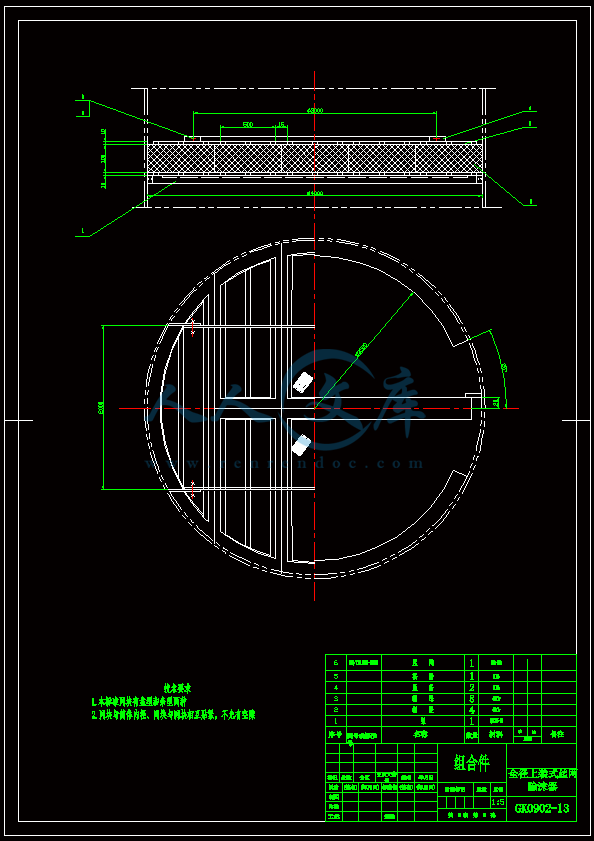

DN4000水煤气洗涤塔设计(包含CAD图、说明书、开题报告、翻译)

收藏

资源目录

压缩包内文档预览:(预览前20页/共69页)

编号:17503317

类型:共享资源

大小:2.59MB

格式:ZIP

上传时间:2019-04-09

上传人:机****料

认证信息

个人认证

高**(实名认证)

河南

IP属地:河南

25

积分

- 关 键 词:

-

DN4000水煤气洗涤塔设计包含CAD图、说明

DN4000水煤气洗涤塔设计

DN4000 水煤气洗涤塔设计

设计说明书水煤气洗涤塔

水煤气洗涤塔

- 资源描述:

-

- 内容简介:

-

DD 大 学毕业设计(论文)任务书学 院: 机械工程学院 题 目 DN4000水煤气洗涤塔设计 论文 (设计) 内容及要求:一、毕业设计(论文)原始依据装置参数:操作压力 常压操作温度 140C入塔物料 半水煤气 水塔高 23.3米, 塔径 4米塔类型: 填料塔环境 衡阳室外二、毕业设计(论文)主要内容设计图纸折合0#图3张以上(其中手工绘图不少于1张1#图)。设计说明书12000字以上,并有20003000字的外文文献翻译和300字左右中英文摘要。三、毕业设计(论文)基本要求设计符合最新国家标准及行业标准。设计图样达到工程设计施工图水平。四、毕业设计(论文)进度安排2013.1.7-2013.1.14 文献查阅2013.1.14-2013.16 开题报告2013.3.1-2013.4.1 总体设计2013.4.2-2013.5.1 强度校核2013.5.1-2013.5.28画图及编写说明书2013.5.28-2013.6.1 准备答辩五、主要参考文献化工设备设计全书(塔设备) 化工原理 化工工艺设计手册 GB150-1998钢制压力容器 指导老师: (签 名) 年 月 日毕业设计(论文)题 目 水煤气洗涤塔 塔设计 学院名称 机械工程学院 指导教师 职 称 班 级 学 号 学生姓名 年 月 日毕业设计(论文)开题报告设计(论文)题目水煤气洗涤塔设计设计(论文)题目来源自选设计(论文)题目类型工程设计起止时间一、 设计(论文)依据及研究意义:水煤气是水蒸气通过炽热的焦炭而生成的气体,主要成份是一氧化碳,氢气,燃烧后排放水和二氧化碳,有微量CO、HC和NOX。燃烧速度是汽油的7.5倍,抗爆性好,据国外研究和专利的报导压缩比可达12.5。热效率提高2040%、功率提高15%、燃耗降低30%,尾气净化近欧IV标准,还可用微量的铂催化剂净化。比醇、醚简化制造和减少设备,成本和投资更低。且水煤气主要用作台成氨、合成液体燃料等的原料,或作为工业燃料气的补充来源。因此,水煤气在现实中需求量是比较大的,水煤气的大量生产也是很有必要的。二、 设计(论文)主要研究的内容、预期目标(技术方案、路线):本次设计的是水煤气洗涤塔。水煤气洗涤塔主要由填料、塔内件及塔体共同构成。因此设计包括的主要内容:填料的选择,塔内设备的选择与设计,塔体的工艺设计(塔封头、筛板、进出口接管及裙座等),绘制图纸等。技术方案及路线:首先进行物料衡算和热量衡算,然后进行塔设备的尺寸计算,最后进行强度计算和校核。三、设计(论文)的研究重点及难点:重点是: 本设计是水煤气洗涤塔设计,且塔高和塔径都已知,操作压力为常压。物料衡算、热量衡算和塔设备的尺寸计算和确定以及强度计算和校核。难点是:由于本次设计的塔为高压塔而且考虑了各种载荷,其难点是对塔体以及一些塔内件的强度计算及校核。四、设计(论文)研究方法及步骤(进度安排):2013.1.7-2013.1.14 文献查阅2013.1.14-2013.16 开题报告2013.3.1-2013.4.1 总体设计2013.4.2-2013.5.1 强度校核213.5.1-2013.6.1 画图及编写说明书五、进行设计(论文)所需条件: 1、要有充分的资料(在图书馆查阅与尿素合成相关的书籍,进行筛选,选出有用的信息)。 2、设计所需设计方法、软件、工具等。六、指导教师意见: 签名: 年 月 日水煤气洗涤塔设计摘要:本次进行的设计是水煤气洗涤塔,水煤气洗涤塔属于填料塔中的吸收塔。进行此次填料塔设计时需要包括以下主要内容:气体和液体的物性参数及工作参数,塔体的设计、塔设备的工艺设计(填料、封头、法兰、进出口接管、液体分布器、吊柱及裙座等等),基础环厚度的设计以及开孔补强等等。并对其要进行载荷的分析以及强度的校核,最后绘制图纸等。通过这次的设计,主要加深了对压力容器的认识,进而达到研究的目的及所期望的结果,同时加深了对国内外一些先进的制造技术和有关压力容器设计及工艺等方面的内容的认识和学习。通过查阅各种相关的文献资料,据此熟悉研究内容、合理的安排课题进度和容器设计路线。关键词: 水煤气 压力容器 填料塔 强度校核 工艺设计 The design of the water-gas scrubbersAbstract: The design of the water-gas scrubbers, water gas scrubber is a packed tower absorber. The packed tower design needs to include the following mainelements: the physical parameters and operating parameters of the gas and liquid, the design of the tower, the process design of the tower (filler, head, flange, take over the importand export, liquid distribution, davit and skirt, etc.), the design of the thickness of the base ring and opening reinforcement. To load analysis and strength check them last drawings. Through this design mainly to deepen the understanding of the pressure vessel, thus achieving the purpose of the study and the desired results, while deepening the understanding of domestic and foreign advanced manufacturing technology and pressure vessel design and process aspects and learning. Access to all relevant documents, pursuant to which familiar with the research, reasonable arrangements for the progress of the topics and the container design line.Keywords: Water Gas Pressure vessel absorption tower Strength check Process Design 目录前 言1第一章 结构设计31.1填料的选择31.2填料层高度的选择:41.3塔内件及其附件的选择41.3.1除沫器的选择51.3.2填料支承装置的选择51.3.3液体再分布器61.3.4塔吊柱的选择61.3.5人孔的设计与选择81.3.6接管法兰的选择81.3.7接管的选择91.3.8压力容器法兰的选择10第二章 塔结构的设计112.1结构设计112.1.1工作参数112.2设计参数的确定112.2.1 设计压力112.2.2设计温度112.2.3塔体材料122.2.4液压试验压力122.2.5焊缝系数132.3筒体的厚度选择132.3.1符号132.3.2设计温度下圆筒的计算厚度142.4球形封头的厚度选择142.4.1符号同1.5.1.1注释142.4.2设计温度下球形封头的计算厚度14第三章 填料塔的载荷分析及强度校核153.1载荷分析153.1.1塔体上各项载荷计算153.1.2地震载荷与地震弯矩的计算173.1.3填料塔自振周期的计算193.1.4塔体的风载荷及风力矩193.1.5偏心弯矩223.1.6最大弯矩223.2塔设备强度校核233.2.1塔体的强度及轴向稳定性验算。233.3裙座的强度及稳定性较核243.3.1裙座各危险截面的校核243.3.2焊缝强度的校核253.4水压试验时塔的强度和稳定性验算253.4.1水压试验时各危险截面的校核253.5裙座基础环的选择和设计263.5.1 对填料塔基础环内外径确定263.5.2填料塔基础环的厚度设计263.6地脚螺栓计算28第4章 开孔及开孔补强设计284.1开孔及开孔的补强方法284.2开孔补强设计准则304.3接管补强判定344.4人孔开孔处补强的判定36参考文献39附录一 外文原文40附录二 外文翻译52结语62DD 大 学毕业设计(论文)综述报告 题 目 DN4000水煤气洗涤塔设计 学院名称 机械工程学院 指导教师 职 称 班 级 学 号 学生姓名 年 月 日1. 本设计(课题)研究的目的和意义在化工、炼油、医药、食品及环境保、护等工业部门,塔设备是一种重要的单元操作设备。目前工业上应用最广泛的还是填料塔及板式塔,填料塔属于微分接触型的气液传质设备,塔内以填料作为气液接触和传质的构件。液体在填料表面呈膜状自上而下流动,气体呈连续相自下而上与液体做逆流流动,并进行气液两相间的传质与传热,两相间的组分浓度或温度沿塔高呈连续变化;填料塔具有效率高、压降低、持液量小、构造简单、安装容易、投资少等优点 , 是石油、化工、化纤、轻工、制药及原子能等工业中广泛应用的气液接触传质设备之一。过去 ,由于其存在着放大效应和壁流效应 , 使其应用仅仅局限于小塔上。近年来 , 人们进行了大量的研究 , 取得了突破性进展 , 目前应用的规整填料最大直径可达 1420m, 突破了仅限于小塔的传统观念 , 并在现代化工生产中得到更为普遍的应用。 塔设备性能的好坏,对生产、产品产量、质量、成本以及环境保护、废料处理等都有较大的影响。因此对塔设备的研究一直是工程界所关注的热点。2. 本设计(课题)国内外研究历史与现状塔设备的使用已有二百多年的历史,现在填料塔设备发展的已经十分完善。设备主要包含填料、塔内设备及塔设备等。目前的研究主要集中在填料、液体分布器和气体分布器等方面。塔填料、塔内件及工艺流程又是填料塔技术发展的关键。随着高效新型填料和其他高性能塔内件的开发,以及人们对填料流体力学、放大效应及传质机理的深入研究,使填料塔技术得到了迅速的发展。目前,国内外已开始利用大型高效塔改造板式搭,并在增加产量、提高产品质量、节能等方面取得了巨大的成就。并且随着一些新型塔板及大通量、低压降、高效规整填料和塔内件的开发应用成功,可以预测 :21世纪的塔器分离技术将向行业化、复合化、节能化、大型化方向发展。3. 目前存在的主要问题填料塔的设计包括塔内填料的选取、塔内件的设计和塔体的设计以及各种设备的优缺点,新的填料的优点以及新元件的适当的选取。4. 本设计(课题)拟解决的关键问题和研究方法重点是填料的选择,塔内设备的选择和设计及塔体的工艺设计。难点是塔内设备的优先选取。其难点是对塔体以及一些塔内件的强度计算及校核。研究方法;从网络上下载最新的学术期刊,并参考化工设计手册,完成数据的计算和各种设备的选取。5. 文献综述填料塔最初出现在十九世纪中叶,在1881年用于精馏操作。填料塔的塔体横截面有圆形,矩形及多边形等,但绝大部分是圆形。塔壳材料可以是碳钢,不锈钢,聚氯乙烯,玻璃钢和砖等。塔内放置着填料(packings)。填料种类很多。用于制造填料的材料有碳钢、不锈钢、陶瓷、聚丙烯、增强聚丙烯等。由于填料与塔体取材面广,故易于解决物料腐蚀问题。填料在填料塔操作中起着重要作用。填料塔的发展史中最主要的是填料的发展史。早期以碎石为填料。自二十世纪初至廿世纪中叶,曾兴起了对填料开发、研制的热潮。在这时期,先后出现了拉西环、Stedman金属纱网规则填料、弧鞍形填料、鲍尔环及矩鞍形填料等。这些新型填料的出现,使填料塔的操作性能得到显著改进。一:填料(1)填料的类型: 常见填料的形状可分为四种类型。短管形填料:最早采用的拉西环是高度与外径之比为1的短管。该填料易于制造,强度好,取材面广,但流体力学及传质性能都不够理想。鞍形填料:鞍形填料不同于短管形填料,其特点是不分内、外表面,整个填料表面由各种曲面组成,填料在塔内任意方位均可使流体舒畅流过。