玉米钵苗移栽打穴机构设计【优秀农业用机械设备全套课程毕业设计含SW三维3D建模及12张CAD图纸+带答辩ppt+22页加正文12000字】

【详情如下】【需要咨询购买全套设计请加QQ1459919609】

3djm.stp

SW三维建模.zip

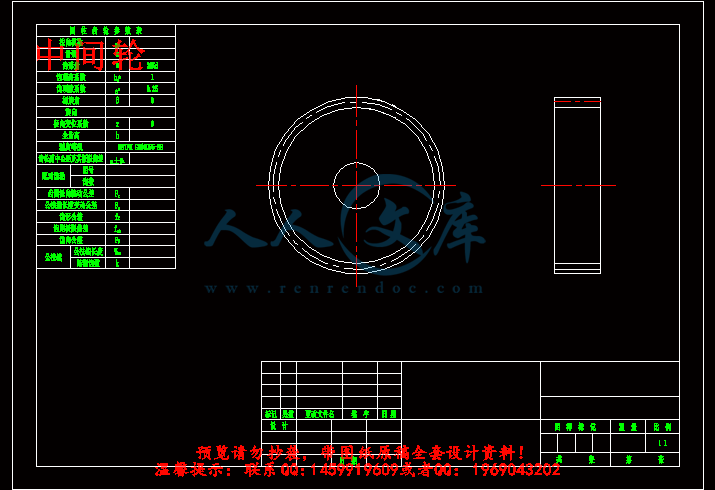

中间轮.DWG

凸轮.DWG

凸轮导块.dwg

凸轮盘.dwg

凸轮顶杆.dwg

参考文献资料.zip

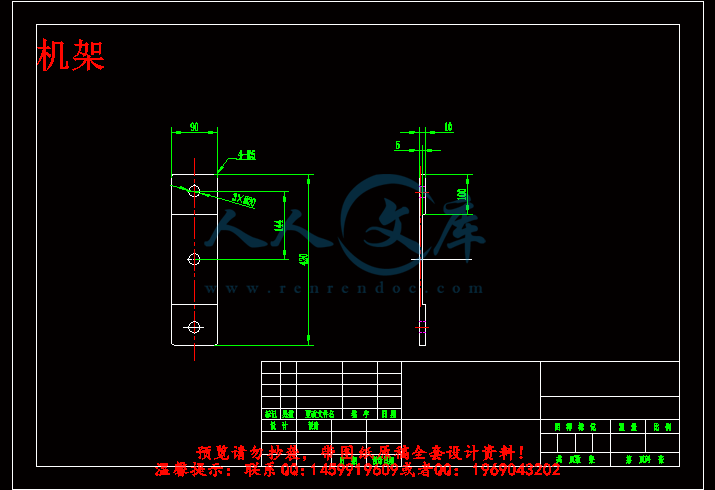

机架.dwg

玉米钵苗移栽打穴机构设计.doc

玉米钵苗移栽打穴机构设计答辩PPT.ppt

行星臂.dwg

行星齿轮.dwg

装配图.dwg

轴.dwg

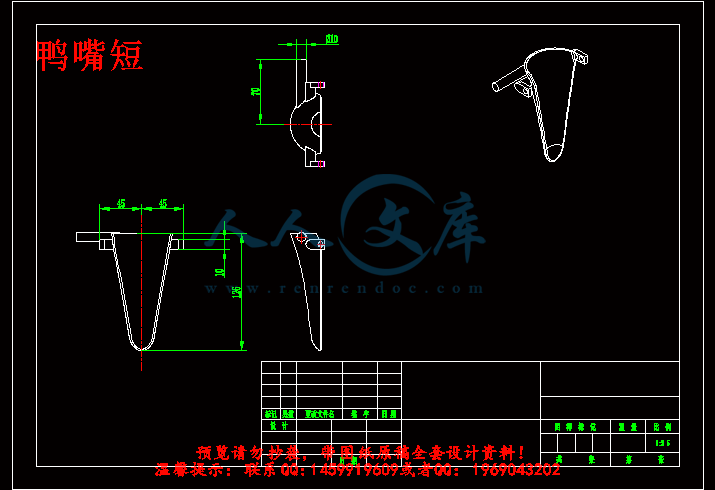

鸭嘴短.DWG

鸭嘴长.DWG

摘要

育苗移栽能够提早作物的生育进程、提高单产,能有效抵御大风、雨害、低温等自然灾害,并且节省种子。由于黑龙江的地理条件等因素,通常都采用铺膜种植的方式来提高地温,保墒,还能够抑制很多杂草。要实现膜上打穴移栽,保质保量的在紧迫的春种季节完成移栽,是农民丰产丰收的前提。

