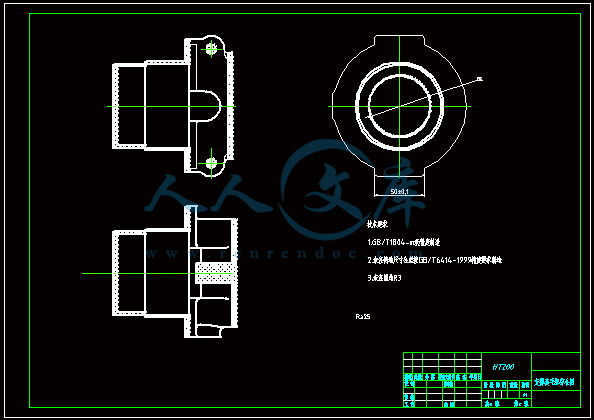

基于支承套零件工艺及工装设计 液压及普通夹具设计【钻底面φ10的孔+铣18H8槽】(全套含CAD图纸)

收藏

资源目录

压缩包内文档预览:

编号:7163077

类型:共享资源

大小:2.14MB

格式:ZIP

上传时间:2018-01-10

上传人:机****料

认证信息

个人认证

高**(实名认证)

河南

IP属地:河南

50

积分

- 关 键 词:

-

基于

支承

零件

工艺

工装

设计

液压

普通

夹具

底面

10

18

h8

全套

cad

图纸

- 资源描述:

-

- 内容简介:

-

英文原文THEMACHINABILITYOFAMATERIAL1THEMACHINABILITYOFAMATERIALUSUALLYDEFINEDINTERMSOFFOURFACTORS1、SURFACEFINISHANDINTEGRITYOFTHEMACHINEDPART2、TOOLLIFEOBTAINED3、FORCEANDPOWERREQUIREMENTS4、CHIPCONTROLTHUS,GOODMACHINABILITYGOODSURFACEFINISHANDINTEGRITY,LONGTOOLLIFE,ANDLOWFORCEANDPOWERREQUIREMENTSASFORCHIPCONTROL,LONGANDTHINSTRINGYCUREDCHIPS,IFNOTBROKENUP,CANSEVERELYINTERFEREWITHTHECUTTINGOPERATIONBYBECOMINGENTANGLEDINTHECUTTINGZONEBECAUSEOFTHECOMPLEXNATUREOFCUTTINGOPERATIONS,ITISDIFFICULTTOESTABLISHRELATIONSHIPSTHATQUANTITATIVELYDEFINETHEMACHINABILITYOFAMATERIALINMANUFACTURINGPLANTS,TOOLLIFEANDSURFACEROUGHNESSAREGENERALLYCONSIDEREDTOBETHEMOSTIMPORTANTFACTORSINMACHINABILITYALTHOUGHNOTUSEDMUCHANYMORE,APPROXIMATEMACHINABILITYRATINGSAREAVAILABLEINTHEEXAMPLEBELOW2MACHINABILITYOFSTEELSBECAUSESTEELSAREAMONGTHEMOSTIMPORTANTENGINEERINGMATERIALSASNOTEDINCHAPTER5,THEIRMACHINABILITYHASBEENSTUDIEDEXTENSIVELYTHEMACHINABILITYOFSTEELSHASBEENMAINLYIMPROVEDBYADDINGLEADANDSULFURTOOBTAINSOCALLEDFREEMACHININGSTEELSRESULFURIZEDANDREPHOSPHORIZEDSTEELSSULFURINSTEELSFORMSMANGANESESULFIDEINCLUSIONSSECONDPHASEPARTICLES,WHICHACTASSTRESSRAISERSINTHEPRIMARYSHEARZONEASARESULT,THECHIPSPRODUCEDBREAKUPEASILYANDARESMALLTHISIMPROVESMACHINABILITYTHESIZE,SHAPE,DISTRIBUTION,ANDCONCENTRATIONOFTHESEINCLUSIONSSIGNIFICANTLYINFLUENCEMACHINABILITYELEMENTSSUCHASTELLURIUMANDSELENIUM,WHICHAREBOTHCHEMICALLYSIMILARTOSULFUR,ACTASINCLUSIONMODIFIERSINRESULFURIZEDSTEELSPHOSPHORUSINSTEELSHASTWOMAJOREFFECTSITSTRENGTHENSTHEFERRITE,CAUSINGINCREASEDHARDNESSHARDERSTEELSRESULTINBETTERCHIPFORMATIONANDSURFACEFINISHNOTETHATSOFTSTEELSCANBEDIFFICULTTOMACHINE,WITHBUILTUPEDGEFORMATIONANDPOORSURFACEFINISHTHESECONDEFFECTISTHATINCREASEDHARDNESSCAUSESTHEFORMATIONOFSHORTCHIPSINSTEADOFCONTINUOUSSTRINGYONES,THEREBYIMPROVINGMACHINABILITYLEADEDSTEELSAHIGHPERCENTAGEOFLEADINSTEELSSOLIDIFIESATTHETIPOFMANGANESESULFIDEINCLUSIONSINNONRESULFURIZEDGRADESOFSTEEL,LEADTAKESTHEFORMOFDISPERSEDFINEPARTICLESLEADISINSOLUBLEINIRON,COPPER,ANDALUMINUMANDTHEIRALLOYSBECAUSEOFITSLOWSHEARSTRENGTH,THEREFORE,LEADACTSASASOLIDLUBRICANTANDISSMEAREDOVERTHETOOLCHIPINTERFACEDURINGCUTTINGTHISBEHAVIORHASBEENVERIFIEDBYTHEPRESENCEOFHIGHCONCENTRATIONSOFLEADONTHETOOLSIDEFACEOFCHIPSWHENMACHININGLEADEDSTEELSWHENTHETEMPERATUREISSUFFICIENTLYHIGHFORINSTANCE,ATHIGHCUTTINGSPEEDSANDFEEDSTHELEADMELTSDIRECTLYINFRONTOFTHETOOL,ACTINGASALIQUIDLUBRICANTINADDITIONTOTHISEFFECT,LEADLOWERSTHESHEARSTRESSINTHEPRIMARYSHEARZONE,REDUCINGCUTTINGFORCESANDPOWERCONSUMPTIONLEADCANBEUSEDINEVERYGRADEOFSTEEL,SUCHAS10XX,11XX,12XX,41XX,ETCLEADEDSTEELSAREIDENTIFIEDBYTHELETTERLBETWEENTHESECONDANDTHIRDNUMERALSFOREXAMPLE,10L45NOTETHATINSTAINLESSSTEELS,SIMILARUSEOFTHELETTERLMEANS“LOWCARBON,”ACONDITIONTHATIMPROVESTHEIRCORROSIONRESISTANCEHOWEVER,BECAUSELEADISAWELLKNOWNTOXINANDAPOLLUTANT,THEREARESERIOUSENVIRONMENTALCONCERNSABOUTITSUSEINSTEELSESTIMATEDAT4500TONSOFLEADCONSUMPTIONEVERYYEARINTHEPRODUCTIONOFSTEELSCONSEQUENTLY,THEREISACONTINUINGTRENDTOWARDELIMINATINGTHEUSEOFLEADINSTEELSLEADFREESTEELSBISMUTHANDTINARENOWBEINGINVESTIGATEDASPOSSIBLESUBSTITUTESFORLEADINSTEELSCALCIUMDEOXIDIZEDSTEELSANIMPORTANTDEVELOPMENTISCALCIUMDEOXIDIZEDSTEELS,INWHICHOXIDEFLAKESOFCALCIUMSILICATESCASOAREFORMEDTHESEFLAKES,INTURN,REDUCETHESTRENGTHOFTHESECONDARYSHEARZONE,DECREASINGTOOLCHIPINTERFACEANDWEARTEMPERATUREISCORRESPONDINGLYREDUCEDCONSEQUENTLY,THESESTEELSPRODUCELESSCRATERWEAR,ESPECIALLYATHIGHCUTTINGSPEEDSSTAINLESSSTEELSAUSTENITIC300SERIESSTEELSAREGENERALLYDIFFICULTTOMACHINECHATTERCANBEAPROBLEM,NECESSITATINGMACHINETOOLSWITHHIGHSTIFFNESSHOWEVER,FERRITICSTAINLESSSTEELSALSO300SERIESHAVEGOODMACHINABILITYMARTENSITIC400SERIESSTEELSAREABRASIVE,TENDTOFORMABUILTUPEDGE,ANDREQUIRETOOLMATERIALSWITHHIGHHOTHARDNESSANDCRATERWEARRESISTANCEPRECIPITATIONHARDENINGSTAINLESSSTEELSARESTRONGANDABRASIVE,REQUIRINGHARDANDABRASIONRESISTANTTOOLMATERIALSTHEEFFECTSOFOTHERELEMENTSINSTEELSONMACHINABILITYTHEPRESENCEOFALUMINUMANDSILICONINSTEELSISALWAYSHARMFULBECAUSETHESEELEMENTSCOMBINEWITHOXYGENTOFORMALUMINUMOXIDEANDSILICATES,WHICHAREHARDANDABRASIVETHESECOMPOUNDSINCREASETOOLWEARANDREDUCEMACHINABILITYITISESSENTIALTOPRODUCEANDUSECLEANSTEELSCARBONANDMANGANESEHAVEVARIOUSEFFECTSONTHEMACHINABILITYOFSTEELS,DEPENDINGONTHEIRCOMPOSITIONPLAINLOWCARBONSTEELSLESSTHAN015CCANPRODUCEPOORSURFACEFINISHBYFORMINGABUILTUPEDGECASTSTEELSAREMOREABRASIVE,ALTHOUGHTHEIRMACHINABILITYISSIMILARTOTHATOFWROUGHTSTEELSTOOLANDDIESTEELSAREVERYDIFFICULTTOMACHINEANDUSUALLYREQUIREANNEALINGPRIORTOMACHININGMACHINABILITYOFMOSTSTEELSISIMPROVEDBYCOLDWORKING,WHICHHARDENSTHEMATERIALANDREDUCESTHETENDENCYFORBUILTUPEDGEFORMATIONOTHERALLOYINGELEMENTS,SUCHASNICKEL,CHROMIUM,MOLYBDENUM,ANDVANADIUM,WHICHIMPROVETHEPROPERTIESOFSTEELS,GENERALLYREDUCEMACHINABILITYTHEEFFECTOFBORONISNEGLIGIBLEGASEOUSELEMENTSSUCHASHYDROGENANDNITROGENCANHAVEPARTICULARLYDETRIMENTALEFFECTSONTHEPROPERTIESOFSTEELOXYGENHASBEENSHOWNTOHAVEASTRONGEFFECTONTHEASPECTRATIOOFTHEMANGANESESULFIDEINCLUSIONSTHEHIGHERTHEOXYGENCONTENT,THELOWERTHEASPECTRATIOANDTHEHIGHERTHEMACHINABILITYINSELECTINGVARIOUSELEMENTSTOIMPROVEMACHINABILITY,WESHOULDCONSIDERTHEPOSSIBLEDETRIMENTALEFFECTSOFTHESEELEMENTSONTHEPROPERTIESANDSTRENGTHOFTHEMACHINEDPARTINSERVICEATELEVATEDTEMPERATURES,FOREXAMPLE,LEADCAUSESEMBRITTLEMENTOFSTEELSLIQUIDMETALEMBRITTLEMENT,HOTSHORTNESSSEESECTION143,ALTHOUGHATROOMTEMPERATUREITHASNOEFFECTONMECHANICALPROPERTIESSULFURCANSEVERELYREDUCETHEHOTWORKABILITYOFSTEELS,BECAUSEOFTHEFORMATIONOFIRONSULFIDE,UNLESSSUFFICIENTMANGANESEISPRESENTTOPREVENTSUCHFORMATIONATROOMTEMPERATURE,THEMECHANICALPROPERTIESOFRESULFURIZEDSTEELSDEPENDONTHEORIENTATIONOFTHEDEFORMEDMANGANESESULFIDEINCLUSIONSANISOTROPYREPHOSPHORIZEDSTEELSARESIGNIFICANTLYLESSDUCTILE,ANDAREPRODUCEDSOLELYTOIMPROVEMACHINABILITY3MACHINABILITYOFVARIOUSOTHERMETALSALUMINUMISGENERALLYVERYEASYTOMACHINE,ALTHOUGHTHESOFTERGRADESTENDTOFORMABUILTUPEDGE,RESULTINGINPOORSURFACEFINISHHIGHCUTTINGSPEEDS,HIGHRAKEANGLES,ANDHIGHRELIEFANGLESARERECOMMENDEDWROUGHTALUMINUMALLOYSWITHHIGHSILICONCONTENTANDCASTALUMINUMALLOYSMAYBEABRASIVETHEYREQUIREHARDERTOOLMATERIALSDIMENSIONALTOLERANCECONTROLMAYBEAPROBLEMINMACHININGALUMINUM,SINCEITHASAHIGHTHERMALCOEFFICIENTOFEXPANSIONANDARELATIVELYLOWELASTICMODULUSBERYLLIUMISSIMILARTOCASTIRONSBECAUSEITISMOREABRASIVEANDTOXIC,THOUGH,ITREQUIRESMACHININGINACONTROLLEDENVIRONMENTCASTGRAYIRONSAREGENERALLYMACHINABLEBUTAREFREECARBIDESINCASTINGSREDUCETHEIRMACHINABILITYANDCAUSETOOLCHIPPINGORFRACTURE,NECESSITATINGTOOLSWITHHIGHTOUGHNESSNODULARANDMALLEABLEIRONSAREMACHINABLEWITHHARDTOOLMATERIALSCOBALTBASEDALLOYSAREABRASIVEANDHIGHLYWORKHARDENINGTHEYREQUIRESHARP,ABRASIONRESISTANTTOOLMATERIALSANDLOWFEEDSANDSPEEDSWROUGHTCOPPERCANBEDIFFICULTTOMACHINEBECAUSEOFBUILTUPEDGEFORMATION,ALTHOUGHCASTCOPPERALLOYSAREEASYTOMACHINEBRASSESAREEASYTOMACHINE,ESPECIALLYWITHTHEADDITIONLEADLEADEDFREEMACHININGBRASSBRONZESAREMOREDIFFICULTTOMACHINETHANBRASSMAGNESIUMISVERYEASYTOMACHINE,WITHGOODSURFACEFINISHANDPROLONGEDTOOLLIFEHOWEVERCARESHOULDBEEXERCISEDBECAUSEOFITSHIGHRATEOFOXIDATIONANDTHEDANGEROFFIRETHEELEMENTISPYROPHORICMOLYBDENUMISDUCTILEANDWORKHARDENING,SOITCANPRODUCEPOORSURFACEFINISHSHARPTOOLSARENECESSARYNICKELBASEDALLOYSAREWORKHARDENING,ABRASIVE,ANDSTRONGATHIGHTEMPERATURESTHEIRMACHINABILITYISSIMILARTOTHATOFSTAINLESSSTEELSTANTALUMISVERYWORKHARDENING,DUCTILE,ANDSOFTITPRODUCESAPOORSURFACEFINISHTOOLWEARISHIGHTITANIUMANDITSALLOYSHAVEPOORTHERMALCONDUCTIVITYINDEED,THELOWESTOFALLMETALS,CAUSINGSIGNIFICANTTEMPERATURERISEANDBUILTUPEDGETHEYCANBEDIFFICULTTOMACHINETUNGSTENISBRITTLE,STRONG,ANDVERYABRASIVE,SOITSMACHINABILITYISLOW,ALTHOUGHITGREATLYIMPROVESATELEVATEDTEMPERATURESZIRCONIUMHASGOODMACHINABILITYITREQUIRESACOOLANTTYPECUTTINGFLUID,HOWEVER,BECAUSEOFTHEEXPLOSIONANDFIRE4MACHINABILITYOFVARIOUSMATERIALSGRAPHITEISABRASIVEITREQUIRESHARD,ABRASIONRESISTANT,SHARPTOOLSTHERMOPLASTICSGENERALLYHAVELOWTHERMALCONDUCTIVITY,LOWELASTICMODULUS,ANDLOWSOFTENINGTEMPERATURECONSEQUENTLY,MACHININGTHEMREQUIRESTOOLSWITHPOSITIVERAKEANGLESTOREDUCECUTTINGFORCES,LARGERELIEFANGLES,SMALLDEPTHSOFCUTANDFEED,RELATIVELYHIGHSPEEDS,ANDPROPERSUPPORTOFTHEWORKPIECETOOLSSHOULDBESHARPEXTERNALCOOLINGOFTHECUTTINGZONEMAYBENECESSARYTOKEEPTHECHIPSFROMBECOMING“GUMMY”ANDSTICKINGTOTHETOOLSCOOLINGCANUSUALLYBEACHIEVEDWITHAJETOFAIR,VAPORMIST,ORWATERSOLUBLEOILSRESIDUALSTRESSESMAYDEVELOPDURINGMACHININGTORELIEVETHESESTRESSES,MACHINEDPARTSCANBEANNEALEDFORAPERIODOFTIMEATTEMPERATURESRANGINGFROMTOTO,ANDTHENCOOLEDSLOWLYANDUNIFORMLYTOROOMTEMPERATURETHERMOSETTINGPLASTICSAREBRITTLEANDSENSITIVETOTHERMALGRADIENTSDURINGCUTTINGTHEIRMACHINABILITYISGENERALLYSIMILARTOTHATOFTHERMOPLASTICSBECAUSEOFTHEFIBERSPRESENT,REINFORCEDPLASTICSAREVERYABRASIVEANDAREDIFFICULTTOMACHINEFIBERTEARING,PULLING,ANDEDGEDELAMINATIONARESIGNIFICANTPROBLEMSTHEYCANLEADTOSEVEREREDUCTIONINTHELOADCARRYINGCAPACITYOFTHECOMPONENTFURTHERMORE,MACHININGOFTHESEMATERIALSREQUIRESCAREFULREMOVALOFMACHININGDEBRISTOAVOIDCONTACTWITHANDINHALINGOFTHEFIBERSTHEMACHINABILITYOFCERAMICSHASIMPROVEDSTEADILYWITHTHEDEVELOPMENTOFNANOCERAMICSANDWITHTHESELECTIONOFAPPROPRIATEPROCESSINGPARAMETERS,SUCHASDUCTILEREGIMECUTTINGMETALMATRIXANDCERAMICMATRIXCOMPOSITESCANBEDIFFICULTTOMACHINE,DEPENDINGONTHEPROPERTIESOFTHEINDIVIDUALCOMPONENTS,IE,REINFORCINGORWHISKERS,ASWELLASTHEMATRIXMATERIAL5THERMALLYASSISTEDMACHININGMETALSANDALLOYSTHATAREDIFFICULTTOMACHINEATROOMTEMPERATURECANBEMACHINEDMOREEASILYATELEVATEDTEMPERATURESINTHERMALLYASSISTEDMACHININGHOTMACHINING,THESOURCEOFHEATATORCH,INDUCTIONCOIL,HIGHENERGYBEAMSUCHASLASERORELECTRONBEAM,ORPLASMAARCISFORCES,BINCREASEDTOOLLIFE,CUSEOFINEXPENSIVECUTTINGTOOLMATERIALS,DHIGHERMATERIALREMOVALRATES,ANDEREDUCEDTENDENCYFORVIBRATIONANDCHATTERITMAYBEDIFFICULTTOHEATANDMAINTAINAUNIFORMTEMPERATUREDISTRIBUTIONWITHINTHEWORKPIECEALSO,THEORIGINALMICROSTRUCTUREOFTHEWORKPIECEMAYBEADVERSELYAFFECTEDBYELEVATEDTEMPERATURESMOSTAPPLICATIONSOFHOTMACHININGAREINTHETURNINGOFHIGHSTRENGTHMETALSANDALLOYS,ALTHOUGHEXPERIMENTSAREINPROGRESSTOMACHINECERAMICSSUCHASSILICONNITRIDE6SUMMARYMACHINABILITYISUSUALLYDEFINEDINTERMSOFSURFACEFINISH,TOOLLIFE,FORCEANDPOWERREQUIREMENTS,ANDCHIPCONTROLMACHINABILITYOFMATERIALSDEPENDSNOTONLYONTHEIRINTRINSICPROPERTIESANDMICROSTRUCTURE,BUTALSOONPROPERSELECTIONANDCONTROLOFPROCESSVARIABLES中文翻译切削加工性1、一种材料的切削加工性通常从四个方面来定义1、已切削部分的表面光洁度和表面完整性。2、刀具的寿命。3、切削力和切削的功率需求。4、切屑控制。由上述可知,好的切削加工性指的是好的表面光洁度和完整性,长的刀具寿命,低切削力和功率需求。至于切屑控制,细长而卷曲的切屑,如果没有及时清理,就会在切削区缠绕,严重影响切削工序。由于切削工序的复杂性,因此很难建立一个定量确定一种材料切削加工性的关系式。在制造厂里,刀具寿命和表面粗糙度通常被认为是切削加工性中最重要的影响因素。尽管切削性能指数使用的并不多,但基本的切削性能指数在下面的材料中仍然被使用。2钢的切削加工性因为钢是最重要的工程材料之一(如第5章所示),所以它的切削加工性已经被广泛地研究过。通过加入铅和硫磺,可以使钢的切削加工性得到大幅度地提高。从而得到了所谓的高速切削钢。二次硫化钢和二次磷化钢硫在钢中形成硫化锰夹杂物(第二相粒子),这些夹杂物在第一剪切区形成应力集中元。其结果是使切屑容易断开而变小,从而改善了切削加工性。这些夹杂物的大小、形状、分布和集中程度显著的影响切削加工性。化学元素如碲和硒,其化学性质与硫类似,在二次硫化钢中起杂质改性作用。钢中的磷有两个主要的作用。第一它加强铁素体,增加硬度。越硬的钢,就会对切屑的形成和表面光洁度越有利。