鼠标上盖注塑模具设计【1模2腔斜顶顶出含SW三维及18张CAD图带外文翻译】

收藏

资源目录

压缩包内文档预览:(预览前20页/共39页)

编号:10241879

类型:共享资源

大小:11.71MB

格式:ZIP

上传时间:2018-06-26

上传人:QQ14****9609

认证信息

个人认证

郭**(实名认证)

陕西

IP属地:陕西

50

积分

- 关 键 词:

-

鼠标

注塑

模具设计

顶顶

sw

三维

18

cad

外文

翻译

- 资源描述:

-

鼠标上盖注塑模具设计【1模2腔斜顶顶出含SW三维及18张CAD图带外文翻译】

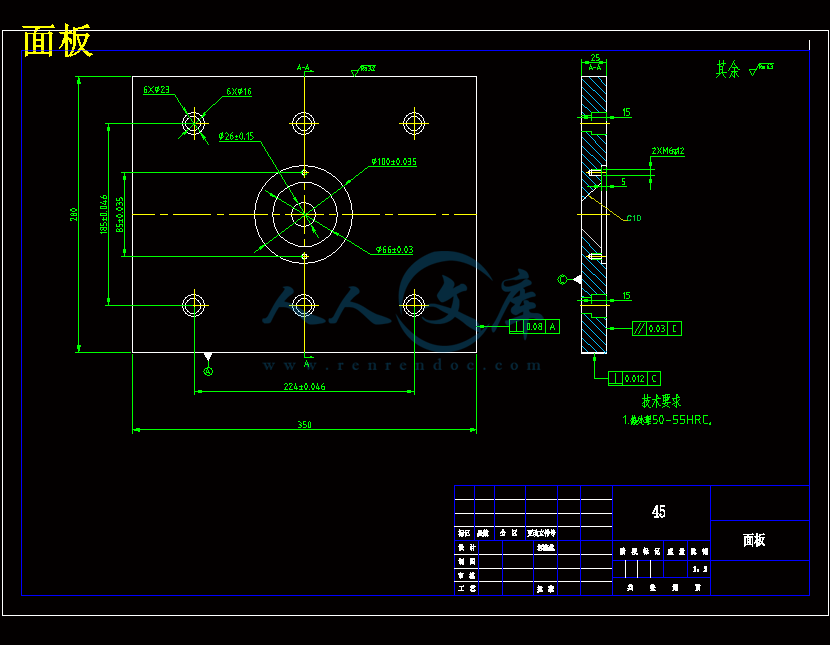

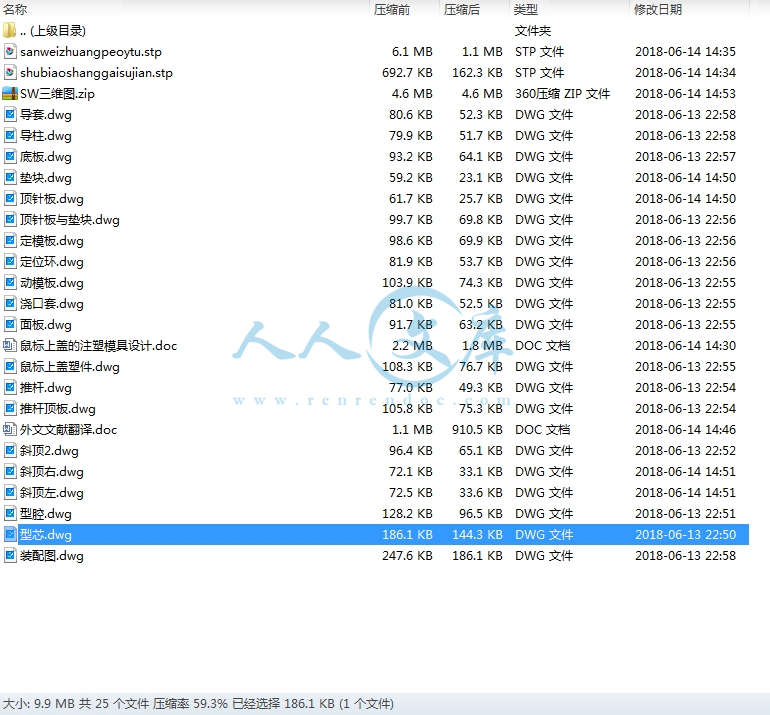

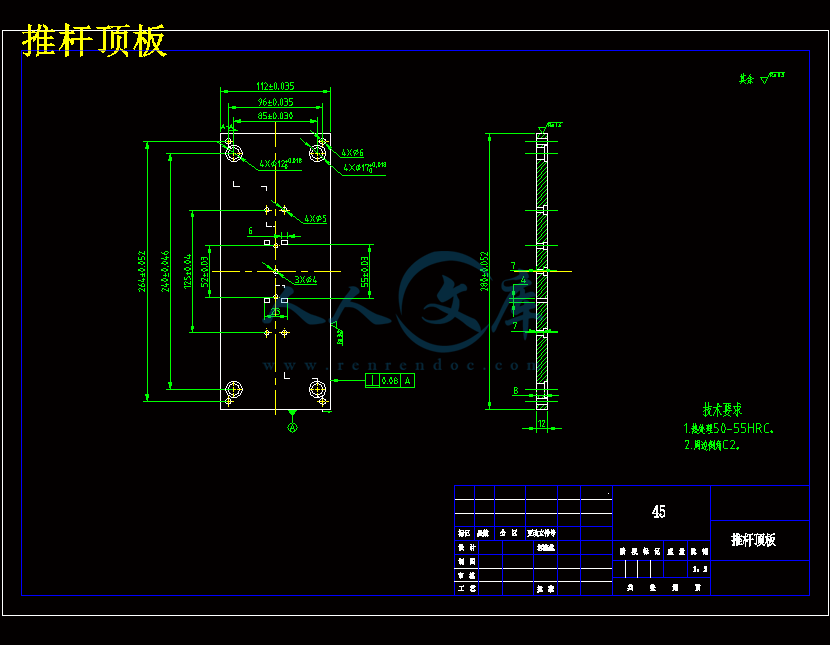

【需要咨询购买全套设计请加QQ1459919609】图纸预览详情如下:

- 内容简介:

-

充值购买- 下载设计文档后,加 Q-1459919609 免费领取图纸I鼠标上盖注塑模具设计摘要本鼠标上盖塑料模具设计综合了产品结构设计,成型工艺分析,模具结构设计等过程于一体。在设计该模具的同时总结了以往模具设计中常用的方法、步骤,模具设计中常见的模具结构、公式及数据。在本次毕业设计中,通过运用三维实体造型软件SolidWorks 对“鼠标上盖”外形进行 3D 造型,同时也设计其塑料外壳注塑模的 3D 模型;还根据所设计的模具尺寸选择安装相应的模架,最终生成了直观的结构设计图;此外还利用 CAD 绘制了模具装配图以及各种成型零件图。关键词:壳体; 注塑模; 模具; SolidWorks; AutoCAD充值购买- 下载设计文档后,加 Q-1459919609 免费领取图纸IIABSTRACTNational revitalization of machinery industry in recent years, every industry pay more and more attention to related to mechanical CAD/CAM technology, not only because of CAD/CAM technology has developed into a relatively mature technology, but also because of the plastic products and mould 3 d design and molding process of 3 d analysis is the plastic mold industry plays a more and more important role.In this graduation design, by using 3 d solid modeling software SolidWorks for “mouse“ on the cover appearance 3 d modelling, but also design the 3 d model of the plastic shell injection mold;Also according to the design of the mould size choose to install the corresponding die set, the resulting intuitive structure design;In addition to use CAD draw the mold assembly drawing as well as a variety of molding part drawing. Keywords: Shell; Injection mold; Mould; SolidWorks; AutoCAD充值购买- 下载设计文档后,加 Q-1459919609 免费领取图纸III目录摘要 .IABSTRACT .II1 绪论 .11.1 我国模具制造业发展状况 .11.2 注塑模具计算机辅助设计、辅助工程与辅助制造 .11.3 课题研究的目的 .22 鼠标上盖设计及其成型工艺的分析 .32.1 塑件分析 .32.2 塑料的选材及性能分析 .32.3 ABS 塑料的注射过程及工艺 .42.4 残余应力引起的龟裂 .43 鼠标上盖模具设计方案 .63.1 分型面方案的设计 .63.2 型腔数量以及排列方式确定 .64 模具设计与对比 .84.1 注塑机选型 .84.2 模具浇注系统设计和浇口的设计 .104.3 成型零件工作尺寸的设计和计算 .124.4 模架的确定和标准件的选用 .154.5 合模导向机构和定位机构 .164.6 脱模推出机构的设计 .174.7 侧向分型与抽芯机构设计 .184.8 排气系统设计 .194.9 冷却系统设计 .194.10 模具材料例表 .215 模具装配 .225.1 塑料模具装配的技术要求 .225.2 塑料模具装配过程 .226 环保性分析 .257 结论 .26附录 1:外文翻译 .28附录 2:外文原文 .30致谢 .35充值购买- 下载设计文档后,加 Q-1459919609 免费领取图纸11 绪论1.1 我国模具制造业发展状况随着我国经济发展,模具制造业得到大力发展。近年来中国模具创造的利润高,每年销售额高达近千亿元人民币,出口额也在几十亿美元。部分产品已经达到或者接近国际水平,并且持续保持快速增长模式。中国模具制造业的发展不仅体现在销售额上,在制造精度和制造难度上也大有提升,高精度的的制造模具业可以生产高光学级别的车灯模具,以及模数较小的高精度齿轮模具;不仅如此在模具制造吨位要求上,已达到单套重达 50t 以上,在腔体数量上一模近万腔的塑封模也可以生产。塑料制件最常用的方法就是注塑成型,对于形状不规则复杂程度高,且要求尺寸精确的塑料制件,注塑成型可以满足这些要求,而且可大批量高效率进行生产,市场广阔前景良好。虽然我国模具制造业发展迅速,经过近半个世纪的快速发展,达到一定的水平,但是与国外先进水平相比,仍然存在很多问题,专业性与柔性化结合程度低,利用计算机辅助设计提高模具制造业整体水平,刻不容缓。1.2 注塑模具计算机辅助设计、辅助工程与辅助制造1.2.1 CAD/CAM/CAE 对模具设计的作用及意义目前市场竞争激烈,再加上种类多,更新快,所以必须走向做出高品质,高质量,高效率,缩短设计周期,降低生产成本的道路。然而,我国塑料模具的发展还停留在依靠经验丰富的设计工艺人员对所做工件进行分析,对于设计的是否合理,方法运用是否得当,设计的制品有无缺陷,只有做出模具进行试模才能做出判断,不仅耗费的资金大成本高,而且周期太长,无法跟进市场变化。而采用计算机辅助设计,可以采用模拟设计替代试模,避免传统方法的各种弊端,例如反复的进行试模,改模,修模。同传统的方法相比,计算机辅助设计CAD/CAM/CAE 技术在在、减轻劳动强度,提高质量,提高效率,降低生产成本、等方面,起到了重要的作用。 近年来公布的数据统计表明,国外采用计算机辅助设计 CAD/CAM/CAE 技术所体现的效果,成本下降了百分之十、制造时间缩短了百分之三十、设计时间缩短了一半、塑料原料节省了百分之七。注射模计算机辅助设计 CAD/CAM/CAE 技术作为一种高效的工具,基本上从根本上,解决了传统模具的一些问题。随着注射模计算机辅助设计 CAD/CAM/CAE 技术发展,将在我国塑料模具工业中起到重要作用。充值购买- 下载设计文档后,加 Q-1459919609 免费领取图纸21.2.2 Solidworks 简介Solidworks 软件功能强大,组件繁多。 Solidworks 可以把想象出来的零部件的立体形状,展现出来。由于 CAD 等软件的二维图纸的表达复杂性和不够直观,需要个人想象能力,正是二维图纸的这些缺点,促使 Solidworks 三维辅助软件的产生,实现缩放、旋转等功能。Solidworks 在功能上容易上手,易学易用。SolidWorks 功能强大,成为主流的三维 CAD 解决方案。其独特的功能,能够拖拽功能,使得我们在使用Solidworks 时可以在很短的时间内完成绘图装配出工程图。SolidWorks 可以很方便的存储 CAD 文件。使用 SolidWorks ,方便快捷的完成大量工作,满足市场高质量的需求。在目前市场上所见到的三维 CAD 解决方案中,SolidWorks 设计过程简便方便快捷的完成设计任务。1.3 课题研究的目的塑料制品的应用已经深入到千家万户对人们的生产生活影响深远,因此对于模具设计的要求不断提高。本课题以鼠标上盖为研究对象,对其浇口位臵、冷却系统、填充系统、翘曲变形进行优化分析,从而得到了最佳浇口位臵和模具的相关结构。