【温馨提示】 购买原稿文件请充值后自助下载。

以下预览截图到的都有源文件,图纸是CAD,文档是WORD,下载后即可获得。

预览截图请勿抄袭,原稿文件完整清晰,无水印,可编辑。

有疑问可以咨询QQ:414951605或1304139763

摘要:电液比例阀是阀内比例电磁铁根据输入的电压信号产生相应动作,使工作阀阀芯产生位移,阀口尺寸发生改变并以此完成与输入电压成比例的压力、流量输出的元件。阀芯位移也可以以机械、液压或电的形式进行反馈。由于电液比例阀具有形式种类多样、容易组成使用电气及计算机控制的各种电液系统、控制精度高、安装使用灵活以及抗污染能力强等多方面优点,因此,电液比例减压阀应用领域日益拓宽。今年来研发生产的插装式比例阀和比例多路阀充分考虑到工程机械的使用特点,具有先到控制、负载传感和压力补偿等功能。它的出现对移动式液压机械整体技术水平的提升具有重要意义。特别是在电控先到操作、无线遥控和有线遥控操作等方面展现了其良好的应用前景。

关键字:电液比例阀 负载感应 压力补偿 先导控制

Electro-hydraulic proportional valve

Summary:Electro-hydraulic proportional valve industry is proportional solenoid valve generates a corresponding action according to the voltage signal input, the working valve spool displacement, and valve port size is changed in order to complete the input voltage is proportional to the pressure, the flow rate output element. Spool displacement can also be mechanical, hydraulic or electrical feedback form . Due to the form of electro-hydraulic proportional valve has a wide variety, easy to use a variety of electro-hydraulic system consisting of electrical and computer-controlled, high control accuracy, flexible installation, and strong anti-pollution and many other advantages.Therefore, electro-hydraulic proportional valve applications increasingly broadened.This year's R & D proportional cartridge valves and proportional multi-way valve fully take into account the characteristics of construction machinery use,Has a first control, load sensing and pressure compensation function.It is important for the emergence of mobile hydraulic machinery to enhance the overall level of technology. Sectors, especially the first operation in the electric control, wireless remote control and a wired remote operation demonstrated its good prospect.

Keyword:Electro-hydraulic proportional valve Load sensing Pressure Compensation Pilot control

