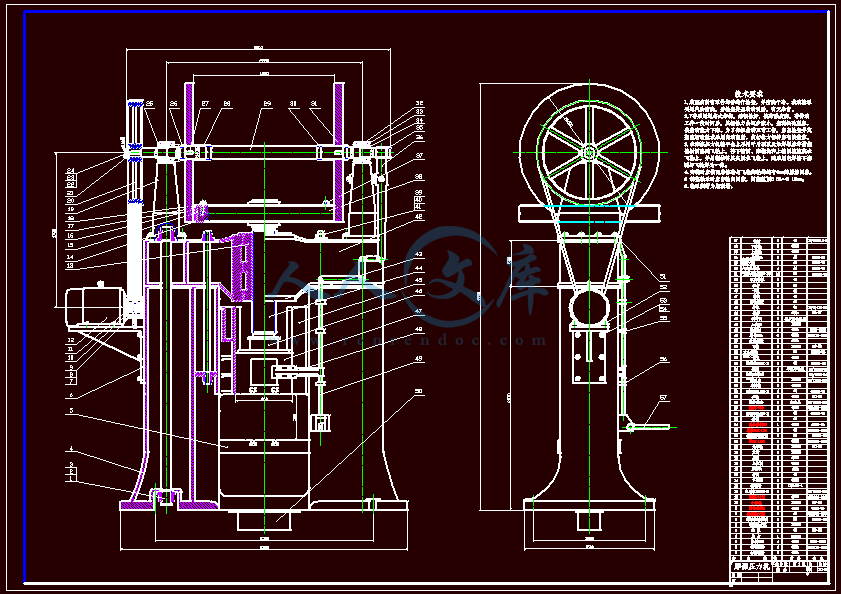

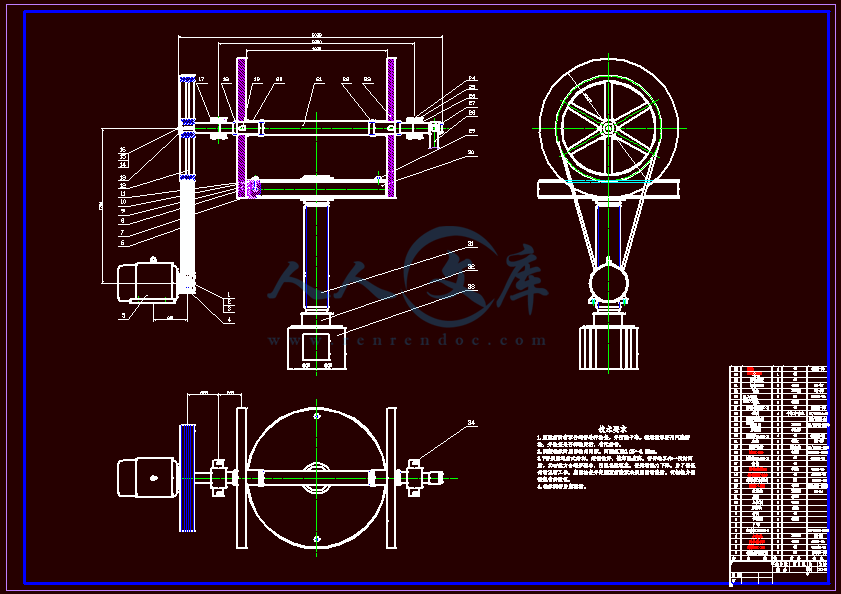

双盘摩擦压力机结构设计【新版本】(全套含CAD图纸)

收藏

资源目录

压缩包内文档预览:

编号:9459294

类型:共享资源

大小:5.18MB

格式:ZIP

上传时间:2018-03-09

上传人:机****料

认证信息

个人认证

高**(实名认证)

河南

IP属地:河南

50

积分

- 关 键 词:

-

摩擦

磨擦

压力机

结构设计

新版本

全套

cad

图纸

- 资源描述:

-

- 内容简介:

