【温馨提示】 购买原稿文件请充值后自助下载。

以下预览截图到的都有源文件,图纸是CAD,文档是WORD,下载后即可获得。

预览截图请勿抄袭,原稿文件完整清晰,无水印,可编辑。

有疑问可以咨询QQ:414951605或1304139763

摘 要

本次设计是对石材立式球磨机的设计。在这里主要包括:传动系统的设计、装夹部位系统的设计、球磨机主轴部位系统的设计这次毕业设计对设计工作的基本技能的训练,提高了分析和解决工程技术问题的能力,并为进行一般机械的设计创造了一定条件。

整机结构主要由电动机产生动力通过联轴器将需要的动力传递到丝杆上,丝杆带动丝杆螺母,从而带动整机运动,提高劳动生产率和生产自动化水平。更显示其优越性,有着广阔的发展前途。

本论文研究内容:

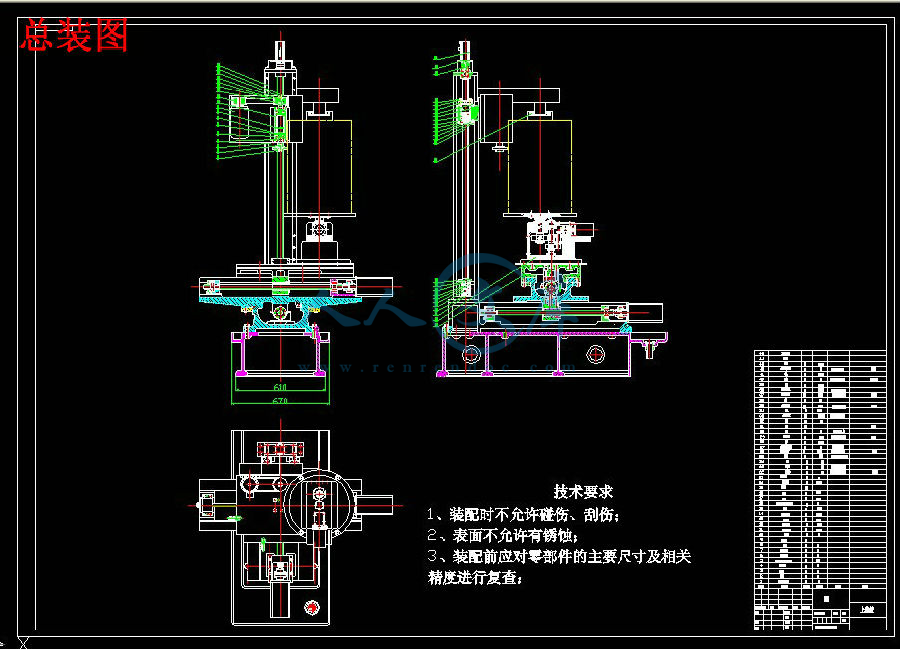

(1) 石材立式球磨机总体结构设计。

(2) 石材立式球磨机工作性能分析。

(3)电动机的选择。

(4) 石材立式球磨机的传动系统、执行部件及机架设计。

(5)对设计零件进行设计计算分析和校核。

(6)绘制整机装配图及重要部件装配图和设计零件的零件图。

关键词:石材立式球磨机, 联轴器,滚珠丝杠

Abstract

This design is the design of vertical mill stone. Here mainly include: design, drive system design, parts of the clamping system of ball mill main part of the system design of the graduation design on the design of the basic skills training, enhancing the analysis and to solve engineering problems, and create a certain condition for general mechanical design.

The structure is mainly produced by the motor power through the coupling will need to transfer the power to the screw rod, the screw rod drives the screw rod nut, thereby driving the movement, improve labor productivity and automation level of production. But also show its superiority, there are broad prospects for the development.

The research of this thesis:

(1) the overall structure of stone vertical mill design.

(2) performance analysis of vertical mill stone.

(3) the choice of motor.

(4) transmission system, execution unit and frame design of stone vertical mill.

(5) the design of components for the design calculation and check.

(6) to draw the assembly drawing and parts assembly diagram and parts diagram design.