整个设计从 2 d 到 3 d 视觉设计,实现 CAD/CAM/CAE 一体化,缩短开发周期,提高竞争力。充值购买- 下载设计文档后,加 Q-1459919609 免费领取图纸32 鼠标上盖设计及其成型工艺的分析2.1 塑件分析图 2-1 鼠标上盖图 2-2 鼠标上盖三维图2.1.1 结构分析如下好的鼠标符合人机工程学,表面光滑手感舒适,在模具设计和制造上要有良好的加工工艺,该塑件属于流线型结构,由许多曲面构成,确保成型零件具有一定的光洁度,模具倒扣部分用斜顶成型完成2.1.2 成型工艺分析精度分析 精度要求不高采用 5 级。外形分析 该塑件壁厚约为 1mm 左右,适合注射成型。 拔模斜度分析 由于壳体左右部分比较浅,ABS 无定型塑料,成型收缩率较小,所以脱模斜度为 1 度;由于下面的倒扣需要用到斜顶模斜度也设置为 1 度。充值购买- 下载设计文档后,加 Q-1459919609 免费领取图纸42.2 塑料的选材及性能分析综合该壳体的抗拉性能,硬度要求,耐磨性能,机械性能的要求。具备这些条件的塑料首选:丙烯腈-丁二烯-苯乙烯,简称 ABS2.2.1 使用特点力学轻度高,具有抗冲击性,稳定性高,电学性能良好,易于成型,适合制作机械结构零部件。2.2.2 成型特征(1)无定形料, 流动性中等,吸湿大,必须充分干燥,表面要求光泽的塑件须长时间预热干燥 80-90 度 ,3 小时。(2)宜取高料温,高模温,但料温过高易分解(分解温度为270 度).对精度较高的塑件,模温宜取 50-60 度,对高光泽.耐热塑件,模温宜取 60-80 度。(3)如需解决夹水纹,需提高材料的流动性,采取高料温、高模温,或者改变入水位等方法。 (4)如成形耐热级或阻燃级材料,生产 3-7 天后模具表面会残存塑料分解物,导致模具表面发亮,需对模具及时进行清理,同时模具表面需增加排气位置。2.3 ABS 塑料的注射过程及工艺注射成型成型成型前准备,对 ABS 进行干燥。ABS 是吸水的塑料,于室温下,24 小时可吸收0.2%-0.35%水分,虽然这种水分不至于对机械性能构成重大影响,但注塑时若湿度超过 0.2%,塑料表面会受大的影响,所以对 ABS 进行成型加工时,一定要事先干燥,而且干燥后的水分含量应小于 0.2%。ABS 的干燥方法: 常压热风干燥 80-85 2-4 小时 ;真空热风干燥 80 1-2 小时。注射过程.塑料在注射机内经过加热、塑化达到流动状态后,由模具的浇注系统进入模具型腔成型,起过程可分为充模、压实、保压、倒流、和冷却 5 个阶段。2.4 残余应力引起的龟裂残余应力主要由于以下三种情况,即充填过剩、脱模推出和金属镶嵌件造成的。作为在充填过剩的情况下产生的龟裂,其解决方法主要可在以下几方面入手。(1)由于直浇口压力损失最小,所以,如果龟裂最主要产生在直浇口附近,则可考虑改用多点分布点浇口、侧浇口及柄形浇口方式。(2) 在保证树脂不分解、不劣化的前提下,适当提高树脂温度可以降低熔融粘度,提高流动性,同时也可以降低注射压力,以减小应力。充值购买- 下载设计文档后,加 Q-1459919609 免费领取图纸5(3)一般情况下,模温较低时容易产生应力,应适当提高温度。但当注射速度较高时,即使模温低一些,也可减低应力的产生。(4)注射和保压时间过长也会产生应力,将其适当缩短或进行 Th 次保压切换效果较好。白化现象最主要发生在 ABS 树脂制品的推出部分。脱模效果不佳是其主要原因。可采用降低注射压力,加大脱模斜度,增加推杆的数量或面积,减小模具表面粗糙度值等方法改善,当然,喷脱模剂也是一种方法,但应注意不要对后续工序,如烫印、涂装等产生不良影响。充值购买- 下载设计文档后,加 Q-1459919609 免费领取图纸63 鼠标上盖模具设计方案3.1 分型面方案的设计分型面是模具上用来取出塑件和浇注系统料可分离的接触面称为分型面,分型面的选择对模具设计方式影响最大,分型面设计是否合理对塑件质量和模具复杂程度具有很大的影响。基本上是一种分型面对应着一种模具设计方案,所以分型面的选择决定着模具总体的设计方案。3.1.1 分型面的选择原则(1)使分型面容易加工。(2)保证塑料制品能够脱模。(3)尽量避免侧向抽芯。(4)使侧向抽芯尽量短。(5)有利于排气。(6)有利于保证塑件的外观质量。(6)尽量减少塑件在合模方向的投影面积。(7)尽可能使塑件留在动模一侧。(8)尽可能满足塑件的使用要求。(9)有利于简化模具结构。(10)长型芯应置于开模方向。综上所述,由于该塑件曲面多,分型面不可能在一个平面上,为了顺利脱模,分型面采用如下模具结构,只需要斜顶出模,加工成本经济,塑件成型精度可靠。图 3.1 分型面形式与位置3.2 型腔数量以及排列方式确定充值购买- 下载设计文档后,加 Q-1459919609 免费领取图纸7图 3.2 型腔排列方式鼠标上盖主要为流线型结构,遂采取一模两腔设计。有如下优点:(1)产品结构较小,采用该设计能保证顺利走胶,改善注射件品质;(2)有利于注塑产品产能提升,减少生产成本,提高生产效率1附录 1:外文翻译注塑成型模具的新设计特点减少废料1.介绍过去一个世纪观察到塑料的迅速增长及其向所有市场的扩散。根据世界原材料消耗量的重量,塑料是最高的与其他旧材料相比铝,钢,橡胶,铜和锌,由其性能和降低生产成本1,2 。注塑是塑料制品生产中最重要的工艺之一,约占三分之一的所有塑料通过注塑成型工艺转化成零件3。注塑成型的应用工艺在许多行业如包装,航空航天和建筑中显着增加建筑,汽车部件和家用物品1,3,4。注射部件的最终质量成型取决于材料特性,模具设计和工艺条件4-6。有三种注塑成型的基本操作。首先,塑料颗粒将转变成熔体。然后,熔融塑料将通过浇道,浇道和浇口系统在压力下注入模腔中最后,模具工具将被打开以将部件从空腔1,7,8中排出。将评估注射部件的质量的参数之一是流道系统。 流道系统是一个浇口和浇口之间的连接线。流道系统的主要目的是转移熔融塑料浇口到门。在冷流道系统中,废料的主要来源是在浇注之后来自浇道和浇口系统的废料。因此,将评估不同的规则用于转轮系统设计,以证明转轮的重要性注塑成型中的系统如(a)较小的流道尺寸以最小化废料; ( b)容易从模具中取出工具和从模制部件中移除; (c)用最小的凹痕和熔接线快速填充空腔9-12。将被认为是流道系统设计的基本参数的三个因素是横截面流道形状,直径和腔体布局9 。转轮的横截面形状有 7 种系统为不同的应用9,10,13。最后,根据要求,不同类型的转轮交叉可以推荐14。本文在考虑现有不同横截面形状之后的贡献是定义流道系统的椭圆几何形状作为有效横截面形状。我们的基本目标设计和使用本文定义的椭圆形横截面形状基本上是具有较小的流道尺寸以最小化废料,减少注射的总循环时间并且容易地从模具中弹出部件。除了我们的预期,检测到与工艺参数和新的相关的显着现象将在另一篇论文中讨论的转轮系统的几何形状。对于本文,将介绍流道系统的椭圆形或横截面形状的设计标准,并进行流道系统的圆形和半椭圆形之间的比较。作者最好的知识,在注塑中已经对工艺参数和材料进行了许多尝试特征,然而对于包括浇道,浇口和浇道的注射系统,存在一些出版物,但没有提及分析和模拟流道系统的椭圆形横截面形状。在本文中,简单介绍了转轮系统的结构,并对椭圆转轮的优点进行了评价。然后,注塑部件带浇道和浇口系统是通过 SolidWorks 设计的。为了得到准确的仿真结果,通过SolidWorks Plastic 有限元法进行考虑。22.流道系统的横截面形状流道系统的主要目的是通过浇口将熔融塑料从浇口转移到所有腔体。有流道系统的不同横截面形状和它们中的每一种具有不同的应用13。设计师应评估不同因素,为特定产品选择适当的流道系统形状。最多两板模具具有最高效率的流道系统的流行形状是圆形。适用于 Threeplate 工具,梯形和修改的梯形是最好的选择,如果跑步只有在制造一半的模板,但仍然是不能接受的,因为门不能放在一条线上中心流10。