摘 要

本次毕业设计的的题目是连杆的工艺工装及夹具设计。连杆是柴油机的主要传动件之一,连杆是汽车发动机中的主要传动部件之一,它在柴油机中,把作用于活塞顶面的膨胀的压力传递给曲轴,又受曲轴的驱动而带动活塞压缩气缸中的气体。本文主要论述了连杆的加工工艺及其夹具设计。连杆的尺寸精度、形状精度以及位置精度的要求都很高,而连杆的刚性比较差,容易产生变形,因此在安排工艺过程时,就需要把各主要表面的粗精加工工序分开。逐步减少加工余量、切削力及内应力的作用,并修正加工后的变形,就能最后达到零件的技术要求。

关键词: 连杆;变形;加工工艺;夹具设计

Abstract

The connecting rod is one of the main driving medium of diesel engine, this text expounds mainly the machining technology and the design of clamping device of the connecting rod. The precision of size, the precision of profile and the precision of position , of the connecting rod is demanded highly , and the rigidity of the connecting rod is not enough, easy to deform, so arranging the craft course, need to separate the each main and superficial thick finish machining process. Reduce the function of processing the surplus , cutting force and internal stress progressively , revise the deformation after processing, can reach the specification requirement for the part finally .

Keyword: Connecting rod;Deformination;Processing technology;Design of clamping device

目 录

摘要···········································································································································Ⅰ

Abstract························································································································Ⅱ

绪论·············································································································································1

1 连杆加工工艺························································································································2

1.1 连杆的结构特点··············································································································2

1.2 连杆的主要技术要求······································································································2

1.2.1 大、小头孔的尺寸精度、形状精度···········································································3

1.2.2 大、小头孔轴心线在两个互相垂直方向的平行度···················································3

1.2.3 大、小头孔中心距·······································································································3

1.2.4 连杆大头孔两端面对大头孔中心线的垂直度···························································3

1.2.5 大、小头孔两端面的技术要求···················································································4

1.2.6 2-Φ15螺栓孔的技术要求··························································································4

1.2.7 有关2-Φ15孔两端面的技术要求··············································································4

1.3 连杆的材料和毛坯········································································································4

1.4 连杆的机械加工工艺过程····························································································6

1.5 连杆的机械加工工艺过程分析······················································································7

1.5.1 工艺过程的安排···········································································································7

1.5.2 定位基准的选择···········································································································8

1.5.3 确定合理的夹紧方法 ·································································································8

1.5.4 连杆两端面的加工 ·····································································································9

1.5.5 连杆大、小头孔的加工·······························································································9

1.5.6 连杆2-Φ15螺栓孔的加工· ·······················································································9

1.6 确定各工序的加工余量、计算工序尺寸及公差·························································9

1.7 工时定额的计算 ··········································································································11

1.7.1粗铣连杆大小头上端面·······························································································11

1.7.2粗铣连杆大小头下端面·······························································································12

1.7.3粗镗、半精镗Φ70H7孔、Φ46H7孔··············································································12

1.7.4精铣连杆大头Φ70H7孔两端面·················································································13

1.7.5粗铣、精铣2-Φ15螺纹孔两端面············································································14

1.7.6铣宽60两侧面···········································································································15

1.7.7铣宽64两侧面···········································································································15

1.7.8钻、扩、铰2-Φ15H8螺栓孔并倒角C1、C1.5······················································16

1.7.9钻2-Φ7孔·················································································································17

1.7.10钻2-Φ5孔(头部Φ10,角度90)····································································17

1.7.11精镗Φ70H7孔、Φ46H7孔并倒角C1····································································18

1.7.12半精镗、精镗Φ40H7铜套孔··················································································18

1.8 连杆的检验··················································································································19

1.8.1 观察外表缺陷及目测表面粗糙度···········································································19

1.8.2 连杆大头孔圆柱度的检验·······················································································19

1.8.3 连杆体、连杆上盖对大头孔中心线的对称度的检验···········································19

1.8.4 连杆大小头孔平行度的检验···················································································20

