINTATWHICHTHESUNGEARANDPLANETARYGEARSAREENGAGEDTOTHEFIXEDRINGGEARBECAUSEOFTHEFACTTHATTHERINGGEARISFIXED,THEPLANETARYGEARISJUSTTRANSMITTINGTHETORQUEFROMTHESUNGEARTOTHEFIXEDRINGGEARWITHOUTPLANETMOTION,EG,ROTATINGITSOWNAXISNOTAROUNDTHESUNGEARWHENTHEROTATINGRINGGEARISMOUNTEDONTOPOFTHEFIXEDRINGGEAR,IE,THETHIRDTESTSTRUCTURE,THEPLANETARYGEARSBEGINTOROTATEAROUNDTHESUNGEARSOTHATTHEPLANETMOTIONAREENABLEDTHEREFORE,ONCEONEOUTPUTGEARISATTACHEDTOTHEROTATINGRINGGEAR,IE,THEFINALTESTSTRUCTURE,THEWHOLEREDUCTIONUNITISCOMPLETEDDISMANTLINGTHEPLANETARYGEARINTOTHREETESTSTRUCTURESALLOWSTHEPINPOINTINGOFPOSSIBLEERRORSINTHEGEARSYSTEMSOLUTIONSPROCEDUREANDEXPECTEDPERFORMANCETHEREDUCTIONRATIOISDEFINEDASTHERATIOBETWEENTHEANGULARVELOCITYOFTHEDRIVERGEARANDTHATOFTHEDRIVENGEARHIGHREDUCTIONRATIOSINDICATETRADINGSPEEDFORTORQUEFOREXAMPLE,A101GEARREDUCTIONUNITCOULDINCREASETORQUEANORDEROFMAGNITUDESINCETHEGEARSINTHEPLANETARYSYSTEMSHOULDBEMESHEDTOONEANOTHER,THEDESIGNOFGEARMODULESHOULDFOLLOWARESTRICTIONFOREXAMPLE,THENUMBEROFTEETHFORTHESUNGEARPLUSEITHERTHATOFTHEFIXEDRINGGEARORTHATOFTHEROTATINGRINGGEARSHOULDBETHEMULTIPLEOFTHENUMBEROFPLANETS,PEQUATION1EQUATION2,WHICHREPRESENTTHEREDUCTIONRATIO,SHOULDOBSERVETHEEQUATION1FIRSTTHENISTHENUMBEROFTHETEETHFORCORRESPONDINGGEARGEARS,A,B,C,DINTHEPLANETARYGEARSYSTEMHAVEATOOTHMODULEOF4M,WHICHISACOMPARABLESIZEOFTHECURRENTGEARREDUCTIONUNITS5,ANDTHETOOTHNUMBERSARE12,29,69,AND72RESPECTIVELYTHEREFORETHEOVERALLREDUCTIONRATIOIS1621FROMEQUATION2RODGERSETAL7REPORTEDA121REDUCTIONUNITUSINGSURFACEMICROMACHINING,WHICHISLESSTHANORDEROFMAGNITUDEFORTHEGEARREDUCTIONRATIOOFTHEPLANETARYGEARSYSTEMALTHOUGHTHEREDUCTIONFROMRODGERSETAL7NEEDSTOBEOCCUPIEDINAPPROXIMATELY0093MM2,THEPLANETARYGEARSYSTEMONLYUTILIZESANAREAOFAPPROXIMATELY0076MM2THUS,THISPLANETARYREDUCTIONDESIGNCANACHIEVEANORDEROFMAGNITUDEHIGHERREDUCTIONRATIOWITHLESSSPACESINCETHEREDUCTIONMODULEISCOMPOSEDOFSEVERALREDUCTIONUNITS,THEADVANTAGEOFUSINGAPLANETARYGEARSYSTEMISSELFEVIDENTINFIGURE3FIGURE3SHOWSTHECOMPARISONOFREDUCTIONRATIOSBETWEENTHEPROPOSEDPLANETARYGEARMECHANISMIE162N,ANDTHESANDIAGEARSYSTEM7,IE12N,ASAFUNCTIONOFTHENUMBEROFUNITS,IE,NTHEORDINATEISDRAWNINLOGSCALESOTHATTHEORDERSOFMAGNITUDEDIFFERENCESBETWEENTWOMODULESAREEVIDENTFOREXAMPLE,INAMODULEWITHFIVENUMBERSOFUNITS,THEREDUCTIONRATIODIFFERENCEBETWEENTWOISAPPROXIMATELYSIXORDERSOFMAGNITUDESFURTHERMORE,THEPLANETARYGEARSYSTEMCANSAVE8500M2INSUCHAFIVEUNITREDUCTIONSYSTEMCONCLUSIONANDDISCUSSIONSTHEPLANETARYGEARREDUCTIONSYSTEMUSINGSURFACEMICROMACHINING,DRIVENBYANONCHIPENGINE,FIRSTAPPEARSINTHISPAPERWITHINTHEAUTHORSKNOWLEDGETHESINGLEREDUCTIONUNITCANACHIEVEANORDEROFMAGNITUDEHIGHERREDUCTIONRATIOTHANTHATOFTHEPREVIOUSDESIGNHOWEVER,DUETOTHESURFACEFRICTION,ANDTHEBACKLASH,WHICHISINEVITABLEFORTHEGEARMANUFACTURINGPROCESS,THEOVERALLREDUCTIONRATIOMAYBELESSTHAN1621INTHEREALSITUATIONEVENTHOUGHSOMELOSSMIGHTBEEXPECTEDINTHEREALAPPLICATION,THEOVERALLREDUCTIONRATIOSHOULDBEORDEROFMAGNITUDEHIGHERANDTHESPACECONSUMPTIONISLESSTHANTHEPREVIOUSDESIGN7THEAUTHORSLEARNEDALOTABOUTTHESURFACEMICROMACHININGPROCESSDURINGTHEPROJECTGRANT,ANDREALIZEDTHATALOTOFTHEDESIGNNEEDEDTOBEREVISITEDANDCORRECTEDTHISBECAMEPREVALENTWHENDRAWINGTHECROSSSECTIONALVIEWSOFTHEDESIGNSINCETHEAUTHORSUTILIZEDTHESUMMITVADVANCEDDESIGNTOOLSSOFTWAREPACKAGEANDVERIFIEDTHEDESIGNRULES,THEPLANETARYGEARLAYOUTISREADYFORFABRICATIONTHEAUTHORSHOPETHATTHISPLANETARYREDUCTIONUNITWILLCONTINUETOBEUPDATEDBYSUCCESSIVERESEARCHERSACKNOWLEDGEMENTTHEAUTHORSWOULDACKNOWLEDGETHATDISCUSSIONSWITHPROFKRISPISTER,PROFARUNMAJUMDAR,MSKARENCHEUNG,ANDMRELLIOTHUICONTRIBUTEDTOTHISWORKTREMENDOUSLYREFERENCES1HORI,K,ANDSATO,A,“MICROPLANETARYREDUCTIONGEAR”PROCIEEE2