钢坯拨钢装置设计(拔钢机)(全套含CAD图纸)

收藏

资源目录

压缩包内文档预览:

编号:11520072

类型:共享资源

大小:1.21MB

格式:ZIP

上传时间:2018-12-02

上传人:机****料

认证信息

个人认证

高**(实名认证)

河南

IP属地:河南

50

积分

- 关 键 词:

-

钢坯

装置

设计

拔钢机

全套

cad

图纸

- 资源描述:

-

- 内容简介:

-

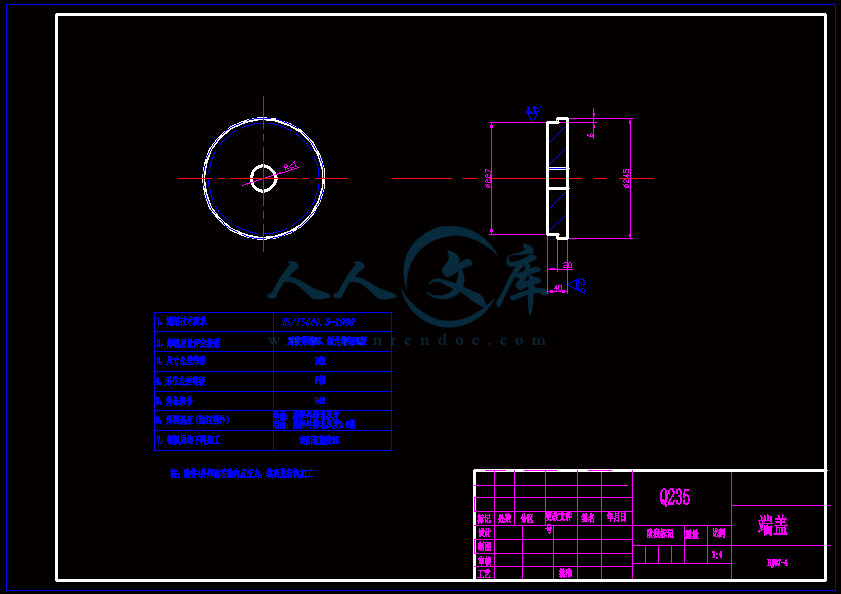

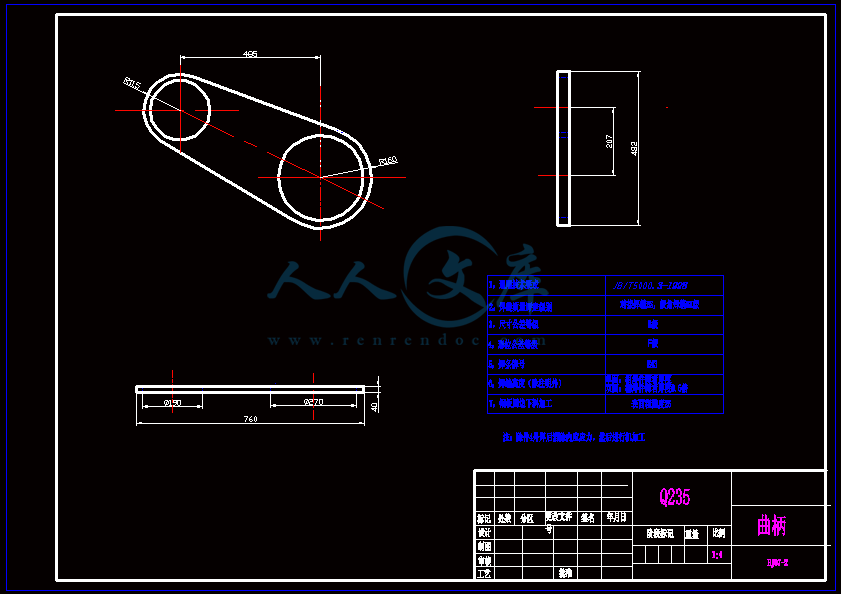

本科毕业论文外文翻译外文译文题目(中文) :Dial the steel machine(拨钢机)学 院:机械自动化学院专 业:机械工程及自动化学 号:学生姓名:指导教师:日 期:目 录前 言.1第一章轧制工艺概况1.1 轧制工艺过程21.2 轧制工艺过程的设计与实施21.3 轧制工艺过程的自动控制3第二章拨钢机简介2.1 拨钢机种类42.2链式拨钢机的结构.42.3 拨钢机的工作过程.5 谢 辞.6 参考文献. 7 前言 轧钢工艺过程是确定轧钢厂生产系统和机械设备的技术基础,设备是实现轧钢工艺要求的工具。 轧钢生产是钢铁工业生产的最终环节,是钢铁材料的一种重要加工方法。轧钢车间担负着生产钢材的任务,因此钢铁轧制在国家工业体系中占有举足轻重的地位。20世纪90年代以前,我国轧钢生产的平均水平与世界主要生产国相比,仍存在一定的差距。轧钢生产以型钢为主,生产线大、中、小型并存。不同企业的技术装备水平参差不齐,能耗、成本较高。很多企业还使用20世纪五六十年代较为陈旧的设备和工艺,这是限制我国钢材质量,品种和效益进一步提升的主要瓶颈。 20世纪90年代后期,随着我国经济的高速发展,尤其是我国加入WTO后,参与国际钢材市场竞争的需要,各大企业纷纷采用当今世界先进的技术和装备,进行了大规模的技术改造,广泛引进新技术,新设备,新工艺,使我国轧钢生产的水平有了长足进步,开发了一批高技术,高附加值的新品种。目前我国轧钢技术创新发展的方向主要为:通用工艺技术,综合节能与环保技术,新品种开发与钢材性能优化技术,信息技术和装备机电控制一体化技术等。我国现在通用的轧钢工艺排列为: 钢坯验收 吊装 计量 编组 入炉加热粗轧 热剪机切头 中轧 飞剪切头 平立交替精轧机 倍尺飞剪 夹送辊 冷床 冷剪定尺 检验称重打包收集 入库 第一章,轧制工艺概况1.1轧制工艺过程1.轧制工艺过程的内容轧制工艺过程是一系列工序的组合,经过这些工序,把钢锭或钢坯轧成形状和性能符合要求的钢材。轧钢工艺过程的好坏直接影响产品的质量和产量。一般情况下,一个轧钢工艺过程是由下列各基本工序组成:1).坯料准备 包括坯料的表面清理,除去表面氧化铁皮和表面缺陷的清理,也包括预先热处理和坯料加热。坯料加热是重要工序。 2).钢材轧制 坯料通过轧制变形来实现对产品在形状和尺寸上的要求,内部组织和性能上的要求以及表面光洁度的要求。轧制过程是轧钢生产工艺过程的核心工序。3).精整 这是轧钢工艺过程的最后一道工序,起保证产品质量的作用。精整工序的内容比较复杂,由产品的技术要求来确定。技术要求不同,其内容也大不相同。一般情况精整工序包括钢材的切断或卷取,轧后冷却,矫直,成品热处理成品表面清理、镀锌、镀锡、涂色等。1.2轧制工艺过程的设计与实施设计轧制工艺过程的主要依据是产品的技术条件、钢种的加工工艺性、生产规模大小、产品成本和工人的劳动条件。其中最主要的依据是产品的技术要求,即钢材的断面形状和尺寸、化学成分、内部组织和机械性能,设计时必须保证工艺过程使产品质量达到相应的技术要求。1.3轧制工艺过程的自动控制 轧钢机工艺过程的自动控制是用电子计算机来实现的。控制技术包括轧机特性和变形阻力等轧制理论、还包括仪表、电气设备的应用技术以及操作决窍等方面的技术。只有这些技术有机地组合,才能实现轧钢过程的自动控制。1.轧制过程数学模型 轧制过程计算机控制的基础是轧制过程的数学模型。对轧制有影响的因素有板厚、变形阻力、张力、辊径及摩擦系数等多种,尤其对连轧过程,前面机架的轧制结果不但直接影响后面机架的轧制条件,而已作用在轧件上的张力还影响所有机架的轧制。因此就必须把连轧机组所有机架当作一个统一的系统进行综合分析。具体数学模型有轧件的塑性变形模型、轧机弹性变形模型、连续轧制模型和表示轧件温度变化的热传导模型等。 例如,在板材轧制中,对于提高板厚精度,必须预测作用在轧辊上的轧制力,这是非常重要的,所以实测出变形阻力就成为各方面研究的前提。为了提高数学模型预测的精度,必须用实测的轧制过程中的各参数的实际数据来标定和修改数学模型,通过所谓自学习控制来吸收掉作业条件的变化和其他外部干扰。为此需要在轧机上安装在线监测系统,通过各种传感器实时监测各工艺参数,首先是变形阻力也就是与它直接相关的轧辊上的轧制压力。 数学模型所用的数据必需准确可靠,能准确反映操作条件和对过程进行分析,还必须满足在线控制的实时性要求。2.计算机控制所需的传感器和仪表如前所述,计算机控制轧制工艺过程之所以能迅速发展,是建立在各种检测工艺参数的传感器和仪表的出现和发展,一些主要的传感器和仪表如下:1)位置检测传感器 用于跟踪轧件位置的传感器有热金属检测器,冷金属检测器,微波检测器,电磁检测器和激光检测器。后三种适合在环境气氛很差的条件下工作。2)压力传感器 准确测定轧制压力的传感器。3)温度传感器 测定开轧和终轧温度及轧制线上各点轨件温度的传感器。4)测厚仪 常用的是射线测厚仪和射线测厚仪,最新发展是板形断面测量和微机自动校正。5)测宽仪 多采用光学测量法和热辐射测量法。6)速度计。3.板厚自动控制(AGC)为提高板材质量,70年代研制出了计算机控制的板厚自动控制装置(AGC),而后不断有新的发展,以适应愈来愈严格的板厚精度要求。近来数字直接控制方式(DDC)已取代了以往的硬件方式(AGC),可以很经济地控制数量较多的活套,还具有维护简便和控制性能高等优点。4.热带钢连轧机计算机控制实例目前国际上计算机控制水平最高的是热带钢连轧工艺过程,这是由于在各种轧机中,热带钢连轧产量大、质量要求高、操作虽复杂但比其他轧制过程易于实现计算机控制。其计算机功能分为在线监测和自动控制两大部分,监测包括信息传送,轧件跟踪,数据记录等。 第二章.拨钢机的简介2.1拨钢机的种类 常见的拨钢机有链式、行星轮式等。它们各自有自身的特点,在不同的加热炉上发挥着各自的作用。 链式拨钢机通过齿轮齿条的啮合传动把电机的旋转运动转变为齿条的直线运动,带动拨杆进行拨钢工作。其工作可靠,传动效率高,推力和行程大,但设备自身重量大。目前链式推钢机应用比较广泛。 