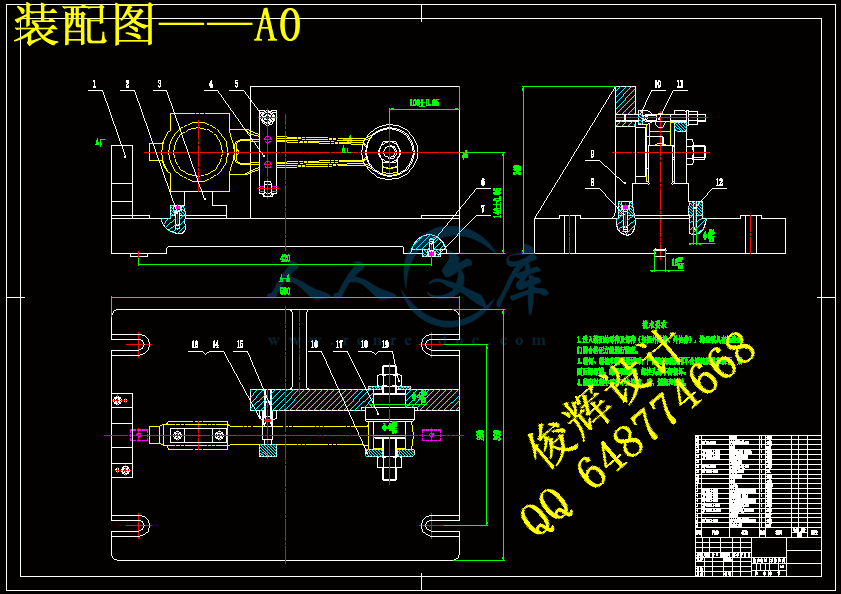

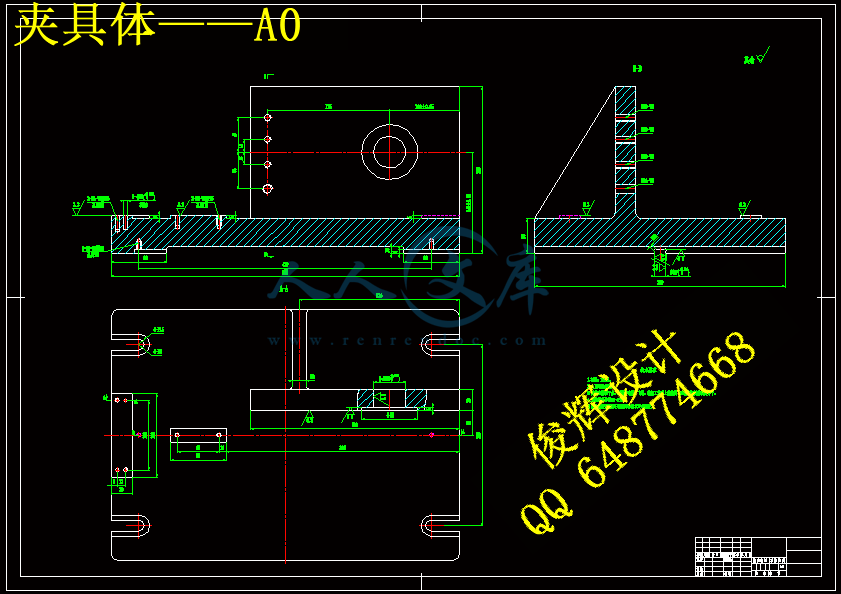

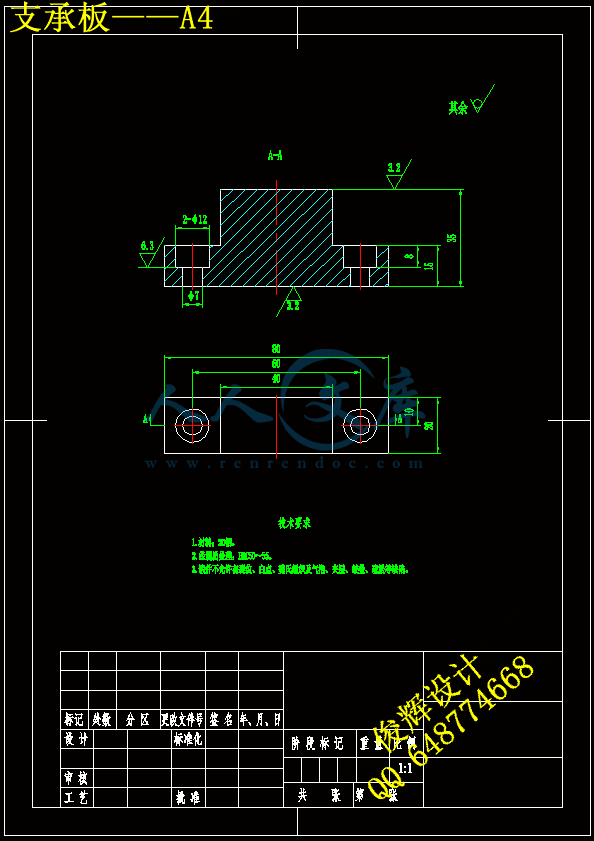

2 夹具设计······························································································································21

2.1问题的提出···················································································································21

2.2 夹具设计······················································································································21

