!【包含文件如下】【机械设计类】CAD图纸+word设计说明书.doc[16000字,38页]【需要咨询购买全套设计请加QQ97666224】.bat

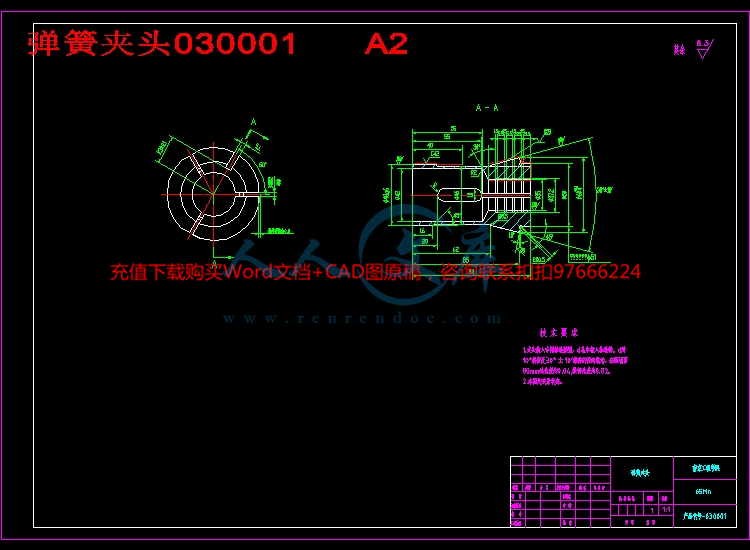

弹簧夹头030001 A2.dwg

拉杆030209 A3.dwg

推承套030005 A3.dwg

支撑架焊接图030010 A2.dwg

法兰030002 A3.dwg

法兰030006 A2.dwg

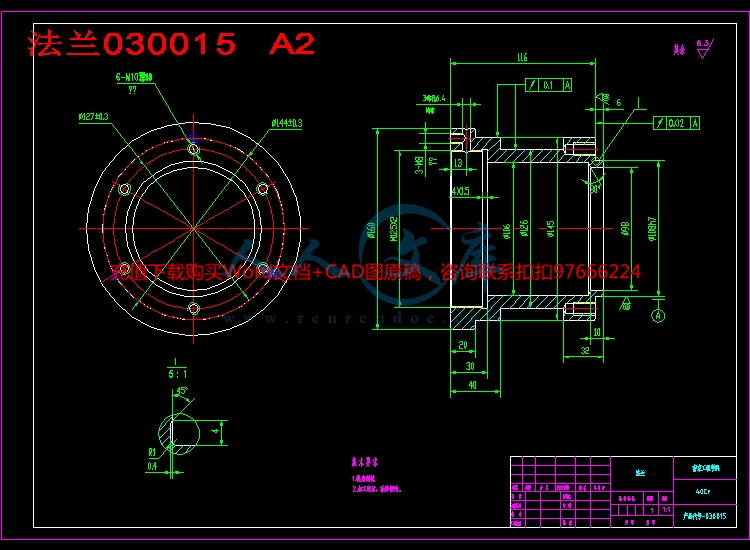

法兰030015 A2.dwg

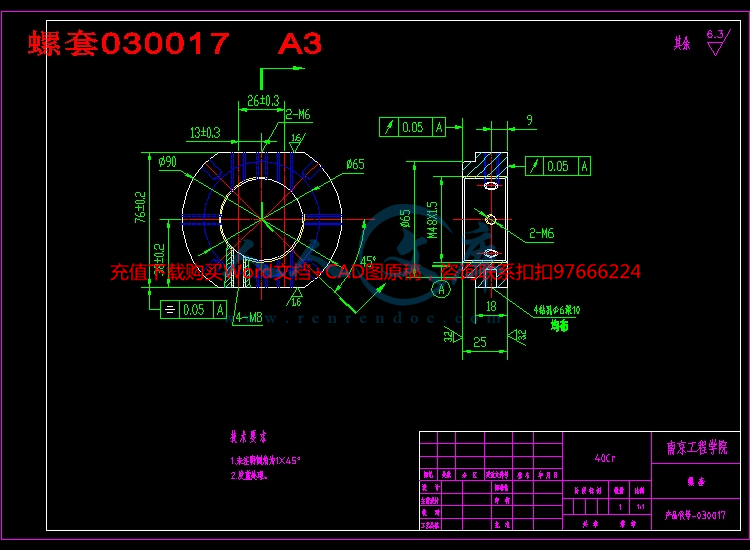

螺套030017 A3.dwg

螺母套030016 A3.dwg

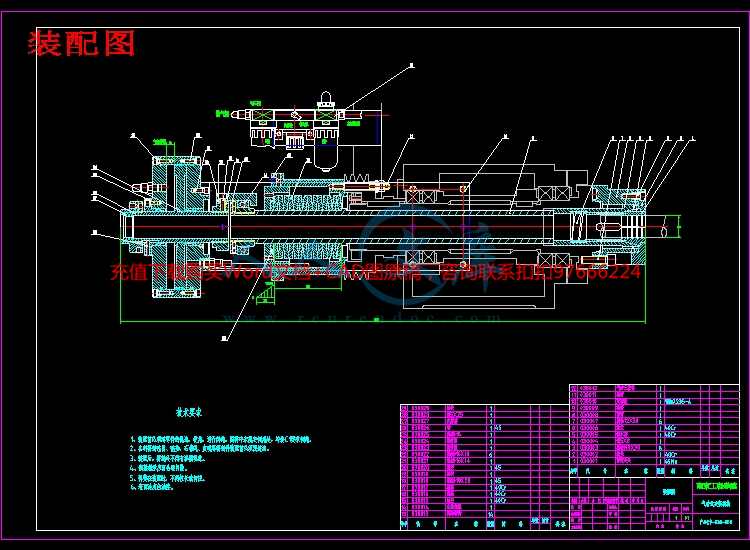

装配图.dwg

英文翻译

开题报告.doc

设计说明书.doc[16000字,38页]