1931年出现的这类填料称弧鞍形填料,是因形如马鞍而得名。这种填料与拉西环相比,填料表面利用率高,阻力小,但因形状设计尚有缺陷,相邻填料有重叠倾向,填料层均匀性较差,且填料易碎,故使用不广。鞍形填料都是乱堆填料。短管形与鞍形填料的结合型填料:现在已开发的这类填料有环矩鞍与共轭环等,开发这类填料的出发点是想使之具有短管形与鞍形两大类填料的优点。试验表明,共轭环的阻力比阶梯环低(4050)%,比鲍尔环低(5055)%,其传质单元高度比阶梯环的约低15%,比鲍尔环的约低30%,可见,新的结合型填料的优点是明显的。波纹整砌填料:这是我国开发成功并于1971年发表的填料类型。该填料的基本件是冲压出45度斜波纹槽的薄板。薄板高度通常为4060mm。若干板片平行组合,但相邻薄板的波纹反向。当塔截面为圆形,则波形板片的组合体为圆柱形。上下相邻的填料组合体,其薄板方向互呈90度交错。波纹填料的材料有碳钢、不锈钢、铝、陶瓷、玻璃钢及纸浸树脂等。薄板厚度:金属板一般为0.51mm,陶瓷板为11.5mm,纸浸树脂及玻璃钢板则为0.10.2mm。这种填料为气、液相提供了一段段带分支的直通道,气流阻力小,允许操作气速较大(如空速可达2m/s),故处理能力大。由于相邻两薄板间波峰接触点多,接触点给液体提供了混合、再铺展的条件,故可促进液体的表面更新,也促进气体湍流程度的增加。此外,这种填料具有较高的比表面积(a值为300900m2/m3).近年来不少工厂采用不锈钢丝网制作的波纹填料,既保留波纹整砌填料的优点,又改善布液的均匀性。这种填料属高效填料(2)填料的选用:填料的选用主要根据效率、通量及压降三个重要的性能参数决定。它们决定了塔的大小及操作费用。在实际应用中,考虑到塔体的投资,一般选用具有中等比表面积的填料比较经济。比表面积较小的填料空隙率大,可用于流体高通量、大液量及物料较脏的场合。在同一塔中,可根据塔中不同高度处两相流量和分离难易而采用多种不同规格的填料。此外,在选择填料时还应考虑系统的腐蚀性、成膜性和是否含有颗粒等因素来选择不同材料,不同种类的填料。二:填料塔的传质问题和放大效应在板式塔上,液体横向流过塔板与气体错流传质,塔内流体的浓度沿塔高呈梯级变化,通常用塔板效率来衡量传质效果。而在填料塔内,气、液体互呈逆流,组成沿填料层高呈连续变化的运动,故常用传质系数、传质单元高度(HTU)和等板高度(HETP)来衡量传质效果。这些系数和高度值受着许多因素的影响,主要有下述五个方面。 (1)气、液体在填料层横截面上的分布:在填料层横截面上,可供气、液体流通的自由截面并不是均匀分布的,近壁处的自由截面相对要大一些,气体在此处的局部流量也会偏高。另一方面,要使液体均匀地分布在填料层上,先要填料层顶部保证液体喷洒均匀,但液体在重力作用之下向下流动时,往往有向壁偏流的倾向。这种气、液体分布不均匀的现象,会使传质系数减小,HTU和HETP值增大。为了减少这种分布不均匀现象,所用填料尺寸要小于塔径的1/101/15,并且当填料层较高时,宜将填料层分段,每段填料上设置液体再分布器,将沿壁流下的液体导向中间。 (2)持液量:持液量可分为两部分:静持量。塔停止喷淋液体和停止排液后,填料层内所积存的液体呈称静持量,以液体/填料(m3/m3)表示,其值只于填料特性及液体性质有关;动持量。将塔停止喷淋液体和停止排液后,同时测的填料层内所排出的液体称动持量,以液体/填料(m3/m3)表示,其值还与液体喷淋量有关,在载点以上又与气速有关。静持量和动持量之和称总持液量。持液量大使塔身重量增大,填料层内的气流通道减小压降增大,并使液体在填料层内的平均停留时间增长,这种停留时间的增长,有利于伴有化学反应的吸收系统。持液量大还使塔操作的惯性效应增大,使操作时组成的波动较小,但使达到稳定操作的开工时间增长,不利于处理贵重液体和精密分馏。持液量的大小还影响填料的有效润湿表面,从而也影响传质的性能。 (3)填料表面的润湿:填料表面的润湿性能直接影响到填料表面上成膜,而成膜是否理想又影响到气、液两相的传质。在物系和操作条件确定后,填料的润湿性能就由填料的材质、表面形状及装填方法所决定。润湿状态还与喷淋量有关,液体喷淋量小时,部分填料表面不能为液体所润湿,即使在液体喷淋量很大的情况下,也难于做到使填料表面完全有效润湿,因在一些液体不流动的静止区中,所有的液体往往为气体所饱和,或气、液体之间已达到平衡,不能再发生传质作用。这些原因都使填料塔的体积传质系数下降,或使HTU或HETP值增大。 (4)传质系数:关于气相和液相的传质膜系数,及其相对大小对总传质系数的影响在吸收专著中均有讨论。对难溶气体的吸收,则宜增大液-气比L/G对总传质系数的增大较为有效。反之,对易溶气体的吸收,则宜增大气体流量以促进传质。文献上积累了许多关于传质系数、HTU和HETP的数据。这些数据多是从小塔试验所得结果。由于各人额试验条件不同,所得数据的差别也很大,用于设计大塔时,可靠性较差,故设计所需数据最好取自相同系统和相同规模装置上或类似条件下的实测数据。有关传质系数、传质单元高度和等板高度的关联式请参见吸收、精馏等有关手册和专著。 (5)轴向返混的影响:在填料塔内气-液两相的逆流并不呈理想的活塞流状态,而是存在不同程度的返混,影响传质效率。返混现象可有多种原因引起,例如:填料层内的气、 液体分布不均;气体和液体在填料层内的沟流;液体喷淋密度大时所造成的气体局部向下运动;塔内气、液体的湍流脉动使气、液体微团停留时间的不一致等。填料塔内流体的返混使塔内每一相沿塔高的浓度梯度减小,也减小了平均推动力,使所需填料层高度增加。按理想的活塞流所设计的填料层高度,往往因存在返混而须将填料层适当加高,以保证预期的分离效果。返混因素常采用湍流扩散数学模型来分析。三:填料塔的内件填料塔的内件是为了保证气液更好的接触,以便发挥填料塔的最大效率和生产能力。内件主要有填料支承装置、填料压紧装置、液体分布装置、液体收集再分布装置等。合理地选择和设计塔内件,对保证填料塔的正常操作及优良的传质性能十分重要。 (1)填料支承装置:填料支承装置安装在填料层底部,其作用是防止填料穿过支承装置而落下;支承操作时填料层的重量;保证足够的开孔率,使气液两相能自由通过。支承装置具备足够的强度及刚度,而且要求结构简单,便于安装,所用的材料耐介质的腐蚀。常用的填料支承装置有栅板型、波纹型、孔管型、驼峰型等。支承装置的选择,主要的依据是塔径、填料种类及型号、塔体及填料的材质、气液流率等。 (2)填料压紧装置:填料上方安装压紧装置可防止在气流的作用下填料床层发生松动和跳动。填料压紧装置分为填料压紧器和床层限位器两大类。 (3)液体分布装置:液体分布器安装由于填料上部,它将液相加料及回流液均匀的分布到填料的表面上,形成液体的初始分布。液体分布装置的种类多样,有喷头式、盘式、管式、槽式及槽盘式等。液体分布器的安装位置一般高于填料层表面150300mm,以提供足够的空间让上升气体不受约束的穿过分布器。 (4)液体收集及再分布装置:液体沿填料层向下流动时,有偏向塔壁流动的现象,这种现象称为壁流。壁流将导致填料层内气液分布不均,使传质效率下降,严重时使塔心的填料不能被也液体润湿而形成干锥。为减小壁流现象,可间隔一定高度在填料层内设置液体再分布装置。最简单的液体再分布装置为截锥式再分布器。截锥式再分布器结构简单,安装方便,但它只起到将壁流向中心汇集的作用,无液体再分布的功能,一般用于直径小于0.6m的塔中。在通常情况下,一般将液体收集器及液体分布器同时使用,构成液体收集及再分布装置。液体收集器的作用是将上层填料流下的液体收集,然后送至液体分布器进行液体再分布。常用的液体收集器为斜板式液体收集器。三:填料塔的研究及改进随着化工生产向大型化发展,人们一直重视填料塔的放大规律,并且把注意力集中在改善气体和液体的分布,以及改进填料的性能两个方面。一般认为拉西环有较严重的流体分布不良效应,自从出现了鲍尔环、矩鞍形填料和阶梯环之后,近年来又特别重视液体喷淋装置和再分布器的改进,使填料塔放大的可能性比过去有所提高。通过对大直径实验塔的测定,证明压降数据与埃克特的通用关联图很相符合,40mm瓷质拉西环乱堆填料的泛点数据也与该图相符合,其他尺寸的几种填料的泛点数据则与图线符合稍差,至于传质单元高度的数据与多数从小塔所得的的关联式计算结果相比,都存在较大误差。试验还表明大塔的气、液体通过能力、流体力学性能和传质效率均与填料层高度无关,还表明在大直径填料塔中只要液体开始分布均匀,则填料层中流体分布可不受填料层高度的影响。规整填料比乱堆填料的放大效应要小,因为不是规整填料,如网波透露了等形状本身具有液体再分布的能力。6. 参考文献 1 刘乃鸿. 塔技术的最新发展与新型填料的开发应用 J . 石油化工设备, 1991, 20 (2) : 4448. 2 Cihla Z, Schmidt O Coll . Behavi or of liquids trickingthrough the packing in a cylindrical column J . CzechChem Comn, 1957, 22 (3) : 896897. 3 Le Goff P, Les p inasee B. Hydr odynamies of packed col2umns J . Rev I nst Fr Pet, 1962, 17 (1) : 2128. 4 魏建华, 伍昭化, 陈大昌, 等. 高效填料塔成套分离工程 J . 现代化工, 1996, 16 (10) : 2933.5 Petre C F, Larachi F, Liuta I , et al . Pressure dropthr ough structured packings : Breakdown int o the contribu2ting mechanis ms by CFD modeling J . Chem Eng Sci,2003, 58 (1) : 163177.6 Brierley R J P . Higlr p ressure distillation is different J .Chem Eng Prog, 1994, 90 (7) : 6877. 7 Olujic Z, Kamerbeek A B, Graauw J A. A corrugationgeometry based model for efficiency of structured distil26) : 683695. 8 喻冬秀, 程江, 杨卓如. 填料塔的理论研究 J . 石油化工设备, 2003, 32 (4) : 4650. 9 白鹏, 刘建新, 王世昌. 规整填料塔的设计计算模型 J . 化工机械, 2001, 28 (4) : 232236. 10 陈强, 王树楹. 塔器技术的发展现状与展望 J .现代化工, 1997, 17 (11) : 1619. 11 Sher wood T K, Pigford . Abs or p tion and extraction J .McGraw Hill, NY, 1995, 23 (12) : 248250. 12 Bllingham J F, BonaquistD P, LockettM J . Character2izati on of the performance of packed distillati on columnliquid distributors A . In: I nstitution of Chemical En2gineers Symposium Series C . Maastricht : I ChemE,1997, 142 (2) : 841851.