结论·········································································································································23

致谢·········································································································································24

参考文献·································································································································25

绪 论

制造业是国家或者地区经济发展的重要支柱,其发展水平标志着该国家或地区经济势力、科技水平、 生活水平和国防势力。国际市场的竞争归根到底是各国制造生产能力的竞争。机械制造业是制造业的核心,是制造机械产品的工业部门,也是为国民经济各部门提供装备的部门。机械制造也的生产能力和发展水平标志着一个国家或地区国民经济现代化的程度。而机械制造业的生产能力主要取决于机械制造装备的先进程度。装备制造业是国家国家综合制造能力的集中体现。重大装备研制能力是衡量一个国家工业化水平和综合国力的重要标准。作为新世纪的大学生,有义务为自己国家社会建设尽一份力,为制造业的发展贡献一份力量,我们要以高度的责任感和使命感,克服发展中存在的问题,推动东北老工业基地的振兴

毕业设计是对我们四年学习和知识的融汇、运用和贯通,是迅速提高我们实践经验的一条重要途径。在实践中教导我们发现问题,以及怎样分析问题并最终解决问题。让我们的综合能力有所提高,扎实巩固专业基础知识。毕业设计是对学生进行工程师基本训练的重要环节。通过毕业设计我们能巩固,熟悉并综合运用所学知识;培养理论联系实际的学风;掌握零件机械加工工艺规程编制,专用工艺装备及组合机床的基本技能;学会查阅,运用各种技术资料,手册。初步掌握对专业范围的生产技术问题进行分析综合研究的能力;使学生受到比较全面的训练

就个人而言,我希望通过这次毕业设计一方面能进一步培养我独立思考的能力,另一方面能提高我与同学们互助协作的能力,为以后工作打下良好基础,为伟大祖国建设贡献我的力量。由于本人能力有限,经验不足,设计过程中有不足之处,希望各位老师给予指教。

1 连杆加工工艺

1.1连杆的结构特点

连杆是汽车发动机中的主要传动部件之一,它在柴油机中,把作用于活塞顶面的膨胀的压力传递给曲轴,又受曲轴的驱动而带动活塞压缩气缸中的气体。连杆在工作中承受着急剧变化的动载荷。为了减少磨损和便于维修,连杆的大头孔内装有薄壁金属轴瓦。轴瓦有钢质的底,底的内表面浇有一层耐磨巴氏合金轴瓦金属。连杆小头用活塞销与活塞连接。小头孔内压入青铜衬套,以减少小头孔与活塞销的磨损,同时便于在磨损后进行修理和更换。

在柴油机工作过程中,连杆受膨胀气体交变压力的作用和惯性力的作用,连杆除应具有足够的强度和刚度外,还应尽量减小连杆自身的质量,以减小惯性力的作用。连杆杆身一般都采用从大头到小头逐步变小的工字型截面形状。为了保证柴油机运转均衡,同一柴油机中各连杆的质量不能相差太大,因此,在连杆部件的大、小头两端设置了去不平衡质量的凸块,以便在称量后切除不平衡质量。连杆大、小头两端对称分布在连杆中截面的两侧。考虑到装夹、安放、搬运等要求,连杆大、小头的厚度相等(基本尺寸相同)。在连杆小头的顶端设有油孔(或油槽),柴油机工作时,依靠曲轴的高速转动,把气缸体下部的润滑油飞溅到小头顶端的油孔内,以润滑连杆小头衬套与活塞销之间的摆动运动副。

连杆的作用是把活塞和曲轴联接起来,使活塞的往复直线运动变为曲柄的回转运动,以输出动力。因此,连杆的加工精度将直接影响柴油机的性能,而工艺的选择又是直接影响精度的主要因素。反映连杆精度的参数主要有5个:(1)连杆大端中心面和小端中心面相对连杆杆身中心面的对称度;(2)连杆大、小头孔中心距尺寸精度;(3)连杆大、小头孔平行度;(4)连杆大、小头孔尺寸精度、形状精度;(5)连杆大头2-Φ15孔与2-Φ15孔端面的垂直度。

1.2 连杆的主要技术要求

连杆上需进行机械加工的主要表面为:大、小头孔及其两端面,连杆大头2-Φ15孔和2-Φ15孔端面等。连杆零件图的主要技术要求(图1.2-1)如下。

图1.2-1 连杆零件图

1.2.1 大、小头孔的尺寸精度、形状精度

为了使大头孔与轴瓦及曲轴、小头孔与活塞销能密切配合,减少冲击的不良影响和便于传热。大头孔公差等级为IT7,表面粗糙度Ra=1.6μm;小头孔公差等级为IT7,表面粗糙度Ra=3.2μm。

