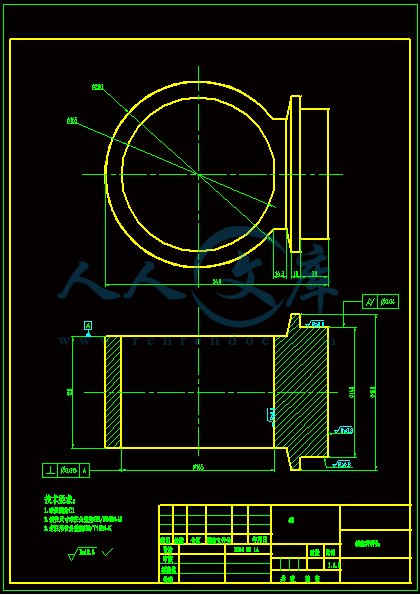

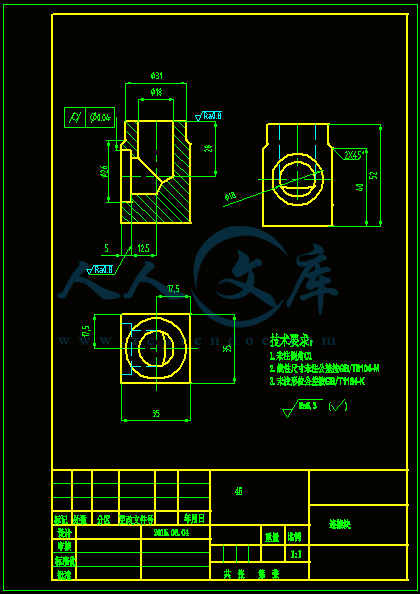

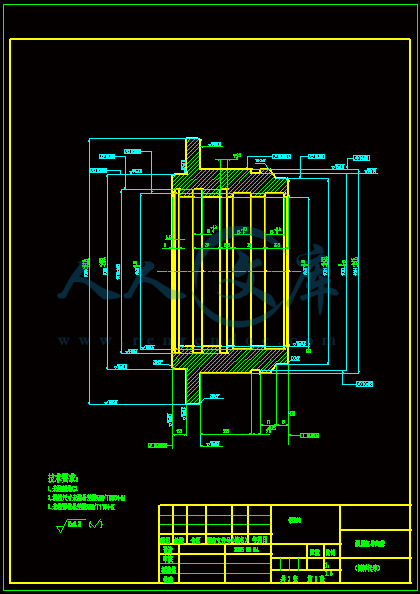

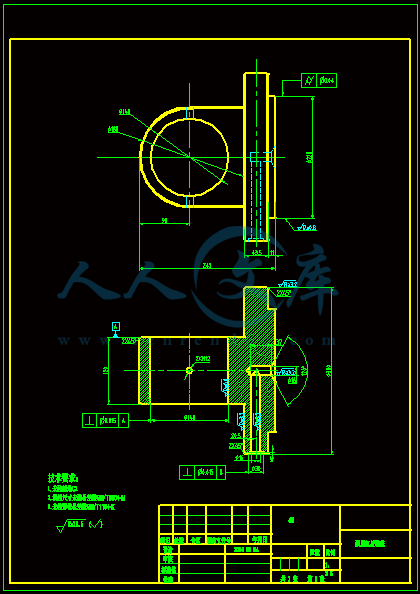

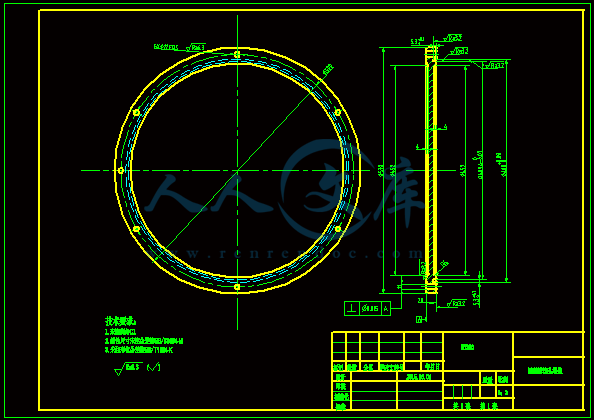

起重机变幅液压系统设计【含14张CAD图纸、说明书】

收藏

资源目录

压缩包内文档预览:

编号:14967191

类型:共享资源

大小:38.19MB

格式:ZIP

上传时间:2019-02-21

上传人:机****料

认证信息

个人认证

高**(实名认证)

河南

IP属地:河南

30

积分

- 关 键 词:

-

含14张CAD图纸、说明书

起重机变幅液压系统设计

起重机设计【

张CAD图纸】

起重机液压系统

含14张CAD图纸

起重机液压系统设计

含CAD图纸

液压起重机设计

CAD 图纸

CADcad

- 资源描述:

-

- 内容简介:

-

IMPLEMENTATION OF HYDRAULICSERVO CONTROLLERS WITH ONLYPOSITION MEASUREAbstractHydraulic actuators have nonlinear dynamics and are often used in environments (robotic, aerospace, underwater explo-rations/inspections, mining) where uncertain disturbances are present. Linear controllers designed using a linearized model of the hydraulic system are widespread. In alternative, nonlinear and ro-bust control techniques can be used to achieve better performances. Among these techniques, sliding mode control with dynamics inversion is a good choice, but it usually requires measurements of actuators velocity and hydraulic pressures in addition to actu-ators position. This paper presents the design and experimental evaluation of a position controller for an hydraulic actuator where the only available measure is the actuators position. A detailed description of servosystem components is firstly presented. Then a linear control law, whose design is based on a linearized model of the actuator, is designed and tested. Finally, a sliding mode control law is developed. Experimental results, carried out on a real case study, have shown the ectiveness of the proposed controllers even when only actuators position is available for feedback.Key Words :Hydraulic actuators nonlinear systems nonlinear control system sliding mode control.1. IntroductionHydraulic actuators are used in many industrial appli-cations as they over the following advantages: ness; compactness; payload capability; high immunity to wear thanks to lubricant action of fluid; high speed of response, with fast starts, stops and speed reversals;ability to main-tain their loading capacity indefinitely, while this would usually cause excessive heat generation in electrical com-ponents 1, 2. Furthermore, their high power-to-weight ratio allows their use in a direct-drive manner, as e.g., in industrial robots, so that wear-sensitive gear-boxes can be avoided. DIIIE, Universita degli Studi di Salerno, Via Ponte Don Melillo, 1-84084, Fisciano(SA), Italy; e-mail: fbasile, ddel-grossounisa.it Recommended by Prof. Zhihua Qu (paper no. 206-3128)One of their major drawbacks is their strongly non-linear behaviour. The main nonlinearities are: magnetic hysteresis in the armature of the servovalve driving the actuator, usually neglected 3, 4; static nonlinear relation between the control input and the flow to the actuator; ori-fices tolerances (overlap/underlap), which generate dead-zones; pressure and temperature dependency of isothermal bulk modulus; asymmetry of the hydraulic cylinder 5; friction force acting on the actuator 6. Another ma-jor drawback is the dis culty of accurately estimating the models parameters, and their variations under dis erent operating conditions. Therefore, to design a servo posi-tion system for an hydraulic actuator nonlinear and robust control techniques have to be used to achieve good per-formances. Today more complex control laws, like inverse dynamics laws, are successfully used in many applications and have been recently applied also to hydraulic servosys-tems 