目 录

0 引言·····················································································································1

1、总体设计方案··················································································································3

1.1总体设计方案论证·······································································································3

1.2总体设计方案的确定···································································································4

2、横向进给机构的设计与计算····························································································4

2.1已知条件·························································································································4

2.2滚珠丝杠副的设计·········································································································5

2.2.1设计步骤··················································································································6

2.2.2设计计算简况···········································································································7

2.3同步带轮的设计·············································································································8

2.3.1设计计算简况···········································································································8

2.3.2带的工作验算··········································································································10

2.4同步带轮的选型···········································································································10

2.5交流伺服电机与选型···································································································10

2.6导轨副的选择···············································································································12

2.7自动转位刀架的设计···································································································12

2.8预期结果·······················································································································13

3结论································································································14

工作小结与致谢··················································································································15

参考文献······································································································16

附件清单·····································································································17

摘要

本文作者主要研究了φ400mm经济型中档精度数控车床的横向进给机构的设计及其改造。其中,主要论述了两种不同的横向手动进给装置,亦即两种不同的设计方案。通过对两种不同设计方案的优缺点比较,根据提高定位精度、重复定位精度等因素,最终确定设计方案二为本次设计的设计方案。在设计计算中, 本文作者主要对数控车床横向进给机构的主要组成部件:滚珠丝杠副、同步带、同步带轮、交流伺服电机、导轨副及其自动转位刀架等进行了设计计算或选型。其中对滚珠丝杠副、同步带、交流伺服电机以及自动转位刀架的设计计算及选型作了重点论述。此外, 本文作者还对各个零部件进行了设计,并绘制了全部零件图以及该数控车床横向进给机构的装配图。此结构简单可靠,可应用于相似的各类数控车床上。

关键词:数控车床 进给机构 进给系统

Abstract

Main research φ 400 mm economical middle-grade precision numerical control crosswise of lathe, author of this text of summary, enter give design of organization and transform. Among them, have described two kinds of different entering horizontal and manually to the device, namely two kinds of different plans of design mainly. Compare through the pluses and minuses to two kinds of different plans of design , according to raising and orientate the precision , orient the factors, such as precision,etc. repeatedly, confirm plan of design two as the plan of design designed this time finally. In design in calculating, have lathe horizontal to enter give main composition part of organization to numerical more control authors of this text mainly: Ball guide screw vice, bring, bring wheel, exchange servo electrical machinery, vice guide and transfer to location knife rest, etc. design calculating or selecting type automatically in step in step. Among them guide screw vice to ball taking, exchange servo electrical machinery and transfer to location design of knife rest calculate and selecting type act as and expound the fact especially automatically in step. In addition author of this text go on and design to each spare part also, draw all part picture and lathe horizontal to enter give installation diagram of organization numerical control this. It is reliable that this is of simple structure, can apply to similar all kinds of numerical control lathes .

Key words: Computer control lathe Feed equipment Feed system

0 引言

该次毕业设计中,我很有幸分在“数控车床小组”,我所设计的课题为“数控车床横向进给机构的设计 (经济型中档精度数控机床)”。进行这一设计主要是为了进一步地提高数控车床横向进给机构的定位精度、重复定位精度以及改造手动进给装置以使其能够可靠地运行。而且,通过这次毕业设计也可以检验自己的学习情况,锻炼自己,对今后的学习和工作也有一定程度上的帮助。

信息时代的高新技术流向传统产业,引起后者的深刻变革。作为传统产业之一的机械工业,在这场新技术革命冲击下,产品结构和生产系统结构都发生了质的跃变,微电子技术、微计算机技术的高速发展使信息、智能与机械装置和动力设备相结合,促使机械工业开始了一场大规模的机电一体化技术革命。随着计算机技术、电子电力技术和传感器技术的发展,各先进国家的机电一体化产品层出不穷。机床、汽车、仪表、家用电器、轻工机械、纺织机械、包装机械、印刷机械、冶金机械、化工机械以及工业机器人、智能机器人等许多门类产品每年都有新的进展。机电一体化到各方面的技术已越来越受关注,它在改善人民生活、提高工作效率、节约能源、降低材料消耗、增强企业竞争力等方面起着极大的作用。在机电一体化技术迅速发展的同时,运动控制技术作为其关键组成部分,也得到前所未有的大发展,国内外各个厂家相继推出运动控制的新技术、新产品。主要有全闭环交流伺服驱动技术(Full Closed AC Servo)、直线电机驱动技术(Linear Motor Driving)、可编程序计算机控制器(Programmable Computer Controller,PCC)和运动控制卡(Motion Controlling Board)等几项具有代表性的新技术。数控机床是一种高科技的机电一体化产品,是综合应用计算机技术、精密测量及现在机械制造技术等各种先进技术相结合的产物。数控机床作为实现柔性制造系统、计算机集成制造系统和未来工厂自动化的基础已成为现在制造技术中不可缺少的生产手段,是机电一体化技术的重要组成部分。随着科学技术的迅速发展,数控技术的应用范围日益扩大。数控机床已成为现在机械制造业中的主要技术装备。数控机床作为机电一体化的典型产品,在机械制造业中发挥着巨大的作用,很好地解决了现代机械制造中结构复杂、精密、批量小、多变零件的加工问题,且能稳定产品的加工质量,大幅度地提高生产效率。经济型中档精度数控车床主要用于对中小型轴类、盘类以及螺纹零件的加工,这些零件加工工艺要求机床应完成的工作内容有:控制主轴正反转和实现其不同切削速度的主轴变速;刀架能实现纵向和横向的进给运动,并具备在换刀点自动改变四个刀位完成选择刀具;冷却泵、润滑泵的启停;加工螺纹时,应保证主轴转一转,刀架移动一个被加工螺纹的螺距或导程。