-

PROCEDIAENGINEERING29201214861491187770582011PUBLISHEDBYELSEVIERLTDDOI101016/JPROENG201201160AVAILABLEONLINEATWWWSCIENCEDIRECTCOMAVAILABLEONLINEATWWWSCIENCEDIRECTCOMPROCEDIAENGINEERING002011000000PROCEDIAENGINEERINGWWWELSEVIERCOM/LOCATE/PROCEDIA2012INTERNATIONALWORKSHOPONINFORMATIONANDELECTRONICSENGINEERINGIWIEEANINVESTIGATIONONTHEIMPACTNOISEOFASIXBARLINKAGEMECHANICALPRESSYANXINLUOA,RUXUDUBASTATEKEYLABOFMECHANICALTRANSMISSION,CHONGQINGUNIVERSITY,CHONGQING,400044,CHINABTHEINSTITUTEOFPRECISIONENGINEERING,THECHINESEUNIVERSITYOFHONGKONG,SHATIN,NT,HONGKONGABSTRACTCONVENTIONALMECHANICALPRESSCONSISTEDOFCRACKANDSLIDERISONEOFTHEMOSTCOMMONLYUSEDFORSTAMPINGBUTITCANNOTSATISFYDEEPDRAWINGOPERATIONS,INWHICHLONGDWELLINGTIMEINTHEBDCISDESIRABLETOAVOIDCRACKORWRINKLETHISMOTIVESTHEDESIGNOFASIXBARLINKAGEFORTHEMECHANICALPRESSHOWEVER,THEWORKINGNOISEISINTRODUCEDBYTHENEWMECHANISMTHISPAPERPRESENTSASYSTEMATICSSTUDYONTHENOISEOFTHEMECHANICALPRESSACOMBINATIONOFNOISESIGNATUREANALYSIS,RIGIDBODYDYNAMICSANALYSISANDFINITEELEMENTMETHODFEMAREADOPTEDTOINVESTIGATETHEROOTCAUSEOFTHENOISEITISFOUNDTHATTHENOISEISCAUSEDBYTHECOLLATIONOFTHEGEARSFINALLY,ANIMPROVEDDESIGNISTHENPROPOSEDANDSOMESUGGESTIONSAREGIVENTOREDUCETHENOISE2011PUBLISHEDBYELSEVIERLTDSELECTIONAND/ORPEERREVIEWUNDERRESPONSIBILITYOFHARBINUNIVERSITYOFSCIENCEANDTECHNOLOGYKEYWORDSSIXBARMECHANICALPRESS,SIGNATUREANALYSIS,IMPACTNOISE,FINITEELEMENTMETHODFEM1INTRODUCTIONCONVENTIONALMECHANICALPRESSCONSISTEDOFCRACKANDSLIDERISONEOFTHEMOSTCOMMONLYUSEDFORSTAMPINGITSTRAJECTORYISNOTCONTROLLABLEATTHEBOTTOMDEADCENTREBDC,ANDHENCEITCANNOTSATISFYTHEDIVERSENEEDS1FOREXAMPLE,LONGDWELLINGTIMEINTHEBDCISDESIRABLETOAVOIDCRACKORWRINKLEFORDEEPDRAWINGOPERATIONS2THISMOTIVESTHEDESIGNOFTHEFIVE,SIX,NINEBARLINKAGEFORTHECORRESPONDINGAUTHORTEL862365106999FAX862365105795EMAILADDRESSYXLUOCQUEDUCN1487YANXINLUOANDRUXUDU/PROCEDIAENGINEERING292012148614912YLUOANDRDU/PROCEDIAENGINEERING002011000000MECHANICALPRESS3,4INGENERAL,INTHEDESIGNOFAMECHANICALMETALFORMINGPRESS,DESIGNERSCONCERNMOSTLYTHEKINEMATICS5FEWHAVESTUDIEDTHEDYNAMICSOFTHEPRESS,THOUGHITISVERYIMPORTANTITSPERFORMANCE6WHENACOMMERCIALPRESSISDESIGNEDANDBUILT,ITSNECESSARYTOINVESTIGATEITSPERFORMANCEANDMAKECONTINUOUSIMPROVEMENTSINTHISRESEARCH,ASIXBARLINKAGEINCLUDINGAFOURBARLINKAGEANDACRANKSLIDERMECHANISMHASBEENADOPTEDTOBUILDACOMMERCIALMECHANICALPRESSWITHTHECAPABILITYOFMAXLOADINGOF300TONDESIGNENGINEERSHADCAREFULLYCHECKEDTHEKINEMATICSOFTHEPRESSANDTHEMANUFACTURINGANDASSEMBLIESWEREDONEWITHINTHEDESIGNSPECIFICATIONANDTHEREFORETHEPRESSWORKSFINETHOUGH,THEPRESSGENERATESLOUDNOISEWITHANDWITHOUTLOADINGTHESOUNDINTENSITYISHIGHERTHAN90DB,WHICHCAUSESVARIOUSCONCERNS,SUCHASTHERELIABILITYOFTHEMACHINEANDTHESAFETYOFTHEOPERATORTHEMECHANISMOFTHEDRIVELINEISILLUSTRATEDINFIG1A,ANDITSCADMODELISSHOWNINFIGURE1BITCONSISTSOFSEVENPARTSAMOTORNOTSHOWNINTHEFIGURETHATCONNECTSTOTHEFLYWHEELTHROUGHTHEHIGHSPEEDSHAFT,AREDUCTIONGEARSETWHICHINCLUDESTHEHIGHSPEEDGEARANDTHELOWSPEEDGEAR,ACOUPLERTHATCONTROLSTHEENGAGEMENTOFTHEGEARSETANDTHECRANK,ACRANKSLIDERMECHANISM,ANDAFOURBARMECHANISMTHATCONNECTSTOTHESLIDERAMONGTHEM,THEFOURBARMECHANISMISTHEKEYASITDOCTRINESTHEDYNAMICPERFORMANCEOFTHEPRESSL145MML2165MML3208MML4260MML580010000MME80MMFIG1AILLUSTRATIONOFTHESIXBARLINKAGEMECHANISMBTHEPHYSICALMODELOFTHEMECHANISMTHISPAPERAIMSTOFINDTHEROOTCAUSESOFTHENOISETHEPRESENTEDRESEARCHWILLINVESTIGATETHENOISEFROMVARIOUSASPECTSANDPROVIDEIMPROVEMENTSOLUTIONSTHERESTOFTHISPAPERISORGANIZEDASFOLLOWSTHESIGNATUREANALYSISOFNOISEISPRESENTEDINSECTION2INSECTION3,THEDYNAMICSOFTHESYSTEMISSTUDIEDBYRIGIDBODYDYNAMICSANALYSISANDFEMINSECTION4,ANIMPROVEDDESIGNISPROPOSEDTOREDUCETHEIMPACTNOISEFINALLY,CONCLUSIONSAREGIVENINSECTION52SIGNATUREANALYSISOFNOISESIGNAL21EXPERIMENTALSETUPASMENTIONEDEARLIER,THENOISEISTHEMAJORCONCERNOFTHEDESIGNTHEFIRSTSTEPISTOANALYZETHENOISESIGNALTHESOUNDSIGNALWASMEASUREDUSINGAMICROPHONEPLACEDCLOSELYTOTHEPRESSFIGURE2SHOWSTHEEXPERIMENTALSETUP,THEMAINAPPARATUSESINCLUDEAMICROPHONEMANUFACTURERBRELANDCTHEIMPACTFREQUENCYIS23HZITISNECESSARYTOANALYZETHEDYNAMICSOFTHEDRIVESYSTEMTOFINDTHEROOTCAUSEOFTHENOISE3DYNAMICSANALYSIS31IMPACTFORCEANALYSISTOINVESTIGATETHESOURCESOFTHENOISE,THEDYNAMICMODELOFTHESYSTEMISNECESSARYFORFURTHERINVESTIGATIONOFMECHANICAL,WHICHMAYREFLECTREALWORKINGCONDITIONS,SHOULDBECONSTRUCTEDFORANACCURATELOADINGANALYSISINTHISRESEARCH,THEDYNAMICANALYSISOFTHEPRESSISCARRIEDUSINGACOMMERCIALSOFTWARESYSTEMRECURDYNALLJOINTFORCEBETWEENTHELINKAGESAREOBTAINEDBYTHISSIMULATION,AMONGWHICHTHECONTACTFORCEBETWEENTHEGEARSISATTRACTEDOURINTERESTINGFIG7SHOWSTHECONTACTFORCEINBLACKBETWEENTHEGEARS,ANDITSDIFFERENTIATIONINORANGEEXAMININGTHEDIFFERENTIATIONOFTHEFORCE,ITISSEENTHATTHECONTACTFORCEQUICKLYCHANGESITSDIRECTIONTWICE,INAANDB,WHENTHEPUNCHISMOVINGUPTHISISVERYLIKELYTOCREATETWOBIGSHOCKSCONSEQUENTLY,ALOUDNOISEWILLBEGENERATEDDIFFERETIATIONN/SPUNCHPOSITIONMMGEARFORCENFIG7IMPACTFORCEBETWEENTHEGEARSINORDERTOFURTHERINVESTIGATETHEFREQUENCYCOMPONENTSINTHENOISESIGNAL,THOUGH,FINITEELEMENTANALYSISFEAISNECESSARY32NATURALFREQUENCIESOFTHEMECHANICALCOMPONENTSITSWELLKNOWNTHATTHEVIBRATIONISUSUALLYCAUSEDBYTHEVIBRATIONOFSTRUCTURE,ANDTHEREFORE,ITSNECESSARYTOFINDTHENATURALFREQUENCYOFTHESTRUCTURETHEANALYTICALMETHODCANBEUSEDTOFINDTHENATURALFREQUENCYHOWEVER,ITISNOTPRECISEBECAUSEOFTHEASSUMPTIONSINPRACTICAL,FEAISAVARIABLEMETHODTOFINDTHEPRECISELYSOLUTIONOFDIFFERENTIALEQUATIONSFORVERIFYINGTHEVIBRATIONOFASTRUCTURETHEREISSOMECOMMERCIALSOFTWAREFORFEASUCHASABAQUS,ANSYS,NASTRAN,ANDETC7,8INTHISRESEARCH,WEUSEDABAQUSTOFINDTHENATURALFREQUENCIESOFTHEMECHANICALCOMPONENTSASSHOWNINTABLE1ALSO,THEFIRSTMODESHAPEOFTHEHIGHSPEEDSHAFTISTORSION,WHICHISINTHESAMEDIRECTIONOFTHETORQUEITISBELIEVEDTHATTHISMODEISRESPONSIBLEFORREPETITIVEFREQUENCYOF23HZANDTHEFOURTHABBA1490YANXINLUOANDRUXUDU/PROCEDIAENGINEERING29201214861491YLUOANDRDU/PROCEDIAENGINEERING0020110000005NATURALFREQUENCYOFHIGHSPEEDGEARANDTHESECONDNATURALOFLOWSPEEDGEARARECLOSETOTHEMAINLYFREQUENCYOFTHENOISEMOREOVER,THECORRESPONDINGMODESHAPEISBENDINGOFTHEGEARTOOTHTHEREFORE,THEGEARTOOTHSHOULDBEFURTHERINVESTIGATEDFIG8ASHOWSTHEFEAMODELOFTHELOWSPEEDGEARTHELOADINGISAPPLIEDTOONEOFTHETEETHTHEAPPLIEDLOADINGISANORMALIZEDFORCEOF1UNIT,INTHEFREQUENCYRANGEFROM1HZTO1,500HZFIG8BSHOWSRESULTSOFTHEFREQUENCYRESPONSEFROMTHEFIGURE,ITISSEENTHATTHEGEARHASTHREEMAINFREQUENCIESAT480HZ,740HZ,AND1,350HZRESPECTIVELYTHELARGESTFREQUENCYCOMPONENTISAT740HZITISBELIEVETHATTHISFREQUENCYISRESPONSIBLEFORTHELOUDNOISETHEDISCREPANCIESBETWEENTHEFEAFREQUENCY740HZANDACTUALNOISEFREQUENCY780HZMAYBEATTRIBUTEDTOTHESIMPLIFICATIONOFTHEFEAMODELINCONCLUSIONS,WEBELIEVETHELOUDNOISEISGENERATEDBYTHECOLLISIONOFTHEGEARS,ANDTHENOISECANBEREDUCEDBYELIMINATINGOFTHEGEARCLEARANCETABLE1MODALFREQUENCIESOFTHEMAINCOMPONENTSOFTHEPRESSHZFIG8AFEMMODELOFTHEGEARPINIONBFREQUENCYRESPONSE4ANIMPROVEDDESIGNBASEDONTHEANALYSISRESULTPRESENTEDEARLIER,THELENGTHOFTHELINKAGESSHOULDNOTBECHANGEASTOKEEPTHETRAJECTORYOFTHEDESIGNALSO,THEINERTIAOFTHEFLYWHEELANDTHESTIFFNESSOFTHEHIGHSPEEDSHAFTETC,CANALSOBEFINETUNEDTOREDUCETHENOISEHOWEVER,THESESOLUTIONISNOTEFFECTIVEBECAUSEOFTHEMECHANICALCOMPONENTSHASSMALLROOMFORIMPROVINGTHEDESIGNDUETOTHESTRENGTHCONSTRAINTSITSANOPTIONTOIMPROVETHEDESIGNBYELIMINATINGTHECLEARANCEBETWEENTHEGEARSTHEPROPOSEDDESIGNISSHOWNINFIG9THEREARETWOGEARSMOUNTEDONTHEHIGHSPEEDSHAFTTOELIMINATETHEGEARCLEARANCEINTHISDESIGN,TWOSETOFGEARPAIRAREUTILIZEDANDONESPIRALSPRINGWILLMOUNTEDBETWEENTHEGEARSTOELIMINATETHEGEARCLEARANCETHEFIRSTSETOFGEARPAIRWILLTRANSMITTHETORQUETOTHECRANKSHAFTFORTHECASEOFTHETORQUEISINCLOCKWISEDIRECTIONWHENTHETORQUECHANGESITSDIRECTION,THESECONDSETOFGEARPAIRWORKSTHEREFORE,ITSBELIEVEDTHATTHEDESIGNWILLREDUCETHENOISEEFFECTIVELYHOWEVER,THEDYNAMICSANALYSISISNEEDEDFORTHENEWDESIGNMODELINTHEFUTUREMODE1ST2ND3RD4TH5TH6THHIGHSPEEDSHAFT2422975482853581010354HIGHSPEEDGEAR673360546617530892911890LOWSPEEDGEAR5931619011478120531278014770UPPERLINKAGE6707478051026185228241491YANXINLUOANDRUXUDU/PROCEDIAENGINEERING292012148614916YLUOANDRDU/PROCEDIAENGINEERING002011000000FIG9ANIMPROVEDDESIGNOFTHEGEARPAIRFORELIMINATINGTHEGEARCLEARANCE5CONCLUSIONSTHISPAPERPRESENTSASTUDYONTHENOISEOFASIXBARMECHANICALPRESSBASEDONTHEDISCUSSIONSABOVE,FOLLOWINGCONCLUSIONSCANBEDRAWNTHEMECHANICALNOISEOFTHEPRESSCONTAINSANUMBEROFCOMPONENTSCORRESPONDINGTOTHENATURALFREQUENCIESOFVARIOUSCOMPONENTSOFTHEPRESSTHENOISEISGENERATEDWHENTHEIMPACTOCCURSTHEIMPACTISARESULTOFTHEFOURBARMECHANISMTHATGENERATESVARIABLESPEEDDURINGTHEOPERATIONTHEVARIABLESPEEDGENERATESVARIABLEFORCE,CAUSINGTHEGEARSIMPACTONEACHOTHERITSANOPTIONTOAVOIDTHECLEARANCEBETWEENTHEGEARPAIRSTOREDUCETHENOISETHECOMBINATIONOFTHESIGNATUREANALYSIS,MECHANICALDYNAMICSANALYSISANDFEMISEFFECTIVEMETHODTOANALYZETHEROOTCAUSEOFMACHINEFAULTSINADDITIONTOTHEAPPLICATIONPRESENTEDABOVE,ITCANBEUSEDFORMANYOTHERAPPLICATIONSTHATINVOLVEMECHANICALMOTIONACKNOWLEDGEMENTSTHIS

- 温馨提示:

1: 本站所有资源如无特殊说明,都需要本地电脑安装OFFICE2007和PDF阅读器。图纸软件为CAD,CAXA,PROE,UG,SolidWorks等.压缩文件请下载最新的WinRAR软件解压。

2: 本站的文档不包含任何第三方提供的附件图纸等,如果需要附件,请联系上传者。文件的所有权益归上传用户所有。

3.本站RAR压缩包中若带图纸,网页内容里面会有图纸预览,若没有图纸预览就没有图纸。

4. 未经权益所有人同意不得将文件中的内容挪作商业或盈利用途。

5. 人人文库网仅提供信息存储空间,仅对用户上传内容的表现方式做保护处理,对用户上传分享的文档内容本身不做任何修改或编辑,并不能对任何下载内容负责。

6. 下载文件中如有侵权或不适当内容,请与我们联系,我们立即纠正。

7. 本站不保证下载资源的准确性、安全性和完整性, 同时也不承担用户因使用这些下载资源对自己和他人造成任何形式的伤害或损失。

人人文库网所有资源均是用户自行上传分享,仅供网友学习交流,未经上传用户书面授权,请勿作他用。

川公网安备: 51019002004831号

川公网安备: 51019002004831号