1

目录

摘要·······················································1

目录·······················································2

前言·······················································4

正文·······················································5

1.绪论······················································5

1.1液压元件的结构分析及实体测绘·······················5

1.2液压技术及应用·····································5

1.3减压阀·············································5

1.4减压阀的分类·······································6

1.5减压阀的工作原理···································6

1.6电液比例减压阀·····································6

1.7阀控制压力的一般原理·······························7

2.比例减压阀的结构·······································7

3.主阀设计················································7

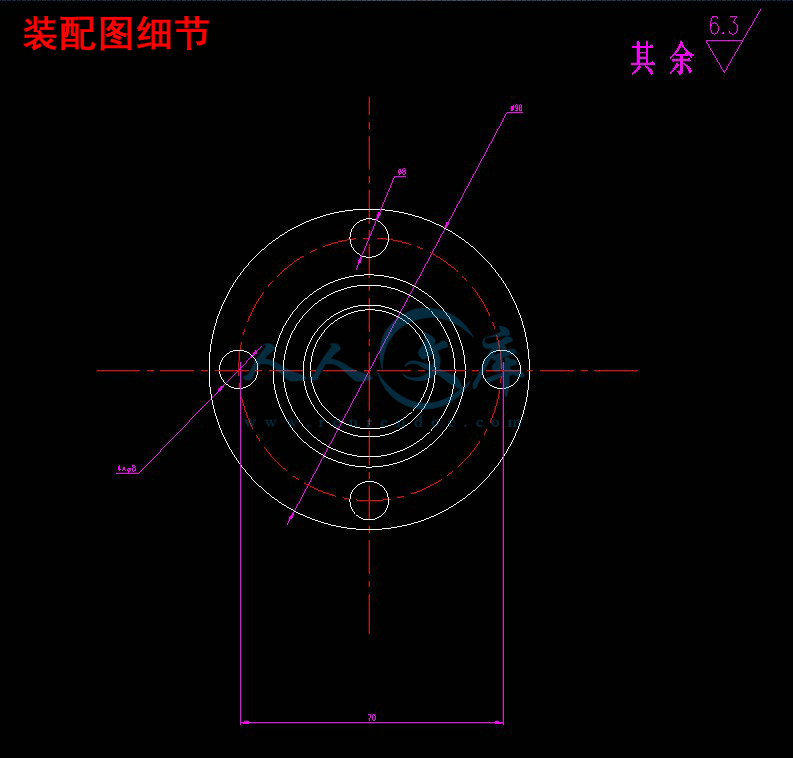

3.1插装式主阀·········································7

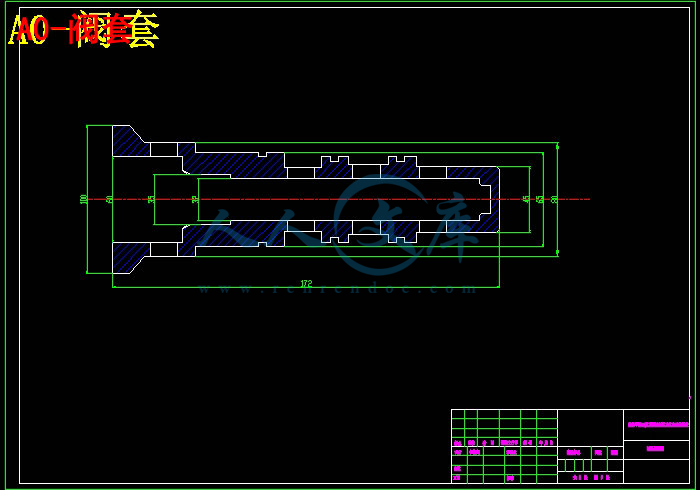

3.2主阀阀套的设计·····································8

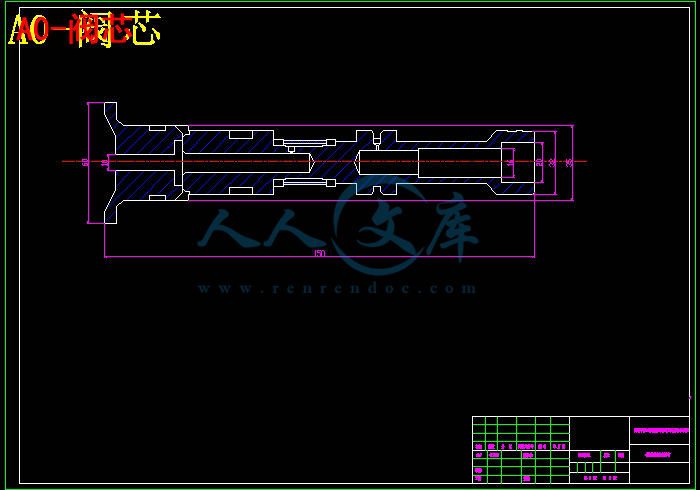

3.3主阀阀芯的设计·····································9

3.4插装式主阀面积比的确定·····························9

3.5主阀阀芯的受力分析·································11

3.6先导阀溢流部分的设计·······························12

3.7先导阀调定压力的增量表达式·························13

3.8先导阀的连接方式···································14

3.9公差与配合的确定···································14

3.10比例放大器········································14

4.减压阀的衔铁结构·······································15

4.1衔铁的类型·········································15

4.2衔铁的受力计算·····································16

5.静态特性分析············································16

5.1进口压力静态特性分析·······························16

5.2静态压力流量特性分析·······························17

5.3静态特性仿真曲线···································17

2

6.电液比例控制系统·······································19

6.1反馈的概念··········································20

