!【包含文件如下】【机械设计类】CAD图纸+word设计说明书.doc[10000字,33页]【需要咨询购买全套设计请加QQ97666224】.bat

外文翻译.pdf

开题报告+文献综述.doc

任务书.doc

设计说明书.doc[10000字,33页]

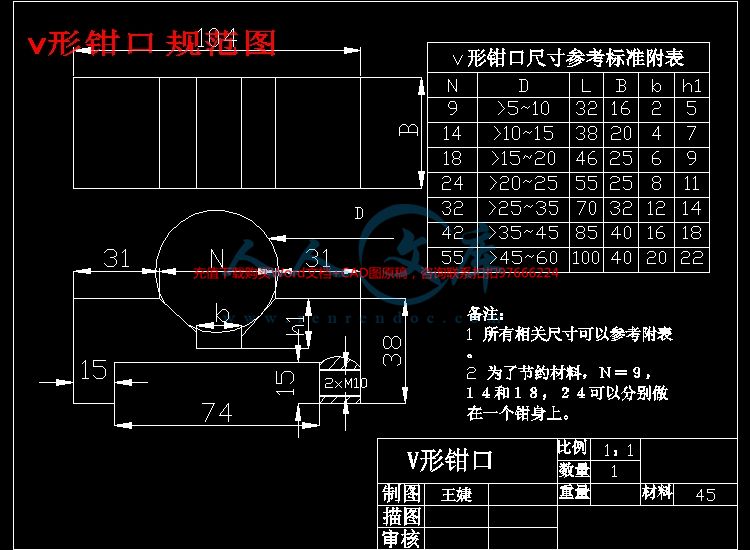

v形钳口规范图.dwg

固定钳身.dwg

方块螺母.dwg

最终装配图.dwg

活动钳口.dwg

虎口板.DWG

部分零件图.dwg

精密虎钳设计及其相关技术研究

摘要:虎钳在机械加工中有着很重要的作用。随着计算机应用的发展和机械加工技术的提高,CAD/CAE/CAPP/CAM技术的发展推动了几乎一切领域的设计、制造技术革命,从根本上改变了传统的设计、生产、管理模式。CAD/CAE/CAPP/CAM应用也用于机械设计中,台虎钳的设计也从过去一直沿用的二维设计方法开始发展为三维设计。在国内的一个小行业的业余爱好者进入一个小行业,取决于独立的夹具或。现代生产要求企业所制造的台虎钳经常更新换代,以适应市场的需求与竞争。然而,一般企业仍然使用传统的台式副,传统的副不好的加载剪辑形状更复杂的工件,夹紧力不强,夹紧速度慢。从而在影响加工效率的同时也造成了一定的经济损失。为了保证正常的生产,减少夹紧速度太慢,导致损失的人必须高度重视的问题,夹紧速度的板凳。设计了一种在生产加工中方便快捷地安装工件的夹紧,强大的夹紧力能较好的保证工件的快速夹紧工件的加工精度是必要的!本文从普通台虎钳入手,结合车床的结构特点,运用丝杠螺母结构,将普通的台虎钳设计成双自由度的台虎钳,满足更多情况下的机械加工的夹紧需要。

关键词:台虎钳,夹具,自由度,设计

Precision vise designs and related technology research

Abstract:Vice has a very important role in machining. With the improvement of the development of computer applications and machining technology, the development of CAD / CAE / CAPP / CAM technology promoted the almost all areas of design, manufacturing technology revolution, fundamentally changed the traditional design, production and management. CAD / CAE / CAPP / CAM application is also used in mechanical design, of the bench vice design from the past has been in use two-dimensional design method began development of 3D design. A vice in the domestic amateur into a small industry depends on the independent fixture or. Benchvice modern production requirements of enterprises have made frequent replacement, in order to adapt to the requirements of market and competition. However, Generally, however, companies are still accustomed to using the traditional bench vise, conventional clamping vise can better shape the more complex parts, the clamping force is not strong clamping slower, etc., thereby affecting the processing efficiency but also caused some economic losses. In order to ensure normal production and reduce losses caused due to the clamp too slow, people must attach great importance bench vise clamping speed issues. A design production and processing easy and fast workpiece clamping, high clamping force, can better ensure the machining accuracy of workpiece clamping vise quickly essential!This article from the ordinary bench vise, combining structural features of lathes, screw nut structure using the ordinary bench vise bench vise is designed with two degrees of freedom, to meet the need for mechanical clamping processing in case of more.

Keywords:bench,Fixture, Freedom,Design

目 录

摘要 I

Abstract II

目录 III

1 绪论 1

1.1 课题背景 1

1.2 台虎钳概述 1

1.3 台虎钳的作用 2

1.4 设计台虎钳的目的? 2

2 普通普通台虎钳的结构设计 3

2.1 台虎钳的结构? 3

2.2 台虎钳的分类?? 3

2.3 普通台虎钳的工作原理 3

2.4 对台虎钳各个零件的设计 4

2.4.1 固定钳座的设计 4

2.4.2 活动钳身的结构设计 5

2.4.3 方块螺母的结构设计 7

2.4.4 钳口板的结构设计 8

2.4.5 固定钳口板用螺钉的结构设计 9

2.4.6 固定活动钳身用螺钉的结构设计 10

2.4.7 螺母M10的选择设计 10

2.4.8 销的选择设计 11

2.4.9 螺杆的结构设计 11

2.4.10 螺杆的强度校核计算 12

2.4.11 垫片的选择设计 12

2.5 普通台虎钳使用的注意事项? 13

3 对台虎钳的部件(钳口)的结构改进 15

3.1 钳口的分析设想 15

3.2 V形钳口的分析 16

3.3 V形钳口的实例设计 18

3.4 V形钳口的实例设计 18

3.5 紧固螺钉的选择 19

4 台虎钳结构的装配 20

4.1 台虎钳的爆炸视图 20

4.2 装上V形钳口的台虎钳效果示意图: 20

5 双自由度设计 21

5.1 双自由度构想 21

5.2 虎钳双自由度结构 22

5.3 使用台虎钳的注意事项 23

5.4 双自由度虎钳设计思考 23

6 设计评定 25

7 结论总结 26

参考文献 27

致谢 29

川公网安备: 51019002004831号

川公网安备: 51019002004831号