外文翻译一:Strain Strengthening Technology of Pressure Vessels of Austenitic Stainless SteelDENG Yangchun1, CHEN Gang1, YANG Xiaofeng2, XU Tong3(1EastChina University of Science and Technology, Shanghai,200237, China;2HubeiSpecialEquipmentSafety Inspection and Research Institute, Wuhan,430077, Hubei, China;3China Special Equipment Inspection and Research Institute, Beijing,100013, China )AbstractThe basic principle of strain strengthening was presented, and twomodels of the strain strengtheningOf pressure vessels of austenitic steelthe strain strengthening Avesta model at normal atmospheric temperatures and the strain strengthening Arde form model at low temperatures, were analyzed. Meanwhile, the selections of permissible stress of austenitic stainless steel were compared and analyzed in several pressure vessel standards. EN13445 Pressure VesselStandardchooses1. 0as the yield strength of austenitic stainless steel In this condition, the value of the safe factor of them aterials is low and practicalKeywordsPressure Vessel Austenitic Stainless Steel Strain Strengthening, Yield StrengthArticle Idz: TQ050 4 +1 Document code A Article ID 0254-6094 (2008) 01-0054-06The austenitic stainless steel having good high temperature performance, low temperature performance and corrosion resistance, and high tensile strength, but the yield strength is lower. By the standard of GB150 pressure vessel, material yield strength and tensile strength, respectively, divided by the safety factor to determine the material allowable stress values, whichever is less, often resulting in austenitic stainless steel allowable stress values low, can not give full play to the material carrying capacity. To this end, the researchers by strain hardening improve the yield strength of austenitic stainless steel, his article will make the technology to commentary. 1 Austenitic stainless steel strain hardening basic principlesShown in Figure 1, the deformation of the material exceeds the material yield strength, k reached after unloading is in elastic state, before re-applying a load to the material stress reaches the k, k equivalent material yield strength, apparently k 0 2. Figure 1 austenitic stainless steel unidirectional tensile FigureFor non-stable austenitic stainless steel, due to the strain generated martensite hardening rate gradually increases due to the increase of strain necking was postponed, up to a maximum elongation. In the same time, the martensite the merit-formed so that the stress concentration is relaxed, showing a phase transformation induced phenomena. Processed at room temperature for stable austenitic stainless steel is not formed martensite grain refinement, the lattice distortion and dislocation density will produce a hardening effect.Austenitic stainless steel strain hardening of this feature, widely used in the fields of bridges, buildings, parts of Europe has been used in the field of pressure vessel. Austenitic stainless steel pressure vessel strain hardening commonly used in two modes: the Avesta mode and Arde form mode.2 austenitic stainless steel pressure vessel at room temperature strain hardening - A-Vesta modeThe austenitic stainless steel pressure vessel at room temperature strain to enhance hydrostatic test to produce about 8% (maximum 10%) of plastic deformation, and can improve the yield and tensile strength of the austenitic stainless steel material, the method is usually called Avesta mode (Cold Stretched Forming). The pressure vessel using the media generally liquid nitrogen, liquid oxygen and liquid hydrogen, the main civilian use. Sweden Avesta Sheffield since 1959, has been engaged in the work of the austenitic stainless steel pressure vessel strain hardening, and applied for a patent in many countries 1. Avesta Sheffield in Sweden in 1959 by special permission, after 15 years of use of austenitic stainless steel strain hardening technology manufacturing pressure vessels, Swedish Pressure Vessel Technical Committee in 1974 austenitic stainless steel pressure vessel strain hardening technology, 1975 into the pressure vessel specific standards - strain hardening Pressure Vessel Code 2 (the Cold-stretching Direction - CSD). In 1977, Sweden, Finland, Norway, Germany, Australia, the Netherlands, the United Kingdom, Spain, Portugal, Czechoslovakia and South Africa and other countries have accepted austenitic stainless steel pressure vessel strain hardening technology 3. The Swedish strain hardening pressure vessel standards CSD, use of materials equivalent to 304 and 316L, the maximum thickness of 30 mm, maximum operating temperature of 400 C. Annealed materials 0 2 to about 210MPa, elongation greater than 35%. The enhanced yield strength about 410MPa, conventional methods of design as a new material, and then take k. Strain hardening hydraulic test pressure is determined by the following formula The Swedish CSD standards that uniaxial tensile specimens, up to 10% strain sufficient to ensure that the material yield strength k value. Plane stress Mises yield criterion, the corresponding strain according to Table 1 the ratio between the calculated.Table 1 stress, strain ratio between The Swedish CSD standard that ensure that new material yield strength k value, the cylindrical ring to the maximum strain is 8.7%; the Spherical maximum strain of 5.0%. The Swedish standard specifies a maximum strain of 10.0%. The actual cylinder maximum strain of 3% to 5%, mainly due to: a. Actual material s larger than the standard value; b actual thickness deviation and calculations rounded margin; c head, receivership strengthen effect. Another important problem is that the 1991 edition of the Swedish CSD standard no longer need to ensure that the new material yield strength k value, simply press the strain hardening k calculate the required pressure hydrostatic testing can be. Abandon the 1975 edition of k computing, the need to ensure the requirements of the minimum strain.The jonson J 1 pointed out that the strain hardening need to ensure the stability of the material organization, not because of the strain have martensite. Commonly stable and metastable austenitic small amount of strain conditions, does not produce martensite. 304L and 316 through 300 to 350 C, 000h aging tests showed that the strain hardening processing materials with no strain hardening material handling, small changes in yield strength and tensile strength values, can improve the use of strain hardening temperature. Strain hardening treatment material 550 to 650 C is still very good creep resistance, fatigue strength. Less than 10% strain hardening material, in a weak oxidizing media such as H2SO4, corrosive and strain hardening material; stress corrosion results. , 304L, 316 steel residual stress due to strain hardening to reduce or eliminate this stress corrosion tests confirmed.HesslingG 4 noted that the strain hardening material savings, with increasing temperature, the amount of material savings reduce BrautigamM 5 noted that the base material and the electrode of the pressure vessel with a stable austenitic stainless steel 304LN, when the strain hardening plasticity variable 20 % when used in liquid nitrogen (including enhanced), none of the base metal, weld and heat affected zone to produce martensite. 321 metastable austenitic 20% strain was generated martensite; liquid helium cryogenic, unfinished martensitic transformation; in 20 C, 250 cycles can accelerate the martensitic transformation, consider -196 C, the cycle of martensitic transformation. 20% strain on the stability of austenitic and the metastable austenitic material impact toughness are affected; does not produce martensite stable austenitic material Impact Toughness distorted crystal structure. Stable austenitic materials, 20% strain result in a material impact greater than the low temperature impact toughness decreases stable the austenitic and metastable austenitic materials; 20% strain at 20, -196, -269 , the impact toughness AD can meet the specifications and ASME Code pressure vessel strain; actual strain hardening only 8% to 10%, in the cryogenic liquid enough impact toughness. Ambrose S 6 1969 strain strengthen technological research, first enacted in 1969 the specification ME/1/69-134 strain hardening pressure vessel (for low temperature), 1999, included in the standard AS1210 Appendix 2. Material 304,316 L, etc.; strain limit of 5%, 10% of the local maximum, than Swedish standard conservative. Limit of 5%, mainly in order to meet the requirements of the the ISO/TC11 (1970). Strain hardening method has three advantages: a. The release of residual stress; B. In many cases, changing the shape, improve the anti-yielding capacity; c improve the fatigue performance. The standard EN13458 EU cryogenic pressure vessel Appendix C 7 strain hardening technology, recommended several materials can also use other stable austenite and metastable austenitic material, provided that they meet the technical requirements. Material maximum thickness of 30mm, the maximum temperature of 50 C, elongation greater than 35%. The annealed material strain hardening, the yield strength k than 0 2 increased up to about 200MPa. Design as a new material, and then the conventional method. Strain hardening required hydrostatic test pressure of 1.5 times the design pressure to ensure that in the course of container in the elastic state. The strengthening of the annealed container, the amount of deformation; materials to strengthen the container the (inadvertently reinforce or plate rolling intends to strengthen) refers to the process, the water pressure smaller deformation. Annealed container the maximum allowable 10% strain in a long time to keep the load in the case of allowable increase of 1% to 2% strain, in fact, generally cylindrical to 3% 5% strain. This strain hardening of the material after to maintain a higher elongation and impact toughness. Rana M D 8 of ISO/TC220 2000 on the low-temperature austenitic stainless steel containers, also accept strain hardening method, consistent with EN13458.3 austenitic stainless steel pressure vessel at low temperature strain strengthen-Arde form modeIn 1961, Arde-Portland annealed 301 austenitic stainless steel container? 