行星式拨钢机由行星轮系推动拨杆工作,结构简单,推力大, 自重轻,速度、行程易控制,但行程不宜太大,但液压系统制作、维护较困难。2.2链式拨钢机的结构 链式拨钢机主要包括电机、减速机、联轴器、齿轮轴、齿条、拨杆、机架等。机架一般为一个多层箱体,箱体间用螺栓联接。齿轮轴位于箱体底层的称为下置式,齿轮轴位于箱体上层的称为上置式。无论采用下置式还是上置式,都存在更换零部件困难的现象,尤其是更换下部零件时,需要把箱体层层拆分开。 状态监测和故障诊断对钢铁工业就具有十分重要的意义。2.3拨钢机的工作过程 主要负责调整钢坯,钢板轧制位置的拨钢机,它的使用好坏直接影响着轧制速度和轧制质量,对板材的质量有着至关重要的地位。在制造过程中,用拨钢机将钢坯从输送辊道输送至链式移钢机上,为保证产品的表面质量,必须保证产品在输送过程中无弯曲变形擦伤等。拨钢的工作节律必须符合生产要求,拨钢速度要求必须和输送辊道,输送链相匹配。我国老式的拨钢机,走轮式拨钢臂结构复杂,制作难度大,维修不便,且在使用的过程中极易卡死。拨钢机主体部分整体性差,压辊轴向,径向定位不理想,造成压辊易倾斜,压簧易掉,轴和轴承及座等部件易损。压辊磨损严重易打滑,推杆磨损易弯曲,支撑架磨损易晃动等一系列的问题造成拨钢,调整钢板,钢坯速度慢,不能准确到位。并且,备件的制作加工安装更换都耗费很大的人力物力。总之,由于拨钢机易损坏,故障多,极易造成停机检修,影响作业率和轧制速度,甚至造成轧废板子,影响板型质量。 针对拨钢机出现的种种问题,研发和技术人员对拨钢机进行了种种改造,走轮式拨钢臂的改为简易的悬臂式拨钢臂的基础上,又针对主体部分把分体支架式改为整体立柱横梁式:(1)底座借用原来的基础,支架部分由原来上下压辊单片支架靠上盖连接一体改为上部整体横梁式,下部整体U型座,靠立柱连接,增加底座及整个拨钢机的强度,有效地避免了支架晃动,为确保拨钢机整体性能奠定了坚实的基础;(2)上从动压辊由原轴承座支撑辊子转动在支架内侧上下移动,支架与支撑座相对滑动,易导致支架和轴承座磨损,轴承座倾斜,致使压辊倾斜。因此改为两整体横梁式固定上下从动压辊,取消轴承座,上下移动靠立柱及压簧控制完成;(3)由原来压下螺丝(螺母固定在支架上盖内)压块弹簧压辊轴承座改为压下螺丝套弹簧直接拧入螺丝中,不但增大了压簧的调整量,而且省去了压下螺母等零件。弹簧不掉,调整简便,压辊不倾斜,保证了压辊的轴向,径向定位,大大抑制了压辊易打滑推杆易弯曲等现象。 合理的的工艺过程,直接影响着产品的质量和产量。然而,新设备是实现新工艺的可靠保证,新工艺的研究要考虑新设备实现的可能性。因此,脱离工艺谈设备,或者脱离设备制定不确实际的工艺,都无济于事。同时还要做些体现人性化设计的工作,重视辅助工序和自动化以减轻工人的劳动强度。这些辅助工序机械化,自动化,智能化对生产具有重要作用,同时又能取得巨大的经济效益。 谢辞 在导师于钟老师的悉心指导下,我的毕业设计终于如期圆满完成了。钟老师渊博的知识、严谨的治学态度和忘我的敬业精神令我受益匪浅。半年来,钟老师在设计上和实习上给了我重要的帮助,在此,我衷心的感谢钟老师半年来的关怀和培养。同时,也要感谢本宿舍的同学对我无私的帮助和支持,给我营造了一个轻松愉快地学习工作环境。特别要感谢和我在一起设计的小组各位同学对我的帮助。由衷的感谢培养和教育过我的武汉科技大学以及机械工程学院的各位老师。向他们致以最崇高的敬意! 参考文献【1】文庆明轧钢机械 【M】 化学工业出版社,2003【2】武汉钢铁设计院轧钢设计参考资料 【M】武汉钢铁设计计院,1978【3】冶金工业设计院板带车间机械设备设计 M 北京:冶金工业出版1981【4】机械设计手册编委会机械设计手册 M 机械工业出版社,2006【5】马鞍山钢铁设计院中小型轧钢机械与设计【M】冶金工业出版社1979【6】王海文轧钢机械设计【M】北京:冶金工业出版社,1982【7】成大光机械设计手册【M】北京:化学工业出版社,2002【8】周国盈带钢卷取设备【M】北京:冶金工业出版社,1985【9】濮良贵机械设计【M】北京:高等教育出版社,2005【10】杨家军机械设计基础【M】武汉:华中科技大学出版社,2002【11】唐曾宝机械设计课程设计【M】武汉:华中科技大学出版社,2006【12】北京钢铁学院轧钢车间辅助设备M北京:北京钢铁学院,1961 13 Tara M.dailey,Dennis L.Claussen,Gregory B.Ladd,Shizuka T.BucknerComparative Biochemistry and PhysiologyJ,Department of Zoology,Miami Uiniversity,Oxford,OH,45056USA 14 From psoriasis to a number and back Ann-Christine Franden,School of Business,Economics and Law,Gotebory University.SE 405 30,Geothenbury,Sweden Warwick Businiss School,The Warwick University,Coventry,CV47AL,UK 15 Self-administered quesition naire and direct observation by checklist:Comparying tow methods for physical exposuresurve eillanceina highly repetitive tasksplat Alexis Descathaa,Yves Roquelauree,Sandrine Carolyf,Bradley Evanoff,Diane Cy,Jean Mariel ,Annette Leclerc USA Preface Rolling steel rolling process is sure of mechanical equipment production system and technical basis, the equipment is to realize steel rolling technology requirements of the tools. Steel-rolling production is the final link steel industrial production, is a kind of important steel materials processing method. Rolling workshop shoulder the task of producing steel and steel