!【包含文件如下】【机械设计类】CAD图纸+word设计说明书.doc[18000字,40页]【需要咨询购买全套设计请加QQ97666224】.bat

任务书开题报告.docx

外文翻译.zip

设计说明书.doc[18000字,40页]

床身与立柱装配图.dwg

床身结构图.dwg

滚动直线导轨组图.dwg

滚珠丝杠组图.dwg

电机座.dwg

联轴器.dwg

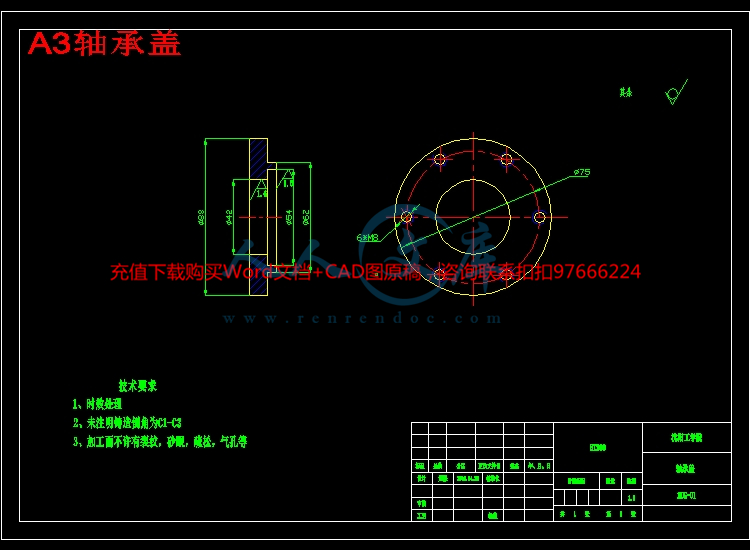

轴承座.dwg

摘 要

床身是立式加工中心非常重要的基础支撑件,它起到了支撑立柱、滑座、工作台等重要零部件的作用,主要承受机床的静载荷以及在加工时产生的切削负载。床身的静动态性能直接影响机床的加工精度和稳定性,因此,床身结构的优化对于立式加工中心的发展具有十分重要的意义,本课题即结合沈阳机床厂VMC850B立式加工中心的性能特点与相关参数,对立式加工中心床身结构进行了科学系统的设计,具体内容如下:

(1)借鉴于同类型的床身结构,根据VMC850B的整机结构设计了床身上表面布局,通过查阅《实用机床设计手册》《机械设计手册》等参考书,科学的设计了床身的截面形状,包括壁厚的选定以及加强肋、方孔、圆孔的合理布置。同时对床身进行了受力分析并利用ANSYS软件对床身模型采取了静态力有限元分析。

(2)针对与床身相关的重要零部件,包括Y方向伺服进给系统的驱动电机、滚珠丝杠、直线导轨、轴承、联轴器,进行了分析与计算,并最终确立了型号与参数。

(3)提出了床身的精度要求,包含加工和装配过程中的几何精度。

关键词:立式加工中心;床身;结构设计;选型计算;有限元分析;精度设计

Abstract

The bed is a very important basis for supporting parts in the vertical machining center, it plays a role that supporting the column, the slide, the workbench and some other important parts. The bed mainly withstands the static load of the machine tool and the cutting load in the processing. The static and dynamic performance of the bed directly affects the machining accuracy and stability. Therefore, the optimization of the bed structure has great significance for the development of the vertical machining centers. The subject, which is combined with the performance characteristics and parameters of the vertical machining center 850B of the Shenyang Machine Tool Factory, have designed the bed structure of the vertical machining center scientifically and systematically, the details are as follows:

(1)Learnt from the bed structure of the same type and designed the layout of the bed top surface under VMC850B’s whole structure, through accessing to <Practical Machine Design Manual> and <Mechanical Design Manual> and other reference books, scientifically designed the cross-sectional shape of the bed, including the selection of the wall thickness as well as the reasonable layout of the reinforcing rib, the square and circle holes. The subject also did the stress analysis for the bed and used the software called ANSYS to do the finite element analysis of the static force for the model of the bed.

(2)For the important parts of the bed, including the Y-direction servo feed drive motor, ball screws, linear guides ,bearings and couplings, did the analysis and the calculation, and eventually established the models and the parameters.

(3)Put forward the accuracy requirements of the bed, including the geometric precision of the machining and assembly process.

Keywords: the vertical machining ;center the bed ; structural design ;selection calculation finite element analysis ; precision design

目 录

1 机床设计现状 1

1.1 课题研究的背景和意义 1

1.2 国内外研究现状与发展趋势 2

1.3 本论文内容概要 4

2 床身结构设计 4

2.1 床身材料 4

2.2 床身时效处理 4

2.3 床身结构设计 5

2.3.1床身重要表面设计 5

2.3.2床身截面形状设计 5

2.4 床身热变形 10

2.5 床身结构确定方案 11

3 床身零部件的计算与选型 12

3.1 Y方向滚珠丝杠副的选择 12

3.1.1 初步计算丝杠导程 13

3.1.2 滚珠丝杠副当量载荷与当量转速计算 14

3.1.3计算预期额定动载荷 17

3.1.4 估算滚珠丝杠允许最大轴向变形 18

3.1.5估算滚珠丝杠副的底径 18

3.1.6 计算滚珠丝杠副预紧力 20

3.1.7 滚珠丝杠副剩余结构尺寸确定 20

3.2 伺服电机的选择 21

3.2.1电机的负载转矩计算 21

3.2.2 惯量匹配计算 22

3.2.3空载启动时最大加速力矩计算: 24

3.2.4快速空载启动时所需最大启动力矩计算 24

3.2.5 电动机连续匀速工作时的最大力矩 25

3.2.6 电动机输出端轴的直径计算 25

3.3 滚动轴承的选择 25

3.3.1 滚动轴承使用条件 26

3.3.2 初选止动球轴承型号 26

3.3.3 止推轴承组配方式 26

3.3.4 止推轴承的选用计算 27

3.3.5 圆柱滚子轴承的选型计算 29

结 论 31

致 谢 33

参考文献 34

川公网安备: 51019002004831号

川公网安备: 51019002004831号