摘 要

该论文主要研究了复合冲压模具设计。通过对三个零件的工艺分析,制定出了模具设计方案,通过比较最终择优选出了复合冲压模具。其中包括两套冲孔落料复合模和一套拉深复合模以及一套单工序拉深模。通过对零件的分析,制定了合适的冲压模设计工艺。该论文对每一副模具,经过工艺分析、结构设计,论证了其可能性,最终保证了制品的质量。本论文具体分析了每副模具的总体结构以及工作过程,对模具中的各个工作零件的设计原则、尺寸确定以及公差等做了具体的叙述。

通过应用三维软件和CAD软件进行复合冲压模具的数字化设计,了解机械行业的先进设计制造技术,掌握先进的设计制造理念。此外,该论文还涉及了模具行业当今的发展状况、发展水平、存在问题以及今后的发展前景等。由于模具的应用领域越来越广,其需求也越来越大,因此通过模具设计,可以更加熟悉模具的生产工艺。

关键词:复合冲压模;工艺分析;三维软件

ABSTRACT

The paper mainly studied the compound stamping die design. Through the analysis of three parts to develop a mold design, then select the final selection of the best compound stamping dies by comparing , including two sets of punching blanking composite modulus and a set of drawing composite modulus and a single process drawing die. Develop a suitable stamping die design process by the analysis of the parts. The papers analyses each mold, include structure design, demonstrates the possibility of the ultimate guarantee of the quality of the products. In this thesis, a detailed analysis of the overall structure and work process per mold for determining the dimensions and tolerances, and so do a specific description of the design principles of the various parts in the mold.

Compound stamping dies through the application of 3D software and CAD software, digital design, advanced design and manufacturing technology of the machinery industry, to master the advanced design and manufacturing philosophy. In addition, the paper also involves the development of mold industry in today's level of development, there are problems and future development prospects. Increasingly wide areas of application of the mold, its demand is also increasing, so the mold design, mold production process can become more familiar with.

