摘 要

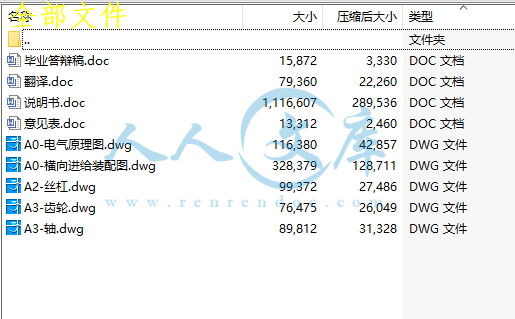

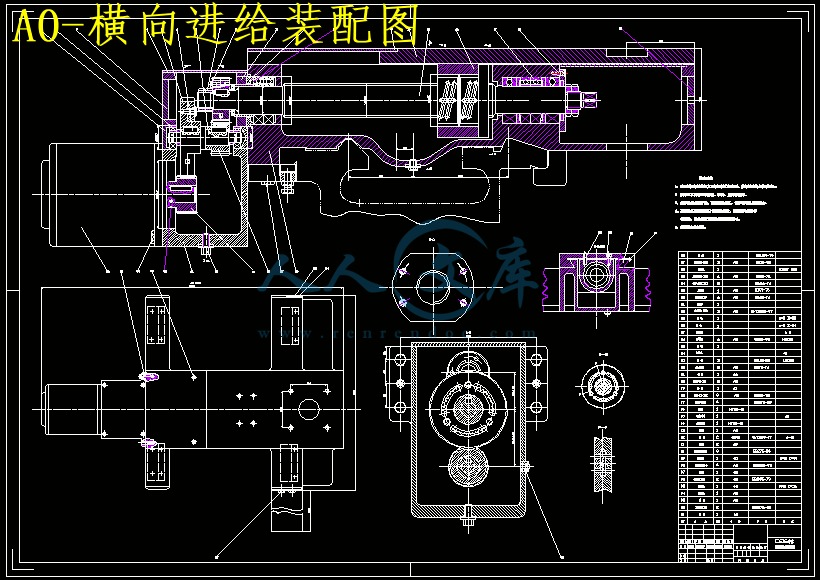

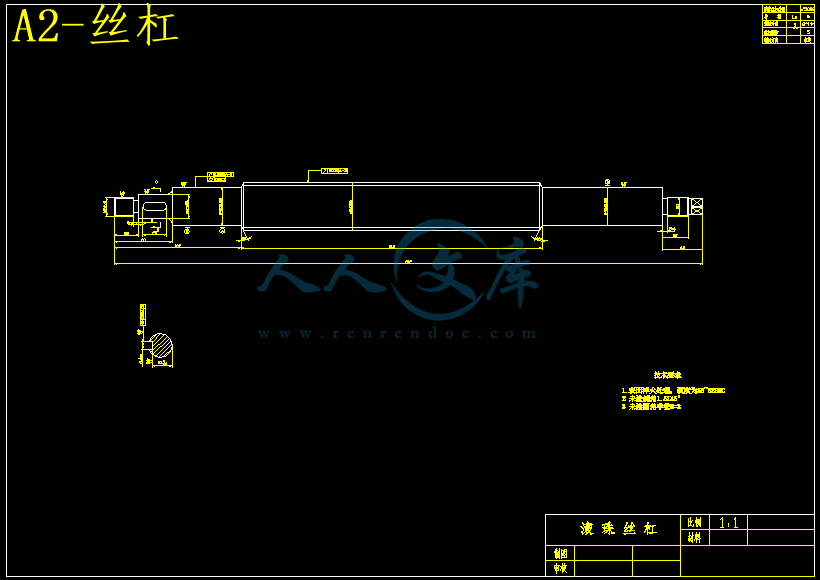

本次设计主要是针对C616车床的横向进给伺服系统改造,机械方面的改造过程是:拆掉原手动刀架和小拖板,安装上数控刀架;拆掉普通丝杆、光杆进给箱和溜板箱,换上滚珠丝杠螺母副;保留原手动机构,用于调整操作,原有的支撑结构也保留,采用一级齿轮减速,步进电机、齿轮箱体安装在中拖板的后侧。

机械部分采用步进电动机驱动滚珠丝杠,然后再通过滚珠螺母副来动工作台运作。电器部分采用MCS—8051单片机来对步进电动机进行适时有效的控制,同时为了便于人机对话,通过输入程序来更好的解决形状复杂、精密、难加工的问题。这次设计可以准确地实现规定的动作、自动化程度较高、能灵活迅速的适应加工零件的更变。

关键字: 车床 步进电动机 单片机 人机对话 精密

abstract

The system is mainly aimed C616 lathe infeed servo system transformation, the transformation process is mechanical: the original manual turret removed and a small carriage, the installation of CNC turret; removed ordinary screw, rod feed box and slide crate, put the ball screw nut; retain the original manual body for adjusting operation, the support structure to retain the original, with a gear, stepper motor, gear box installed in the extension unit back.

Stepping motor drive mechanical ball screw, and then through the ball nut to move the operation table. Electrical part to the use of MCS-8051 single-chip stepper motor for timely and effective control, and in order to facilitate the man-machine dialogue, by entering the program to better solve the shape of the complex, sophisticated and difficult to process problems. The design can be accurately specified action to achieve high degree of automation, flexibility to quickly adapt to change more parts processing.