数控车床的进给系统包括横向进给系统(X轴)和纵向进给系统(Y轴),它们是由伺服电机经同步齿形带传动,驱动滚珠丝杠螺母副机构,来实现刀架的运动。根据GB/T16462-1996《数控卧式车床精度检验》,机床的位置精度包括重复定位精度、反向偏差和定位精度。当机床的中心距DC=3000mm时,其重复定位精度X轴0.007mm,Z轴0.020mm;反向偏差X轴为0.006mm,Z轴为0.012mm;定位精度X轴为0.016mm,Z轴为0.050mm。可以看出,进给轴设计与主轴设计相比,具有相同的重要性。因而,进给轴的设计应从动、静两方面充分考虑,位置精度才能达到该标准的要求。 对于X轴,由于其位置误差值复映在零件加工尺寸上为直径值,故放大了2倍,X轴移动质量不大,要求的快移速度较低,因而要求X轴应有更高的位置精度。因X轴滚珠杠直径比Z轴小,长度短,并且采用降速传动,使得折算在X轴电机上的转动惯量减小。因此,X轴的设计应着重以达到所要求的位置精度为主要矛盾进行设计,而选用的电机扭矩比Z轴小些。为了达到这目标,X轴应从提高重复定位精度、反向偏差及定位精度三个方面,从设计上解决。在数控车床进给系统的设计中,根据横向、纵向的不同精度要求,不同移动质量及转动惯量等特点,分别解决设计中的主要矛盾。以期望设计结果能满足各项性能指标的要求,达到预期的结果,即满足设计任务书的要求。限于编者水平,书中错误和不妥之处在所难免,殷切期望读者批评指正。

1、 总体设计方案

1.1 总体设计方案论证

与普通机床相比,数控机床进给系统的设计要求除了具有较高的定位精度外,还具有良好的动态响应特性。为了确保数控机床的传动精度和工作平稳性,在设计机械了机构时,通常还应提出无间隙、低摩擦、高刚度以及有适宜的阻尼比要求等。为了达到这些要求,在机械传动设计中,主要采取如下措施:

1、尽量采用低摩擦的传动副;

2、选用最佳的降速比;

3、尽量缩短传动链以及用预紧的方法提高传动系统的刚度;

4、尽量消除传动间隙,减少反向行程误差。

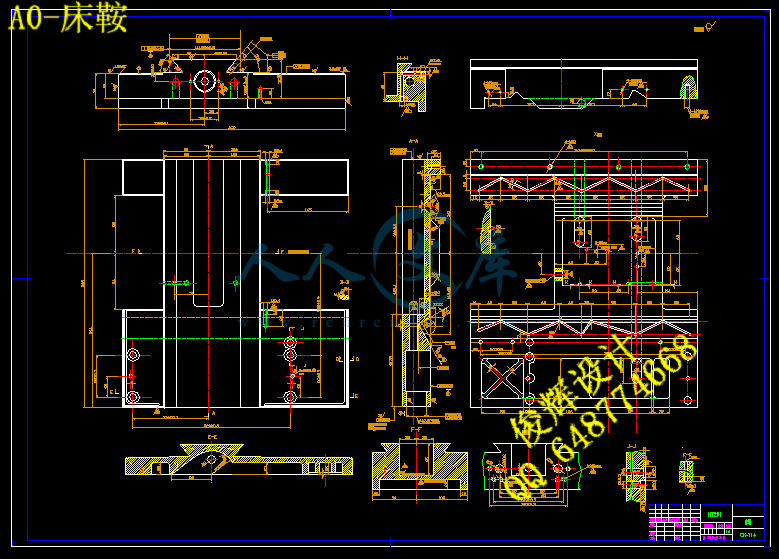

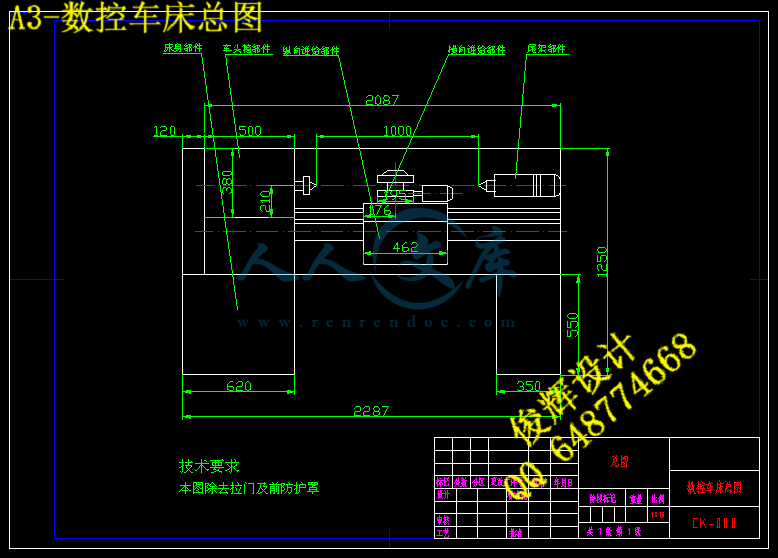

数控车床的总体总体设计方案示意图如下图所示:

川公网安备: 51019002004831号

川公网安备: 51019002004831号