!【包含文件如下】【机械设计类】CAD图纸+word设计说明书.doc[7000字,48页]【需要咨询购买全套设计请加QQ97666224】.bat

1轴装配图.dwg

2轴装配图.dwg

3轴装配图A2.dwg

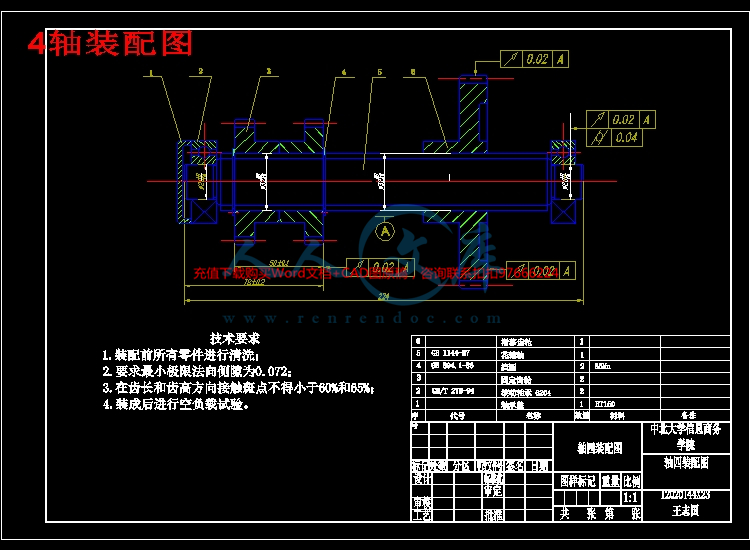

4轴装配图.dwg

主轴装配图.dwg

二维总装配图.dwg

任务书.doc

外文翻译 -.doc

开题报告+文献综述.doc

设计说明书.doc[7000字,48页]

摘要:CA6140车床作为主要的车削加工机床,在机械加工行业中得到了普遍的应用。CA6140车床主轴箱的主要功用是支撑并且传动主轴,使车床的主轴带动工件用特定的转速转动。本次毕业设计运用计算、验算、实验等方法,确定了运动方案和实现结构优化设计,通过功能设计与计算,运用Solidworks三维软件完成了零部件的建模与装配、实现装配动态仿真。将CA6140车床主轴箱的内部结构以及工作原理,更生动形象的表达出来。

关键词:CA6140机床主轴箱;建模与装配;三维结构设计;运动仿真

Three dimensional design and Simulation of the transmission of the CA6140 lathe main axle box

Abstract:The CA6140 lathe as the main turning processing machine tool, has been popular applied in the manufacturing industry. The main function of CA6140 lathe headstock is the support and transmission shaft, the lathe spindle drives the workpiece rotate with the prescribed speed. The design is based on the computation, analogy and experimental methods, completed to determine the motion scheme and structure design, the design and calculation, modeling and assembly, using Solidworks 3D software complete parts assembly,dynamic display. the internal structure of CA6140 lathe headstock and working principle, more vivid image expression。

Keywords: CA6140 machine; headstock; dimensional animation

目 录

摘要…………………………………………………………………………………………Ⅰ

Abstrat ……………………………………………………………………………………Ⅱ

目录…………………………………………………………………………………………Ⅲ

1 绪论..................................................................1

1.1 研究意义.............................................................1

1.2 研究现状.............................................................1

1.3 课题研究内容与方法...................................................1

1.4 设计方案可行性分析...................................................2

1.5 小结.................................................................2

2 总体设计方案..........................................................3

2.1 主轴箱的组成和特点...................................................3

2.2 主轴箱的主要参数.....................................................3

2.3 传动系统及其方案的确定...............................................4

3 车床主轴箱的设计计算..................................................6

3.1 主轴箱的箱体.........................................................6

3.2 Ⅰ轴主要零件设计计算.................................................7

3.3 Ⅱ轴主要零件设计计算................................................16

3.4 Ⅲ轴主要零件设计计算................................................22

3.5 Ⅳ轴主要零件设计计算................................................28

3.6 Ⅴ轴主要零件设计计算................................................31

3.7 Ⅵ轴主要零件设计计算................................................34

3.8 主轴箱的装配效果图..................................................36

3.9 小结................................................................39

4 车床主轴箱的运动仿真........................................................41

总结与展望.......................................................................43

致谢.............................................................................44

参考文献.........................................................................45

川公网安备: 51019002004831号

川公网安备: 51019002004831号