Keywords: Lathe; Stepper motor; SCM; Man-machine dialogue; Precision

目 录

摘要 II

Abstract III

绪 论 2

1 机械部分改造的设计及计算 3

1.1 课题的来源与意义及总体方案的确定 3

1.1.1 课题的来源与意义: 3

1.1.2 总体方案的确定: 4

1.2 滚珠丝杠副的计算和选型 5

1.2.1 确定系统的脉冲当量 5

1.2.2 切削力计算 6

1.2.3 传动效率 8

1.3 步进电动机的选择 10

1.3.1 传动比的计算 10

1.3.2 转动惯量的计算 11

1.4 齿轮设计及强度校核计算 15

1.4.1 选定齿轮类型,精度等级,材料及齿数 15

1.4.2 按照齿面接触疲劳强度校核 16

1.4.3 校核齿根弯曲疲劳强度 18

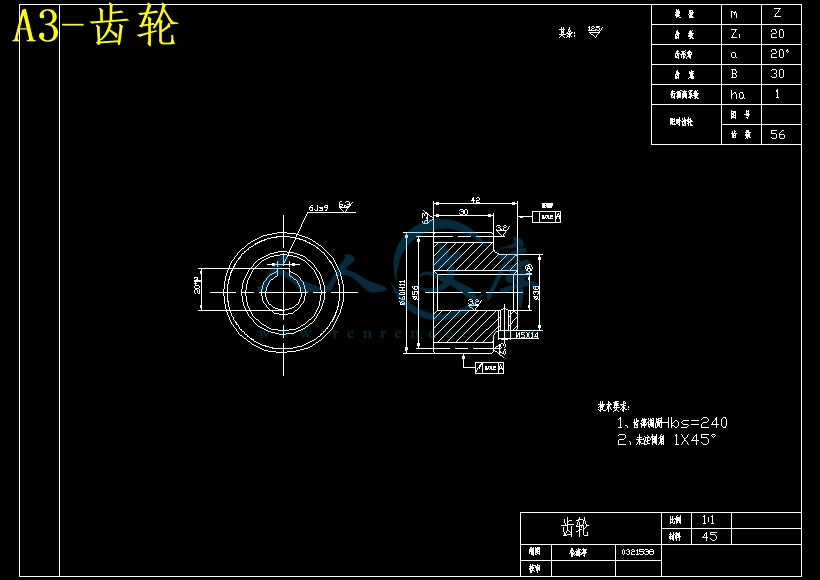

1.5 轴的设计(中间轴)及校核 19

1.5.1 选择轴的材料 19

1.5.2 初步估算轴的最小直径 19

1.5.3 轴的结构设计 20

1.5.4 按弯扭合成应力校核轴的强度 20

1.5.5 精确校核轴的疲劳强度 23

1.6 滚动轴承的选择和计算 28

1.7 键联接的选择和强度校核(即中间轴) 29

1.7.1 大齿轮2与轴的键联接 29

1.7.2小齿轮3和轴的键联接 30

2 机床横向伺服进给单元电气控制部分设计 31

2.1 电气控制系统方案的确定 31

2.1.1 步进电动机与丝杠的联接 32

2.1.2 8051单片机的选择 32

2.2 步进电动机开环控制系统设计 32

2.2.1 脉冲分配器 33

2.2.2 光隔离电路 36

2.2.3 步进电动机驱动电路 37

2.3 8255可编程控制芯片的扩展 39

2.4 辅助电路的设计 40

2.4.1 8051单片机的时钟电路 40

2.4.2 复位电路 41

2.4.3 越界报警电路 41

2.5 操作面板设计的简要介绍 42

2.6 绘制机床电气控制电路原理图 42

结 论 44

致 谢 45

参考文献 46

绪 论

随着我国生产技术进步,在机械制造业中,数控机床越来越受到企业的欢迎。企业一方面投入大量资金购买数控车床,另一方面更新改造现有普通机床,通过 为普通机床添加数控装置,将普通机床改造成数控机床,这是许多中小型企业面临的重要技改措施。

数控机床能够适应市场对产品多样化、高精度的要求。因此得到了越来越广泛的应用。但是,商品化的数控机床价格高,一致于推广应用受到限制,而我国又现存有大量的普通机床,利用较先进的数控 系统,对现有普通机床进行技术改造,对提高我国机械行业的数控加工技术具有 更重要意义。数控机床是衡量一个国家机械制造业水平的重要指标。根据我国机床拥有量大,生产 规模小的具体国情,将普通机床通过数控化改造为经济型数控机床是我国机械工业技术改造的这样目标。但从我国目前机械工业制造水平与发达国家相比差距较大, 而且从目前企业所面临的情况看,因数控机床价格较贵,一次性投资较大,使企业心有余而力不足。

因此,我国作为机床大国。对普通机床数控化改造作为一种良好的有效途径。这样机床改造花费少,改造设计针对性强、时间短,改造设计后的机床大多能够克服机床的缺点和存在的问题,生产效率高。

1 机械部分改造的设计及计算

1.1 课题的来源与意义及总体方案的确定

1.1.1 课题的来源与意义:

社会发展的今天,现代工业发展非常迅速突出,普通机床已越来越不能满足现代加工工艺及提高劳动生产率的要求。如果设备全部更新换代不仅资金投入大,成本太高,而且原有设备的闲置又将造成极大浪费。所以最简易经济的办法就 是进行数控化改造。数控机床作为机电一体化的典型产品,在机械制造业中发挥着巨大的作用,很好的解决了现代机械制造中结构复杂、精密、批量小、多变零件的加工问题,且能稳定产品的加工质量,大幅度地提高生产效率。但从我国目前机械工业制造水平与发达国家相比差距较大,而且从目前企业所面临的情况看,因数控机床价格较贵,一次性投资较大,使企业心有余而力不足。因此,我国作为机床大国。对普通机床数控化改造作为一种良好的有效途径。这样机床改造花费少,改造设计 针对性强、时间短,改造设计后的机床大多能够克服机床的缺点和存在的问题,生产效率高。

川公网安备: 51019002004831号

川公网安备: 51019002004831号