!【包含文件如下】【机械设计类】CAD图纸+word设计说明书.doc[15000字,34页]【需要咨询购买全套设计请加QQ97666224】.bat

右侧板.dwg

块.dwg

套.dwg

工作台.dwg

左侧板.dwg

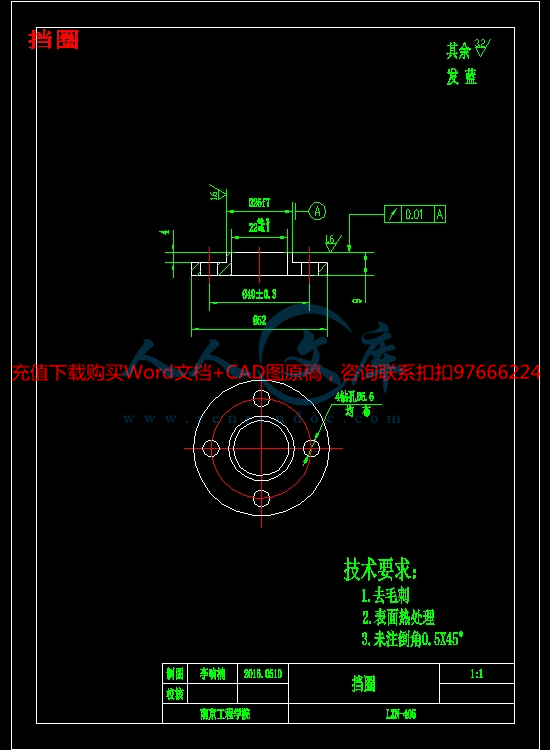

挡圈.dwg

挡块.dwg

数控铣床X轴进给系统结构设计-开题报告.doc

数控铣床X轴进给系统结构设计-英文翻译

设计说明书.doc[15000字,34页]

滚珠丝杆.dwg

螺母座.dwg

装配图.dwg

齿形皮带轮.dwg

摘要:

本文主要设计数控铣床X轴进给系统结构部分,熟悉数控铣床X轴进给系统主要零件。设定好进给系统机械传动部分刚度要求以及承载能力,分析计算X向受力要求,到进给传动各零件进行成本分析。采用类比法,进行数控铣床X轴进给系统的设计。保证工作台行程能够达到要求,进给系统要求结构紧凑、便于操纵、容易维护、加工及装配工艺性好,同时要保证足够传动精度,传动要平稳。机械结构采用伺服电机与滚珠丝杠间接相连的方式,使用同步带相连接。设计过程中对各个零件的受力分析以及X轴向惯量匹配、转矩匹配和进给力的精确计算增加了进给系统的传动精度以及平稳性。滚珠丝杠副即承受转矩又承受扭矩,所以选择角接触轴承。轴承采用串联背靠背配置方式,丝杠采用两端固定,在进给传动中要求有较好的润滑效果。本论文提高设计者对进给系统机械传动零件选择与设计,以及对零件采购与设计制造成本进行分析计算的能力。

关键词:进给传动 滚珠丝杠 轴承

毕业设计说明书(论文)英文摘要

Title Structure design of X axis feed system of NC milling machine

Abstract

In this paper, the design of CNC milling machine X axis feed system structure, familiar with CNC milling machine X axis feed system main parts. Set up the mechanical drive part of the feed system, as well as the load capacity, the analysis and calculation of the X to the force requirements, to feed and drive the cost analysis of the parts. The design of X axis feed system of CNC milling machine is carried out by analogy method. Ensure that the work station can meet the requirements, the system requires a compact structure, easy to operate, easy maintenance, processing and assembly process is good, but also to ensure adequate transmission accuracy, transmission to smooth. The mechanical structure adopts the method that the servo motor is connected with the ball screw in an indirect way, and the mechanical structure is connected with the synchronous belt. In the design process of the various parts of the force analysis and X axial inertia matching torque matching and the precision of the feed force to increase the transmission accuracy and stability of the feed system. Ball screw pair is bearing torque and torque, solid angle contact bearing. Bearing with series back-to-back configuration, with fixed ends, the feed drive requires a good lubrication effect. In this paper, the designer of the feed system to improve the mechanical transmission parts selection and design, as well as parts procurement and design manufacturing cost analysis and calculation of the ability.

Key words: Feed drive Ball screw pair Bearing

目录

前言 1

第一章?绪论 2

1.1选题背景及意义 2

1.2数控机床出现与影响 2

1.3数控系统演变 4

1.4数控铣床构成部件 5

1.5数控铣床功能特点 6

1.6数控机床分类及应用 7

第二章数控铣床进给传动部分设计 8

2.1传动方式选用 8

2.1.1进给传动特点 8

2.1.2滚珠丝杠副使用 8

2.2电机与丝杠连接方式的选择 10

2.3支承方法的选用 10

2.3.1轴承的选择 10

2.3.2轴承的配置方式 10

2.3.3预紧与间隙消除 12

第三章 X向进给系统结构设计 14

3.1已知条件数据 14

3.2滚珠丝杠副的计算 14

3.3 电机匹配计算 14

3.3.1 惯量匹配计算 14

3.3.2 转矩匹配计算 16

3.4 进给力计算 16

第四章?数控铣床进给传动的润滑与密封 17

4.1数控铣床进给传动润滑与密封的目的 17

4.2数控铣床进给传动的润滑 17

4.3数控铣床进给传动的密封 18

第五章 数控铣床X轴进给传动结构设计经济分析 19

5.1技术成本分析的目的与意义 19

5.2成本计算的依据 19

5.3成本材料的构成 20

5.3.1非标准件费用 20

5.3.2标准件购买花费 21

第六章?总结 23

致谢 26

参考文献 28

附录A 装配图 零件图 29

附录B 毕业论文光盘资料 30

川公网安备: 51019002004831号

川公网安备: 51019002004831号