rolling in country, so industrial system plays a very important role. The 20th century in China before the 1990s, the average level of steel-rolling production, compared with the main producers there still exists certain gap. Steel-rolling production line with steel primarily, large, medium and small coexist. Different enterprise technical equipment level irregular, energy consumption, high cost. Many enterprise also USES the 1950s and 1960s relatively old equipment and technology, this is to limit the country steel quality, variety and benefit the main bottleneck further ascent. The late 1990s, along with our countrys high-speed economic development, especially after Chinas entry into WTO, participate in international steel the requirements of market competition, each big enterprise are used in todays world of advanced technology and equipment, on a large scale technical renovation, widely introducing new technology, new equipment, new technology, make our country steel-rolling production levels had great progress, the development of a batch of high technology, high value-added new varieties. At present our country steel rolling technology innovation development direction mainly for: gm technology, comprehensive energy conservation and environmental protection technology, new development and steel performance optimization technology, information technology and equipment mechanical and electrical control integration technology, etc. Chinas current general steel rolling technology for: billet arranged acceptance measurement lifting charging heating six-car rough rolling hot cut machine top-end fly in rolling shear head lianfeng alternately flat vertical flying shear as feet clips to send roller cold cold-bed.it cut scale weighing inspection incoming pack collection. firstly rolling process Outlines1.1 rolling process 1. The content of the rolling processRolling process is a series of working procedure, after the combination of these processes, the ingot or billet rolling into shape and performance to meet the requirements of steel. Rolling process will have a direct impact on the quality of the products and production. Normally, a rolling process is composed by the following the basic process: 1). The blank ready to include blank surface clearing up, remove surface oxidation iron sheets and surface defect cleaning, also including heat treatment and blank heating in advance. Heat is important process blank. 2.) steel rolling stock through the rolling deformation to achieve products in shape and dimension of the demands of the internal organization and performance, the request and surface finish requirements. Rolling process is steel-rolling production process core processes. 