196 C (liquid nitrogen) insulation, strain hardening hydraulic test, resulting in about 10% (maximum 13%) plastic deformation 301 steel yield and tensile strength, some then after 427 C, and 20h aging treatment, to further improve the yield and tensile strength of 301 steel 9, usually known as the method for Arde form mode (Cryogenic Stretch Forming). The austenitic stainless steel pressure vessels used in the aerospace field, the use of media for liquid nitrogen, liquid oxygen and liquid hydrogen. Of Arde-Portland company Alper RH 10 for a more detailed experimental study of Arde-form mode performance. Ball of the same size (301 steel),? 196 C after strain hardening, without aging treatment at room temperature for more than 2h? 196 C blasting, the yield stress ratio strain enhanced stress a small amount of the increase, indicating that at room temperature under certain aging effect; After 427 C, 20h aging treatment, yield stress ratio strain enhanced stress were significantly increased, and with a different strain hardening stress; stress closer to both blast. Annealed spherical? 196 C Blow, yield stress equivalent to the yield stress of the material at this temperature, which is generated starting strain hardening stress; blasting lower stress, but considering the material is thinned, according to the true stress calculation, blasting stress and strain hardening ball stress more consistent. The blasting experiments conducted at ambient temperature, not after the aging treatment the ball vary depending on the yield stress ball original strain hardening stress; higher yield stress after the aging treatment of the ball, and also higher rupture stress. At the same time, the use of smooth specimens subjected to a tensile test (uniaxial stress),? 196 C, with the strain to enhance stress increases, the room temperature tensile yield strength and tensile strength are increased; samples after aging treatment than without aging The treated samples have a higher yield strength and tensile strength. In order to study the biaxial stress, with notched specimens for tensile test at? 196 C, with the strain strengthen the stress increases, little change in the yield stress of aging sample; without aging treatment increased the yield stress of the specimen; Not after aging the yield stress of the treated samples than the original strengthen stress increases, further strengthening effect at room temperature. ? 196 C to a tensile test, notched specimen, and the tensile strength ratio smooth, without aging the sample, with the original strengthen the stress increases; However, after aging the sample, with the original strengthen when the stress increases. That is, the stress increases with the original strengthen the notch sensitivity increase. Test summary, the following conclusions: a low temperature can be used to strengthen to improve the strength, the manufacture of pressure vessels; b without limitation of strain hardening stainless steel? 196 C have a higher notch toughness; c strengthen the limitation of strain stainless steel,? 196 C and has high strength at room temperature; d in? 196 C generating strain hardening, requires a certain amount of stress. Arde-Portland Henderson SW 11: strain hardening and then after aging can improve strength; improve the material strain hardening creep resistance and notched strength; without the limitation of strain hardening stainless steel, high temperature performance is also good. Below the yield stress, in a strongly oxidizing environment, corrosion resistance and annealed pressure vessel. Summary of strain hardening main advantages: high strength; high creep strength; high notch toughness; distorted low temperature aging at 427 ; improve reliability, the the cylinder deformation of 12% to 14%, the ball deformation of 7% to 8%, testable ray undiscovered defects; reduce stress concentration; for the benefit of the weld, the weld and base metal; improve corrosion resistance.ArdePortland Arthur C 12 pointed out that, Arde form mode manufacturing pressure vessels mainly due to the non-proliferation of type face-centered cubic lattice into a body-centered cubic lattice, austenite into martensite, and after the aging , to further enhance its strength at room temperature. Its successful application in that three important factors: a chemical composition, the material has the best combination of strength and toughness, ease of welding; b welding will produce a contraction of 1%, strain hardening, and the strength of the base metal, It is essential that the welds smooth transition, these can not be achieved by the traditional method; deformation (c design, pressure vessel deformation amount of theoretical calculations mentioned earlier, this is completely unnecessary, pressure vessel deformation simply to or greater than the amount of deformation of the theoretical calculation of the pressure vessel can be). Also, strain hardening, the container to the most natural geometry changes, such as head shape to spherical.4 two austenitic stainless steel pressure vessel strain hardening modeTable 2 Comparison of two austenitic stainless steel strain