!【包含文件如下】【机械设计类】CAD图纸+word设计说明书.doc[10000字,28页]【需要咨询购买全套设计请加QQ97666224】.bat

数控铣床主轴.dwg

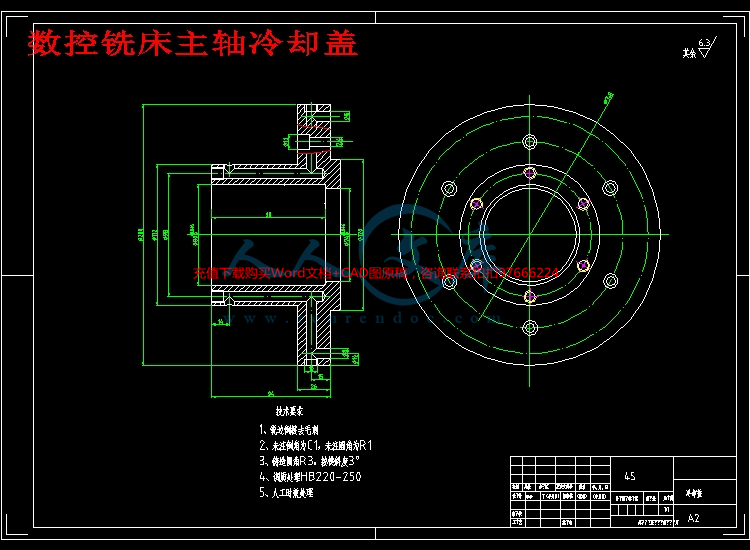

数控铣床主轴冷却盖.dwg

数控铣床主轴前轴承盖.dwg

数控铣床主轴后轴承盖.dwg

数控铣床主轴大外套.dwg

数控铣床主轴大套.dwg

数控铣床主轴密封盖.dwg

数控铣床主轴装配图.dwg

设计说明书.doc[10000字,28页]

中文.docx

任务书.doc

开题报告+文献综述.doc

英文.pdf

机床主轴设计及相关技术研究

摘要:随着我们的机械加工的不断发展,对于我们的加工零件的要求也在不断的变化和提高,在如今的加工设备中,有用到很多的铣床设备,数控铣床就是比较新式的加工设备,能够实现对我们的各种零部件进行各个工序的铣削加工,加工的精度比较高,生产的效率也高,尤其是对一些形状和结构尺寸比较特殊的工件,能够满足各个部位的精准加工工序,可以满足加工企业的各种要求。

本次我们设计的是数控铣床的主轴结构,是我们数控铣床的关键的零部件,也是我们加工设备的最主要核心部件,主轴的前端部分是跟我们的夹具结构直接连接的部分,带动我们的被夹持的工件进行高速旋转运动的,本次的主轴的工作时候的转速达到8000r/min,输出的功率达到5KW,此主轴结构能够使用40把不同的刀具。主轴的性能和质量的好坏直接会对我们加工的零件产生影响,因此我们对于主轴的设计,必须要求能够有好的强度和韧性,这样才能保证我们的铣床设备有着比较好的加工切削性能,满足我们对于工件的加工的需求。如今市面上的用的主轴结构种类较多,我们对于主轴结构的设计,可以在现有的主轴的基础上,更加注重去考虑工艺方面的完善,选择一个合理又比较经济的传动的方案,并对我们选用的相关的零部件进行计算和相应的校核,最后画出我们结构的装配图跟零件图。运用我们所学的机械传动的知识跟基础原理,完成毕业设计的任务,也能提高我们的动手操作的能力。

关键词:数控铣床;主轴;设计计算

Machine tool spindle design and related technology research

Abstract:With the continuous development of our machine, for the requirements of the processing parts also in constant change and improve, in today's processing equipment, useful to a lot of milling machine, CNC milling machine is a relatively new processing equipment to achieve various processes of milling to all parts of our, relatively high precision machining, production efficiency is high, especially for some of the shape, size and structure of special workpiece, can meet the needs of the various parts of the high precision machining process, and can satisfy the requirement of processing enterprises of all.

This we design is CNC milling machine spindle structure, is the key to our numerical control milling machine parts, is also our processing equipment the main core components, part of the front end of the spindle is with our fixture structure directly connected, driven by our by clamping the workpiece high-speed rotation movement, achieve the working time of the spindle 8000r / min speed and power output to 5kW, the spindle structure to 40 different tools to use. Spindle performance and quality is good or bad will directly influence to our processing of parts, so we for the design of the spindle must request to note Oh ah good strength and toughness, so as to ensure our milling equipment has a good cutting performance and satisfy our demand for machining the workpiece. Now on the market with the spindle structure of many kinds, we design for the main structure of can on the basis of existing spindle, pay more attention to to consider the improvement of process, select a reasonable and economical transmission scheme, and the checking calculation and corresponding to our selection of related parts, and finally draw the assembly drawing and parts drawing. Using the knowledge of the mechanical transmission and the basic principles, the completion of the task of graduation design, but also to improve the ability of our hands.

Key words: CNC milling machine ; principal axis ; design calculation

目 录

摘 要 Ⅰ

Abstract Ⅱ

目 录 Ⅳ

1 绪 论 1

2 数控铣床主轴的介绍 3

2.1 电主轴的工作原理 3

2.2 电主轴的特征 3

3 电主轴结构设计 5

3.1 电主轴结构图原理 5

3.2主轴伺服驱动器的选择 5

3.3 主轴的转子和定子的设计 5

3.4 轴承的选择 7

3.5 冷却系统的设计 8

3.5.1 热源的主要构成 8

3.5.2 主轴传动的热平衡计算 8

4 主轴的设计 10

4.1主轴的主要结构参数 10

4.1.1 前端悬伸量 10

4.1.2主支承间的跨距 10

4.1.3构造 10

4.1.4材料和热处理 10

4.1.5主轴的轴径 11

4.2 轴的强度校核计算 12

4.3 轴的刚度校核计算 15

5 轴承的校核 17

5.1 角接触球轴承的校核 17

5.2 深沟球轴承的校核 18

总结 20

参考文献: 21

致 谢 22

川公网安备: 51019002004831号

川公网安备: 51019002004831号