从具有矩形,正方形和多边形形状的腔中推出流道系统具有挑战性的。它是从不同横截面的现有拐角产生的。压降导致如果设计者没有完全填充空腔和高水平的热传递到模具壁将发生确定流道系统的适当横截面形状及其尺寸9,13,15。因此,不同可以考虑流道系统的横截面来调节熔融塑料的流速。最后,形状和通道的长度对于具有最佳流动和因此具有较少缺陷的最佳产品是重要的16。3.具有椭圆形横截面形状的转轮系统在注塑成型中,流道系统最常见的截面形状是圆形。在选择轮形状对于特定零件设计,应评估的三个主要元素是(a)较小的流道尺寸,以最小化废料; (b)更容易从模具中弹出; (c)用最小的凹痕快速填充空腔,焊接线和没有短射。 9-11。因此,考虑用于流道系统的新几何形状以最小化废料,以与门的中央流动流成直线,适当地填充一个或多个腔,并且弹出该部分容易从模具工具是本文的目标。最后,考虑椭圆形横截面形状转轮系统。为了得到具有最小塑料缺陷的注塑部件,进行准确的比较需要在转轮系统的圆形和椭圆形横截面形状之间。为了证明转子的椭圆形横截面形状的意义及其选择的原因在模具设计中的重要问题,评估其他几何形状的浇道系统是必要的。最好的几何截面来比较圆和椭圆是矩形和正方形。矩形是一种有不同的正方形宽度。根据不同的应用,将选择具有不同宽度比的矩形浇道系统。与正方形相比,矩形形状的优点之一是最小化流道系统的废料,并且更容易从模具中弹出,但是压降是将会发生的缺点之一减小方形的宽度13 。圆和椭圆之间具有与正方形和矩形相同的结构。 D 是圆的直径,a 是长轴长度,b 是椭圆的短轴长度。主轴长度固定,短轴长度具有不同的速率,这取决于不同的工业应用。虽然为减少废料,更容易将部件排出腔外,并且减少循环时间,最好减少次要的长度轴,这取决于零件设计。因此,b 的不同比率取决于部件设计的许多因素,例如尺寸和厚度。减少废料,更容易将部件排出腔,循环时间减少和中心流动的浇口系统与圆形相比具有椭圆形横截面形状的优点。3附录 2:外文原文Available online at ScienceDirectProcedia Manufacturing 2 (2015) 241 2452nd International Materials, Industrial, and Manufacturing Engineering Conference, MIMEC2015, 4-6 February 2015, Bali IndonesiaNew Design Feature of Mold in Injection Molding For ScrapReductionMehdi Moayyediana,*Kazem Abharya, Romeo MarianaaUniversity of South Australia, School of Engineering, Mawson Lakes CampusAbstractThis paper presents a new cross sectional shape of runner system in the injection molding. The aim of the new geometry is to reduce the scrap and cycle time and also the easier ejection of runner system from mold tools. Short shot defect in the plastic part during the injection molding process is analyzed by SolidWorks Plastic to validate the new proposed geometry. Runner system with elliptical cross section is proposed with different ratio for two circular flat plates with thickness of 1mm. Finite Element Method (FEM) is employed in SolidWorks Plastic for simulation of injected part. Filling time, melt temperature, mold temperature, pressure holding time, and pure cooling time are chosen as input for the injection machine. The contribution of this study is the design of new geometry of cold runner system for reduction in scrap and cycle time and also easier ejection of runner system in injection molding. This study outcomes show no short shot defect with the new geometry. Also, it was shown the significant reduction in scarp and cooling time. 25% and 2.5% reduction in scrap and cooling time were achieved compared to round cross section, respectively. Reduction in contact surface of runner system with mold walls improved the easier ejection of runner system out of the cavity as well. 2015 The Authors. Published by ElsevierB.V. This is an open access article under the CC BY-NC-ND license . by B.V.(/licenses/by-nc-nd/4.0/).Selection and Peer-review under responsibility of the Scientific Committee of MIMEC2015.Selection and Peer-review under responsibility of the Scientific Committee of MIMEC2015Keywords:Injection molding process, Mold design, Runner geometry, Short shot defect1. IntroductionThe past century has observed the rapid increase of plastics and their proliferation into all markets. According to world consumption of raw materials by weight, plastic is the highest in comparison with other old materials such as aluminum, steel, rubber, copper, and zinc, resulting from its properties and lower production cost 1, 2. Injection* Mehdi