NDINTSYMPMICROMACHINEANDHUMANSCIENCES,PP536019912SUZUMORI,K,MIYAGAWA,T,KIMURA,M,ANDHASEGAWA,Y,“MICROINSPECTIONROBOTFOR1INPIPES”,IEEE/ASMETRANSONMECHATRONICS,VOL4,NO3,PP28629219993TAKEUCHI,H,NAKAMURA,K,SHIMIZU,N,ANDSHIBAIKE,N,“OPTIMIZATIONOFMECHANICALINTERFACEFORAPRACTICALMICROREDUCER”,PROCIEEE13THINTSYMPMICROELECTROMECHANICALSYSTEMS,PP17017520004SANDIANATIONALLABORATORIES,“DESIGNRULESDESIGNRULES”,MICROELECTRONICSDEVELOPMENTLABORATORY,VERSION08,20005KRYGOWASK,TW,SNIEGOWASK,JJ,RODGERS,MS,MONTAGUE,S,ANDALLEN,JJ,“INFRASTRUCTURE,TECHNOLOGYANDAPPLICATIONSOFMICROELECTROMECHANICALSYSTEMSMEMS”,SENSOREXPO199919996SNIEGOWSKI,JJ,MILLER,SL,LAVIGNE,GF,RODGERS,MS,ANDMCWHORTER,PJ,“MONOLITHICGEAREDMECHANISMSDRIVENBYAPOLYSILICONSURFACEMICROMACHINEDONCHIPELECTROSTATICMICROENGINE”,SOLIDSTATESENSORANDACTUATORWORKSHOP,PP178182,19967ROGERS,MS,SNIEGOWSKI,SS,MILLER,S,ANDLAVIGNE,GF,“DESIGNINGANDOPERATINGELECTROSTATICALLYDRIVENMICROENGINES”,PROCEEDINGSOFTHE44THINTERNATIONALINSTRUMENTATIONSYMPOSIUM,RENO,NV,MAY37,PP56651998FIGURE1THESCHEMATICOFTHEPLANETARYGEARMECHANISMGENERATEDFROMSUMMITVDESIGNLAYOUTSOFTWAREFIGURE2ASCHEMATICCROSSSECTIONOFTHEPLANETARYGEARSYSTEMGENERATEDBYSUMMITVTECHNOLOGYFIGURE3THECOMPARISONOFREDUCTIONRATIOSASAFUNCTIONOFTHENUMBEROFUNITS中文翻译采用表面微加工技术制造微型行星齿轮减速器摘要这篇文章论述了一种结构紧凑、传动比高的微型行星齿轮减速机构。这种机构的加工方法采用桑迪亚国家实验室研发的过度平面的多极微机电系统技术去除整体结构的冗余部分,而且这种设计原理已经得到承认。为了充分利用表面微加工技术,我们在设计加工这种行星减速齿轮时,需要使用安装在芯片上的微电机。我们将计算这种齿轮预期的减速比,并把它与传统的链传动和齿轮传动相比较。在这篇论文中演示的微行星轮占用较少的空间,消耗较少的材料,减速比却有望达到1621。这比以前的论文中设计的减速器的传动比要高的多,简直是一个神话。关键字微机电行星齿轮减速器表面微加工过度平面的多极微机电系统的加工(简称为SUMMITV)术语A太阳轮B行星轮C内齿圈(固定)D内齿圈(旋转)N齿轮系组成单元的数目D节圆的直径N齿数P行星轮的数目角速度介绍在微机电系统中的齿轮结构通常希望用来在微小的体积内产生较大的扭矩。但是没有较大重量的减速器,往往是很难达到这样的目的。研究发现拥有微行星齿轮的减速机构能够在狭小的空间内增加扭矩,这好像有点自相矛盾。这是因为微行星齿轮系统能在每单位体积内产生更大的传动比。然而它的结构是如此的复杂,以至于我们很少尝试将齿轮系统微型化。