3). Finishing this is rolling process since the last procedure, to ensure the product quality role. Finishing process by the content is more complex, the technical requirements to determine product. Technical requirements are different, its content is very different. General situation of finishing process including steel cut or coiling, rolling, straightening, finished after cooling surface cleaning, galvanized heat treatment products, tin plating, color, etc.1.2 rolling process design and implementationDesign rolling process products is the main basis of technological condition, kind of steel for processing manufaturability, production scale size, the cost of product and Labour conditions. One of the main basis for the technical requirements of the product, namely the steel cross-section shapes and sizes, chemical composition, internal organization and mechanical properties, design must ensure that process its product quality reaches the corresponding technical requirements. 130 rolling process automatic controlRolling process with the automatic control is to realize the electronic computer. Control technology including mill characteristics and deformation resistance etc rolling theory, also includes instrument, electrical equipment application technology and operating know-how the technology. Only these technologies can realize the organic combination, steel rolling process of automatic control. 1. Rolling process mathematical modelRolling process computer control is the foundation of the mathematical model of the rolling process. The factors of rolling have a thickness and deformation resistance, tension, roller diameter and friction coefficient and so on many kinds of, especially for rolling process, front frame rolling results not only directly affect the rolling conditions behind frame, just rolled pieces of role in the tension still affect all frame rolling. Therefore we must combine rolling unit as a unity of all frame system analysis. Specific mathematical model has rolled piece of plastic deformation model, mill elastic deformation model, continuous rolling model and said the rolled-piece temperature changes such as heat transfer model.For example, in plate rolling, for thickness accuracy, must on the prediction function in the roller rolling force, it is very important, so the measured out deformation resistance becomes various aspects research premise. In order to improve the prediction precision of mathematical model, and we must use a measured rolling process of the parameters of the actual data to calibration and modify mathematical model, through the so-called self-learning control to absorb the change of operation condition and other external interference. Therefore, it is necessary to install in mill, through all sorts of on-line monitoring system for real-time sensor monitoring the process parameters, first is deformation resistance with it is directly related to the rolling pressure on the roll.Mathematical model data