!【包含文件如下】【机械设计类】CAD图纸+word设计说明书.doc[10000字,37页]【需要咨询购买全套设计请企鹅97666224】.bat

大V带轮.dwg

大齿轮.dwg

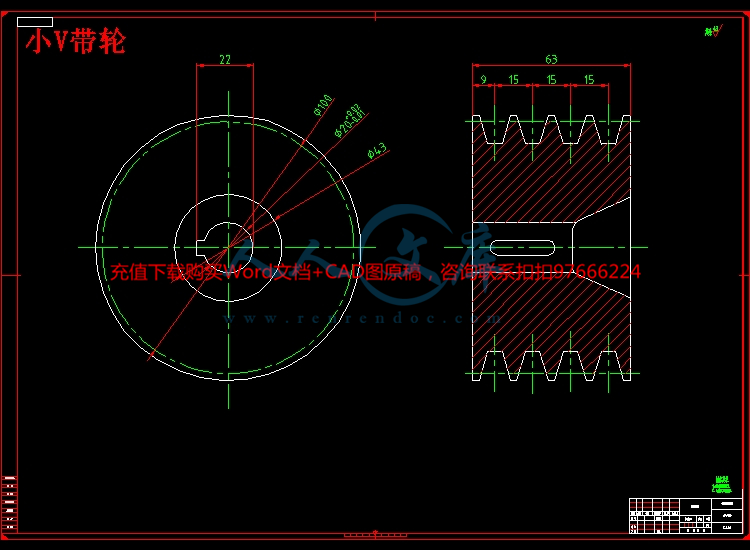

小V带轮.dwg

小型绞肉机CAD图纸.DWG

搅碎刀.dwg

搅碎板.dwg

旋盖.dwg

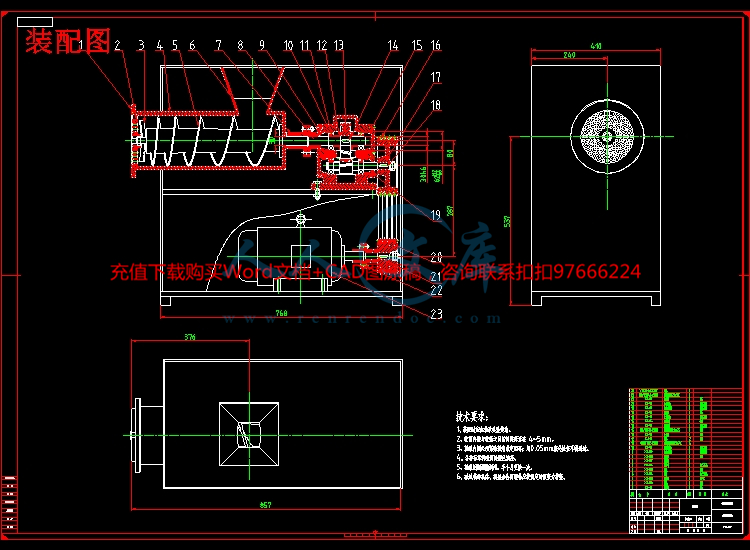

装配图.dwg

齿轮轴.dwg

小型绞肉机的设计12.31.doc

小型绞肉机的设计开题报告.doc

设计说明书.doc[10000字,37页]

任务书.doc

摘 要

本文论述了小型肉类加工器具—小型绞肉机的工作原理,各个零部件的组合,传动机构的设计计算和工作效率分析。

本设计的小型绞肉机为普通家用型,除了可以用来绞肉之外,还可以用来绞碎瓜果,辣椒,碎冰等食物。它所需的功率比较小,采用电力驱动,合理的结构合计,能满足普通家庭基本的肉类食品绞碎工作。

本次小型绞肉机的设计,大大地提高了传统绞肉机的工作效率和质量,并且对后续的小型绞肉机的开发和研制都有着一定的影响,在某种程度上大大提升了该设备在国内外的竞争力,体现了机械工业重要性这一核心价值。

关键词:绞肉机 结构设计 绞刀

Abstract

The environment of global economic development, china industries affected by other countries advanced technology at the same time, foreign enterprises and brand spread to more.

In the production equipment of enterprises, give full consideration to the possible problems in the operation of the equipment, so as to reduce the noise pollution caused by vibration or improper operation of equipment phenomenon and manufacturing of domestic pipe pressing equipment with global appeal, economic, security and stability of the theme consistent. Increase

Graduation project this time is a tube axial compressive loading machine. This paper introduces the theoretical calculation to design sleeve pressing machine structure, working principle and main parts of the strength check and the advantages of the sleeve.

Key words: meat chopper reame processing

目 录

摘要...............................................................I

Abstrac...........................................................II

前言............................................................ 1

1结构及工作原理.................................................. 2

1.1绞肉机的结构................................................ 2

1.2绞肉机的工作原理............................................ 3

2 螺旋供料器的设计................................................ 3

2.1绞笼的设计.................................................. 3

2.2绞筒的设计................................................. 4

3 传动系统的设计.................................................. 4

3.1电机的选择.................................................. 5

3.2带传动的设计................................................ 5

3.3齿轮传动设计................................................ 10

3.3.1选择材料,确定和及精度等级...................... 10

3.3.2按接触强度进行初步设计................................... 10

3.3.3校核齿面接触强度......................................... 12

3.3.4校核齿根的强度........................................... 14

3.3.5齿轮副精度的检验计算..................................... 15

3.4轴的设计..................................................... 16

3.4.1按扭转强度计算........................................... 16

4 绞刀的设计...................................................... 18

4.1绞刀的设计.................................................. 18

5 生产能力分析................................................... 25

5.1绞刀的切割能力.............................................. 25

5.2 绞肉机的生产能力............................................ 25

5.3功率消耗.................................................... 26

总结.............................................................. 27

致谢.............................................................. 28

参考文献.......................................................... 29

川公网安备: 51019002004831号

川公网安备: 51019002004831号