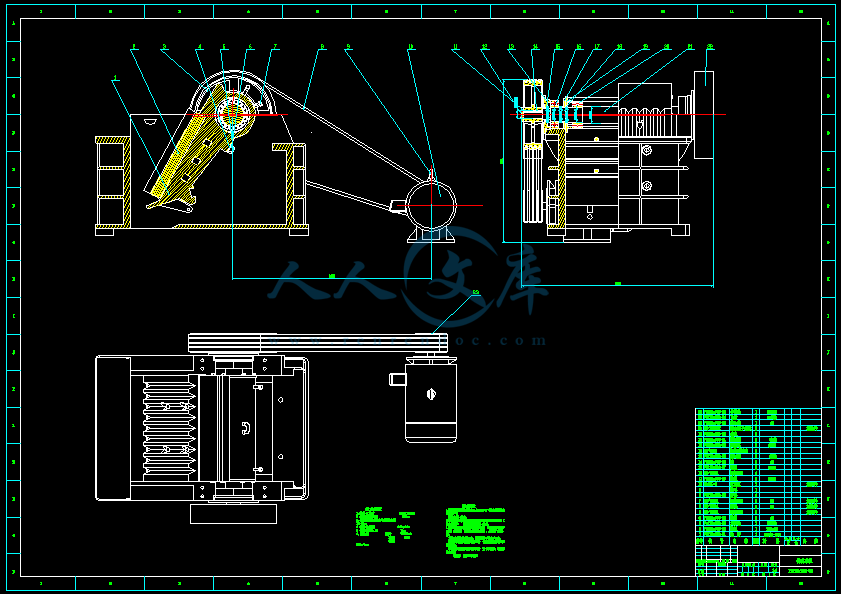

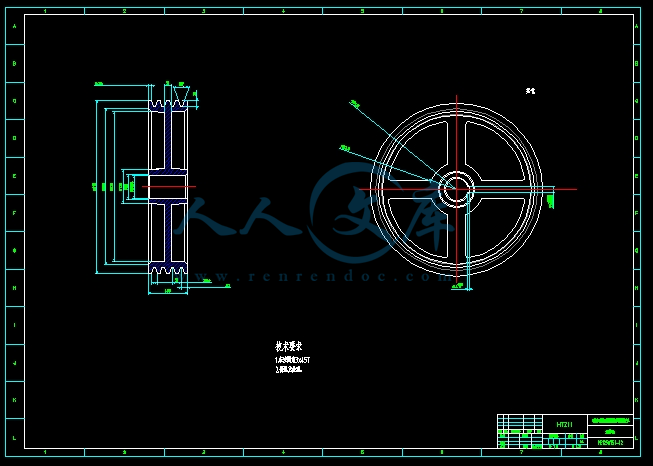

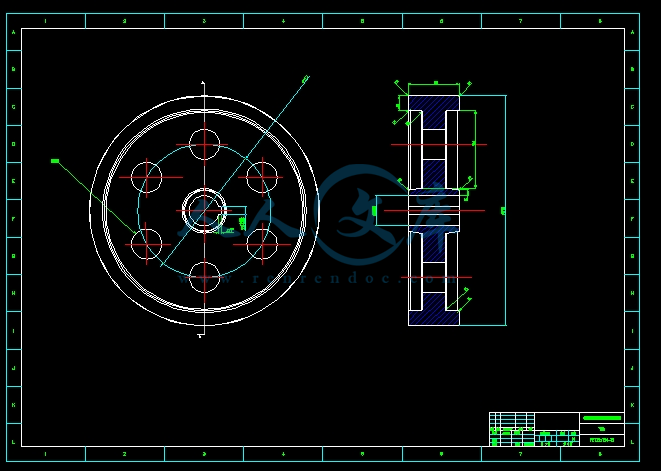

颚式破碎机传动系统设计【PE125x750型号】【含CAD图纸+word说明书文档】

收藏

资源目录

压缩包内文档预览:

编号:17532379

类型:共享资源

大小:2.24MB

格式:ZIP

上传时间:2019-04-10

上传人:机****料

认证信息

个人认证

高**(实名认证)

河南

IP属地:河南

50

积分

- 关 键 词:

-

PE125x750型号

含CAD图纸+word说明书文档

WORD说明书】

- 资源描述:

-

- 内容简介:

-

河南理工大学万方科技学院本科毕业论文 附录: 外文资料: 外文资料与 中文翻译 NC Technolog y Shigley J E.1、 Research current situation of NC lathe in our times Research and development process to such various kinds of new technologies as numerical control lathe , machining center , FMS , CIMS ,etc. of countries all over the world, linked to with the international economic situation closely. The machine tool industry has international economy to mutually promote and develop, enter 21 alert eras of World Affairs, the function that peoples knowledge plays is more outstanding , and the machine tool industry is regarded as the foundation of the manufacturing industry of the machine, its key position and strategic meaning are more obvious. Within 1991 -1994 years, the economic recession of the world, expensive FMS, CIMS lowers the temperature, among 1995-2000 years, the international economy increases at a low 1 河南理工大学万方科技学院本科毕业论文 speed, according to requisition for NC lathe and the world four major international lathes exhibition in order to boost productivity of users of various fields of present world market (EMO , IMTS , JIMTOF , China CIMT of Japan of U.S.A. of Europe), have the analysis of the exhibit, there are the following several points mainly in the technical research of NC lathe in our times: ( 1 ) Pay more attention to new technology and innovation Worldwide , are launching the new craft , new material , new structure , new unit , research and development of the new component in a more cost-effective manner, developmental research of for instance new cutter material , the new electric main shaft of main shaft structure , high speed , high-speed straight line electrical machinery ,etc. Regard innovating in improvement of the processing technology as the foundation, for process ultra and hard difficult to cut material and special composite and complicated part , irregular curved surface ,etc. research and develop new lathe variety constantly. 2 河南理工大学万方科技学院本科毕业论文 (2)Improve the precision and research of machine tooling In order to improve the machining accuracy of the machining center , are improving rigidity of the lathe , reduction vibration constantly, dispel hotly and out of shape, reduce the noise , improve the precision of localization of NC lathe , repeat precision , working dependability , s tability , precision keeping, world a lot of country carry on lathe hot error , lathe sport and load out of shape software of error compensate technical research, take precision compensate , software compensate measure improve , some may make this kind of error dispel 60% already. And is developing retrofit constantly, nanometer is being processed. (3)Improve the research of the machine tooling productivity World NC lathe, machining center and corresponding some development of main shaft , electrical machinery of straight line , measuring system , NC system of high speed, under the prerequisite of boosting productivity. (4)What a lot of countries have already begun to the numerical control system melt intelligently, 3 河南理工大学万方科技学院本科毕业论文 openly, study networkedly A、 elligent r esearch of the numerical control system Mainly showing in the following aspects: It is intelligent in order to pursue the efficiency of processing and process quality, the self-adaptation to the processing course is controlled, the craft parameter produces research automatically; Join the convenient one in order to improve the performance of urging and use intelligently, to the feedback control , adaptive operation , discerning automatically load selects models automatically , since carries on research whole definitely ,etc. of the electrical machinery parameter; There are such research of the respect as intelligent automatic programming , intelligent man-machine interface , intelligence diagnosing , intelligent monitoring ,etc. B、 The numerical control system melts and studies open Mainly showing in the following aspects: The development of the numerical control system is on unified operation platform, face the lathe producer and support final ly, through changing, increasing or cutting out the structure target(numerical control target ), form the seriation, and can use users specially conveniently and the technical know -how is integrated in the control system, realize the open numerical control system of different variety , different grade fast, form leading brand 4 河南理工大学万方科技学院本科毕业论文 products with distinct distinction. System structure norm of the open numerical control system at present, norm , disposing the norm , operation platform , numerical control systematic function storehouse and numerical control systematic function software developing instrument ,etc. are the core of present research to pass through. C、Meeting the manufacture system of the production line , demand for the information integration of the manufacturing company networkedly greatly of numerical control equipment, it is a basic unit of realizing the new manufacture mode too. 2、Classification of the machining center (1)Process according to main shaft space position when it classifies to be as follows, horizonta l an d ve rtical machining center. Horizontal machining center, refer to the machining center that the axis level of the main shaft is set up . Horizontal machining center for 3-5 sport coordinate axis, a common one three rectilinear motion coordinate axis and one turn the coordinate axis of sports round (turn the workingbench round), it can one is it is it finish other 4 Taxi processing besides installing surfaces and top surfaces to insert to install in work piece, 5 河南理工大学万方科技学院本科毕业论文 most suitable for processing the