used by must accurate, can accurately operating conditions and the process in analysis, also must satisfy the on-line control in real-time. 2. Computer control required sensor and instrumentationAs mentioned previously, computer control rolling process is able to develop rapidly, is built on various testing process parameters of the sensor and instrumentation, developed some main sensor and instrumentation is as follows: 1) position detection sensor used for tracking the rolled-piece position sensor are hot metal detector, the cold metal detector, microwave detector, solenoid detector and laser detector. After three kinds of suits in atmosphere under the working conditions of the poor. 2) pressure sensor accurately determination of rolling pressure sensors. 3) temperature sensor measuring open rolling and finishing temperature and rolling online at various points. The sensor rail a temperature 4) thickness gauge common is ray thickness gauge and ray thickness gauge, the latest development is the strip shape section measurement and microcomputer automatic calibration. 5) mesurement instrument by optical measurement method and more thermal radiation measuring method. 6) speedometer. 3. Thickness automatic control (AGC)In order to improve the plank quality, 1970s developed computer control thickness automatic control device (AGC), and then constantly have new development, so as to adapt to the increasingly strict thickness accuracy. Recent figures directly control methods (DDC) has replaced the previous hardware methods (AGC), can be very economic control of large number of live, have convenient maintenance and control the advantages of high performance. 4. Tropical steel even mill computer control examplesThe international computer control level is the highest tropical steel continuous rolling process, this is due to different rolling steel rolling, tropical yield, high quality requirements, operation is complicated, but easy realization rolling process than other computer control. Its computer functions into online monitoring and automatic control of two parts, including information transmitted, monitoring the rolled-piece tracking, data record, etc. Secondly, Dial the steel machine profile 2.1 dial the steel machine typesCommon dial the steel machine have chain-type, planetary wheel etc. They all have their own characteristics in different heating furnace, playing their role.Chain dial the steel machine through the meshing rack-and pinion rotating shift of the motor for the linear motion, driving the rack is to dial the steel work shifter lever. Its reliable work, high transmission efficiency, thrust and travel, but with the device itself a big weight. At present the chain pushed steel machine is widely.The planet type planetary gear train by steel machine to dial push the shifter lever, simple structure, light weight, thrust large, speed, easy to control, but travel itinerary shoulds not be too big, but hydraulic system production, maintenance is difficult. 