Keywords: coupling stone, vertical mill, ball screw

【温馨提示】 购买原稿文件请充值后自助下载。

以下预览截图到的都有源文件,图纸是CAD,文档是WORD,下载后即可获得。

预览截图请勿抄袭,原稿文件完整清晰,无水印,可编辑。

有疑问可以咨询QQ:414951605或1304139763

目 录

摘 要 II

Abstract III

目 录 IV

第1章 绪论 1

1.1异型石材的分类 1

1.1.1异型石材的分类 1

1.1.2按加工方法分 1

1.1.3按截面尺寸分 1

1.2异形石材的装饰效果 2

1.3异形石材加工的损耗介绍 2

1.4石材加工机械分类 3

1.5国内异形石材加工机械设备现状与发展 4

第2章 石材立式球磨机总体结构设计 1

2.1 石材立式球磨机的构成 1

2.2 球磨机磨削部分计算 1

2.2.1 同步带计算选型 1

2.2.2 同步带的主要参数(结构部分) 4

2.2.3 同步带的设计 6

2.2.4 同步带轮的设计 7

第3章 主轴组件要求与设计计算 9

3.1 主轴的基本要求 9

3.1.1 旋转精度 9

3.1.2 刚度 9

3.1.3 抗振性 10

3.1.4 温升和热变形 10

3.1.5 耐磨性 11

3.2 主轴组件的布局 11

3.3 主轴结构的初步拟定 14

3.4 主轴的材料与热处理 14

3.5 主轴的技术要求 15

3.6 主轴直径的选择 15

3.7 主轴前后轴承的选择 16

3.8 轴承的选型及校核 17

3.9 主轴前端悬伸量 19

3.10 主轴支承跨距 20

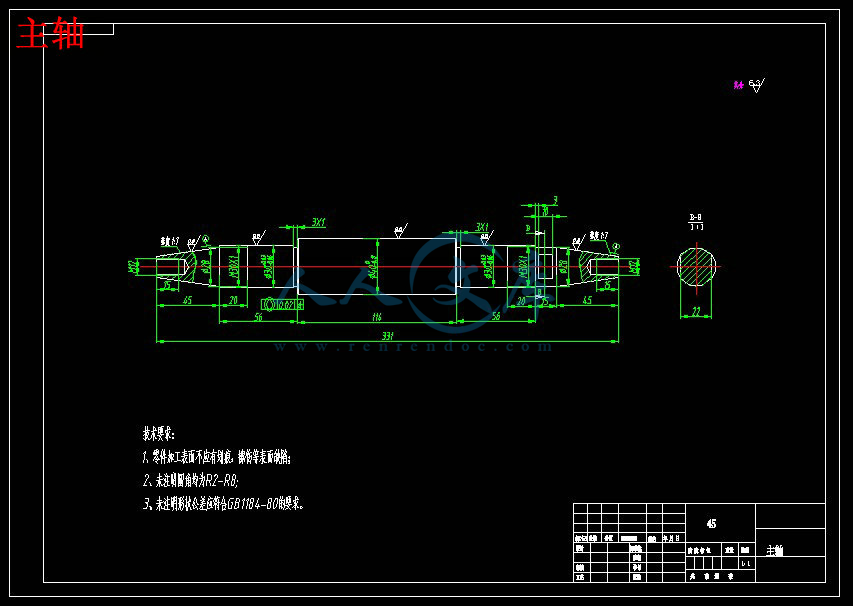

3.11 主轴结构图 21

3.12 主轴组件的验算 21

3.12.1 支承的简化 21

3.12.2 主轴的挠度 22

3.12.3 主轴倾角 23

第4章 X结构及传动设计 24

4.1 X向滚珠丝杆副的选择 25

4.1.1导程确定 25

4.1.2确定丝杆的等效转速 25

4.1.3估计工作台质量及负重 25

4.1.4确定丝杆的等效负载 25

4.1.5确定丝杆所受的最大动载荷 26

4.1.6精度的选择 27

4.1.7选择滚珠丝杆型号 27

4.2校核 28

4.2.1 临界压缩负荷验证 28

4.2.2临界转速验证 29

4.2.3丝杆拉压振动与扭转振动的固有频率 30

4.3电机的选择 30

4.3.1电机轴的转动惯量 31

4.3.2电机扭矩计算 32

第5章 Y向结构设计 34

5.1 Y轴滚动导轨副的计算和选择 34

5.2 滚珠丝杠计算和选择 35

5.3 步进电机惯性负载的计算 38

第6章 Z轴机械结构设计 41

6.1 确定脉冲当量 41

6.2滚珠丝杠螺母副的计算和选型 41

6.2.1 精度的选择 41

6.2.2丝杠导程的确定 41

6.2.3 最大工作载荷的计算 41

6.2.4 最大动载荷的计算 42

6.2.5 滚珠丝杠螺母副的选型 43

6.2.6 滚珠丝杠副的支承方式 43

6.2.7 传动效率的计算 44

6.2.8 刚度的验算 44

6.2.9 稳定性校核 45

6.2.10 临界转速的验证 46