Keywords: Compound?stamping die; Process Analysis; 3D software

目 录

摘 要 III

ABSTRACT IV

1 绪论 1

1.1 模具行业的现状和发展 1

1.1.1 模具行业的现状 1

1.1.2 中国模具技术的进步 1

1.1.3 中国模具工业的发展方向 3

1.2 课题的来源与意义 5

1.2.1 课题的来源 5

1.2.2 课题的意义 5

2 冲孔落料复合模 6

2.1冲裁件的工艺分析 6

2.1.1 材料 6

2.1.2 生产批量 6

2.1.3 精度等级 6

2.1.4 结构形状 6

2.2 制订生产方案 6

2.3 零件的工艺计算 7

2.3.1 工作零件刃口尺寸的计算 7

2.3.2 排样 9

2.3.3 冲裁力 11

2.3.4 卸料力、推件力 12

2.3.5 压力机公称压力的确定 13

2.3.6 压力中心的计算 13

2.4 冲裁模设计与制造 13

2.4.1 工作零件 13

2.4.2 定位零件 16

2.4.3 卸料与推料零件 18

2.4.4 模架及零件 20

3 落料、拉深、冲孔复合模 22

3.1 零件工艺分析 22

3.2 零件工艺方案的确定 23

3.3 分析零件的冲压工艺性并确定工艺方案 23

3.4 工艺计算 24

3.4.1 冲裁力、卸料力、推件力、拉深力的计算及选出压力机 24

3.4.2 排样、冲裁模间隙及凹模、凸模刃口尺寸公差计算 26

3.4.3 首次无凸缘拉深的有关计算 29

3.5 有关模具零件结构的计算 30

3.5.1 冲孔凸模 30

3.5.2 落料凹模 30

3.5.3 拉深凸模(冲孔凹模) 30

3.5.4 拉深凹模(落料凸模) 31

3.5.5 卸料装置 31

3.5.6 定位零件 32

3.5.7 固定板、垫板 32

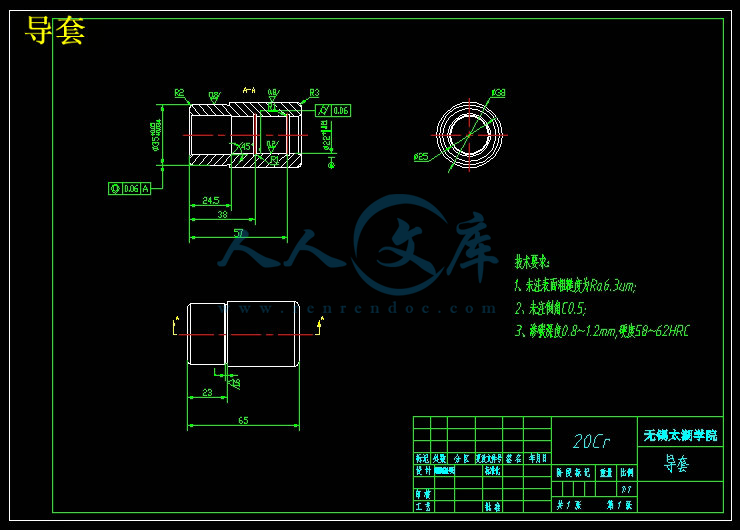

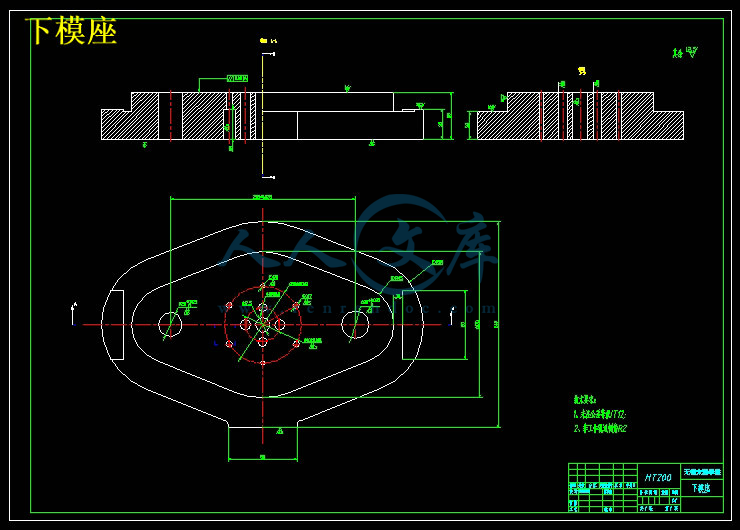

3.5.8 模架、导柱、导套 32

4 拉深模 33

4.1 工艺分析 33

4.2 工艺计算 33

4.2.1 拉深直径 33

4.2.2 拉深力的计算 33

4.2.3 圆角半径 34

4.2.4 拉深模具的间隙 34

4.2.5 拉深高度 34

4.2.6 拉深凹模和凸模的尺寸 34

4.3 有关模具零件结构的计算 34

4.3.1 拉深凸模 34

4.3.2 拉深凹模 35

4.3.3 模架及其他 35

5 复合冲压模具 37

5.1 冲裁件的工艺分析 37

5.1.1 材料 37

5.1.2 生产批量 37

5.1.3 精度等级 37

5.1.4 结构形状 37

5.2 制订生产方案 37

5.3 零件的工艺计算 37

5.3.1 工作零件刃口尺寸的计算 37

5.3.2 排样 39

5.3.3 冲裁力 39

5.3.4 卸料力、推件力 40

5.3.5 压力机公称压力的确定 40

5.4 冲裁模设计与制造 40

5.4.1 工作零件 41

5.4.3 卸料与推料零件 42

5.4.4 模架及零件 43

6 结论 45

致 谢 46

参考资料 47

1 绪论

1.1 模具行业的现状和发展

1.1.1 模具行业的现状

在当今社会,模具生产技术水平的高低已经成为衡量一个国家产品制造水平高低的重要标志,因为模具在很大程度上决定着产品的质量、效益和新产品的开发能力。随着我国加入WTO,我国模具工业的发展将面临着新的机遇和挑战,也日益受到人们的重视和关注,日前对“模具是工业生产的基础工艺装备”这一观念也已经取得了共识。在电子、汽车、电机、电器、仪器、仪表、家电和通信等产品中,60%~80%的零部件都要依靠模具成型。用模具生产制件所具备的高精度、高复杂程度、高一致性、高生产率和低消耗,是其它加工制造方法所不能比拟的。模具又是“效益放大器”,用模具生产的最终产品的价值,往往是模具自身价值的几十倍,甚至上百倍。近几年来,我国模具工业一直以每年15%左右的增长速度迅速发展。

目前我国模具工业的发展步伐日益加快,但在整个模具设计制造水平和标准化程度上,与德国、美国、日本的发达国家相比还存在相当大的差距。在经济全球化的新形势下,随着资本、技术和劳动力后市场的重新整合,我国装备制造业在加入WTO以后,将成为世界装备制造业的基地。而在现代制造业中,无论哪一行业的工程装备,都越来越多地采用由模具工业提供的产品。为了适应用户对模具制造的高精度、短交货期、低成本的迫切要求,模具工业应广泛应用现代先进制造技术来加速模具工业的技术进步,满足各行各业对模具这一基础工艺装备的迫切需求,以实现我国模具工业的跨越式发展。

1.1.2 中国模具技术的进步

我国模具工业的技术水平近年来也取得了长足的进步。大型、精密、复杂、高效和长寿命模具上了一个新台阶。大型复杂冲模以汽车覆盖件模具为代表,已能生产部分新型轿车的覆盖件模具。体现高水平制造技术的多工位级进模的覆盖面,已从电机、电器铁芯片模具,扩展到接插件、电子枪零件、空调器散热片等家电零件模具。在大型塑料模具方面,已能生产48英寸电视的塑壳模具、6.5K g大容量洗衣机全套塑料模具,以及汽车保险杠、整体仪表板等模具。在精密塑料模具方面,已能生产照相机塑料模具、多型腔小模数齿轮模具及塑封模具等。在大型精密复杂压铸模方面,国内已能生产自动扶梯整体踏板压铸模及汽车后桥齿轮箱压铸模。其他类型的模具,例如子午线轮胎活络模具、铝合金和塑料门窗异型材挤出模等,也都达到了较高的水平,并可替代进口模具。具体表现在以下模具领域中:

川公网安备: 51019002004831号

川公网安备: 51019002004831号