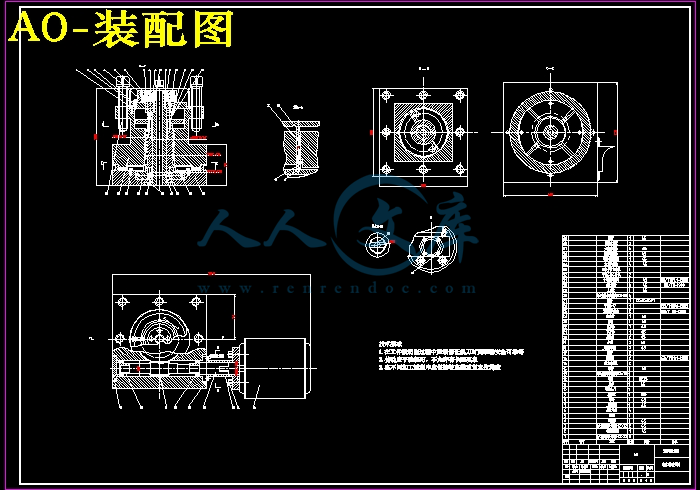

MJ—50型数控车床电动刀架设计【说明书+CAD】

收藏

资源目录

压缩包内文档预览:

编号:10052878

类型:共享资源

大小:2.58MB

格式:RAR

上传时间:2018-04-24

上传人:柒哥

认证信息

个人认证

杨**(实名认证)

湖南

IP属地:湖南

38

积分

- 关 键 词:

-

mj

50

数控车床

电动

刀架

设计

说明书

仿单

cad

- 资源描述:

-

【温馨提示】 购买原稿文件请充值后自助下载。

以下预览截图到的都有源文件,图纸是CAD,文档是WORD,下载后即可获得,所见即所得。

预览截图请勿抄袭,原稿文件完整清晰,无水印,可编辑。

有疑问可以咨询QQ:12401814

- 内容简介:

-

INTEGRATEDMANUFACTURINGCELLFORMATIONTECHNOLOGYORIENTINGMULTIPRODUCTTYPEANDVARIANTVOLUMEPRODUCTIONABSTRACTWHATISPURSUEDBYMULTIPRODUCTTYPEANDVARIANTVOLUMEMPTVVPRODUCTIONISRAPIDRESPONSEANDQUICKSWITCHING,SOTHATSTRUCTUREOFTRANSFERRINGLINEINMANUFACTURINGSYSTEMISNOLONGERUNALTERABLECELLFORMATIONCFALGORITHMISTHEKEYTECHNOLOGYOFCELLULARMANUFACTURINGSYSTEMCMSCURRENTLY,CFMETHODSAREMAINLYEXTENDEDONTHEIDEAOFGROUPTECHNOLOGYGTTHATCOVERSALOTONANALYSISOFRESOURCECAPABILITYMATCHINGANDITSALGORITHMVARIOUSCONSTRAINTSARECONSIDERED,BUTSELDOMUTILIZEDCOMPREHENSIVELYAIMEDTOTHEPROBLEMOFMANUFACTURINGCELLMCFORMATIONUNDERMPTVVPRODUCTIONMODE,INTEGRATEDFORMATIONTECHNOLOGIESFORTYPICALMCASGROUPTYPEOFCELLGC,FLOWTYPEOFCELLFCANDINHERITEDCELLICAREPRESENTEDBASEDONTECHNICALANALYSISOFCFORIENTEDTOPRACTICALPRODUCTIONCONSTRAINTSLIKEDELIVERYTIME,PRODUCTBATCH,EQUIPMENTABILITY,KEYMACHINE,KEYPARTANDMACHINESHARING,ETC,ANIMEGRATEDFORMATIONMODELISCONSTRUCTEDANDINTEMALIMTERRELATIONSOFTHESECONSTRAINTSAREANALYZEDSYNTHETICALLYULTERIORLY,FORMATIONGOALSOFTYPESOFMCSANDTHEIRFORMATIONPROCEDURESUNDERJOINTEFFECTOFFORMATIONCONSTRAINTSANDRULESARESPREADINCASESTUDY,THREEHIGHLYBALANCEDGCAREFORMEDFIRSTTHENFCFORMATIONAREIMPLEMENTEDBASEDONTHESAMEDATAWHICHINDICATEGOODBALANCINGEFFECTOFCELLLOADANDFLOWSTYLEPRODUCTIONFORKEYTASKS;WHENTASKISADJUSTED,ANEWSCHEMEISCONSTRUCTEDONTHERESULTOFFCCONFIGURATIONBYUSINGICFORMATIONMETHOD,ANDMOREOPTIMALPERFORMANCEOFFLOWSTYLEPRODUCTIONISMANIFESTEDTHEPROPOSEDCOMPARATIVESTUDYOFDIFFERENTTYPEOFCELLSSTRONGLYEXPLAINSTHEVALIDATIONOFINTEGRATEDMCFORMATIONINSUPPORTOFRAPIDMANUFACTURINGRESOURCETRANSFORMATIONUNDERMPTVVPRODUCTIONMODEKEYWORDSMULTIPRODUCTTYPEANDVARIANTVOLUMEPRODUCTION,CELLFORMATION,FLOWSTYLEMANUFACTURINGCELL,INHERITINGMANUFACTURINGCELL1INTRODUCTIONNOWADAYS,MULTIPLETYPEANDVARIABLEPRODUCTIONMODEHASBEENANINEVITABLECHOICEFORMOSTENTERPRISES,WHICHISANATURALRESULTINTHECOURSEOFADAPTINGORBEINGADAPTEDTOTHEEVERCHANGINGNEEDSOFOURSOCIETYASAMODEPOSITIONEDBETWEENFEWTYPEANDMASSPRODUCTIONOFFLOWINGDEDICATEDPRODUCTIONLINEANDMULTIPLETYPEANDSMALLORMEDIUMPRODUCTIONOFDISCRETEFLEXIBLEPRODUCTIONLINE,MULTIPLETYPEANDVARIABLEPRODUCTIONHASBOTHADVANTAGESOFEFFICIENCYANDFLEXIBILITYTARGETINGVARIABILITYANDRAPIDRESPONSEOFSYSTEMCELLULARMANUFACTURINGISAFORMOFPRODUCTIONORGANIZATIONWHICHCANACCOMMODATETOSUCHTYPEOFPRODUCTIONMODE,ANDWELLSUPPORTRAPIDRESPONSEOFMANUFACTURINGSYSTEMTHECOREOFCELLULARMANUFACTURINGISTHEREORGANIZATIONANDREUSEOFMANUFACTURINGRESOURCES;MANUFACTURINGCELLCHARACTERIZEDWITHSELFGOVERNMENT,COLLABORATIONANDFLEXIBILITYISTHECORECOMPONENTTHEREFORE,TECHNOLOGIESOFCELLFORMATIONANDRECONFIGURATIONAREALSOTHEKEYSINIMPLEMENTATIONOFCMSPRESENTLY,TECHNOLOGIESOFCELLFORMATIONCFAREMAINLYFOCUSINGONITSCONSTRUCTIONALGORITHMLIKELYASPECTSOFFORMATIONRULESANDCONSTRAINTSSUCHASMULTIROUTESANDEQUIPMENTTYPES,WORKTIMEASSIGNMENT,BATCHPRODUCTION,EQUIPMENTSHARING,BALANCINGOFUNITANDMACHINECAPACITYHAVEALLBEENINVOLVED,BUTTHEREISANABSENCEOFINTEGRATEDAPPLICATIONOFTHESEFACTORSRESEARCHERSLIKEYASUDA,ETAL1ANDGARBIE,ETAL2USEDSIMILARITYCOEFFICIENTFORCELLANALYSISTBSOLVETHEPROBLEMOFFORMATIONOFCLUSTERSANDCELLSUNDERCHANGINGMARKET,PILLAI,ETAL3,PROPOSEDAROBUSTDESIGNMETHODBASEDONDEMANDFORECASTANDTHERESULTCELLSTRUCTURETURNEDOUTTOBERELATIVELYSTABLEINTELLIGENTALGORITHMWASINTRODUCEDFORCFSOLVINGCONSIDERINGFACTORSLIKEPARTNUMBER,ROUTE,PROCESSINGTIME,EQUIPMENTCAPACITYEQUIPMENTSTATUSANDOBJECTIVESOFCELLBALANCINGANDMINIMIZATIONOFINTERCELLMOVINGASOKAN,ETAL4,PRABHAKARAN,ETAL5,ANDMANYOTHERSCHOLARSADOPTEDANTCOLONYALGORITHMVENKATARAMANAIAH,ETAL6,CONSTRUCTEDANUNITCONFIGURATIONWITHEXCEPTIONALELEMENTSUSINGHYBRIDHEURISTICALGORITHMMAHAPATRA,ETA7,CONCENTRATEDONCELLLOADBALANCINGANDMINIMIZATIONOFINTERCELLMOVINGANDEMPLOYEDGAFORSOLUTIONMANSOURI,ETAL8,STUDIEDCONSTRAINTSOFBOTTLENECKEQUIPMENTS,EXCEPTIONALPARTSANDEQUIPMENTSHARINGUSINGGAMETHODWON,ETAL9,ADOPTEDFUZZYARTNNALGORITHMTOSOLVEGROUPINGPROBLEMOFCOMPLICATEDPARTSANDEQUIPMENTSDEFERSHA,ETAL10,INTRODUCEDGAPARALLELARITHMETICINTOCF,INWHICHMANYPRACTICALRESTRICTIONLIKECELLCONFIGURATION,SUBSTITUTEPROCESS,EQUIPMENTSSHARINGANDCAPACITYANDLOADBALANCINGORTHEM,ANDPRODUCTIONFEESWERETAKENINTOACCOUNTFTS,ETAL11,CUTCFPROCEDUREINTOTWOSTEPSFIRSTLY,MULTIOBJECTIVEFUNCTIONWASCONSTRUCTEDFORSCALINGUNITS,ANDTHENASINGLEOBJECTIVEFUNCTIONWASEMPLOYEDTARGETINGOPTIMIZATIONOFMOVINGWITHINANDBETWEENUNITSBAI,ETAL12,PAIDTHEIRATTENTIONTOFCFORMATIONTHEORYANDTECHNIQUEFOREMERGENCYMOBILIZATIONBATCHVOLUMEPRODUCTIONASAWHOLE,ABOVERESEARCHESAREMAINLYFOCUSEDONSTATICCELLFORMATION,WHILESTUDIESONSUSTAINABLEDYNAMICFORMATIONARESELDOM,EVENNOTTOSAYINTEGRATEDFORMATIONOFMULTICELLTYPESMAINFOCUSOFTHISARTICLEWILLBEONTHEPROBLEMOFMANUFACTURINGCELLMCDIVERSIFICATIONUNDERMULTIPRODUCTTYPEANDVARIANTVOLUMEMPTVVPRODUCTIONMODEFROMTHEVIEWOFINTEGRATEDCONSTRUCTIONOFMULTITYPEMCS,INTEGRATEDFORMATIONMODELANDMETHODBASEDONUNIFIEDCONSTRAINTS,RULESANDALGORITHMSWILLBESTUDIED,ANDDECISIONMAKINGTOOLSWILLBEDEVELOPED2TECHNICALCHALLENGEUNDERMPTVVPRODUCTIONMODE,PRODUCTTYPEANDVOLUMEISONCONSTANTCHANGEATDIFFERENTPERIODOFTIMEORSTAGESOFDIFFERENTPERIODSTEMMINGFROMMARKETREQUIREMENTCHANGESOTHEDIRECTREASONBRINGINGCONFIGURATIONCHANGEOFMANUFACTURINGSYSTEMISDYNAMICREQUIREMENTINCELLULARMANUFACTURINGSYSTEMCMS,SUCHCHANGEWILLFINALLYIMPUTETOCELLSFORMED,ORBEUNDERTAKENANDREALIZEDBYCELLSTHEESSENTIALOFCELLFORMATIONANDRECONFIGURATIONISOPTIMIZINGASSIGNMENTOFMANUFACTURINGRESOURCEITISAKINDOFALLOCATIONORREALLOCATIONOFABILITYOFMANUFACTURINGRESOURCERESOURCEASSIGNMENTNEEDSTOTRADEOFFBETWEENEXTREMECASESOF“ONEMACHINEISONECELL”AND“THEWHOLELINEISALSOONECELL”MOREOVERTOREALIZERAPIDRESOURCETRANSFORMATION,OTHERTHANMATCHINGBETWEENTASKANDRESOURCE,RESOURCEASSIGNMENTANDOPTIMIZATIONUNDERCONDITIONSLIKEDELIVERYTIME,BATCH,KEYMACHINE,KEYPARTANDEQUIPMENTSHARINGHAVETOBECONSIDEREDALSOIMPORTANTREASONOFUNSUCCESSFULIMPLEMENTATIONAPPLYINGTRADITIONALCFTECHNOLOGIESISIN1ACKOFCOMPREHENSIVECONSIDERATIONTHEOUTCOMEOFCFISLOGICALCELLS,SOTHEREARENOCLEARBOUNDARIESAMONGCELLSANDMACHINESINCELLSHAVENOFIXEDATTRIBUTIONMACHINESMAYACTASASTANDALONE“DEVICEUNIT”FORSCATTEREDTASKS,ORTHEYCANSHARETHEIRCAPACITYWITHOTHERCELLSANDACCOMPLISHTASKSWITHOTHERMACHINESINTHISCASE,ITSPOSSIBLETHATDISCRETEUNITSWILLEMERGETHERESULTCONFIGURATIONISAPLURALSTRUCTURECOMPOSEDBYCOMPLETE”UNITSANDADISCRETEUNITTRADITIONALANALYSISEMPHASIZESINDEPENDENCEOFPARTFAMILYANDCELLSTOOMUCHTHATMAYRESULTINUNHARMONIOUSPRODUCTIONTHUS,BOTTLENECKOPERATIONSANDEQUIPMENTSWILLAPPEARANDREQUIREMENTOFMATINGPRODUCTIONFORASSEMBLYCANNOTBESATISFIEDMOREOVER,CELLLOADDISTRIBUTIONISUNEVENANDMACHINESCANNOTBESHAREDAMONGCELLSCELLTYPESUNDERMPTVVPRODUCTIONMODESHOULDBEFLEXIBLEANDVARIOUSINMULTIPRODUCTTYPEANDSMALLVOLUMEORTRIALPRODUCTION,CELLFORMOFGROUPTYPEOFCELLGCISREQUIRED,WHILEINMASSVOLUMEPRODUCTION,CONTINUOUSPRODUCTIONHASTOBEREALIZEDFURTHERMORE,DURINGDIFFERENTPERIOD,INHERITINGSUSTAINABLERECONFIGURATIONWILLBEABASICDEMANDTHEDIRECTREASONOFHARDADVANCINGOFTRADITIONALGROUPTECHNOLOGYGTBASEDTECHNOLOGIESISTHATFREQUENTLAYOUTADJUSTMENTDUETORAPIDCHANGEOFREQUIREMENTISDIFFICULTTOREALIZEASARIGIDFORMATIONTECHNOLOGY,TOOMANYEFFORTSHAVETOBECOSTONPHYSICALLAYOUTADJUSTMENTCONSTRUCTIONMETHODBASEDONSIMILARITYOFEQUIPMENTSANDPARTSONLYEMPHASIZESADAPTATIONOFEXISTEDRESOURCESTOREQUIREMENTS,BUTNOTFLUENCYOFPRODUCTIONFLOWINTHEVIEWOFROUTESOFTASKSWHICHISALSOANIMPORTANTPROBLEMCONSENTEDBYORGANIZERSFLOWLINETYPERUNNINGISALSOANIMPORTANTOBJECTIVEINMCFORMATIONAGAINSTPERIODICALCHANGINGREQUIREMENTS,TOLESSENCOSTANDINFLUENCEOFMACHINEADJUSTING,CFPROCEDUREHASTOINHERITORIGINALPRODUCTIONLINEEXISTEDCFANALYSISMAINLYFOCUSESONGC,RESEARCHESONTYPEOFCELLFCANDINHERITEDCELLICARECOMPARATIVELYSELDOM,ANDSAMESTATUSPRESENTSINFORMATIONCONSTRAINTANALYSISANDUNIFIEDCONSTRUCTIONOFDIFFERENTTYPESOFMCSGC,FCANDICREPRESENTDIFFERENTOBJECTIVESANDTARGETSOFCFANDARETYPICALCELLFORMSINMANUFACTURINGSYSTEMTECHNICALANALYSISONINTEGRATEFORMATIONFORMULTITYPECELLWILLBECARRIEDOUTORIENTINGTHEM3INTEGRATEDMODELOFMCFORMATIONANDITSCONSTRAINTSANALYSISMCISFORMEDUNDERMULTIPLERELATEDCONSTRAINTSDURINGMCFORMATION,EXTERNALFACTORSLIKEPRODUCTIONREQUIREMENT,DELIVERYTIMEANDINTERNALONESASBATCH,PROCESSINGTIME,MACHINEABILITY,KEYEQUIPMENTANDSELECTABLEMACHINEHAVETOBECONSIDEREDTOGETHERALSO,PRODUCTIONGOALSINCYCLETIME,COST,EQUIPMENTUTILITYHAVETOBESATISFIED,THUSTHECOURSEOFMCFORMATIONISAGAINONEMULTIOBJECTIVEOPTIMIZATIONPROCEDURE,INWHICHNOOPTIMUMBUTMANYSUBOPTIMUMSOLUTIONEXISTSCOMMONLYHERE,CONSTRAINTSANDGOALSAREDECOMPOSEDANDTHEIRINTERRELATIONSTODIFFERENTTYPEOFMCSAREILLUSTRATEDINFIG1RESOURCEROUTEANDTASKARETHREEMAINDATANEEDEDINCF,YETINHERITEDCFHASTOUSEFORMERCONFIGURATIONSCHEMASASSOURCEDATAFORCOMPARINGCFRULESINCLUDEROUTESELECTION。MACHINETYPESELECTIONANDMACHINETASKASSIGNMENTRULESMAINCFCONSTRAINTSHEREAREMACHINEABILITYBATCH,KEYORMASSPANSANDKEYEQUIPMENTOUTPUTPOLICIESARECOMPOSEDOFPARTITIONRULESFORCELLANDEQUIPMENTANDPANFAMILYINCASEOFSHORTAGEOFMACHINEABILITYINRESOURCEASSIGNMENT,THREESCENARIOSOFOVERTIME,OUTSOURCEANDEQUIPMENTPROCUREMENTCANBESELECTEDINTHEPROCESSOFDIFFERENTTYPESOREVENSTAGESOFMCFORMATION,QUANTITATIVEINDEXESINCLUDINGSIMILARITYCOEFFICIENT,INTERCELLOPERATIONNUMBER,CELLLOADANDTAKTTIMEBALANCINGHAVETOBEADOPTEDALLTHESERULES,CONSTRAINTSANDGOALSCONSTRUCTFORMATIONCONSTRAINTSOFMULTITYPECELLMOSTOFTHEMARESHAMBLE,BUTSOMEAREFORSPECIALPURPOSEFOREXAMPLE,FORFCFORMATION,THERERERULESTHATEMPHASIZEOPERATIONBALANCINGOFROUTEANDPRODUCTIONTAKTTIMEOFEQUIPMENT,ANDGOALSTHATSTRESSTAKTBALANCINGINCELLFORMATIONOFTHREETYPEOFCELLISNOTINDEPENDENTBUTINTERRELATED,MAINSTAGESEQUIPMENTCLUSTERRESOURCESELECTIONANDASSIGNMENT,CELLOPTIMIZATIONANDADJUSTINGANDCELLOUTPUTCANALLBEREUSEDCLUSTERANDOUTPUTPROCESSAREENTIRELYUNIVERSAL,WHILEASSIGNMENTANDOPTIMIZATIONISDIFFERENTFORDIFFERENTTYPEOFCELLTHATRULES,CONSTRAINTSANDGOALSCANBESELECTEDINDEMANDACCORDINGTOFIG1,GCANDFCARETWOBASICCELLBC,ANDTHATFCISEXTENDEDONGCANDICCANBESEEMEDASEXTENSIONOFBCASAWHOLEGCCONSTRUCTSTHECONSTRAINTSOFFCLIKETHATBCTOIC4OBJECTIVEANDPROCEDUREOFINTEGRATEDFORMATIONFORCONVENIENCE,THEFLOWINGSYMBOLSARETAKENTOEXPRESSCONSTRAINTSINFIG11BASEDATASETS0D1,D2,D3,D4DLDENOTESPRODUCTIONTASKS;D2DENOTESPARTROUTES;D3DENOTESEQUIPMENTRESOURCES;D4DENOTESCONFIGURATIONSCHEMES2FORMATIONRULESSETS1ELE11,E12,E13,E14,E15,E2E2L,E22,E3E3L,E32ELDENOTESROUTESSELECTIONRULES,INCLUDING;E1LDENOTESMEFIRSTROUTEE12DENOTESLEASTMACHINETYPE;E13DENOTESSHORTESTMACHININGTIME;E14DENOTESLEASTINTERCELLOPERATIONTIME;E15DENOTESHIGHESTBALANCINGINDEXOFOPERATIONSE2DENOTESMACHINETYPESELECTIONRULES;E2LDENOTESCURRENTMACHINETYPE;E22DENOTESSHORTESTMACHININGTIME;E23DENOTESMACHININGTIMELIMITEDBYTAKTTIMEE3DENOTESMACHINETASKASSIGNMENTRULES;E31DENOTESTASKDISPERSEDANDAVERAGEUSEOFMACHINES;E32DENOTESTASKCONCENTRATEDANDFOCUSUSEOFMACHINES3FORMATIONCONSTRAINTSSETS2F1,F2,F3,F4,F5F1DENOTESMACHINEABILITY;F2DENOTESBATCH;F3DENOTESKEYPARTS;F4DENOTESMASSPARTS;F5DENOTESKEYEQUIPMENT4OUTPUTRULESSETS3G1,G2,G3G1DENOTESCELLPARTITIONRULES;G2DENOTESPARTPARTITIONRULES;G3DENOTESSHARABLEEQUIPMENTPARTITIONRULES5FORMATIONGOALSSETS4H1H11,H12,H2,H3H3L,H32,H4HLDENOTESSIMILARITYCOEFFICIENT,H11DENOTESSIMILARITYCOEFFICIENTHL2DENOTESUNSIMILARITYCOEFFICIENTH2DENOTESLEASTINTERCELLOPERATIONNUMBER;H3DENOTESCELLLOADBALANCING;H31DENOTESCELLLOADRATIO;H32DENOTESRATIOOFBALANCEDCELLLOADH4DENOTESTAKTTIMEBALANCINGINCELL6TREATMENTSETFORSHORTAGEOFEQUIPMENTS5I1,I2,I3ILDENOTESOVERTIME;I2DENOTEOUTSOURCE;I3DENOTEEQUIPMENTPROCUREMENT7FOURSTEPSOFCFAREDESCRIBEDASFOLLOWSSTEP1DENOTESEQUIPMENTCLUSTER;STEP2DENOTESRESOURCEASSIGNMENT;STEP3DENOTESCELLOPTIMIZATIONANDADJUSTING;STEP4DENOTESSCHEMAOUTPUTINTHISPAPER,FOURSTEPSWITHDIFFERENTCONSTRAINTSANDOBJECTIVESARE

- 温馨提示:

1: 本站所有资源如无特殊说明,都需要本地电脑安装OFFICE2007和PDF阅读器。图纸软件为CAD,CAXA,PROE,UG,SolidWorks等.压缩文件请下载最新的WinRAR软件解压。

2: 本站的文档不包含任何第三方提供的附件图纸等,如果需要附件,请联系上传者。文件的所有权益归上传用户所有。

3.本站RAR压缩包中若带图纸,网页内容里面会有图纸预览,若没有图纸预览就没有图纸。

4. 未经权益所有人同意不得将文件中的内容挪作商业或盈利用途。

5. 人人文库网仅提供信息存储空间,仅对用户上传内容的表现方式做保护处理,对用户上传分享的文档内容本身不做任何修改或编辑,并不能对任何下载内容负责。

6. 下载文件中如有侵权或不适当内容,请与我们联系,我们立即纠正。

7. 本站不保证下载资源的准确性、安全性和完整性, 同时也不承担用户因使用这些下载资源对自己和他人造成任何形式的伤害或损失。

人人文库网所有资源均是用户自行上传分享,仅供网友学习交流,未经上传用户书面授权,请勿作他用。

川公网安备: 51019002004831号

川公网安备: 51019002004831号