6.3 步进电动机的选择 46

6.4 丝杠轴的校核 49

6.5 键的校核 50

6.6 轴承的校核 50

6.7 直线滚动导轨副的计算和选择 52

第7章 减速器机构的设计 55

7.1电机选择 55

7.1.1 计算输出轴的转矩 55

7.1.2 确定各轴传动比 57

7.1.3 传动装置的运动和动力参数 57

7.2齿轮设计与计算 59

7.2.1高速级齿轮设计与计算 59

7.2.2 低速级齿轮设计与计算 64

7.3 轴的设计与计算 68

7.3.1输入轴的设计与计算 68

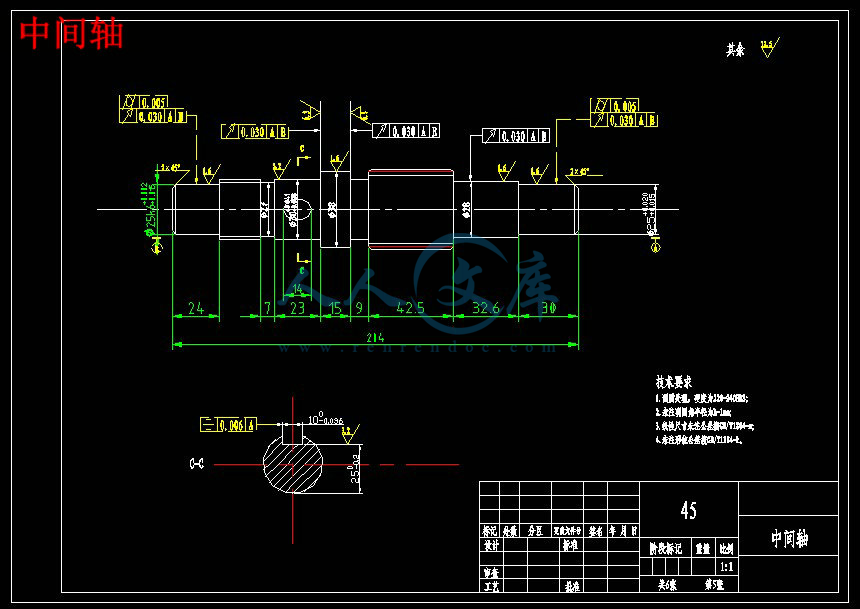

7.3.2 中间轴的设计与计算 71

7.3.3输出轴的设计与计算 74

7.4 轴承的校核 76

7.4.1 输入轴上轴承寿命计算 76

7.4.2 中间轴上轴承寿命计算 77

7.4.3 输出轴上轴承寿命计算 78

7.5 键的选择和校核 80

7.5.1键的选择 80

7.5.2键的校核 80

结论 82

参考文献 83

致 谢 85

第1章 绪论

所谓异型石材:广泛的说,为除了石头板材(平板)以外的所有的其他的石材制成品,比如说是路沿石、柱子、柱头、雕刻、线条、台阶、台面、拱门、窗台、门框、石凳、石桌、洗手盆、车止石等等。

1.1异型石材的分类

1.1.1异型石材的分类

从大的分类可分为天然异型石材,人造石异型石材。从制作工艺分类由于异型石材制品可以指除了石头平板材以外的所有的石材制成品,所以其种类非常的繁多,分类也很多。

1.1.2按加工方法分

1).立体异型石材产品:包括立体的人像、动物、抽象、以及其他题材或造型的石雕品, 平面浮雕,带雕刻的柱子、柱头、柱座,雕刻家具,栏杆扶手,石头壁炉,花盆花瓶,墓碑,喷泉,带雕刻的窗套门套,工艺品等等。可以是规则的对称产品,也可 以是不规则的非对称产品。其中立体类的异型石材的加工方式主要方式是:劈、剁、磨、铲、凿、钻等,并可以是通过手工加工完成,或是采用机械化加工来实现。

2).平面异型石材产品:如像是厨卫的台面板,常规的石材线条,水刀拼花板材,工作台面板和桌面,常规的路沿石,拐 角等等,其形状可以是对称的,也可以是不对称的。平面型的异型石材其加工相对来说比较简单,主要通过切、磨、抛光等简单的加工工序就能生产出来;其主要是 由机器加工完成的。

3).曲面板材产品:比如弧型板、圆柱、规则弧度的曲线线条等,其形状基本是对称的。曲面异型石材的加工也是相对来 说比较简单(会比平面异型石材难度大些),主要通过切、磨、抛等简单加工完成,但是其设备教先进,是专门用来加工曲线截面的(比如说金刚石绳锯),其主要 也是由机器加工完成的。

1.1.3按截面尺寸分

1).等截面异形产品:即无论主体的形状及其截面的是怎样的,按柱体轴线的垂直面来剖开,其所得的各截面图是相同的,即为等截面异形石材。等截面异形石材是一种对称的异型石材。

2).非等截面异形产品:是指无论主体的形状及其截面的是怎样的,如果按柱体轴线的垂直面来剖开,其所得的各截面图是并没有处处相同的,则是非等截面异形石材。非等截面异形石材是非对称异型石材,其主要是有着复杂结构的石材产品。

3.此外还有其他的一些分类方法。

川公网安备: 51019002004831号

川公网安备: 51019002004831号