需要注意的是软钢是很难加工的,因为软钢加工容易产生积削瘤而且表面光洁度差。第二个作用是硬度增加会引起短切屑的形成而不是连续细长的切屑的形成,因此提高切削加工性。铅钢钢中高含量的铅在硫化锰杂质尖端析出。在非二次硫化钢中,铅呈细小而分散的颗粒。铅在铁、铜、铝和它们的合金中是不能溶解的。由于它的低抗剪强度,铅在切削时充当固体润滑剂,被涂在刀具和切屑的分界处。这一特性已经被证实在切削加工铅钢时,在刀具横向表面的切屑上有高浓度的铅存在。当温度足够高时例如,在高的切削速度和进刀速度下铅在刀具前直接熔化,并且充当液体润滑剂。除了这个作用外,铅还可以降低第一剪切区中的剪应力,减小切削力和降低功率消耗。铅能用于各种型号的钢,例如10XX,11XX,12XX,41XX等等。铅钢由型号中第二和第三数码中的字母L识别(例如,10L45)。(需要注意的是在不锈钢中,字母L指的是低碳,这是提高不锈钢耐腐蚀性的先决条件)。然而,因为铅是众所周知的毒素和污染物,因此在钢的使用中存在着严重的环境隐患(在钢产品中每年大约有4500吨的铅消耗)。于是,消除铅在钢中使用是一个必然的趋势(无铅钢)。铋和锡现正作为最可能替代钢中铅的物质而被人们所研究。脱氧钙钢一个重要的发展是脱氧钙钢,在脱氧钙钢中可以形成硅酸钙的氧化物片。这些片状物,可以减小第二剪切区中的应力,降低刀具和切屑分界处的摩擦和磨损。温度也相应地降低。于是,这种钢产生更小的月牙洼磨损,特别是在高速切削时更是如此。不锈钢通常奥氏体钢很难进行切削加工。振动可能是一个问题,这必需要求机床有足够的刚度。然而,铁素体不锈钢有很好的切削加工性。马氏体钢易磨蚀,易于形成积屑瘤,并且要求刀具材料有高的热硬性和耐月牙洼磨损性。经沉淀硬化的不锈钢强度高、磨蚀性强,因此要求刀具材料硬度高而耐磨。钢中其它元素对切削加工性能的影响钢中铝和硅元素的存在总是有害的,因为这些元素结合氧会生成氧化铝和硅酸盐,而氧化铝和硅酸盐硬度高且具有磨蚀性。这些化合物会加快刀具磨损,降低切削加工性。因此生产和使用净化钢是非常必要的。根据它们的构成,碳和锰在钢的切削加工性方面有各种不同的影响。低碳钢(少于015的碳)容易形成积屑瘤而使毛坯的表面光洁度很低。铸钢的切削加工性和锻钢的大致相同,但铸钢更容易磨蚀。工具钢和模具钢很难用于切削加工,通常是在切削加工之前进行退火处理。大多数钢的切削加工性在冷加工后都有所提高,冷加工能使材料变硬而减少积屑瘤的形成。其它合金元素,例如镍、铬、钼和钒,能改善钢的特性,而通常会钢减小切削加工性。硼的影响可以忽视。气态元素比如氢和氮在钢的特性方面有特别有害的影响。氧已经被证明了在硫化锰夹杂物的纵横比方面有很强的影响。含氧量越高,纵横比越低且切削加工性越好。在选择各种元素以改善切削加工性时,我们应该考虑这些元素对已加工零件在使用中的性能和强度的不利影响。例如,当温度升高时,铅会使钢变脆,尽管其在室温下对机械性能没有影响。由于硫化铁的构成,硫元素能严重的降低钢的热加工性,除非有足够的锰元素来防止这种结构的形成。在室温下,二次硫化钢的机械性能取决于变形的硫化锰夹杂物的定位(各向异性)。二次磷化钢具有更小的延展性,被单独生成来提高切削加工性。3其它不同金属的切削加工性尽管越软的材料更易于生成积屑瘤而导致很差的表面光洁度,但铝通常很容易进行切削加工。这需要高的切削速度,高的前角和后角。铸铝合金和高含量硅的锻铝合金可能具有磨蚀性,它们要求刀具材料硬度更高。在加工铝材料的工件时尺寸公差控制可能会是一个难题,这是因为它具有高热膨胀系数和相对较低的弹性模数。铍和铸铁相似。由于它更具磨蚀性和毒性,于是它需要在可控环境下进行加工。灰铸铁通常是可进行切削加工的,但也有磨蚀性。铸件中的游离碳化物降低它们的切削加工性,容易导致刀具破裂或裂口,因此它需要具有强韧性的刀具。在刀具具有足够硬度的情况下球墨铸铁和可锻铸铁是可加工的。钴

- 温馨提示:

1: 本站所有资源如无特殊说明,都需要本地电脑安装OFFICE2007和PDF阅读器。图纸软件为CAD,CAXA,PROE,UG,SolidWorks等.压缩文件请下载最新的WinRAR软件解压。

2: 本站的文档不包含任何第三方提供的附件图纸等,如果需要附件,请联系上传者。文件的所有权益归上传用户所有。

3.本站RAR压缩包中若带图纸,网页内容里面会有图纸预览,若没有图纸预览就没有图纸。

4. 未经权益所有人同意不得将文件中的内容挪作商业或盈利用途。

5. 人人文库网仅提供信息存储空间,仅对用户上传内容的表现方式做保护处理,对用户上传分享的文档内容本身不做任何修改或编辑,并不能对任何下载内容负责。

6. 下载文件中如有侵权或不适当内容,请与我们联系,我们立即纠正。

7. 本站不保证下载资源的准确性、安全性和完整性, 同时也不承担用户因使用这些下载资源对自己和他人造成任何形式的伤害或损失。

人人文库网所有资源均是用户自行上传分享,仅供网友学习交流,未经上传用户书面授权,请勿作他用。

川公网安备: 51019002004831号

川公网安备: 51019002004831号