在我国,打穴移栽作为一种常规的农业生产技术己在生产实际中得到广泛应用,但是,传统的人工打穴移栽方法存在的劳动强度大、劳动生产率低、移栽速度慢、经济效益差等问题始终没有得到有效的解决,实现打穴移栽机械化已成为生产中迫切需要解决的问题。

由于需要栽植的作物及作业条件的不同,相应的移栽方式及栽植机械也有多种类型。按照移栽作物种类来分,有玉米移栽、甜菜移栽、棉花移栽、蔬菜移栽、烟叶移栽、花卉及树苗移栽等;按照栽植的土地情况来分,有平地移栽、垄上移栽、膜上移栽、打穴移栽和免耕覆盖地移栽等;按照移栽秧苗的状态来分,有钵苗(营养土钵、纸钵、穴盘基质钵等)移栽和裸苗(无土苗)移栽。在移栽的同时,还要进行注水、施肥、施药及铺膜等联合作业。

栽植机械的核心部件是栽植器。按照栽植器的不同,栽植机械主要有钳夹式、链夹式、挠性圆盘式、导苗管式、吊杯式和输送带式等型式。

按照打穴栽植与零速植苗运动要求,提出了一种摆线形栽植轨迹,并引入了设计参数。在此基础上,研究了平行四边形机构、六连杆机构,并最终设计了行星轮转臂式栽植机作为所设计的栽植机构,它调整简单方便,能够较大的提高整机的工作效率,降低了漏苗率。通过对现有移栽机的各种优点进行学习借鉴,并以三维设计软件solidwbrks为平台,绘制了移栽机构的三维模型及图纸。为今后的移栽机发展提供了提供了技术支撑。

关键词:打穴;行星轮转臂;移栽机;钵苗

Based on SolidWorks membrane

drum planting design

ABSTRACT

Seedling transplanting to early birth process, improve the yield of crop, can effectively resist natural disasters, such as wind, rain, low temperatures and save seeds. Due to factors such as geographical condition of heilongjiang, usually adopts the membrane planting way to increase the ground temperature, keep moisture, also can inhibit many weeds. To achieve constructio n membrane transplanting, complete transplanting in pressing spring season with good quality, is the precondition of farmers rich harvest.

Constructio n in our country, the transplant as a conventional agricultural production technology has widely used in the actual production, however, the traditional artificial constructio n transplanting method existing in the labor intensity, low labor productivity, transplanting problem of slow speed and poor economic benefits always haven't been solved effectively, and realize the constructio n of transplanting mechanization has become an urgent need to solve problems in production.

Due to the different need planting crops and their work conditions, the corresponding way of transplanting and planting machinery also has a variety of types. Points, according to the transplanting crop varieties have corn, sugar beets transplanting transplanting, cotton transplanting transplanting, vegetables, tobacco transplanting, flower and seedling transplanting, etc; Points, according to the cultivated land situation have flat transplanting, transplanting ridges, membrane transplanting, constructio n transplanting and no-till cover transplanting and so on; Points, according to the state of transplanting seedlings have pot seedling (nutritional soil bowls, paper pot, pot hole tray matrix, etc.) transplanting and naked seedling soilless seedling transplanting. While transplanting, and water, fertilizer, pesticide and membrane joint operations.

The core component of plant machinery is planting apparatus. According to the planting of different, plant machinery mainly pliers clip type, chain type, flexible disc type, seedling guide tube, hanging cup type and type of conveyor, etc.