hardening mode. Relatively, Arde form mode strain greater degree of enhancement, the adverse impact on the material properties are also relatively large, its high cost, the process is more complex, mainly for the aerospace field 13, few reports. Avesta method has been accepted in many European countries, EN13458 Appendix C has been adopted, with more experience.Table 2 austenitic stainless steel pressure vessel strain hardening Comparison5 types of pressure vessel standard austenitic stainless steel allowable stress value comparisonAustenitic stainless steel pressure vessel strain hardening upon the conventional approach to design, manufacturing process and select the material allowable stress values. Austenitic stainless steel pressure vessel unique strain hardening is to increase the allowable stress value and improve the sharpest increase the pressure vessel material yield strength. And the other to improve the austenitic stainless steel material allowable stress value is the yield strength to select and adjust the yield factor of safety, the material is not plastically deformed. United States ASME -1 and ASME VIII -2 required for the austenitic stainless steel materials, allowable stress values to allow a small amount of pressure vessel deformation occasions, the highest desirable design temperature 0 90 2 to it than 0 2/ns. Germany for austenitic stainless steel, the yield strength has value by 1. 0,. Usually, 1 than 0 2 high-40MPa, such as 304, the material will increase the yield strength value of 20%. 50 to 60 years in the last century the United Kingdom, Norway, Sweden, Australia and many other countries. EU EN13445 Pressure Vessel Code also used this approach. Of Pressure Vessel Code for austenitic stainless steel, conventional design standards GB150 and stress analysis and design standard JB4732 at temperatures greater than 100 C, Xu with stress value value with the U.S. ASME -1 and ASME -2 basically the same; lower than 100 C, austenitic stainless steel material allowable stress value varies with carbon steel allowable stress value value the same way. Due to the lower yield strength of austenitic stainless steel materials, the allowable stress values by the yield strength of material decisions, showing that of austenitic stainless steel material allowable stress value is very low. Seen from Table 3, with an austenitic stainless steel material,ASME VIII -1 and EN13445 austenitic stainless steel material allowable stress values than GB150 different degree, and the design pressure, the material of the above three criteria are in elastic state, no plastic deformation of the overall structure of the pressure vessel. EN13458 Appendix C strain hardening method (Avesta mode) material allowable stress values than three standard has greatly improved, the least amount of material, with greater economic value; design pressure, the material in a plastic state, the pressure The overall structure of the container has a significant plastic deformation occurs. , Arde form mode strain hardening better, mainly for the aerospace industry.Table 3 austenitic stainless steel pressure vessel design allowable stress values selected Table 4 lists several austenitic stainless steel material 0.2 1.0, k value. The jonson J 14 from room temperature to 400 C or less, the same kind of austenitic stainless steel pressure vessel standards allowable stress values, as shown in Figure 2. According to the type of material, EN13445 than ASME VIII -1 allowable stress value of 20% 35%; 200 C when the material savings of 2% to 20%. Table 4 several austenitic stainless steel yield strength values Figure 2 different standard the same austenitic stainless steel under the maximum allowable stress values6 Conclusion6.1 austenitic stainless steel pressure vessel technology can greatly save material strain hardening. Avesta mode has some experience, easy to implement, and has good application prospects.The yield strength of.6.2 EU EN13445 standard austenitic stainless steel pressure vessel by 1. 0 select, material safety factor lower value, to save material, the use of a wider range of manufacturing, no special requirements, very practical. References1Jonson J. Coldstretched Austenitic Stainless Steel Pressure Vessels. Second International Conference on Pressure Vessel Technology, PartMaterials, Fabricationand Inspection. 1973. 115711652Cold-Stretching Directions 1991. Swedish Pressure Vessel Standardization3Malstrom U. Design Criteria Involving Factors of Safety onTensile Strength. Yield Strength and Creep RuptureStress. 1977. 29344Hessling G. Design Criteria for Boilers and Pressure Vessels. Papers Presented at the Sixth International Conference on Pressure Vessel Technology. 1988. 67965Brauti gam M. Pressure Vessels for Cryogenic Service Some New Aspects of Materials and Construction. The Seventh International Conference on Pressure Vessel Technology. 1992. 8878996Ambrose S. Australian Practice with Cold Stretched Pressure Vessels. The Ninth International Conference on Pressure Vessel Technology. 2000. 