4, 710. It is important to point out that in all these works control laws are presented which rely on mea-surement of at least actuatorss position and velocity and hydraulic pressures. Figure 1. Control architectures overview.The hydraulic actuator considered in this work is com-posed of a flapper-nozzle type two-stage servovalve and an asymmetric hydraulic cylinder. A servo position system has to be devised. First, an accurate model of the actu-ator has been written obtained which takes into account the main phenomena influencing its behaviour. Dynamic parameters were partly available by the supplier. To vali-date these parameters and identify the others, it was not possible to procede with open-loop experiments but it was mandatory for safety requirements to move the actuator only if closed-loop controlled. To this purpose, a discrete-time linear controller has been first designed based on a linearized model of the actuator. Then, a sliding mode con-trol law has been designed in the continuous-time domain by using a Lyapunov-based approach and implemented in discrete-time without requiring direct measurements of ve-locity and pressures. As it is commonly accepted in prac-tice 11 for control engineers the sliding mode controller designed in continuous-time domain has been implemented in the discrete-time by selecting a ciently fast sampling rate. The model uncertainties, the fact that pressures are not directly measured and frictions are not compensated,and the time delays make the chattering reduction crit-ical 11. To avoid this undesirable phenomenon 12 a boundary layer approach has been adopted.The main contribution of this paper is to prove that low-cost robust control of hydraulic actuators is possible even if not all the required direct measurements are avail-able. In fact, the proposedcontrollers requires only direct measurement of actuators position.2. Experimental Setup2.1 Control ArchitectureThe hydraulic actuator taken into account in this work is a linear single-rod cylinder whose pistons position is measured by a Linear Variable Dis erential Transformer (LVDT) sensor. The digital control architecture, shown in Fig. 1, has the following features:PowerPC CPU running at 500 MHz; The sampling rate is 500 Hz; 12 bit A/D and D/A converters; Voltage-to-current and current-to-voltage converters with a bandwidth of 10 KHz; LVDT Current Conditioningand Transmitter (LCCT) with a bandwidth of 250 Hz; A 100 Hz second-order Butterworth anti-aliasing filter; Hydraulic system (the actuator) including an LVDT sensor for position measuring. Notice that The only available measure is pistons position; The digital implementation and the presence of limited bandwidth circuits and filters makes possible to neglect all components over 100 Hz; The presence of quantizers produces a measurement noise, in fact the measures resolution is 2.3 105 m; The actuator has to work in a wide and variable range of temperatures. 2.2 Implementation IssuesExperimental tests on the real architecture have drawn the attention to some important aspects for the design of both the linear and the robust controller.1. Time delays on feedback chain: A time delay on the feedback chain of about 6 ms has been measured which heavily influences the dynamics and must be taken into account in designing the controllers.2. Noise in the positions measure: The LVDT sensors non-ideal behaviour, joint with the presence of quan-tizers, produces a not-negligible measurement noise. Then, it is necessary to verify the filtering capacity of the controllers, to avoid vibrations of the actuator. 