Moayyedian. Tel.: +61883025561E-mail address: Mehdi.moayyedian.au42351-9789 2015 The Authors. Published by Elsevier B.V. This is an open access article under the CC BY-NC-ND license (/licenses/by-nc-nd/4.0/).Selection and Peer-review under responsibility of the Scientific Committee of MIMEC2015 doi:10.1016/mfg.2015.07.042242 Mehdi Moayyedian et al. / Procedia Manufacturing 2 (2015) 241 245molding is one of the most significant processes for manufacturing of plastic products and approximately one-third of all plastics are converted into parts using injection molding processes 3. The application of injection molding processes is increasing significantly in many industries like packaging, aerospace and aviation, building and construction, automotive parts and household articles 1, 3, 4 . the final quality of injected parts in injection molding depends on the material characteristics, the mold design and the process conditions 4-6. There are three fundamental operations in injection molding. First, the Plastic granules will be converted into a melt. Then, the molten plastic will be injected into the mold cavity or cavities under pressure via sprue, runner and gate systems and finally, the mold tools will be opened to eject the part from the cavities 1, 7, 8.One of the parameters which will assess the quality of injected part is Runner system. Runner system is a connection line between sprue and gates. The main purpose of runner system is to transfer the molten plastic from sprue to gates. In cold runner system, the main source of scrap is the scrap from runner and gate system after de-gating. Hence, different rules will be evaluated for runner system design to demonstrate the significance of runner systems in the injection molding such as (a) smaller runner size to minimize the scrap; (b) easy ejection from mold tools and removal from molded parts; (c) filling the cavities quickly with minimum sink marks and weld lines 9-12. Three factors which will be considered as fundamental parameters for runner system design are cross sectional shape of runner, the diameter and the cavity layout 9. There are 7 types of cross sectional shapes for runner systems for different applications 9, 10, 13. Finally, depending on the requirements, different types of runner cross sections can be recommended 14.The contribution of this paper after the consideration of existing different cross sectional shapes is to define the elliptical geometry for runner system as an effective cross sectional shape. Our fundamental objectives, for designing and using the elliptical cross sectional shape defined in this paper, are basically to have smaller runner size to minimize the scrap, to reduce the total cycle time of injection and to eject the part easily from the mold tools. Further than our anticipation, remarkable phenomena was detected which are related to process parameters and new geometry of runner system that will be discussed in another paper.For this paper, the design criteria of elliptical or cross sectional shape for runner system will be introduced, and a comparison between round shape and semi-elliptical shape of runner system will be conducted. To the authors best of knowledge, many attempts have been taken in injection molding for process parameters and material characteristics, however