2.2 chain dial the structure of steel machineChain dial machine mainly include motor, steel shaft coupling, reducer, gear axle, rack, dial the pole, frame, etc. Frame for a multilayer box, general with bolt connection between box. The gear axis is located in the bottom of the box is called underneath type, the gear axis is located in the top of the box called placed on type. Whether using underneath type or placed on type, have the replacement parts are difficult phenomena, especially when the lower parts change, want to dismantle separate layers box. The condition monitoring and fault diagnosis in steel industry has the extremely vital significance. 2.3 dial the working process of the steel machineMainly responsible for adjustment, steel rolling position of billet steel machine, it to dial direct influence use rolling rolling speed and quality of plate quality, have very important position. In the manufacturing process, use dial the steel billet machine will be transported to the chain from roller conveyer move on to assure product steel, the surface quality, we must ensure products in conveying process without bending deformation scratch etc. Dial the steel work rhythm production requirements, dial must conform to the steel speed requirements must be and roller conveyer matching, conveying chain. Our old dial the steel machine, go wheeled dial complex structure, make steel arm difficult, maintenance, and in use inconvenience easily in the process jammed. Dial the steel machine body part integrity is poor, pressure roller, radial orientation to not ideal, roller is apt to tilt over, caused by compression spring easy drop, axis and bearings and seat, etc. Parts of vulnerability. Roller badly worn easy skid, push rod wear easily bend, supporting frame wear easily and so on a series of problems caused by shaking steel, steel, adjust to dial billet speed is slow, not accurate in position. And, spare parts manufacturing and processing installation replacement costs big manpower. In short, easily damaged due to dial the steel machine, fault, is caused extremely easily downtime repair, affect work rates and rolling speed, even cause rolling waste board, influence plate type quality. According to dial the steel machine problems, appear to dial research and technical personnel on the various reform steel machine, walk instead of wheeled dial the steel arm simple cantilevered dial the steel arm on the basis of, and according to the main part of the overall pillar instead of scaffolding fission type: (1) the base beam based, borrow originally from the original stented segment up on roller monolithic stents connected to the upper cover, lower overall beams type, on