6.2闭环与开环控制······································20

6.3电液比例控制系统的组成······························21

6.4电液比例控制系统的特点······························22

结束语·····················································23

致谢························································24

参考文献···················································25

附录························································26

3

前言

从1795年世界上第一台水压机诞生,到现在液压技术已有200多年的历史。至上世纪50~70年代,随着工艺水平的极大提高,液压技术也得到迅速发展,成为实现现代传动和控制的关键技术,其发展速度仅次于电子技术。特别是近年来流体技术与微电子、计算机技术相结合,是液压与气动技术进入了一个新的发展阶段。据有关资料记载,国外生产的90%的工程机械、90%的数控加工中心、95%的自动生产线,均采用了液压与气动技术。在国民紧急很多领域均需应用液压与气动技术,其水平的高低已成为一个国家工业发展水平的重要标志之一。因此液压技术在机械类及近机类高等教育的课程中,已成为一门重要的专业基础课,而且也是一门能直接用于工程实际技术的学科。通过本课程的学习,可以开发学生的智力,培养学生敏锐的观察能力、丰富的想象能力、科学的思维能力以及解决生产实际问题的能力。

本课题旨在服务于液压实践教学。本课题是通过对液压元件的结构分析,绘制相关元件图形,应用软件建其模型库。直观地展示了液压元件的结构和工作原理。

4

正文

绪论

1.1液压元件结构分析及实体测绘

液压元件的工作原理是利用有压流体(液压油)为介质来实现自动控制的各种机械的传动,它在工业生产的各个领域均有广泛应用,在机械类及近机类高等教育的课程中已成为研究发展的重要方向,而且而是能直接用于工程实际的重要技术,它在油压系统的应用中比较广泛。

1.2液压技术及应用

液压由于其传动力量大,易于传递及配置,在工业、民用行业应用广泛。在各部件制造中,对密封性、耐久性有很高的技术要求,目前在液压部件制造中已广泛采用——滚压工艺,很好的解决了圆度、粗糙度的问题。特别是液压缸制造中广泛采用。液压工具可以解决液压制造各种问题。

由于液压技术有很多突出的优点,从民用到国防、由一般传动到精确度很高的控制系统,都得到了广泛地应用。

在国防工业中,陆、海、空三军的很多武器装备都采用了液压传动与控制,如飞机、坦克、舰艇、雷达、火炮、导弹和火箭等。

在机床工业中,目前机床传动系统有85%采用液压传动与控制,如磨床、铣床刨床、拉床、压力机、剪床和组合机床等。

在冶金工业中,电炉控制系统、轧钢机的控制系统、平炉装料、转炉控制、高炉控制、带材跑偏和恒张力装置都采用了液压技术。

在工程机械中,普遍采用了液压传动,如挖掘机、轮胎装载机、汽车起重机、履带推土机、轮胎起重机、自行式铲运机、平地机和振动式压路机等。

1.3减压阀

减压阀是通过调节,将进口压力减至某一需要的出口压力,并依靠介质本身的能量,是出口压力自动保持稳定的阀门。从流体力学的观点来看,减压阀是一个局部阻力可以变化的节流元件,即通过改变节流面积,是流速及流体的动能改变,造成不同的压力损失,从而达到减压的目的。然后依靠控制与调节系统的调节,使阀后压力的波动于弹簧力相平衡,使阀后压力在一定的误差范围内保持恒定。

减压阀广泛用于高层建筑、城市给水管网水压过高的区域、矿井及其他场合,以保证给水系统中各用水点获得适当的服务水压和流量。鉴于水的漏失率和浪费程度几乎同给水系统的水压大小成正比,因此减压阀具有改善系统运行工况和潜在节水作用。

5

1.4减压阀的分类

减压阀是使出口压力低于进口压力的压力控制阀。减压阀可分为定压输出减压阀、定差减压阀和定比减压阀三种。定压输出阀有输出减压阀有直动型和先导型两种结构形式。在先导型中又有“出口压力控制式”和“进口压力控制式”两种控制方式。

川公网安备: 51019002004831号

川公网安备: 51019002004831号