for injection system which includes runner, gate, and sprue, there are a few publications, but there is no reference to analyze and simulate the elliptical cross sectional shape of runner system. In this paper, the structure of runner system is simply introduced and advantages of elliptical runner will be evaluated. Then, the injected part with runner and gate system is designed via SolidWorks. For accurate result of simulation, FEM is considered via SolidWorks Plastic.2. Cross sectional shape of runner systemThe main purpose of runner system is to transfer the molten plastic from sprue to all cavities via gate. There are different cross sectional shapes of runner systems and each of them have different applications 13. A designer should evaluate different factors for selecting the right shape of runner system for a specific product. The most popular shape of runner system which has the highest efficiency for two plates mold tools is round shape. For Three-plate tools, the trapezoidal and modified trapezoidal are the best options if the runner is to be manufactured only in one half of the mold plates, but still they are not acceptable because the gate cannot be positioned in line with the central flow stream 10. Ejecting a runner system from the cavity with rectangular, square, and polygon shape is challenging. It has resulted from the existing corners of different cross sections. Pressure drop which leads to incomplete filling of cavities and high level of heat transfer to the mold walls will occur if a designer does not determine the appropriate cross sectional shape of runner system and their dimensions9, 13, 15. Hence, different cross-sections of runner system can be considered to regulate the flow rate of molten plastic. Finally, the shape and the length of the channel are significant to have an optimal flow and therefore the best product with less defects 16.3. Runner system with elliptical cross sectional shapeIn injection molding, the most common cross section shape for runner system is round shape. In selecting the round shape for specific part design, three main elements which should be evaluated are (a) smaller runner size to5Mehdi Moayyedian et al. / Procedia Manufacturing 2 (2015) 241 245 243minimize the scrap; (b) easier ejection from mold tools; (c) filling the cavity quickly with minimum sink marks, weld lines and no short shot. 9-11. Hence, consideration of new geometry for runner system to minimize the scrap, to be positioned in line with the central flow stream of gate, fill the cavity or cavities properly, and eject the part easily from mold tools is the goal of this paper. Finally, elliptical cross sectional shape is taken into account for runner system. In order to yield an injection-molded part with minimal plastic defects, an accurate comparison between round and elliptical cross sectional shape of runner system is necessary.To demonstrate the significance of elliptical cross sectional shape of runner and the reason it is selected as a significant issue in mold design, evaluation of other geometries of runner system is necessary. The best geometry of cross section to compare the circle and ellipse is rectangle and square. Rectangle is a kind of square with different width. According to different applications, rectangular runner system