case body work piece . Compared with strength type machining center it, the structure is complicated, the floor space is large, quality is large, the price is high. Vertical machining center, the axis of the main shaft of the vertical machining center, in order to set up vertically, its structure is mostly the regular post typ e, the workingbench is suitable for processing parts for the slippery one of cross, have 3 rectilinear motion coordinate axis generally , can find a room for one horizontal numerical control revolving stage (the 4th axle ) of axle process the spiral part at workingbench. The vertical machining center is of simple structure, the floor space is small, the price is low, after allocating various kinds of enclosures , can carry on the processing of most work pieces . Large-scale gantry machining center, the main shafts are mostly set up vertically, is especially used in the large-scale or with complicated form work piece , is it spend the many coordinate gantry machining center to need like aviation , aerospace industry , some processing of part of large-scale steam turbine. Five machining centers, this kind of machining center has function of the vertical and horizontal machining center, one is it after inserting , can finish all five Taxi processing besides installing the surface to install in work piece, the processing way can make form of work piece error lowest , save 6 河南理工大学万方科技学院本科毕业论文 2 times install and insert working, thus improve production efficiency , reduce the process cost. (2)Classify by craf t use Is it mill machining center to bore, is it mill for vertical door frame machining center , horizontal door frame mill the machining center and Longmen door frame mill the machining center to divide into. Processing technology its rely mainly on the fact that the door frame is milled, used in case body, shell and various kinds of complicated part special curve and la rge processes , curved surface of outline process, suitable f or many varieties to produce in batches small. Complex machining center, point five times and compound and process mainly, the main shaft head can be turned round automatically, stand, lie and process, after the main shaft is turned round automatically, realize knowing that varies in the horizontal and vertical direction. (3)Classify by spe cial function Single workingbench , a pair of workingbench machining center; Single axle , dual axle , three axle can change machining center , main shaft of case; Transfer vertically to the tower machining center and transfer ; One hundred sheets of storehouses adds the main shaft and changes one one hundred sheets of machining centers; One hundred sheets o f storehouses connects and writes hands to 7 河南理工大学万方科技学院本科毕业论文 add the main shaft and change one hundred sheets of machining centers;One hundred sheets of storehouses adds the manipulator and adds one pair of main shafts to transfer to the tower machining center. 3、Development trend of the current numerical control lathe At present, the advanced manufacturing technology in the world is rising constantly, such application of technology as ultrafast cutting , ultraprecision processing ,etc., the rapid development of the flexible manufacturing system and integrated system of the computer one is constant and ripe, have put forward higher demand to the process technology of numerical control. Nowadays the numerical control lathe i s being developed in several following directions. (1)The speed and precision at a high speed , high accuracy are two important indexes of the numerical control lathe , it concerns directly that processes efficiency and product quality. At present, numerical control system adopt-figure number, frequency high processor, in order to raise basic operation speed of system. Meanwhile , adopt the super large-scale integrated circuit and many microprocessors structure, in order to improve 8 河南理工大学万方科技学院本科毕业论文 systematic data processing ability , namely improve and insert the speed and precision of mending operation. Adopt the straight line motor and urge the straight line of the lathe workingbench to be servo to enter to the way directly, it is quite superior that its responds the characteristic at a high speed and dynamically. Adopt f eedforward control technology , make it lag behind error reduce g reatly , thus improve the machining accuracy cut in corner not to track. For meet ultrafast demand that process, numerical control lathe adopt main shaft motor and lathe structure form that main shaft unite two into one, realize frequency conversion motor and lathe main shaft integrate , bearing , main shaft of electrical machinery adopt magnetism float the be aring , liquid sound pigeonhole such forms as the bearing or the ceramic rolling bearing ,etc. At present, ceramic cutter and diamond coating cutter have already begun to get application. (2 )Multi-functional to is it change all kinds of machining centers of organization (a of capacity of storehouse can up to 100 of the above ) automati cally to furnished with, can realize milling paring , boring and pares , bores such many kinds of processes as paring , turning , reaming , reaming , attacking whorl ,etc. to process at the same time on the same lathe , modern numerical control lathe adopt many main shaft , polyhedron cut also , carry on different cutting of way process to one different 9 河南理工大学万方科技学院本科毕业论文 position of part at the same time. The numerical control system has because adopted many CPU structure and cuts off the control method in grades, can work o ut part processing and procedure at the same time on a lathe , realize