SUZUMORI以及他的小组成员曾经用类似的行星齿轮结构来驱动一个机器人,并使它在直径为一寸的钢管里前后移动。他们利用一个马达来驱动高传动比的齿轮机构,通过微电线的放电加工技术能够实现这种齿轮机构的精确加工。但是这些部件应该在装配驱动马达之前安装在齿轮箱上。TAKEUCHI等人也用这种技术制造了微行星齿轮。他们建议用特殊的含陶合金和高碳钢作为最佳选择材料。当这种齿轮系统的传动比达到200的时候,才可以安装马达并使之驱动。为了实现用芯片的方法来实现行星齿轮的驱动,在研究中我们采用SUMMITV方法来加工微行星齿轮。SUMMITV过程是唯一可以实现对于总数为五层其中一层为地平面的硅中释放四层的铸造过程由于这个原因,它经常被用来通过安装在芯片上的电子执行器来驱动复杂的齿轮机构。然而,在许多情形,微电机不可能提供充足的转力矩来驱动机械负荷,因为它们的静电梳的典型驱动只产生几十微牛顿的力。幸运的是,这些引擎能容易地达到每分钟几万转的速度。这就使将转矩转化为速度变成是可行的。罗杰等人设计了二个传动比为121的双重的水平齿轮。如此六个这样的模组的传输集合在以占据极大的空间为代价的前提下可以达到2,985,9841的传动比。为了达到结构紧凑,同时达到高传动比的目的少比,行星齿轮系统将被作为研究对象。根据作者的认识,它将会是第一个使用表面微加工原理设计的行星齿轮结构。我们还将阐述行星齿轮的操作规则,加工过程和希望达到的行星齿轮系统的性能。操作原则使用齿轮传输转矩的其它可行的方法是将一个或者多个的齿轮,也就是,行星齿轮,在另一个齿轮的外面旋转,也就是太阳轮。按照传统的尺寸设计的行星齿轮减速器是使整体结构紧凑的常用的传输系统。图1是上述的行星齿轮的示意图。自从用AUTOCAD设计SUMMITV以来,图(1)可以通过软件自动产生附1。一个完整的行星齿轮系统是由六个齿轮组成的一个太阳齿轮A,三个行星齿轮B,一个固定的内齿圈C,一个旋转的内齿圈D,和一个输出齿轮E。除了行星齿轮之外,每个齿轮的齿数都不相同。太阳齿轮A是输入齿轮,由与微引擎连接的机械手驱动。内齿圈D,被视为输出齿轮。举例来说,如果机械手驱动太阳轮按照顺时针方向方向旋转,那么行星轮B,将绕着它们自己的轴按照逆时针方向宣战,同时也将绕着太阳轮按照顺时针方向的方向旋转,这样就形成了行星运动。由于多个行星齿轮B和固定内齿圈C之间的运动相似,所以旋转的内齿圈D将按照逆时针方向旋转。这也被叫做3K行星齿轮。加工过程和结构测试SUMMITV程序的特征体现了硅层结构、电解聚乙烯,以及传统的集成电路处理等技术水平的四个层次。SUMMITV技术尤其适应于齿轮机构。行星齿轮机构由芯片上的微引擎驱动,而且这也是采用SUMMITV技术的另一个理由。因为桑迪亚程序是一款众所周知的程序,所以我们只简要的作些解释。图2是图1的截面视图,也是由AUTOCAD按照附录1设计产生的,其中截面中的不连续的部分是为了钻孔而设置的。聚乙烯1灰色用来制造轮毂以及固定的内齿圈C,太阳齿轮A,旋转的内齿圈C,而输出齿轮是由聚乙烯2制造的。图1是由SUMMITV设计软件

- 温馨提示:

1: 本站所有资源如无特殊说明,都需要本地电脑安装OFFICE2007和PDF阅读器。图纸软件为CAD,CAXA,PROE,UG,SolidWorks等.压缩文件请下载最新的WinRAR软件解压。

2: 本站的文档不包含任何第三方提供的附件图纸等,如果需要附件,请联系上传者。文件的所有权益归上传用户所有。

3.本站RAR压缩包中若带图纸,网页内容里面会有图纸预览,若没有图纸预览就没有图纸。

4. 未经权益所有人同意不得将文件中的内容挪作商业或盈利用途。

5. 人人文库网仅提供信息存储空间,仅对用户上传内容的表现方式做保护处理,对用户上传分享的文档内容本身不做任何修改或编辑,并不能对任何下载内容负责。

6. 下载文件中如有侵权或不适当内容,请与我们联系,我们立即纠正。

7. 本站不保证下载资源的准确性、安全性和完整性, 同时也不承担用户因使用这些下载资源对自己和他人造成任何形式的伤害或损失。

人人文库网所有资源均是用户自行上传分享,仅供网友学习交流,未经上传用户书面授权,请勿作他用。

川公网安备: 51019002004831号

川公网安备: 51019002004831号