1.2.2 大、小头孔轴心线在两个互相垂直方向的平行度

两孔轴心线在连杆轴线方向的平行度误差会使活塞在汽缸中倾斜,从而造成汽缸壁磨损不均匀,同时使曲轴的连杆轴颈产生边缘磨损,所以两孔轴心线在连杆轴线方向的平行度公差较小;而两孔轴心线在垂直于连杆轴线方向的平行度误差对不均匀磨损影响较小,因而其公差值较大。两孔轴心线在连杆的轴线方向的平行度在100 mm长度上公差为0.015 mm;在垂直与连杆轴心线方向的平行度在100 mm长度上公差为0.06 mm。

1.2.3 大、小头孔中心距

大小头孔的中心距影响到汽缸的压缩比,即影响到发动机的效率,所以规定了比较高的要求:275±1 mm。

1.2.4 连杆大头孔两端面对大头孔中心线的垂直度

连杆大头孔两端面对大头孔中心线的垂直度,影响到轴瓦的安装和磨损,甚至引起烧伤;所以对它也提出了一定的要求:规定其垂直度公差等级应不低于IT9(大头孔两端面对大头孔的轴心线的垂直度在100 mm长度上公差为0.06 mm)。

1.2.5 大、小头孔两端面的技术要求

连杆大、小头孔两端面间距离的基本尺寸相同,但从技术要求是不同的,大头两端面的尺寸公差等级为IT9,表面粗糙度Ra=3.2μm, 小头两端面的尺寸公差等级为IT10,表面粗糙度Ra=12.5μm。这是因为连杆大头两端面与曲轴连杆轴颈两轴肩端面间有配合要求,而连杆小头两端面与活塞销孔座内档之间没有配合要求。连杆大头端面间距离尺寸的公差带正好落在连杆小头端面间距离尺寸的公差带中,这给连杆的加工带来许多方便。

1.2.6 2-Φ15螺栓孔的技术要求

在前面已经说过,连杆在工作过程中受到急剧的动载荷的作用。这一动载荷又传递到连杆的两个螺栓及螺母上。因此除了对螺栓及螺母要提出高的技术要求外,对于安装这两个动力螺栓孔及端面也提出了一定的要求。规定:螺栓孔按IT8级公差等级和表面粗糙度Ra=3.2μm加工。

1.2.7 有关2-Φ15螺栓孔两端面的技术要求

在连杆受动载荷时,2-Φ15螺栓孔两端面的歪斜使连杆沿着端面产生相对错位,影响到曲轴的连杆轴颈和轴瓦结合不良,从而产生不均匀磨损。结合面的平行度将影响到连杆贴合的紧密程度,因而也影响到螺栓的受力情况和曲轴、轴瓦的磨损。对于本连杆,要求2-Φ15螺栓孔两端面的垂直度的公差为0.015 mm。

1.3 连杆的材料和毛坯

连杆在工作中承受多向交变载荷的作用,要求具有很高的强度。因此,连杆材料一般采用高强度碳钢和合金钢;如Cr12、45钢、55钢、40CrMnB等。近年来也有采用球墨铸铁的,粉末冶金零件的尺寸精度高,材料损耗少,成本低。随着粉末冶金锻造工艺的出现和应用,使粉末冶金件的密度和强度大为提高。因此,采用粉末冶金的办法制造连杆是一个很有发展前途的制造方法。

连杆毛坯制造方法的选择,主要根据生产类型、材料的工艺性(可塑性,可锻性)及零件对材料的组织性能要求,零件的形状及其外形尺寸,毛坯车间现有生产条件及采用先进的毛坯制造方法的可能性来确定毛坯的制造方法。根据生产纲领为大量生产,连杆多用模锻制造毛坯,由于锻造的连杆毛坯具有材料损耗少、锻造工时少、模具少等优点,故用得越来越多,成为连杆毛坯的一种主要形式。总之,毛坯的种类和制造方法的选择应使零件总的生产成本降低,性能提高。

目前我国有些生产连杆的工厂,采用了连杆辊锻工艺。图(1.3-1)为连杆辊锻示意图.毛坯加热后,通过上锻辊模具2和下锻辊模具4的型槽,毛坏产生塑性变形,从而得到所需要的形状。用辊锻法生产的连杆锻件,在表面质量、内部金属组织、金属纤维方向以及机械强度等方面都可达到模锻水平,并且设备简单,劳动条件好,生产率较高,便于实现机械化、自动化,适于在大批大量生产中应用。辊锻需经多次逐渐成形。

川公网安备: 51019002004831号

川公网安备: 51019002004831号