with different ratios of width will be chosen. One of the advantages of rectangular shape in comparison with square is in minimizing the scrap of runner system, and easier ejection from mold tools, but pressure drop is one of the disadvantages which will be happen by decreasing the width of the square 13.The comparison between circle and ellipse has the same structure with square and rectangle. D is the diameter of circle, a is major axis length, and b is minor axis length of ellipse. Major axis length is fixed and the minor axis length has different rates which depend on different industrial applications. Although for reducing the scrap, easier ejection of part out of cavity, and reduction in cycle time it is better to reduce the length of the minor axis, it depends to the part design. Hence, different ratio of b depends on many factors of part design such as size and thickness. Reduction in scrap, easier ejection of part out of cavity, cycle time reduction, and central flow stream of gate with runner system are the advantages of elliptical cross sectional shape in comparison with round shape.4. SimulationAfter designing two circular parts as two samples for this application, the next step is to simulate the part using SolidWorks Plastic. For simulation part, defining the injection system is necessary. Hence, designing the sprue, runner with b=0.7a and gate system is considered as shown in Fig. 1a. To make sure that the analysis results are accurate, Finite Element Analysis (FEM) will play a significant role in simulation as shown in Fig. 1b. According to the geometry of samples, the triangle shape of surface meshes for finite element analysis will be chosen. The selected material for this simulation is polypropylene (P.P). Different sizes were evaluated for the surface mesh and finally surface mesh size of 1mm are chosen for injected part but for the injection system which include sprue, runner and gate, smaller sizes were considered, resulting from the sensitivity of injection system as a critical area of this simulation. Hence, surface mesh size of 0.3mm for sprue and runner and 0.2mm for gate are selected for both elliptical and round cross sectional shape of runner in SolidWorks Plastic. The runner and gate length in total is 28mm for two circular parts with diameter of 100mm. Also, the sprue has 60 mm length with draft angle 1.5.(a) (b)Fig.1 (a) Finalized part with sprue, runner and gate system; (b) Finite element analysis of finalized partThe next step is to define the process parameters. Based on the selected materials and injection machine, filling time is 0.59 sec , melt temperature is 230C, mold temperature is 50C, pressure holding time is 2.04 sec, and pure cooling time is 3.9 sec. The geometry and size of the injection system are evaluated as significant criteria whose effect the operation cycle time, cooling time, different defects such as sink mark and short shot. The main factors to check if the new runner system is acceptable in terms of new geometry and size, are ease of fill, filling time analysis, sink mark analysis, and injection pressure at the end of injection. As shown in Fig. 2a, ease of fill for elliptical cross section is at green area which is in the most acceptable level. Another common defect which is related to gate and runner