In accordance with requirements of the constructio n planting and seeding zero speed movement, put forward a kind of pendulum linear trajectory, planting and introduced the design parameters. On this basis, the parallelogram mechanism, six bar linkage is studied, and the final design of the planetary rotary arm type planting machine as the planting design institution, it can be changed easily, can great enhance the working efficiency, reduces the leakage rate. Through the various advantages of existing transplanting machine learning model, and with 3 d design software solidwbrks for platform, mapped the transplanting mechanism of 3 d model and drawings. For the future of the transplanter development provides technical support.

Key words: construction; Planetary rotary arm; Transplanting machine; Pot seedling

目 录

摘要 II

ABSTRACT II

目 录 1 -

1前言 - 1 -

1.1课题研究的目的和意义 - 1 -

1.2国内外研究现状 - 1 -

1.2.1国内移栽机研究现状 - 1 -

1.2.2国外移栽机研究现状 - 2 -

1.2.3移栽机栽植机构的研究现状 - 3 -

1.3研究内容 - 6 -

2栽植机构选型 - 7 -

2.1栽植机构轨迹要求 - 7 -

2.2关于零速投苗问题 - 7 -

2.3栽植机构选型 - 8 -

2.3.1平行四边形栽植机构 - 8 -

2.3.2六杆式栽植机构 - 8 -

3行星轮转臂式栽植机构设计 - 9 -

3.1行星轮转臂式栽植机构结构组成 - 9 -

3.2行星轮转臂式栽植机构的运动分析 - 10 -

3.3行星轮转臂式栽植机构设计参数关系 - 11 -

3.3.1移栽机前进速度、株距和栽植频率的关系 - 11 -

3.3.2 栽植器数量、栽植器转速与栽植器频率的关系 - 11 -

3.3.3 行星架长度、株距和栽植器数量的关系 - 11 -

3.3.4 结构参数的确定 - 11 -

4鸭嘴式栽植器及其开合机构的设计 - 12 -

4.1鸭嘴式栽植器的选型 - 12 -

4.2鸭嘴式栽植器的结构设计 - 12 -

4.3鸭嘴式栽植器开和机构的设计 - 12 -

4.4 凸轮推程设计 - 13 -

结论 - 15 -

参考文献 - 16 -

致谢 - 18 -

1前言

1.1课题研究的目的和意义

众所周知作物栽培方式一般分为两大类:一类是直播方式,用播种机具或人将作物种子直接播于大田中的传统栽植方式:另一种是移栽方式,用机械的方式或人工将在温室中培育的钵苗栽植于田问。移栽相比于直播方式有以下优点:

(1)提高保苗率。我国北方地区春季气温低、有风沙、冻害、干旱等自然灾害,提前室外播种保苗率较低。采用温室或工厂化育苗移栽方法,幼苗期改在苗床培育,可以通过控制土壤温度、湿度、光照等幼苗期的生长环境,提高幼苗成活率和生长速度,减少外界不利环境对幼苗的侵害,提高保苗率。

(2)育苗移栽的作物钵苗根系发达、成熟一致,为机械化移栽、田间管理,收获等环节提供有力条件。

(3)调高土地利用率和复种指数。在外界环境温度低,气候不易种植的季节,可以在温室内小面积育苗,待外界环境适宜,再进行田间大面积移栽,使作物的生长在时间和空间上重叠,可以有效的缩短作物在大田的生长周期,有效利用土地资源,增加经济收入。这对无霜期短的地区(如我国的东北地区)和一年多茬种植地区,尤其具有重要意义。

育苗移栽相对于直播方式有很大优点,但是我国的育苗移栽机械种类单一,如比较成熟的钳夹式移栽机、吊杯式移栽机、挠性圆盘式移栽机与导苗管式移栽机,上述移栽机受栽植器的限制,栽植时都需要与开沟器配合使用,而玉米的栽植往往先起垄后移栽或者需要起垄覆膜移栽,上述栽植器往往不能够完成玉米的栽植,所以,设计能够进行垄上栽植或者是垄上覆膜栽植的栽植机构成为我国移栽机械化需要迫切解决的问题。

川公网安备: 51019002004831号

川公网安备: 51019002004831号