3. Unavailable measures: The only available measure is the actuators position. Thus, the proposed sliding mode controller works without the chambers pressure measures as commonly required. Actuators velocity and acceleration have instead been obtained from the position measure by using a derivative filter (see Fig. 2) for which the considered transfer function is: Filters parameters have been tuned to realize a deriva-tive behaviour up to 100 Hz without amplifying high-frequency components.Figure 2. Re-constructor filter.3. Model DescriptionThe structure of the electro-hydraulic servoactuator, com-posed of a nozzle-flapper flow control servovalve and an asymmetric hydraulic actuator, is shown in Fig. 3 where the scale factors for the valve and the actuator are erent for sake of clarity. All the symbols reported in Fig. 3 are defined in Table 1 and will be used in the model description below.Figure 3. Hydraulic servoactuator layout.3.1 Servovalve Model3.1.1 Servovalve Nonlinear ModelThe nonlinear model of the nozzle-flapper valve 1, 2 can be represented by the scheme in Fig. 4 where its main elements are shown. The input is the electrical current of the torque motor I which is transformed in a torque at the armature:As the rotation of the armature is very small, a simplified linear relation is often considered:The equation describing the armature flappers dy-namics relating armature torque to flapper displacement (in case of small rotation) is:The equations describing nozzles flows relating flapper displacement to flows on spools sides are:液压伺服控制器的执行位置测量摘 要 液压执行器有非线性动力特性,并且经常在机械,航空航天,水下检验环境中使用,检测其中的不确定干扰存在。线性控制器的设计普遍采用线性模型的液压系统。如果使用非线性和鲁棒控制技术作为替代可以实现更好的性能。在这些技术中,采用动态逆滑模控制是一个很好的选择,但它通常需要除了实际位置的测量还需要执行器的速度和液压压力测量。本文提出的是一个液压制动器的位置控制器设计的实验。一个详细说明的伺服系统组件首先被提出。然后,是基于线性模型的执行机构的线性控制法的设计和测试。最后,研制了一种滑模控制律。实验结果,在一个真实的案例研究,证明所提出控制器即使当只有致作动器的位置是可用于反馈的时候依然有效。关键词 : 液压作动器 非线性系统 非线性控制系统 滑模控制第一章 介绍 液压执行器有许多工业应用因为以下优点:刚性,紧凑性,载荷能力,由于液体流动的高抗磨损性;响应速度快,具有快速启动,停止和速度逆转;保持无限容量装载的能力,但这通常会导致电气部件过热。此外,他们的高功率重量比允许他们使用直接驱动的方式,例如,在工业机器人中,这样可以避免磨损敏感的齿轮箱。其主要缺点之一是其强烈的非线性行为。主要的非线性是:伺服阀驱动致动器电枢中的磁滞,这经常被忽视;在输入控制和执行器流动中的静态非线性关系;产生死区的孔公差;压力和等温体积弹性模量的温度依赖性;液压缸的不对称;作用在致动器摩擦力。另一个主要的缺点是难以准确估计模型的参数和不同试验条件下的变化的参数。因此,为了为液压致动器技术的非线性设计一个伺服位置系统,需要应用鲁棒控制技术以获得更好的性能。今天,更复杂的控制规律,如逆动力学规律,成功地应用在许多应用程序并且最近也适用于液压伺服系统。需要指出的是,在所有这些工作的控制律的提出依靠执行器位置和液压压力的测量。这项工作中的液压执行机构是由喷嘴挡板式二级电液伺服阀和非对称液压缸组成。一个伺服位置系统必须设计。首先,已经提到执行器的精确模型需要考虑到那些影响其性能的主要现象。一部分动态参数可从供应商获得。为了验证这些参数并确定其他参数,进行开环试验是不可能的,安全需求当闭环控制去移动执行器是强制性的。为了这个目的,基于线性模型的执行器首先设计出了一个离散时间线性控制器。然后,一个滑动模式控制法已被设计在连续时间域通过使用一个Lyapunov为基础的方法,在离散时间实现

- 温馨提示:

1: 本站所有资源如无特殊说明,都需要本地电脑安装OFFICE2007和PDF阅读器。图纸软件为CAD,CAXA,PROE,UG,SolidWorks等.压缩文件请下载最新的WinRAR软件解压。

2: 本站的文档不包含任何第三方提供的附件图纸等,如果需要附件,请联系上传者。文件的所有权益归上传用户所有。

3.本站RAR压缩包中若带图纸,网页内容里面会有图纸预览,若没有图纸预览就没有图纸。

4. 未经权益所有人同意不得将文件中的内容挪作商业或盈利用途。

5. 人人文库网仅提供信息存储空间,仅对用户上传内容的表现方式做保护处理,对用户上传分享的文档内容本身不做任何修改或编辑,并不能对任何下载内容负责。

6. 下载文件中如有侵权或不适当内容,请与我们联系,我们立即纠正。

7. 本站不保证下载资源的准确性、安全性和完整性, 同时也不承担用户因使用这些下载资源对自己和他人造成任何形式的伤害或损失。

人人文库网所有资源均是用户自行上传分享,仅供网友学习交流,未经上传用户书面授权,请勿作他用。

川公网安备: 51019002004831号

川公网安备: 51019002004831号