dimension and geometry is sink marks. A sink mark is the depression on the surface of6244 Mehdi Moayyedian et al. / Procedia Manufacturing 2 (2015) 241 245injection molded plastic which occur during the cooling process 17. As shown in Fig. 2b, there is no sink marks for the injected part except for the sprue which is not in a critical region and also the surface quality of sprue and runner are not significant because they consider as scrap at the end of the injection. Therefore the surface quality of injected part for both round and elliptical cross section is the same.(b)(a)Fig. 2 (a) Easy filling of injected part with elliptical cross; (b) Sinks marks simulation for elliptical cross sectional shape of runner systemOne of the common defects in injection molding is short shot. Short shot will occur far from the gate if there are long flow distances or on thin walls 17. According to the simulation result, this part can be successfully filled and even the filling time for elliptical cross sectional shape of runner is lower than that of for the round cross sectional shape as shown in Fig. 3.(a) (b)Fig. 3 Filling time for (a) Elliptical cross section and (b) Round cross sectionAnother parameter to make sure that there is no short shot for the injected part is to evaluate the flow front central temperature which represents the flow front temperature at every region of injected part. SolidWorks Plastic recently added this module which is suitable for short shot analysis. As shown in Fig. 4, based on SolidWorks Plastic simulation, the flow front central temperature in every region of the injected part is 230.15C for both elliptical cross sectional shape of runner and round cross sectional shape. It means that the possibility of short shot in the cavities is low for both geometries.(a) (b)Fig. 4 Flow front central temperature for (a) Elliptical cross section and (b) Round cross sectionOne of the most significant parameter which is necessary to evaluate for determination of the right size of runner and gate system is the maximum inlet pressure. This part can be successfully filled with injection pressure 42.1 MPa. The injection pressure is less than 66% of the maximum injection pressure limit which is satisfactory as shown in Fig. 5. The injection pressure for round cross section is 39.655 MPa which is close to elliptical cross7Mehdi Moayyedian et al. / Procedia Manufacturing 2 (2015) 241 245 245section.5040Pressure3020Round10Elliptical0MaximumInlet(Mpa)0 0.5 1Time(Sec)Fig. 5 Injection pressure for both round and elliptical cross section shape of runner system5. ConclusionThe main reason of scrap in cold runner system of injection molding is the feeding system which consists of sprue, runner and gate system. Runner has different cross sections for different applications.

- 温馨提示:

1: 本站所有资源如无特殊说明,都需要本地电脑安装OFFICE2007和PDF阅读器。图纸软件为CAD,CAXA,PROE,UG,SolidWorks等.压缩文件请下载最新的WinRAR软件解压。

2: 本站的文档不包含任何第三方提供的附件图纸等,如果需要附件,请联系上传者。文件的所有权益归上传用户所有。

3.本站RAR压缩包中若带图纸,网页内容里面会有图纸预览,若没有图纸预览就没有图纸。

4. 未经权益所有人同意不得将文件中的内容挪作商业或盈利用途。

5. 人人文库网仅提供信息存储空间,仅对用户上传内容的表现方式做保护处理,对用户上传分享的文档内容本身不做任何修改或编辑,并不能对任何下载内容负责。

6. 下载文件中如有侵权或不适当内容,请与我们联系,我们立即纠正。

7. 本站不保证下载资源的准确性、安全性和完整性, 同时也不承担用户因使用这些下载资源对自己和他人造成任何形式的伤害或损失。

人人文库网所有资源均是用户自行上传分享,仅供网友学习交流,未经上传用户书面授权,请勿作他用。

川公网安备: 51019002004831号

川公网安备: 51019002004831号