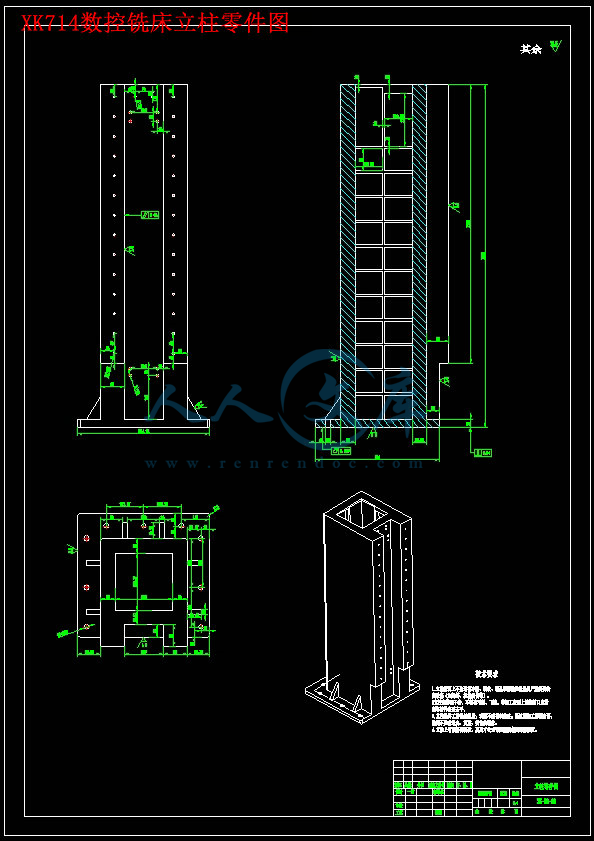

XK714数控铣床总体设计及主传动系统的设计 立柱设计 床身设计【全套9张CAD图纸和毕业答辩论文】

收藏

资源目录

压缩包内文档预览:

编号:13847177

类型:共享资源

大小:28.42MB

格式:ZIP

上传时间:2019-01-27

上传人:好资料QQ****51605

认证信息

个人认证

孙**(实名认证)

江苏

IP属地:江苏

50

积分

- 关 键 词:

-

全套9张CAD图纸和毕业答辩论文

XK714数控铣床总体设计及主传动系统的设计

立柱设计

床身设计【全套9张CAD图纸和毕业答辩论文】

xk714

数控

铣床

总体

整体

设计

传动系统

立柱

床身

全套

- 资源描述:

-

【温馨提示】 购买原稿文件请充值后自助下载。

以下预览截图到的都有源文件,图纸是CAD,文档是WORD,下载后即可获得。

预览截图请勿抄袭,原稿文件完整清晰,无水印,可编辑。

有疑问可以咨询QQ:414951605或1304139763

购买下载后请联系QQ 获取三维源文件,三维较大无法上传,请理解

- 内容简介:

-

EXTENDING BEARING LIFEAbstract:Nature works hard to destroy bearings, but their chances of survival can be improved by following a few simple guidelines. Extreme neglect in a bearing leads to overheating and possibly seizure or, at worst, an explosion. But even a failed bearing leaves clues as to what went wrong. After a little detective work, action can be taken to avoid a repeat performance. Keywords: bearings failures life Bearings fail for a number of reasons,but the most common are misapplication,contamination,improper lubricant,shipping or handling damage,and misalignment. The problem is often not difficult to diagnose because a failed bearing usually leaves telltale signs about what went wrong However,while a postmortem yields good information,it is better to avoid the process altogether by specifying the bearing correctly in The first placeTo do this,it is useful to review the manufacturers sizing guidelines and operating characteristics for the selected bearing. Equally critical is a study of requirements for noise, torque, and runout, as well as possible exposure to contaminants, hostile liquids, and temperature extremes. This can provide further clues as to whether a bearing is right for a job. 1 Why bearings fail About 40% of ball bearing failures are caused by contamination from dust, dirt, shavings, and corrosion. Contamination also causes torque and noise problems, and is often the result of improper handling or the application environmentFortunately, a bearing failure caused by environment or handling contamination is preventable,and a simple visual examination can easily identify the cause Conducting a postmortem il1ustrates what to look for on a failed or failing bearingThen,understanding the mechanism behind the failure, such as brinelling or fatigue, helps eliminate the source of the problem. Brinelling is one type of bearing failure easily avoided by proper handing and assembly. It is characterized by indentations in the bearing raceway caused by shock loadingsuch as when a bearing is dropped-or incorrect assembly. Brinelling usually occurs when loads exceed the material yield point(350,000 psi in SAE 52100 chrome steel)It may also be caused by improper assembly, Which places a load across the racesRaceway dents also produce noise,vibration,and increased torque. A similar defect is a pattern of elliptical dents caused by balls vibrating between raceways while the bearing is not turningThis problem is called false brinelling. It occurs on equipment in transit or that vibrates when not in operation. In addition, debris created by false brinelling acts like an abrasive, further contaminating the bearing. Unlike brinelling, false binelling is often indicated by a reddish color from fretting corrosion in the lubricant. False brinelling is prevented by eliminating vibration sources and keeping the bearing well lubricated. Isolation pads on the equipment or a separate foundation may be required to reduce environmental vibration. Also a light preload on the bearing helps keep the balls and raceway in tight contact. Preloading also helps prevent false brinelling during transit. Seizures can be caused by a lack of internal clearance, improper lubrication, or excessive loading. Before seizing, excessive, friction and heat softens the bearing steel. Overheated bearings often change color,usually to blue-black or straw coloredFriction also causes stress in the retainer,which can break and hasten bearing failure Premature material fatigue is caused by a high load or excessive preloadWhen these conditions are unavoidable,bearing life should be carefully calculated so that a maintenance scheme can be worked out Another solution for fighting premature fatigue is changing materialWhen standard bearing materials,such as 440C or SAE 52100,do not guarantee sufficient life,specialty materials can be recommended. In addition,when the problem is traced back to excessive loading,a higher capacity bearing or different configuration may be used Creep is less common than premature fatigueIn bearingsit is caused by excessive clearance between bore and shaft that allows the bore to rotate on the shaftCreep can be expensive because it causes damage to other components in addition to the bearing0ther more likely creep indicators are scratches,scuff marks,or discoloration to shaft and boreTo prevent creep damage,the bearing housing and shaft fittings should be visually checked Misalignment is related to creep in that it is mounting relatedIf races are misaligned or cockedThe balls track in a noncircumferencial pathThe problem is incorrect mounting or tolerancing,or insufficient squareness of the bearing mounting siteMisalignment of more than 1/4can cause an early failure Contaminated lubricant is often more difficult to detect than misalignment or creepContamination shows as premature wearSolid contaminants become an abrasive in the lubricantIn addition。insufficient lubrication between ball and retainer wears and weakens the retainerIn this situation,lubrication is critical if the retainer is a fully machined typeRibbon or crown retainers,in contrast,allow lubricants to more easily reach all surfaces Rust is a form of moisture contamination and often indicates the wrong material for the applicationIf the material checks out for the job,the easiest way to prevent rust is to keep bearings in their packaging,until just before installation 2 Avoiding failures The best way to handle bearing failures is to avoid themThis can be done in the selection process by recognizing critical performance characteristicsThese include noise,starting and running torque,stiffness,nonrepetitive runout,and radial and axial playIn some applications, these items are so critical that specifying an ABEC level alone is not sufficient Torque requirements are determined by the lubricant,retainer,raceway quality(roundness cross curvature and surface finish),and whether seals or shields are usedLubricant viscosity must be selected carefully because inappropriate lubricant,especially in miniature bearings,causes excessive torqueAlso,different lubricants have varying noise characteristics that should be matched to the application. For example,greases produce more noise than oil Nonrepetitive runout(NRR)occurs during rotation as a random eccentricity between the inner and outer races,much like a cam actionNRR can be caused by retainer tolerance or eccentricities of the raceways and ballsUnlike repetitive runout, no compensation can be made for NRR. NRR is reflected in the cost of the bearingIt is common in the industry to provide different bearing types and grades for specific applicationsFor example,a bearing with an NRR of less than 0.3um is used when minimal runout is needed,such as in diskdrive spindle motorsSimilarly,machinetool spindles tolerate only minimal deflections to maintain precision cutsConsequently, bearings are manufactured with low NRR just for machine-tool applications Contamination is unavoidable in many industrial products,and shields and seals are commonly used to protect bearings from dust and dirtHowever,a perfect bearing seal is not possible because of the movement between inner and outer racesConsequently,lubrication migration and contamination are always problems Once a bearing is contaminated, its lubricant deteriorates and operation becomes noisierIf it overheats,the bearing can seizeAt the very least,contamination causes wear as it works between balls and the raceway,becoming imbedded in the races and acting as an abrasive between metal surfacesFending off dirt with seals and shields illustrates some methods for controlling contamination Noise is as an indicator of bearing qualityVarious noise grades have been developed to classify bearing performance capabilities Noise analysis is done with an Anderonmeter, which is used for quality control in bearing production and also when failed bearings are returned for analysis. A transducer is attached to the outer ring and the inner race is turned at 1,800rpm on an air spindle. Noise is measured in andirons, which represent ball displacement in m/rad. With experience, inspectors can identify the smallest flaw from their sound. Dust, for example, makes an irregular crackling. Ball scratches make a consistent popping and are the most difficult to identify. Inner-race damage is normally a constant high-pitched noise, while a damaged outer race makes an intermittent sound as it rotates. Bearing defects are further identified by their frequencies. Generally, defects are separated into low, medium, and high wavelengths. Defects are also referenced to the number of irregularities per revolution. Low-band noise is the effect of long-wavelength irregularities that occur about 1.6 to 10 times per revolution. These are caused by a va

- 温馨提示:

1: 本站所有资源如无特殊说明,都需要本地电脑安装OFFICE2007和PDF阅读器。图纸软件为CAD,CAXA,PROE,UG,SolidWorks等.压缩文件请下载最新的WinRAR软件解压。

2: 本站的文档不包含任何第三方提供的附件图纸等,如果需要附件,请联系上传者。文件的所有权益归上传用户所有。

3.本站RAR压缩包中若带图纸,网页内容里面会有图纸预览,若没有图纸预览就没有图纸。

4. 未经权益所有人同意不得将文件中的内容挪作商业或盈利用途。

5. 人人文库网仅提供信息存储空间,仅对用户上传内容的表现方式做保护处理,对用户上传分享的文档内容本身不做任何修改或编辑,并不能对任何下载内容负责。

6. 下载文件中如有侵权或不适当内容,请与我们联系,我们立即纠正。

7. 本站不保证下载资源的准确性、安全性和完整性, 同时也不承担用户因使用这些下载资源对自己和他人造成任何形式的伤害或损失。

人人文库网所有资源均是用户自行上传分享,仅供网友学习交流,未经上传用户书面授权,请勿作他用。

川公网安备: 51019002004831号

川公网安备: 51019002004831号