the whole u-shaped seat mast connection, increase base and the whole dial the intensity of the steel machine, and avoids the wobble, to ensure that dial stent overall performance of steel machine laid a solid foundation; (2) by the original follower pressure roller bearing support roller rotation move up and down in the guard on the inside part of turning a scaffold, and relative sliding, easy to support and housings, which wear, pressure roller bearing tilt to tilt. So instead of two integral beam fixed climbing-up and down driven roller bearing, cancel, move up and down by pillar and the compression spring control completion; (3) by original press screws (nut fixed on the stent cover inside) - press block - spring - pressure roller instead of bearing pressing screw in the screw directly twist spring compression spring, not only increased the adjustment quantity, but also tell the press nut and other parts. Spring do not drop, adjustment is simple, pressure roller, guarantee the tilt not the axial pressure roller, radial orientation, greatly suppresses pressure roller easy skid push-rod easy bending wait for a phenomenon. Reasonable process, the direct impact on the quality of the products and production. However, new equipment is to realize the reliable guarantee of new technology, new technical research to consider new equipment implementation possibility. Therefore, from process about equipment, or from actual process equipment formulate inaccuracies, to no avail. Also do some humane design work, attention technologyof assistant and automation in order to reduce labor intensity. These technologyof assistant mechanization, automation, intelligent plays an important role in production, and also achieve the huge economic benefits. Thank-you speech actually In raising the tutor in clock under the guidance of teachers, my graduation design finally duly successfully finished. Clock teacher profound knowledge, rigorous doing scholarly research manner and selfless dedication to my benefited. Over the last six months, in design and clock teacher gave me the internship, on this important help, my heartfelt thanks clock, care and six months of teacher training. At the same time, also thanks to the dormitory of the classmate my selfless help and support, give me build a relaxed learning environment to work. Spe

- 温馨提示:

1: 本站所有资源如无特殊说明,都需要本地电脑安装OFFICE2007和PDF阅读器。图纸软件为CAD,CAXA,PROE,UG,SolidWorks等.压缩文件请下载最新的WinRAR软件解压。

2: 本站的文档不包含任何第三方提供的附件图纸等,如果需要附件,请联系上传者。文件的所有权益归上传用户所有。

3.本站RAR压缩包中若带图纸,网页内容里面会有图纸预览,若没有图纸预览就没有图纸。

4. 未经权益所有人同意不得将文件中的内容挪作商业或盈利用途。

5. 人人文库网仅提供信息存储空间,仅对用户上传内容的表现方式做保护处理,对用户上传分享的文档内容本身不做任何修改或编辑,并不能对任何下载内容负责。

6. 下载文件中如有侵权或不适当内容,请与我们联系,我们立即纠正。

7. 本站不保证下载资源的准确性、安全性和完整性, 同时也不承担用户因使用这些下载资源对自己和他人造成任何形式的伤害或损失。

人人文库网所有资源均是用户自行上传分享,仅供网友学习交流,未经上传用户书面授权,请勿作他用。

川公网安备: 51019002004831号

川公网安备: 51019002004831号