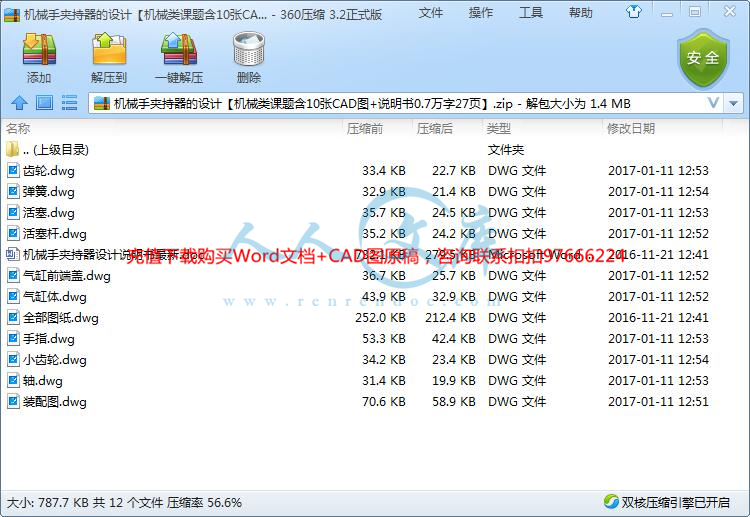

!【包含文件如下】【机械设计类】CAD图纸+word设计说明书.doc[7000字,27页]【需要咨询购买全套设计请企鹅97666224】.bat

全部图纸.dwg

小齿轮.dwg

弹簧.dwg

手指.dwg

气缸体.dwg

气缸前端盖.dwg

活塞.dwg

活塞杆.dwg

装配图.dwg

轴.dwg

齿轮.dwg

设计说明书.doc[7000字,27页]

摘要

本次的设计来源于机械手夹持器设备更新换代基础之上,通过设计出机械手夹持器,从而来满足当今机械手组成部件之一的机械手夹持器各方面性能不足的缺陷。本毕业设计课题来自于企业的生产实际,通过设计出新型机械手夹持器,从而来掌握机械手夹持器的整个设计生产流程,培养工程意识。

我国生产的机械手夹持器从仿制开始起步,近期产品的质量较早期有所提高。但受国产配套件质量及设计水平等的影响,我国目前生产的机械手夹持器的总体水平与进口产品及港口用户的要求仍有较大差距,机械手夹持器的生产也是如此,为满足市场需求,开发出一种新型的机械手夹持器势在必行!

本文运用大学所学的知识,提出了机械手夹持器的结构组成、工作原理以及主要零部件的设计中所必须的理论计算和相关强度校验,构建了机械手夹持器总的指导思想,从而得出了该机械手夹持器的优点是高效,经济,并且安全系数高,对提高机械手的工作效率,减少人工投入,增强夹持质量等等起到了很大的作用的结论。

关键词:机械手夹持器机;高效;人工投入;结论

Abstract

This paper mainly introduces the current situation and development prospect of automotive beauty decoration industry, car beauty industry is experiencinga hitherto unknown development opportunity, there are good prospects for development. But due to the current situation of enterprise development disorder, not standardized, quality of personnel is low, which seriously restrict the development of the industry.

that car decoration and beauty will be the century of China's most promising gold industry, known as the automotive industry "second gold", isa sunshine industry.China attaches great importance to the status of the degreeis not enough, and the baby chair to drive innovation design, to achieve a "chair", to improve the above situation.Therefore, this paper carries on research on scheme selection.

Through the professional knowledge of the designer to master the relevantinformation on the Internet, as well as the current situation at home and abroad, the design scheme, after a detailed investigation, this graduation design is to design a set of practical multifunctional baby chair.This design is begins with the argument, introduces in detail the scheme analysis, design process and calculating process.

Key words:Machine manufacture;Crankshaft;Processing craft;Fixture;

目 录

摘要 I

Abstract II

1 绪论 1

1.1课题的来源与研究的目的和意义 1

1.2机械手的组成 2

1.2.1机械手的组成 3

1.3国内外发展状况 5

2 机械手的设计方案 6

2.1座标型式与自由度的设计 8

2.2手部结构方案的设计 10

2.3手腕结构方案的设计 14

2.4手臂结构方案的设计 16

3 机械手夹持器结构的设计 18

3.1夹持式手部结构 19

3.1.1手指的形状和分类 20

3.1.2设计时考虑的几个问题 20

3.1.3手部夹紧气缸的设计 21

3.2 气缸驱动力矩的计算 22

3.3 气缸驱动力矩的计算校核 23

4 机械手夹持器中关键零部件的强度计算与校核 23

4.1 齿轮的强度计算与校核 24

4.2 轴的强度计算与校核 25

结论 26

致谢 27

参考文献 28

川公网安备: 51019002004831号

川公网安备: 51019002004831号