991077Cryogenic vessels-Static Vacuum Insulated VesselsEN13458, 20008RanaM D. Development of ISO Standards for CryogenicVessels, Pressure Vessel and Piping Codes and Standards. ASME PVP453, 2005. 2252349Cryogenic Forming: New Process Stretches and Strengthens. The Iron Age, 1961, 188(8): 616310Alper R H. Cryogenically Stretch-Formed Type 301Stainless Steel for Cryogenic Service. Materials Research& Standards, 1964, 4(10): 52553211 Henderson S W. High Strength Pressure Vessels by Stretch Forming. Materials in Design Engineering,1964, 60(6): 10410612 ArthurC. Cryogenic Stretch Forming Improves Strength Of Vessels. Metal Progress, 1969, 96(1): 646713 HurllichA.Metals and Fabrication Methods used for the Atlas. Metal Progress, 1959, 76(5): 657314Jonson J. Comparison of New EN and ASME Pressure vessel Rules for Stainless Steel The Ninth International Conference on PressureVesselTechnology.2000, 5764外文翻译二: 奥氏体不锈钢压力容器的应变强化技术*邓阳春陈钢杨笑峰徐彤(华东理工大学) (湖北省特种设备安全检验检测研究院) (中国特种设备检验研究院)摘要介绍了应变强化基本原理,并分析奥氏体不锈钢压力容器应变强化两种模式常温应变强化Avesta模式和低温应变强化Ardeform模式。同时,分析比较几种压力容器标准关于奥氏体不锈钢材料的许用应力选取,其中欧盟EN13445压力容器标准奥氏体不锈钢屈服强度按1. 0选取,材料安全系数取值较低,非常实用。关键词压力容器奥氏体不锈钢应变强化屈服强度中图分类号TQ0504+1文献标识码A文章编号0254-6094(2008)01-0054-06奥氏体不锈钢材料具有很好的高温性能、低温性能和抗腐蚀性能,而且抗拉强度很高,但屈服强度却较低。按GB150压力容器标准,以材料屈服强度和抗拉强度为基准,分别除以相应的安全系数,取其小值来确定材料许用应力值的方法,往往导致奥氏体不锈钢材料许用应力值偏低,不能充分发挥材料承载能力。为此,研究人员通过应变强化实现了提高奥氏体不锈钢材料的屈服强度,本文将对该技术作以评述。1 奥氏体不锈钢应变强化基本原理 如图1所示,材料变形超过材料屈服强度,达到k后卸载,当重新施加载荷,材料应力到达k之前,处于弹性状态,k相当于材料的新屈服强度,显然k0. 2。 图1奥氏体不锈钢单向拉伸图 对于非稳定奥氏体不锈钢,因应变产生马氏体,使加工硬化率因应变的增加而逐渐增大,缩颈被推迟,故延伸率可达最大值。同时,马氏体变体的择优形成使应力集中被松驰,呈现了相变诱导现象。对于稳定奥氏体不锈钢,在室温下加工不会形成马氏体组织,但其晶粒细化、晶格扭曲和位错密度增大也会产生硬化效应。 奥氏体不锈钢应变强化这一特性,广泛用于桥梁、建筑领域,欧洲部分国家已用于压力容器领域。奥氏体不锈钢压力容器应变强化常用两种模式:Avesta模式和Ardeform模式。2奥氏体不锈钢压力容器常温应变强化A-vesta模式将奥氏体不锈钢压力容器在常温进行应变强化水压试验,产生8%左右(最大10% )塑性变形,可提高奥氏体不锈钢材料的屈服强度和抗拉强度,通常称该方法为Avesta模式(Cold StretchedForming )。该压力容器使用介质一般为液氮、液氧和液氢等,主要民用。瑞典Avesta Sheffield公司从1959年开始,一直从事压力容器奥氏体不锈钢应变强化工作,并在很多国家申请了专利1。Avesta Sheffield公司1959年在瑞典通过特别许可,在经过了15年采用奥氏体不锈钢应变强化技术制造压力容器后,于1974年瑞典压力容器技术委员会通过压力容器奥氏体不锈钢应变强化技术, 1975年纳入压力容器专门标准应变强化压力容器标准2(Cold-stretching DirectionCSD)。1977年,瑞典、芬兰、挪威、德国、澳大利亚、荷兰、英国、西班牙、葡萄牙、捷克斯洛伐克及南非等国已接受压力容器奥氏体不锈钢应变强化技术3。瑞典应变强化压力容器标准CSD,使用材料相当于304和316L等,最大厚度30mm,最高使用温度400。退火态材料0. 2为210MPa左右,延伸率大于35%。强化后,屈服强度取k为410MPa左右,作为新材料,再按常规方法进行设计。应变强化水压试验压力由下式确定瑞典CSD标准指出,单向拉伸试样,最大10%应变足够保证该材料新的屈服强度k值。平面应力按Mises屈服准则计算,相应的应变按表1的比例关系计算。表1应力、应变比例关系瑞典CSD标准指出,为保证材料新的屈服强度k值,对于圆筒环向最大应变为8. 7%;球罐最大应变为5. 0%。瑞典标准规定最大应变为10. 0%。实际圆筒最大应变为3% 5%,主要原因: a.实际材料s比标准值偏大; b.实际板厚偏差及计算圆整后有余量; c.封头、接管等有强化作用。另一个值得重视的问题是, 1991年版的瑞典CSD标准不再需要保证材料新的屈服强度k值,只需按应变强化k计算所需压力进行水压试验即可。摒弃了1975年版根据k计算,需保证最小应变的要求。 Jonson J1指出,应变强化需保证材料组织稳定,不因应变产生马氏体。常用稳定和亚稳定奥氏体在少量应变条件下,不会产生马氏体。304L和316经过300350、2 000h时效试验表明,应变强化处理材料与未应变强化处理材料一样,屈服强度值和抗拉强度值变化较小,说明可提高应变强化的使用温度。应变强化处理材料后,550650蠕变性能仍很好,疲劳强度提高。低于10%应变强化处理材料,在弱氧化性介质如H2SO4中,腐蚀性与未应变强化处理材料一样;应力腐蚀结果也一样。另外, 304L、316钢的残余应力由于应变强化减少或消除,这一点已被应力腐蚀试验证实。 HesslingG4指出,应变强化可节省材料,随温度升高,节省材料量降低BrautigamM5指出,压力容器母材和焊条采用稳定奥氏体不锈钢材料304LN,当应变强化塑性应变量为20%时(包括强化后在液氮下使用),母材、焊缝和热影响区均未产生马氏体组织。321为亚稳定奥氏体, 20%应变明显产生马氏体;在液氦低温使用一年,未完成马氏体转变;在20、250次循环可加速马氏体转变,需考虑-196,循环对马氏体转变的影响。20%应变,对稳定奥氏体和亚稳定奥氏体材料冲击韧性均有影响;对于不产生马氏体稳定奥氏体材料冲击韧性的影响可能是由于晶体结构扭曲造成的。包括稳定奥氏体材料, 20%应变导致材料冲击韧性降低比低温影响更大; 20%应变后稳定奥氏体和亚稳定奥氏体材料在20、-196、-269时,其冲击韧性均能满足AD规范和ASME规范等;实际应变强化压力容器应变只有8% 10%,在低温液体中有足够的冲击韧性。Ambrose S61969年开始进行应变强化技术研究, 1969年首次制定规范ME/1/69-134应变强化压力容器(用于低温), 1999年纳入标准AS1210附录2。材料采用304、316L等;应变限制在5%,局部最大10%,比瑞典标准保守。限制5%,主要为了满足ISO/TC11(1970)的要求。应变强化方法具有3个优点: a.释放残余应力; b.在很多情况下改变形状,提高抗屈服能力; c.提高疲劳性能。欧盟低温压力容器标准EN13458附录C7采用应变强化技术,推荐了几种材料,也可使用其它稳定奥氏体和亚稳定奥氏体材料,但需满足相应的技术要求。材料最大厚度30mm,最高使用温度50,延伸率大于35%。退火态材料应变强化后,屈服强度k比0. 2最多增加200MPa左右。作为新材料,再按常规方法进行设计。应变强化所需水压试验压力为设计压力的1. 5倍,保证在使用过程中容器处于弹性状态。退火态容器强化时,变形量较大;材料已强化的容器(指加工过程无意中强化或板材轧制的有意强化),水压变形量较小。退火态容器最大容许10%应变,在较长时间保持载荷情况下,可容许增加1% 2%应变,实际上,一般圆筒为3% 5%应变。这样应变强化后材料仍能保持较高的延伸率和冲击韧性。RanaM D8介绍了ISO/TC220 2000关于低温奥氏体不锈钢容器,也接受应变强化方法,与EN13458基本一致。3奥氏体不锈钢压力容器低温应变强化Ardeform模式 1961年,Arde-Portland公司将退火态301奥氏体不锈钢容器,在?196(液氮)保温,进行应变强化水压试验,产生10%左右(最大13% )塑性变形,提高了301钢的屈服强度和抗拉强度,有的再经过427、20h时效处理,进一步提高301钢的屈服强度和抗拉强度9,通常称该方法为Ardeform模式(Cryogenic Stretch Forming)。该奥氏体不锈钢压力容器用于航天领域,使用介质为液氮、液氧和液氢等。Arde-Portland公司的Alper R H10对Arde-form模式性能进行较为详细的实验研究。同一尺寸的球(301钢),在?196经过应变强化,不经过时效处理,但在室温放置2h以上,在?196爆破时,屈服应力比应变强化应力有少量的升高,说明室温下也有一定时效作用;经过427、20h时效处理,屈服应力比应变强化应力有很大的升高,并随不同应变强化应力而不同;但两者爆破时应力较接近。退火态的球罐,在?196爆破时,屈服应力相当于材料在该温度下的屈服应力,这也是产生应变强化的起始应力;爆破时应力较低,但是考虑材料减薄,按真应力计算,爆破时应力与经过应变强化球的应力较一致。在常温下进行爆破实验,未经过时效处理的球屈服应力取决于球原先应变强化应力;经过时效处理的球屈服应力较高,爆破应力也较高。同时,采用光滑试样进行拉伸实验(单向应力),在?196,随应变强化应力增大,室温拉伸屈服强度和抗拉强度均增加;经过时效处理的试样比未经时效处理的试样有较高的屈服强度和抗拉强度。为了研究双向应力,采用带缺口试样进行拉伸实验,在?196,随应变强化应力增大,时效

- 温馨提示:

1: 本站所有资源如无特殊说明,都需要本地电脑安装OFFICE2007和PDF阅读器。图纸软件为CAD,CAXA,PROE,UG,SolidWorks等.压缩文件请下载最新的WinRAR软件解压。

2: 本站的文档不包含任何第三方提供的附件图纸等,如果需要附件,请联系上传者。文件的所有权益归上传用户所有。

3.本站RAR压缩包中若带图纸,网页内容里面会有图纸预览,若没有图纸预览就没有图纸。

4. 未经权益所有人同意不得将文件中的内容挪作商业或盈利用途。

5. 人人文库网仅提供信息存储空间,仅对用户上传内容的表现方式做保护处理,对用户上传分享的文档内容本身不做任何修改或编辑,并不能对任何下载内容负责。

6. 下载文件中如有侵权或不适当内容,请与我们联系,我们立即纠正。

7. 本站不保证下载资源的准确性、安全性和完整性, 同时也不承担用户因使用这些下载资源对自己和他人造成任何形式的伤害或损失。

人人文库网所有资源均是用户自行上传分享,仅供网友学习交流,未经上传用户书面授权,请勿作他用。

川公网安备: 51019002004831号

川公网安备: 51019002004831号