【温馨提示】 购买原稿文件请充值后自助下载。

以下预览截图到的都有源文件,图纸是CAD,文档是WORD,下载后即可获得。

预览截图请勿抄袭,原稿文件完整清晰,无水印,可编辑。

有疑问可以咨询QQ:414951605或1304139763

双螺杆压缩机的设计

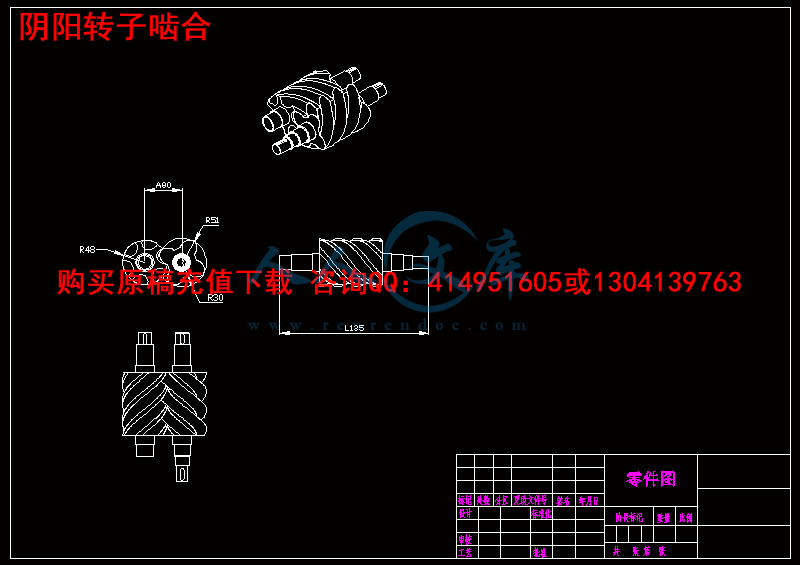

【摘要】双螺杆压缩机是一种比较新颖的压缩机,因其可靠性高、操作维修方便、动力平衡性好、适应性强等优点,而广泛地应用于矿山、化工、动力、冶金、建筑、机械、制冷等工业部门。双螺杆压缩机已经超过所有工业压缩机的50 %,其市场份额超过80 %,今后其市场份额还将继续扩大。可见,研究双螺杆压缩机具有十分重要的意义。本课题主要是设计通用的喷油双螺杆空气压缩机,采用单边不对称摆线-销齿圆弧型型线,阴、阳转子齿数比为6:4。设计新型转子型线,目的是使接触线长度、泄漏三角形面积和封闭余隙容积3者达到最优化设计,以进一步提高双螺杆压缩机的机械性能。重点研究的是双螺杆压缩机的转子型线设计、几何特性、受力分析、热力学计算。

【关键词】双螺杆压缩机 转子型线 啮合线 齿间容积

The design of twin screw compressor

[Abstract] The twin-screw compressor is a kind of newly emerging compressor. Because of its high reliability, easy repair, good balance and good adaptability etc, and widely applied to such industrial departments as mine, chemical industry, power, metallurgy, architecture, machinery, refrigeration, etc. By designing the project, the volumetric efficiency is 70%, the compressed temperature is more 80℃。It is very important to design and research a twin-screw compressor in industrial. The project is to design a universal twin-screw air compressor, and to adopt single side asymmetric swept line unilaterally and dowel tooth circular rotor profile. There are six lobes on the female rotor and four lobes on the male rotor. The aim of designing a new rotor profile is to optimize the contact line length, blowhole area and clearance volume. That can improve the mechanical performance of a twin-screw compressor further. The project is mainly to research a twin-screw compressor rotor profile, geometry characteristic, mechanics analysis, thermodynamics calculation

[Keywords] A twin-screw compressor, rotor profile, mesh curve, tooth space volume.

