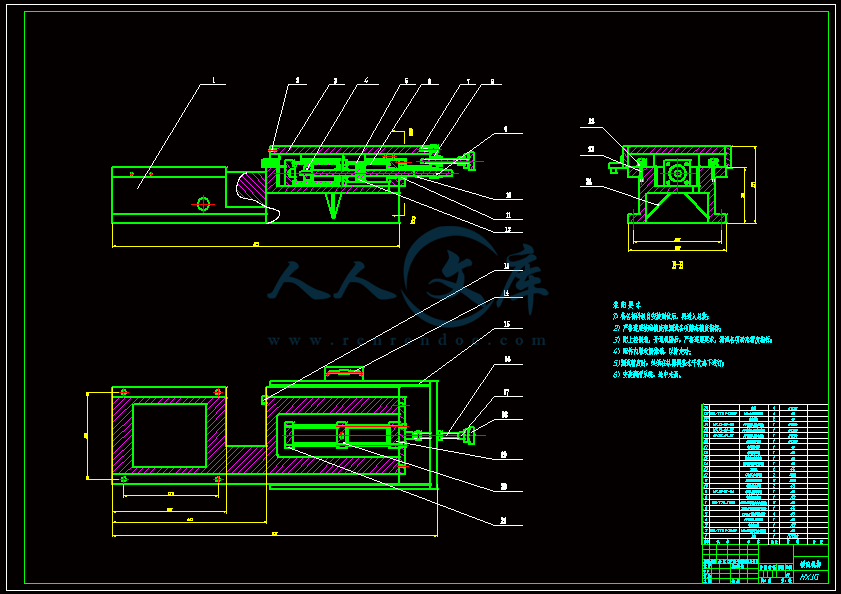

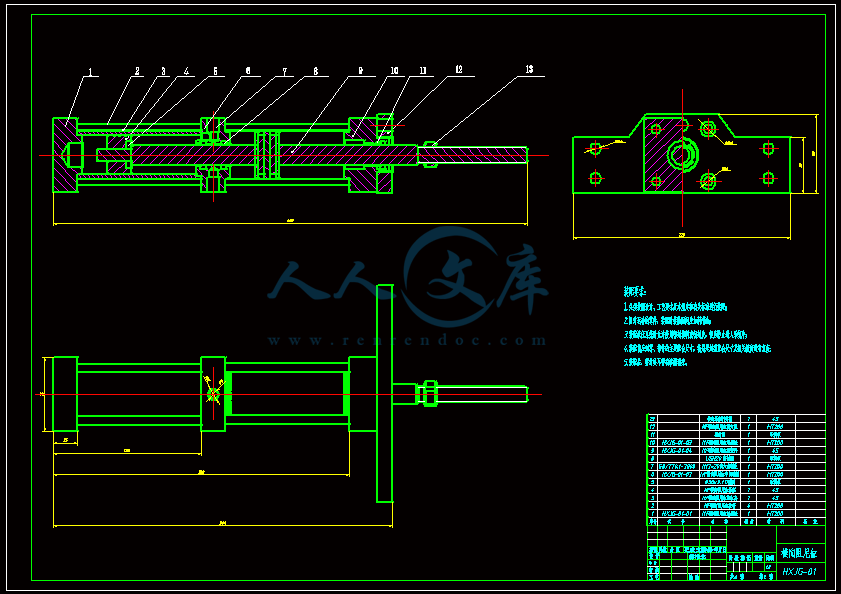

轴承内外圈加工专用机床横向机构设计(全套含CAD图纸)

收藏

资源目录

压缩包内文档预览:

编号:9973900

类型:共享资源

大小:2.37MB

格式:ZIP

上传时间:2018-04-08

上传人:机****料

认证信息

个人认证

高**(实名认证)

河南

IP属地:河南

50

积分

- 关 键 词:

-

轴承

内外

加工

专用

机床

横向

机构

设计

全套

cad

图纸

- 资源描述:

-

- 内容简介:

-

0英文原文HYDRAULICACTUATIONSYSTEMDESIGNANDCOMPUTATION1CLEARINGABOUTTHEDESIGNREQUESTTOCARRYONTHEOPERATINGMODEANALYSISWHENDESIGNHYDRAULICSYSTEMBELOW,FIRSTSHOULDBECLEARABOUTTHEQUESTION,ANDTAKESITASTHEDESIGNBASISMAINENGINEUSE,TECHNOLOGICALPROCESS,OVERALLLAYOUTASWELLASTOHYDRAULICGEARPOSITIONANDSPATIALSIZEREQUESTTHEMAINENGINETOTHEHYDRAULICSYSTEMPERFORMANCEREQUIREMENT,LIKETHEAUTOMATICITY,THEVELOCITYMODULATIONSCOPE,THEMOVEMENTSTABILITY,THECOMMUTATIONPOINTINGACCURACYASWELLASTHEREQUESTWHICHTOTHESYSTEMEFFICIENCY,WARMPROMOTESHYDRAULICSYSTEMWORKINGCONDITIONS,LIKETEMPERATURE,HUMIDITY,VIBRATIONIMPACTASWELLASWHETHERHASSITUATIONANDSOONCORROSIVENESSANDHEATSENSITIVEMATERIALEXISTENCEININTHEABOVEWORKFOUNDATION,SHOULDCARRYONTHEOPERATINGMODEANALYSISTOTHEMAINENGINE,THEOPERATINGMODEANALYSISINCLUDINGTHEMOVEMENTANALYSISANDTHEMECHANICALANALYSIS,ALSOMUSTESTABLISHTHELOADANDTHEOPERATINGCYCLECHARTTOTHECOMPLEXSYSTEM,FROMTHISUNDERSTOODTHEHYDRAULICCYLINDERORTHEOILMOTORLOADANDTHESPEEDCHANGEASNECESSARYTHERULE,BELOWMAKESTHECONCRETEINTRODUCTIONTOTHEOPERATINGMODEANALYSISCONTENT11MOVEMENTSANALYSESTHEMAINENGINEFUNCTIONALELEMENTACCORDINGTOTHETECHNOLOGICALREQUIREMENTMOVEMENTSITUATION,MAYUSETHEDISPLACEMENTCIRCULATIONCHARTLT,THESPEEDCIRCULATIONCHARTVT,ORTHESPEEDANDTHEDISPLACEMENTCIRCULATIONCHARTINDICATED,FROMTHISCARRIESONTHEANALYSISTOTHEMOVEMENTRULE111DISPLACEMENTSCIRCULATIONATTEMPTSLTTHECHART11ISTHEHYDRAULICPRESSHYDRAULICCYLINDERMOVESTHECIRCULATIONCHART,THEYCOORDINATELEXPRESSIONPISTONMOVES,THEXCOORDINATETEXPRESSIONSTARTSFROMTHEPISTONTOTHEREPOSITIONTIME,THERATEOFCURVEEXPRESSIONMOVEMENTOFPLUNGERSPEEDCHART11DISPLACEMENTSCIRCULATIONCHART112SPEEDSCIRCULATIONCHARTVTORVLINTHEPROJECTTHEHYDRAULICCYLINDERMOVEMENTCHARACTERISTICMAYINDUCEISTHREEKINDOFTYPESTHECHART12ISTHREEKINDOFTYPESHYDRAULICCYLINDERSVTCHART,THEFIRSTKINDOFLIKECHART12CENTERSOLIDLINESSHOW,THEHYDRAULICCYLINDERSTARTSTOMAKETHEUNIFORMACCELERATEDMOTION,THENUNIFORMMOTION,1CHART12SPEEDSCIRCULATIONCHARTFINALLYUNIFORMRETARDEDMOTIONTOENDPOINTTHESECONDKIND,THEHYDRAULICCYLINDERPRECEDINGPARTLYMAKESTHEUNIFORMACCELERATEDMOTIONINTHEOVERALLTRAVELLINGSCHEDULE,INANOTHERONEPARTLYMAKESTHEUNIFORMRETARDEDMOTION,ALSOTHEACCELERATIONVALUEISEQUALTHETHIRDKIND,THEHYDRAULICCYLINDERONEMOSTABOVEMAKESTHEUNIFORMACCELERATEDMOTIONINTHEOVERALLTRAVELLINGSCHEDULEBYASMALLERACCELERATION,THENUNIFORMDECELERATESTOTHETRAVELLINGSCHEDULEENDPOINTVTCHARTTHREEVELOCITYCURVE,NOTONLYCLEARLYHASINDICATEDTHREEKINDOFTYPESHYDRAULICCYLINDERSMOVEMENTRULE,ALSOINDIRECTLYHASINDICATEDTHREEKINDOFOPERATINGMODESDYNAMICPERFORMANCE12MECHANICALANALYSES121HYDRAULICCYLINDERSLOADSANDDUTYCYCLECHART1211HYDRAULICCYLINDERSLOADSTRENGTHCOMPUTATIONSWHENTHEOPERATINGMECHANISMMAKESTHESTRAIGHTRECIPROCATINGMOTION,THEHYDRAULICCYLINDERMUSTOVERCOMETHELOADISCOMPOSEDBYSIXPARTS11BMGIFCFFINTHEFORMULAFCINORDERTORESISTANCETOCUTTINGFFINORDERTOFRICTIONDRAGFIFORINERTIARESISTANCEFGFORGRAVITYFMINORDERTOSEALTHERESISTANCEFBINORDERTODRAINTHEOILTHERESISTANCE1212HYDRAULICCYLINDERSCYCLEOFMOTIONVARIOUSSTAGESOVERALLLOADSTRENGTHTHEHYDRAULICCYLINDERCYCLEOFMOTIONVARIOUSSTAGESOVERALLLOADSTRENGTHCOMPUTATION,GENERALLYINCLUDESTHESTARTACCELERATION,QUICKLYENTERS,THELABORENTERS,QUICKLYDRAWSBACK,DECELERATESAPPLIESTHEBRAKEANDSOONSEVERALSTAGES,EACHSTAGEOVERALLLOADSTRENGTHHASTHEDIFFERENCE1STARTSTHEACCELERATIONPERIODBYNOWTHEHYDRAULICCYLINDERORTHEPISTONWEREINFROMSTATICENOUGHTOSTARTSANDACCELERATESTOTHECERTAINSPEED,ITSOVERALLLOADSTRENGTHINCLUDINGGUIDERAILFRICTIONFORCE,PACKINGASSEMBLYFRICTIONFORCEACCORDINGTOCYLINDERMECHANICALEFFICIENCYM09COMPUTATION,GRAVITYANDSOONITEM,NAMELY12BMGIFFF2FASTSTAGE13BGF3THELABORENTERSTHESTAGE(14)4BMGFCFFDECELERATES15BGIFTOTHESIMPLEHYDRAULICSYSTEM,THEABOVECOMPUTATIONPROCESSMAYSIMPLIFYFOREXAMPLEUSESTHESINGLEPROPORTIONINGPUMPTOSUPPLYTHEOIL,ONLYMUSTCALCULATETHELABORTOENTERTHESTAGETHEOVERALLLOADSTRENGTH,IFTHESIMPLESYSTEMUSESTHELIMITINGPRESSURETYPEVARIABLEDISPLACEMENTPUMPORAPAIROFASSOCIATIONPUMPSFORTHEOIL,THENONLYMUSTCALCULATETHEFASTSTAGEANDTHELABORENTERSTHESTAGETHEOVERALLLOADSTRENGTH2122OILMOTORSLOADWHENTHEOPERATINGMECHANISMMAKESTHEROTARYMOTION,THEOILMOTORMUSTOVERCOMETHEOUTSIDELOADIS16IFEM1221OPERATINGDUTIESMOMENTOFFORCEMETHEOPERATINGDUTYMOMENTOFFORCEISPOSSIBLYADEFINITEVALUE,ALSOPOSSIBLYASNECESSARYCHANGES,SHOULDCARRYONTHECONCRETEANALYSISACCORDINGTOTHEMACHINEWORKINGCONDITION1222FRICTIONMOMENTSINORDERTOREVOLVETHEPARTJOURNALPLACEFRICTIONMOMENT,ITSFORMULAIS17NGFRFINTHEFORMULAGISREVOLVESTHEPARTWEIGHTNFISTHERUBBINGFACTOR,WHENTHESTARTFORTHEFACTOR,AFTERTHESTARTFORMOVESTHERUBBINGFACTORRISTHEJOURNALRADIUSM1223MOMENTOFINERTIAMITHEMOMENTOFINERTIAWHICHINORDERTOREVOLVETHEPARTACCELERATIONORDECELERATESWHENPRODUCES,ITSFORMULAIS18NTJIINTHEFORMULAISTHEANGLEACCELERATIONR/S2ISTHEACCELERATIONORDECELERATESTHETIMESJISTREVOLVESTHEPARTROTATIONINERTIA,2MKGGDJ41INTHEFORMULAINORDERTOROTATETHEPARTTHEFLYWHEELEFFECT2GD2MNEACHKINDMAYLOOKUPACCORDINGTOTHETYPE16,SEPARATELYFIGURESOUTTHEOILMOTORINAOPERATINGCYCLEVARIOUSSTAGESLOADSIZE,THENMAYDRAWUPTHEOILMOTORTHEDUTYCYCLECHART2DETERMINATIONSHYDRAULICSYSTEMMAINPARAMETER21HYDRAULICCYLINDERSDESIGNCALCULATIONS211INITIALLYDECIDESTHEHYDRAULICCYLINDERWORKINGPRESSUREINTHEHYDRAULICCYLINDERWORKINGPRESSUREMAINBASISCYCLEOFMOTIONVARIOUSSTAGESBIGGESTOVERALLLOADSTRENGTHDETERMINED,INADDITIONBELOW,BUTALSONEEDSTOCONSIDERTHEFACTOR2111EACHKINDOFEQUIPMENTDIFFERENTCHARACTERISTICANDUSESITUATION2112CONSIDERATIONSECONOMIESANDTHEWEIGHTFACTOR,THEPRESSUREELECTSLOWLY,THENPARTSIZEBIG,THEWEIGHTISHEAVYTHEPRESSURECHOOSESHIGHSOMEWHAT,THENPARTSIZESMALL,THEWEIGHTISLIGHT,BUTTOTHEPARTMANUFACTUREPRECISION,THESEALINGPROPERTYREQUESTSHIGHTHEREFORE,THEHYDRAULICCYLINDERWORKINGPRESSURECHOICEHASTWOWAYSONE,ELECTSACCORDINGTOTHEMECHANICALTYPETWO,ACCORDINGTOCUTSTHELOADTOELECTIFTHETABLE21,THETABLE22SHOWSTHETABLE21PRESSESTHELOADTOCHOOSETHEEXECUTIONFILETHEWORKINGPRESSURE3LOAD/N50005001000010000200002000030000300005000050000WORKINGPRESSURE/MPA08115225334455THETABLE22PRESSESTHEMECHANICALTYPETOCHOOSETHEEXECUTIONFILETHEWORKINGPRESSUREENGINEBEDMECHANICALTYPEGRINDERAGGREGATEMACHINETOOLDRAGONGATEDIGSTHEBEDBROACHINGMACHINEFARMMACHINERYPROJECTMACHINERYWORKINGPRESSURE/MPAA23588101016203222OILMOTORSDESIGNCALCULATION221COMPUTATIONSOILMOTORDISPLACEMENTUNDEROILMOTORDISPLACEMENTACCORDINGTOTHETYPEDECIDEDTHAT,212863MINRPTVMINTHEFORMULATISTHEOILMOTORLOADMOMENTOFFORCENMFOROILMOTORIMPORTANDEXPORTMPRESSUREDIFFERENCEN/M3ISTHEOILMOTORMECHANICALEFFICIENCY,THECOMMONGEARANDTHEPLUNGERMOTORTAKES09095,THELEAFBLADEMOTORTAKES0809222COMPUTATIONSOILMOTORNEEDSTHECURRENTCAPACITYOILMOTORTHEMAXIMUMCURRENTCAPACITY223MAXAXSNVQINTHEFORMULAISTHEOILMOTORDISPLACEMENTM3/RISTHEOILMOTORHIGHESTROTATIONALSPEEDMAXR/S3HYDRAULICPRESSUREPARTSCHOICE31HYDRAULICPUMPSDETERMINATIONSWITHNEEDTHEPOWERTHECOMPUTATION3111DETERMINESTHEHYDRAULICPUMPTHEBIGGESTWORKINGPRESSURETHEHYDRAULICPRESSUREPUMPINGSTATIONMUSTTHEWORKINGPRESSUREDETERMINATION,MAINLYACTSACCORDINGTOTHEHYDRAULICCYLINDERINTHEOPERATINGCYCLEVARIOUSSTAGESTOHAVEMOSTTREMENDOUSPRESSUREP1,INADDITIONTHEOILPUMPLOSESSIGMADELTAPTHEOILMOUTHTOTHECYLINDERPLACEALWAYSPRESSUREP,NAMELY31PB14LOSES,THEPIPELINEINCLUDINGTHEOILAFTERTHEFLOWVALVEANDOTHERPARTSLOCALPRESSURESALONGTHEPREGULATIONLOSSANDSOON,BEFORESYSTEMPIPELINEDESIGN,MAYACTACCORDINGTOTHESIMILARSYSTEMEXPERIENCETOESTIMATE,COMMONPIPELINESIMPLETHROTTLEVALVEVELOCITYMODULATIONSYSTEMPIS25105PA,WITHTHEVELOCITYMODULATIONVALVEANDPIPELINECOMPLEXSYSTEMIS515105PA,ALSOMAYONLYPPCONSIDERFLOWSAFTERVARIOUSCONTROLVALVESPRESSURELOSS,BUTIGNORESTHECIRCUITRYALONGTHEREGULATIONLOSS,VARIOUSVALVESRATEDPRESSURELOSESMAYSEARCHESFROMTHEHYDRAULICPRESSUREPARTHANDBOOKORTHEPRODUCTSAMPLE,ALSOMAYREFERTOTHETABLE13SELECTIONSTHETABLE31ISCOMMONLYUSED,THELOWPRESSUREEACHKINDOFVALVEPRESSURELOSESPNVALVEPN105PAVALVEPN105PAVALVEPN105PAVALVEPN105PACONEWAYVALVE0305CONEWAYVALVE38CONEWAYVALVE152CONEWAYVALVE152CROSSVALVE153CROSSVALVE23CROSSVALVE153CROSSVALVE35312DETERMINESTHEHYDRAULICPUMPCURRENTCAPACITYQBPUMPSTHECURRENTCAPACITYBASISFUNCTIONALELEMENTOPERATINGCYCLEMUSTTHEMAXIMUMCURRENTQBCAPACITYANDTHESYSTEMDIVULGESTHEDETERMINATIONQMAX3121ATTHESAMETIMEWHENMORETHANHYDRAULICCYLINDERSMOVEMENT,THEHYDRAULICPUMPCURRENTCAPACITYMUSTBEBIGGERTHANTHEMAXIMUMCURRENTCAPACITYWHICHATTHESAMETIMETHEMOVEMENTSEVERALHYDRAULICCYLINDERSORMOTORNEEDS,ANDSHOULDCONSIDERTHESYSTEMDIVULGINGWEARSTHEVOLUMETRICEFFICIENCYDROPAFTERTHEHYDRAULICPUMP,NAMELY323MAXSQKBINTHEFORMULAKISTHESYSTEMLEAKAGECOEFFICIENT,GENERALLYTAKES1113,THEGREATCURRENTCAPACITYTAKESTHESMALLVALUE,THESMALLCURRENTCAPACITYTAKESTHEGREATVALUEFORATTHESAMETIMEMAXQMOVEMENTHYDRAULICCYLINDERORMOTORISBIGGESTM3/S3122CHOOSESTHEHYDRAULICPUMPTHESPECIFICATIONTABLE32HYDRAULICPUMPSOVERALLEFFECTIVENESSINDICESHYDRAULICPUMPTYPEGEARPUMPTHESCREWRODPUMPSVANEPUMPRAMPUMP5OVERALLEFFECTIVENESSINDEX0607065080060075080085ROTATIONALSPEEDANDPUMPSWHICHACCORDINGTOTHEABOVEPOWER,MAYSELECTTHESTANDARDELECTRICMOTORFROMTHEPRODUCTSAMPLE,AGAINCARRIESON,CAUSESWHENTHEELECTRICMOTORSENDSOUTTHEMAXIMUMWORKRATE,INPERMISSIONSCOPE32VALVESCLASSPARTSCHOICE321CHOICESBASESTHECHOICEBASISISRATEDPRESSURE,MAXIMUMCURRENTCAPACITY,MOVEMENTWAY,INSTALLMENTFIXEDWAY,PRESSURELOSSVALUE,OPERATINGPERFORMANCEPARAMETERANDWORKINGLIFEANDSOON322SELECTORVALVESCLASSPARTSSHOULDPAYATTENTIONQUESTION3221SHOULDSELECTTHESTANDARDSTEREOTYPIAPRODUCTASFARASPOSSIBLE,ONLYIFDOESNOTHAVEALREADYTIMEONLYTHENINDEPENDENTLYDESIGNSSPECIALPURP3222VALVESCLASSPARTSSPECIFICATIONMAINBASISCLASSAFTERTHISVALVEFATLIQUORMOSTTREMENDOUSPRESSUREANDMAXIMUMCURRENTCAPACITYSELECTIONWHENCHOOSESTHEOVERFLOWVALVE,SHOULDACCORDINGTOTHEHYDRAULICPUMPMAXIMUMCURRENTCAPACITYSELECTIONWHENCHOOSESTHETHROTTLEVALVEANDTHEVELOCITYMODULATIONVALVE,SHOULDCONSIDERITSMINIMUMSTABLECURRENTCAPACITYSATISFIESTHEMACHINELOWSPEEDPERFORMANCETHEREQUEST33ACCUMULATORSCHOICES331ACCUMULATORSUSEINTOSUPPLEMENTWHENTHEHYDRAULICPUMPSUPPLIESTHEOILINSUFFICIENCY,ITSDISCHARGEABLECAPACITYIS333MTQKLAVBIINTHEFORMULAAISTHEHYDRAULICCYLINDERACTIVESURFACEM2LISTHEHYDRAULICCYLINDERTRAVELLINGSCHEDULEMKISTHEHYDRAULICCYLINDERLOSSCOEFFICIENT,WHENTHEESTIMATEMAYTAKEK12SUPPLIESTHEOILCURRENTCAPACITYFORTHEHYDRAULICPUMPM3/STISTHEOPERATINGTIMES332ACCUMULATORSMAKETHEEMERGENCYENERGY,ITSDISCHARGEABLECAPACITYIS343TQLAVBIWHENTHEACCUMULATORUSESINABSORBSTHEPULSATIONTORELAXTHEHYDRAULICPRESSUREIMPACT,SHOULDTAKEITASINTHESYSTEMALINKIFTOBECONNECTEDPARTIALLYTOGETHERSYNTHESIZESCONSIDERSITSDISCHARGEABLECAPACIACCORDINGTOTHEDISCHARGEABLECAPACITYWHICHEXTRACTSANDCONSIDEREDOTHERREQUESTS,THENCHOOSESTHEACCUMULATORTHEFORM34PIPELINESCHOICES341DRILLTUBINGSTYPESCHOICE6INTHEHYDRAULICSYSTEMUSESTHEDRILLTUBINGDIVIDESTHEHARDTUBEANDTHEHOSE,THECHOICEDRILLTUBINGSHOULDHAVEENOUGHPASSESFLOWSTHESECTIONANDTHEBEARINGPRESSUREABILITY,SIMULTANEOUSLY,SHOULDREDUCETHEPIPELINEASFARASPOSSIBLE,AVOIDSTHEEXTREMETURNANDTHESECTIONSUDDENCHANGE3411STEELPIPESCENTERTHEHIGHTENSIONSYSTEMSELECTSTHESEAMLESSSTEELPIPE,THELOWPRESSURESYSTEMSELECTSTHEWELDEDSTEELPIPE,THESTEELPIPEPRICELOWLY,PERFORMANCEGOOD,THEUSEISWIDESPREAD3412COPPERPIPESTHECOPPERTUBEWORKINGPRESSUREBELOW6510MPA,THEINSTABLETUNE,ISADVANTAGEOUSFORTHEASSEMBLYYELLOWCOPPERPIPEWITHSTANDINGPRESSUREHIGHER,REACHES25MPA,WASINFERIORTOTHECOPPERTUBEISEASYTOBECURVINGCOPPERPIPEPRICEHIGH,EARTHQUAKERESISTANCEABILITYWEAK,ISEASYTOCAUSETHEFATLIQUOROXIDATION,SHOULDASFARASPOSSIBLELITTLEUSE,ONLYUSESINTHEHYDRAULICUNITTOMATCHMEETSNOTTHECONVENIENTSPOT342DRILLTUBINGSSIZESDETERMINATION3421DRILLTUBINGSINSIDEDIAMETERSDPRESSESDOWNTHETYPECOMPUTATIONINTHEFORMULAQISPASSESTHEDRILLTUBINGTHEMAXIMUMCURRENTCAPACITYM3/SVSPEEDOFFLOWWHICHPERMITSFORTHEPIPELINEINM/STHECOMMONOILSUCTIONPIPETAKES055M/STHEPRESSUREOILPIPETAKES255M/STHEOILRETURNPIPETAKES152M/S342DRILLTUBINGSSIZESDETERMINATION35DPINTHEFORMULAPISINTHETUBETHEBIGGESTWORKINGPRESSUREWHENNISTHESAFETYCOEFFICIENT,STEELPIPEP175MPA,TAKESN4ACCORDINGTODRILLTUBINGINSIDEDIAMETERANDWALLTHICKNESSWHICHCALCULATES,LOOKSUPTHEHANDBOOKSELECTIONSTANDARDSPECIFICATIONDRILLTUBING35FUELTANKDESIGNTHEFUELTANKFUNCTIONISTHEOILSTORAGE,DISPERSESTHEOILDISCHARGETHEQUANTITYOFHEAT,INTHEPRECIPITATIONOILTHEIMPURITY,ISLEISURELYINTHEOILTHEGAS351FUELTANKSDESIGNSMAINPOINT3511FUELTANKSSHOULDHAVETHEENOUGHVOLUMETOSATISFYTHERADIATION,SIMULTANEOUSLYITSVOLUMESHOULDGUARANTEEINTHESYSTEMTHEFATLIQUORCOMPLETELYFLOWSWHENTHEFUELTANKDOESNOTSEEPOUT,THEFATLIQUORLIQUIDLEVELSHOULDNOTSURPASSTHEFUELTANKHIGHLY803512SUCTIONBOXESTUBESANDTHEOILRETURNPIPESPACINGSHOULDBEASFARASPOSSIBLEBIG3513FUELTANKSBASESSHOULDHAVETHESUITABLEASCENT,RELEASESTHEOILMOUTHTOSETTOTHEMOSTLOWSPOT,INORDERTODRAINSTHEOIL36OILFILTERSCHOICESCHOOSESTHEOILFILTERTHEBASISTOHAVEFOLLOWINGSEVERAL361BEARINGCAPACITIESACCORDINGTOSYSTEMPIPELINEWORKINGPRESSUREDETERMINATION362FILTERSTHEPRECISIONACCORDINGTOISPROTECTEDTHEPARTTHEPRECISIONREQUESTDETERMINATION7363FLOWTHEABILITYACCORDINGTOTHROUGHMAXIMUMCURRENTCAPACITYDETERMINATION364RESISTANCEPRESSUREDROPSSHOULDTHESATISFIEDFILTERMATERIALINTENSITYANDTHECOEFFICIENTREQUEST4HYDRAULICSYSTEMSPERFORMANCEINORDERTOJUDGETHEHYDRAULICSYSTEMTHEDESIGNQUALITY,NEEDSTOLOSETOTHESYSTEMPRESSURE,TOGIVEOFFHEAT,THEEFFICIENCYANDSYSTEMDYNAMICCHARACTERISTICANDSOON41CIRCUITRIESPRESSURELOSESAFTERHYDRAULICPRESSUREPARTSPECIFICATIONMODELANDPIPELINESIZEDETERMINATION,MAYTHEMOREACCURATECOMPUTINGSYSTEMPRESSURELOSS,THEPRESSURELOSSINCLUDETHEOILLOSES,THELOCALPRESSUREAFTERTHELPPIPELINEALONGTHEREGULATIONPRESSUREDAMAGESFLOWSAFTERTHEVALVECLASSPARTPRESSURELOSS,CPVPNAMELY41VCLPSYSTEMADJUSTMENTPRESSURE4210INTHEFORMULAP0FORHYDRAULICPUMPWORKINGPRESSUREORLEGADJUSTMENTPRESSUREP1INORDERTOEXECUTIONWORKINGPRESSUREIFCALCULATESINTHEPRIMARYELECTIONSYSTEMWORKINGPRESSURETIMETHEISSKETCHIERTHANDESIGNATIONPRESSURETOLOSEISMUCHBIGGERTHAN,SHOULDREMOVEENTIRERELATEDPART,AUXILIARYSPECIFICATION,AGAINDEFINITEPIPELINESIZE42SYSTEMSGIVEOFFHEATTHESYSTEMGIVESOFFHEATORIGINATESFROMTHESYSTEMINTERIORENERGYLOSS,LIKETHEHYDRAULICPUMPANDTHEFUNCTIONALELEMENTPOWERLOSS,THEOVERFLOWVALVEOVERFLOWLOSES,THEHYDRAULICVALVEANDTHEPIPELINEPRESSURELOSSANDSOONTHESYSTEMGIVESOFFHEATTHEPOWERPCOMPUTATION431WBINTHEFORMULAPBISTHEHYDRAULICPUMPPOWERINPUTWISTHEHYDRAULICPUMPOVERALLEFFECTIVENESSINDEXIFINAOPERATINGCYCLEHASSEVERALWORKINGPROCEDURES,THENMAYACTACCORDINGTOEACHWORKINGPROCEDURETHECALORIFICCAPACITY,EXTRACTSTHESYSTEMUNITTIMETHEAVERAGECALORIFICCAPACITY441WTPTINIBIINTHEFORMULATISTHEOPERATINGCYCLECYCLESTIFORIWORKINGPROCEDUREOPERATINGTIMESPIISINTHECIRCULATIONTHEIWORKINGPROCEDUREPOWERINPUTW843SYSTEMSEFFICIENCYTHEHYDRAULICSYSTEMEFFICIENCYISBYTHEHYDRAULICPUMP,THEFUNCTIONALELEMENTANDTHEHYDRAULICPRESSURERETURNROUTEEFFICIENCYDETERMINEDTHEHYDRAULICPRESSURERETURNROUTEEFFICIENCYGENERALLYMAYUSETHETYPETOCALCULATEC45221BBCQPINTHEFORMULAP1,Q1;P2,Q2;FOREACHFUNCTIONALELEMENTWORKINGPRESSUREANDCURRENTCAPACITYPB1,QB1;PB2,QB2ISEACHHYDRAULICPUMPSUPPLIESTHEOILPRESSUREANDTHECURRENTCAPACITYHYDRAULICSYSTEMOVERALLEFFECTIVENESSINDEX46CMBINTHEFORMULAFORHYDRAULICPUMPOVERALLEFFECTIVENESSINDEXINORDERTOFUNCTIONALELEMENTBMOVERALLEFFECTIVENESSINDEXFORRETURNROUTEEFFICIENCYC5DRAWSUPTHEREGULARWORKERMAPPINGANDTHECOMPILATIONTECHNOLOGYDOCUMENTPASSESTHROUGHAFTERTHEHYDRAULICSYSTEMPERFORMANCEANDTHEESSENTIALREVISION,THENMAYDRAWUPTHEREGULARWORKERMAPPING,ITINCLUDINGPLANHYDRAULICSYSTEMSCHEMATICDIAGRAM,SYSTEMPIPELINEASSEMBLYDRAWINGANDEACHKINDOFNONSTANDARDPARTDESIGNDRAWINGINTHEOFFICIALHYDRAULICSYSTEMSCHEMATICDIAGRAMMUSTMARKVARIOUSHYDRAULICPRESSUREPARTTHEMODELSPECIFICATIONREGARDINGAUTOMATICITYHIGHERENGINEBED,BUTALSOSHOULDINCLUDETHEMOVEMENTPARTTHECYCLEOFMOTIONCHARTANDTHEELECTROMAGNET,THEPRESSURESWITCHACTIVESTATUS51DETERMINATIONSHYDRAULICSYSTEMPARAMETERMAYKNOWBYTHEOPERATINGMODEANALYSISIN,THELABORENTERSTHESTAGETHELOADSTRENGTHTOBEBIGGEST,THEREFORE,THEHYDRAULICCYLINDERWORKINGPRESSUREACCORDINGTOTHISLOADSTRENGTHCOMPUTATION,ACCORDINGTOTHEHYDRAULICCYLINDERANDTHELOADRELATIONS,P140105PATHISENGINEBEDFORTHEDRILLHOLEAGGREGATEMACHINETOOL,FORPREVENTEDDRILLSTHROUGHBEFOREWHENOCCURSFLUSHESTHEPHENOMENON,THEHYDRAULICCYLINDEROILDISCHARGECAVITYSHOULDHAVETHEBACKPRESSURE,、P26105PA,FORCAUSESQUICKLYTOENTERQUICKLYDRAWSBACKTHESPEEDTOBEEQUAL,SELECTSTHEDIFFERENTIALMOTIONCYLINDER,THEHYPOTHESISQUICKLYENTERSTHE21AOILDISCHARGEPRESSUREWHICH,QUICKLYDRAWSBACKTOLOSEFORP7105PA52CHOICESHYDRAULICPRESSUREPART521CHOOSESTHEHYDRAULICPUMPANDTHEELECTRICMOTOR5211DETERMINESTHEHYDRAULICPUMPTHEWORKINGPRESSUREFRONTHADDETERMINEDTHEHYDRAULICCYLINDERTHEBIGGESTWORKINGPRESSUREFOR40105PA,SELECTSTHEINTAKEPIPEROADPRESSURETOLOSEP8105PA,ITSADJUSTMENTPRESSUREISGENERALLYBIGGERTHANTHESYSTEMBIGGESTWORKINGPRESSURE5105PA,THEREFOREPUMPSWORKINGPRESSUREPB408510553105PA9THISISTHEWORKINGPRESSUREWHICHTHEHIGHPRESSUREDSMALLCURRENTCAPACITYPUMPSTHEHYDRAULICCYLINDERQUICKLYDRAWSBACKWHENTHEWORKINGPRESSUREQUICKLYENTERSWHENISBIGGERTHAN,TAKESITSPRESSURETOLOSEDELTAP4105PA,THENQUICKLYDRAWSBACKTIMEPUMPSTHEWORKINGPRESSUREISPB1644105204105PATHISISTHEWORKINGPRESSUREWHICHTHELOWPRESSUREGREATCURRENTCAPACITYPUMPS5212HYDRAULICPUMPSCURRENTCAPACITIESQUICKLYENTERSWHENTHECURRENTCAPACITYISBIGGEST,ITSVALUEIS30L/MIN,THEQUANTITYENTERSWHENTHELABOR,ITSVALUEIS051L/MIN,TAKESK12,THENQB120510336L/MINBECAUSETIMETHEOVERFLOWVALVESTEADYWORKMOSTISSMALLIS3L/MIN,THEREFORESLIGHTLYPUMPSTHECURRENTCAPACITYTOTAKE36L/MINCALCULATESACCORDINGTOABOVE,SELECTSTHEYYBAA36/6BDOUBLEJOINTVANEPUMP5213DEFINITEPIPELINESSIZESACCORDINGTOTHEWORKINGPRESSUREANDTHECURRENTCAPACITY,ACCORDINGTOTHETYPE35,THETYPE36DETERMINETHEPIPELINEINSIDEDIAMETERANDWALLTHICKNESSOMITS5214DETERMINATIONSFUELTANKCAPACITYFUELTANKCAPACITYMAYACCORDINGTOTHEEMPIRICALFORMULAESTIMATE,TAKEV57QINTHISEXAMPLEV6Q6636252LRELATEDSYSTEMPERFORMANCEOMITS10中文翻译液压传动系统设计与计算1明确设计要求进行工况分析在设计液压系统时,首先应明确以下问题,并将其作为设计依据。主机的用途、工艺过程、总体布局以及对液压传动装置的位置和空间尺寸的要求;主机对液压系统的性能要求,如自动化程度、调速范围、运动平稳性、换向定位精度以及对系统的效率、温升等的要求;液压系统的工作环境,如温度、湿度、振动冲击以及是否有腐蚀性和易燃物质存在等情况。在上述工作的基础上,应对主机进行工况分析,工况分析包括运动分析和动力分析,对复杂的系统还需编制负载和动作循环图,由此了解液压缸或液压马达的负载和速度随时间变化的规律,以下对工况分析的内容作具体介绍。11运动分析主机的执行元件按工艺要求的运动情况,可以用位移循环图LT,速度循环图VT,或速度与位移循环图表示,由此对运动规律进行分析。111位移循环图LT图11为液压机的液压缸位移循环图,纵坐标L表示活塞位移,横坐标T表示从活塞启动到返回原位的时间,曲线斜率表示活塞移动速度。图11位移循环图112速度循环图VT或VL工程中液压缸的运动特点可归纳为三种类型。图12为三种类型液压缸的VT图,第一种如图12中实线所示,液压缸开始作匀加速运动,然后匀速运动,最后匀减速运动到终点;第二种,液压缸在总行程的前一半作匀加速运动,在另一半作匀减速运动,且加速度的数值相等;第三种,液压缸在总行程的一大半以上以较小的加速度作匀加速运动,然后匀减速至行程终

- 温馨提示:

1: 本站所有资源如无特殊说明,都需要本地电脑安装OFFICE2007和PDF阅读器。图纸软件为CAD,CAXA,PROE,UG,SolidWorks等.压缩文件请下载最新的WinRAR软件解压。

2: 本站的文档不包含任何第三方提供的附件图纸等,如果需要附件,请联系上传者。文件的所有权益归上传用户所有。

3.本站RAR压缩包中若带图纸,网页内容里面会有图纸预览,若没有图纸预览就没有图纸。

4. 未经权益所有人同意不得将文件中的内容挪作商业或盈利用途。

5. 人人文库网仅提供信息存储空间,仅对用户上传内容的表现方式做保护处理,对用户上传分享的文档内容本身不做任何修改或编辑,并不能对任何下载内容负责。

6. 下载文件中如有侵权或不适当内容,请与我们联系,我们立即纠正。

7. 本站不保证下载资源的准确性、安全性和完整性, 同时也不承担用户因使用这些下载资源对自己和他人造成任何形式的伤害或损失。

人人文库网所有资源均是用户自行上传分享,仅供网友学习交流,未经上传用户书面授权,请勿作他用。

川公网安备: 51019002004831号

川公网安备: 51019002004831号