摘要:

本文是设计了一种车床用碟形弹簧做动力时弹簧夹头夹紧及松开机构。该机构主要由弹簧夹头、拉杆、碟形弹簧、气动三联件等几部分组成。工作原理主要是通过螺母套对碟形弹簧施加一定的轴向力,碟形弹簧安装在拉杆上,间接对拉杆产生推动力推动推承套向右移动,推成套装配在弹簧夹头上,弹簧夹头与法兰相接触,利用推承套上的锥度形状将轴向力转换成径向力,使弹簧夹头产生夹紧力对工件实现夹紧。再通过气动三联件对气缸活塞杆产生推动力,而活塞杆与拉杆通过拨块相连接,所产生的推动力大于螺母套施加的力,拉杆得以向左移动,推承套失去推动力与弹簧夹头分离,弹簧夹头实现对工件的松开。

而本次设计的夹具与以往的卡爪式夹紧松开机构相比较,拥有更好的平衡性能、夹紧牢靠、结构紧凑、便于操作、加工及更换方便等主要优点。在主轴高速旋转的情况下,也能达到需要的平衡要求。是高效率和良好精度特点的现代车床夹具,可以有效地减少时间基本和配套工件加工的时间,大大提高了劳动生产率,有效地降低了劳动强度。

关键词:数控车床 夹紧机构 弹簧夹头 夹紧动力

毕业设计说明书 英文摘要

Title Design Control collet chuck clamping and release mechanism is in a lathe powered by a conical spring

Abstract

This article is designed to do when one kind of lathe with power disc spring collet chuck clamping and release mechanism. The agency consists of several parts collets, rod, disc springs, pneumatic FRL and other components. Works mainly on the disc springs exert a certain axial force through the nut sleeve, disc springs mounted on the rod, the rod indirectly generate driving force pushing the push bearing sleeve moves to the right, push the spring clip assembly head sets, spring chuck in contact with the flange using push bearing sleeve taper shape of the axial force is converted into a radial force, so that collet chuck generate clamping force on the workpiece clamping realization. And then the driving force generated by the cylinder piston rod pneumatic FRL, and the piston rod and the rod is connected by dialing block, the driving force is greater than the force exerted by the nut sleeve, lever to move to the left, push the bearing sleeve lose impetus with the spring chuck separation collets achieve workpiece release.

The design of the fixture and conventional jaw clamp release mechanism compared with a better balance of performance, clamping reliable, compact, easy to operate, processing and easy replacement of major advantages. In the case of the main shaft rotates at high speed, but also to achieve the desired balance requirements. Modern lathe fixture high efficiency and good accuracy characteristics, can effectively reduce the time basic and auxiliary workpiece machining time, greatly improving labor productivity, effectively reducing labor intensity.

Keywords: CNC lathes Clamping mechanism Collet chuck Clamping force

目 录

目 录 I

前 言 1

第一章 绪论 2

1.1车床夹具及其应用 2

1.1.1车床夹具的概述 2

1.1.2车床夹具的分类 3

1.1.3车床夹具的组成 4

1.2选题目的和意义 4

1.3国内外的研究现状和发展趋势 6

1.3.1弹簧夹头的发展 6

1.4车床上用碟簧作动力时弹簧夹头夹紧及松开机构。 8

第二章 弹簧夹头 10

2.1弹簧夹头及其应用 10

2.2弹簧夹头的主要尺寸 12

2.3弹簧夹头夹紧力计算 12

2.4弹簧夹头的技术要求 15

第三章 碟形弹簧 16

3.1碟形弹簧的结构和类型 16

3.1.1蝶形弹簧的基本概念 16

3.1.2碟形弹簧的分类 17

3.2碟形弹簧的尺寸系列 17

3.3碟形弹簧的设计计算 17

第四章 拉杆的设计 21

4.1确定拉杆的直径 21

4.2 设计拉杆的长度 21

4.3 拉杆的强度校核 21

第五章 气缸的选型分析 23

5.1确定气缸体的尺寸 23

5.2气缸的选择 24

5.3气缸密封件的选型分析 24

第六章 气动式夹紧机构的成本分析 25

6.1 成本分析的目的与意义 25

6.2 材料的成本计算 25

6.3 材料成本的构成 26

6.3.1 非标准件 26

6.3.2标准件购买花费 27

6.4 总成本的统计计算 28

结 论 29

致 谢 31

参考文献 32

附录A 装配图 零件图 33

附录B 毕业论文光盘资料 34

川公网安备: 51019002004831号

川公网安备: 51019002004831号