目 录

毕业设计(论文)任务书…………………………………………………………………..Ⅰ

开题报告………………………………………………………………………………….Ⅱ

指导教师审查意见……………………………………………………………………….Ⅲ

评阅教师评语…………………………………………………………………………….Ⅳ

答辩会议记录…………………………………………………………………………….Ⅴ

中文摘要………………………………………………………………………………….Ⅵ

外文摘要………………………………………………………………………………….Ⅶ

前言…………………………………………………………………………………. ….1

1选题背景……………………………………………………………………………. ….3

1.1研究双螺杆压缩机的目的和意义……………………………………………3

1.2双螺杆压缩机的特点和应用前景……………………………………………3

1.3国内外双螺杆压缩机研究的进展……………………………………………5

1.4双螺杆压缩机基本结构和工作原理…………………………………………6

2双螺杆压缩机的转子型线设计……………………………………………………. ….9

2.1转子型线设计原则……………………………………………………………9

2.2型线方程和啮合线方程………………………………………………………10

2.3单边不对称摆线-销齿圆弧型线………………………………………… … 10

3双螺杆压缩机螺杆尺寸的确定……………………………………………………. …23

4几何特性……………………………………………………………………………. …23

4.1齿间面积和面积利用系数……………………………………………………23

4.2齿间容积及其变化过程………………………………………………………24

4.3扭角系数及内容积比…………………………………………………………27

5双螺杆压缩机的热力学计算……………………………………………………. …28

5.1内压力比………………………………………………………………………28

5.2容积流量及容积效率…………………………………………………………28

5.3轴功率…………………………………………………………………………29

5.4电动机功率……………………………………………………………………31

5.5电功率…………………………………………………………………………31

6双螺杆压缩机的结构设计……………………………………………………………31

7双螺杆压缩机的力学计算……………………………………………………………31

7.1径向力的计算…………………………………………………………………32

7.2轴承支反力的计算……………………………………………………………34

7.3轴向力的计算…………………………………………………………………34

8双螺杆压缩机的吸、排气孔口设计…………………………………………………35

8.1吸气孔口………………………………………………………………………36

8.2排气孔口………………………………………………………………………37

9主要零部件设计和选材……………………………………………………………. .38

10双螺杆压缩机压力脉动计算………………………………………………………39

结束语………………………………………………………………………………. …43

参考文献…………………………………………………………………………. …. .44

附录………………………………………………………………………………. …. .Ⅸ

前 言

双螺杆压缩机属于回转式压缩机。回转式压缩机是一种工作容积作旋转运动的容积式气体压缩机械。气体的压缩是通过容积的变化来实现,而容积的变化又是借压缩机的一个或几个转子在气缸里作旋转运动来达到。回转式压缩机的工作容积不同于往复式压缩机,它除了周期性地扩大和缩小外,其空间位置也在变更。

回转式压缩机靠容积的变化来实现气体的压缩,这一点与往复式压缩机相同,它们都属于容积式压缩机;回转式压缩机的主要机件(转子)在气缸内作旋转运动,这一点又与速度式压缩机相同。所以,回转式压缩机同时兼有上述两类机器的特点。

回转式压缩机没有往复运动机构,一般没有气阀,零部件(特别是易损件)少,结构简单、紧凑,因而制造方便,成本低廉;同时,操作简便,维修周期长,易于实现自动化。

回转式压缩机的排气量与排气压力几乎无关,与往复式压缩机一样,具有强制输气的特征。

回转式压缩机运动机件的动力平衡性良好,故压缩机的转数高、基础小。这一优点,在移动式机器中尤为明显。

回转式压缩机转数高,它可以和高速原动机(如电动机、内燃机、蒸汽轮机等)直接相联。高转数带来了机组尺寸小、重量轻的优点。同时,在转子每转一周之内,通常有多次排气过程,所以它输气均匀、压力脉动小,不需设置大容量的储气罐。

回转式压缩机的适应性强,在较大的工况范围内保持高效率。排气量小时,不像速度式压缩机那样会产生喘振现象。

在某些类型的回转式压缩机(如罗茨鼓风机、螺杆式压缩机)中,运动机件相互之间,以及运动机件与固定机件之间,并不直接接触,在工作容积的周壁上无需润滑,可以保证气体的洁净,做到绝对无油的压送气体(这类机器成为无油回转压缩机)。同时,由于相对运动的机件之间存在间隙以及没有气阀,故它能压送污浊和带液滴、含粉尘的气体。

但是,回转式压缩机也有它的缺点,这些缺点是:

由于转数较高,加之工作容积与吸排气孔口周期性地相通、切断,产生较为强烈的空气动力噪声,其中螺杆式压缩机、罗茨鼓风机尤为突出,若不采取消音措施,即不能被用户所利用。

许多回转式压缩机,如螺杆式、罗茨式、转子式等,运动机件表面多呈曲面形状,以其啮合运动使工作容积改变,这些曲面的加工及其校验均较复杂,有的还需使用专用设备。

回转式压缩机工作容积的周壁,大多不是圆柱形,使运动机件之间或运动机件与固定机件之间的密封问题较难满意解决,通常仅以其间保持一定的运动间隙达到密封,气体通过间隙势必产生泄漏,这就限制了回转式压缩机难以达到较高的终了压力。

回转式压缩机的形式和结构类型较多,分类也各有不同。

按转子的数量区分:单转子和双转子回转式压缩机,个别情况下还有多转子回转式压缩机;

按气体压缩的方式区分:有内压缩和无内压缩回转式压缩机;

按工作容积是否有油(液)区分:有无油(液)和喷油(液)回转式压缩机。

通常都按结构元件的特征区分和命名,目前广为使用的有罗茨鼓风机、滑片式压缩机和螺杆式压缩机。此外,单螺杆压缩机、液环式压缩机、偏心转子式压缩机以及旋转活塞式压缩机等在不同领域内也得到应用。

上述各种回转式压缩机,除罗茨鼓风机属无内压缩的机器外,其余均是有内压缩的机器。

双螺杆压缩机是一种很年轻的压缩机型,在最近二十五年才发展成熟,形成系列化。约在一百多年前,人们已经知道双螺杆压缩机的工作原理,但类似今天设计的双螺杆压缩机的诞生日,则应该是在1934年,SRM工厂的总工程师A•利斯霍尔姆(A•Lysholm)的专利出现的时候。后来,又发明了圆弧形齿,非对称齿形SRM和今天的第四代节能型。

回转式压缩机大多作为中、小排气量,中、低压压缩机或鼓风机之用。目前,回转式压缩机在冶金、化工、石油、交通运输、机械制造以及建筑工程等工业部门得到广泛的应用;随着人民生活水平的逐步提高,在耐用消费品中也将得到广泛的应用。

1 选题背景

1.1 研究双螺杆压缩机的目的和意义

本设计题目来源是自选科研。本课题主要是设计通用的喷油双螺杆空气压缩机。在深刻理解前人研究的理论基础上,在给定设计参数和设计要求的条件下,研究双螺杆压缩机的转子型线、几何特性、工作过程、受力分析及转子的加工,以进一步提高双螺杆压缩机的机械性能。设计新型转子型线,使接触线长度、泄漏三角形面积和封闭余隙容积3者达到最优化。利用自备砂轮修正器的转子专用数控磨床,快速加工出新型线的转子,使转子的精度和表面粗糙度预计超过现有的值。设计吸气孔口的形状和合理位置,来提高压缩机效率。同时,研究型线和孔口配置等因素对噪声的影响指标,从而更有效地降低噪声。通过设计双螺杆压缩机,可以了解双螺杆压缩机的发展历程、研究现状和发展方向;深入理解双螺杆压缩机的基本结构、特点、主要零部件设计选型、主机结构设计和机组系统设计;重点研究的是双螺杆压缩机的转子型线、几何特性、工作过程、受力分析、转子加工和主要设计参数的确定。通过设计,能了解设计的一般要求和规则,能将理论知识与生产实际联系起来。

双螺杆压缩机是一种比较新颖的压缩机,因其可靠性高、操作维修方便、动力平衡性好、适应性强等优点,而广泛地应用于矿山、化工、动力、冶金、建筑、机械、制冷等工业部门。统计数据表明,螺杆压缩机的销售量已占所有容积式压缩机销售总量的80%以上,在所有正在运行的容积式压缩机中,有50%是螺杆压缩机,今后螺杆压缩机的市场份额仍将不断扩大。可以看出,螺杆压缩机的设计研究在工业生产中具有十分重要的意义。通过本设计,可以充分了解双螺杆压缩机的有关知识,以及如何进一步改善其性能和扩大其应用范围,使双螺杆压缩机能得到更好的发展,为生产和生活服务。可以将所学理论知识与生产实际联系起来,并积累了宝贵的经验,为以后的工作打下了一个坚实的基础。

川公网安备: 51019002004831号

川公网安备: 51019002004831号