so -called the front desk processes , the backstage supporter is an editor . In order to meet the needs of integrating the systematic one in flexible manufacturing system and computer, numerical control system have remote serial interface , can network , realize data communication , numerical control of lathe, can control many numerical control lathes directly too. (3)Intelligent modern numerical control lathe introduce the adaptive control technology, according to cutting the change of the condition, automatic working parameter, make the processing course can keep the best working state , thus get the higher machining accuracy and roughness of smaller surface , can improve the service life of the cutter and production efficiency of the equipment at the same time . Diagnose by oneself , repair the function by oneself, among the whole working state, the system is diagnosed, checked by oneself to CNC system and various kinds of equipment linking to each other with it at any time. While breaking down , adopt the measure of shutting down etc. immediately , carry on the fault alarm, brief on position , reason to break down ,etc. Can also make trouble module person who take off automatically , put through reserve module , so as to ensure 10 河南理工大学万方科技学院本科毕业论文 nobody demand of working environment. For realize high trouble diagnose that requires , its development trend adopts the artificial intelligence expert to diagnose the system. ( 4 ) Numerical control programming automation with the development of application technology of the computer, CAD/CAM figure interactive automatic programming has already get more application at present, it is a new trend of the technical development of numerical control. It utilize part that CAD draw process pattern , is it calculate the trailing punishing to go on by cutter orbit data of computer and then, thus produce NC part and process the procedure automatically, in order to realize the integration of CAD and CAM. With the development of CIMS technology , the full-automatic programming way in which CAD/CAPP/CAM integrates has appeared again at present, it, and CAD/CAM systematic programming great difference their programming necessar y processing technolo gy parameter neednt by artificial to participate in most, get from CAPP database in system directly. ( 5 ) The dependability of the dependability maximization numerical control lathe has been the major indicator that users cared about most all the time . The numerical control system will adopt the circuit chip of higher integrated level , will utilize the extensive or super large-scale special-purpose and composite integrated circuit, in order to reduce the quantity of the 11 河南理工大学万方科技学院本科毕业论文 components and parts , to improve dependability . Through the function software of the hardware, in order to meet various kinds of demands for controlling the function, adopt the module , standardization , universalization and seriation of the structure lathe noumenonn of the hardware at the same time , make not only improve the production lot of the hardware but also easy to is it produce to organize and quality check on. Still through operating and starting many kinds of diagnostic programs of diagnosing , diagnosing , diagnosing off-line online etc. automatically, realize that diagnoses and reports to the police the trouble to hardware , software and various kinds of outside equipment in the sys tem. Utilize the warning suggestion, fix a breakdown in time; Utilize fault-tolerant technology, adopt and design the important part redundantly , in order to realize the trouble resumes by oneself; Utilize various kinds of test , control technology , exceed Cheng , one one hundred sheets of damages , interfering , cutting out ,etc. at the time of various kinds of accidents as production, carry on corresponding protection automatically. (6)Control system miniaturization systematic miniaturization of numerical control benefit and combine the machine , electric device for an organic whole. Adopt the super large-scale integrated component , multi-layer printed circuit board mainly at present, adopt the three -dimensional installation method , 12 河南理工大学万方科技学院本科毕业论文 make the electronic devices and components must use the high density to install, narrow systematic occupying the space on a larger scale. And ut ilize the new-type s lim display of color ed liquid crystal to substitute the traditional cathode ray tube, will make the operating system of numerical control miniaturize further. So can install it on the machine tool conveniently, benefit the operation of the numerical control lathe correctly even more. 本 文出 自 : Shigley J E. Mechanical Engineering Design. New York: McGraw-Hill, 1998 中文翻译 : 13 河南理工大学万方科技学院本科毕业论文 数控技术 一、当前世界 NC 机床的研究现状 世界各国对数控机床、加工中心以至 FMS、CIMS 等各种新技术的研究与发展 进程,是与世 界经济形势 紧密相连的。 机床工业有 世界经济相互促进和发展,进入 21 世界知识机警时代,人们的知识所起的作用更加突出 ,而机床工业 作为机器制 造业的基础, 其重点地位 与战略意义也更加明显。在 19911994 年间,世界经济衰退,昂贵的 FMS,CIMS 降温,1995 2000 年间,世界经济在低速增长,根据当前世界市场各方面用户为提高生产率对 NC 机床的要求以及世界四大国际机床展(欧洲的 EMO、美国的 IMTS、日本的 JIMTOF、中国的 CIMT)上展品的分析,当前世界 NC 机床的技术研究主要有以下几点: (1)、更加重视新技术和创新 在世界范围内, 对新工艺、新材 料、新结构、新单 元、新元件的研究开发工 作正在大力开 展,如新的 刀具材料、新 的主轴结构 、高速电主轴、高速直线电机等的开发研究。以加工工艺的改进创新为基础,为加工超硬 、难切削材料 及特殊复合 材料及复杂零 件、不规则 曲面等在不断研究开发新机种。 (2)、提高机床加工的精度和研究 为了提高加工中心的加工精度,不断提高机床的刚度、减少振动,消除热变形,降低噪声,提高 NC 机床的定位精度、重复精度、工作可靠性、稳定 性、精度保持 性,世界很 多国家都在进 行机床热误 差、机床运动及负 载变形误差的 软件补偿技 术研究,并采 取精度补偿 、软件补偿等措施加以改善,有的已经可以使此类误差消除 60%。并在不断开发精细加工,纳米加工。 14 河南理工大学万方科技学院本科毕业论文 (3)、提高机床加工生产率的研究 世界 NC 机床、加工中心及相应的高速点主轴、直线电机、测量系统、NC 系统的开发,均以提高生产率为前提。 (4)、 许多国家 都已经开 始对数控系 统的智 能化、开放化、网络化研究 A、数控系统的智能化的研究 主要表现在:为 追求加工效率和 加工质量的智能化 ,对加工过程的自适应控 制,工艺参数 自动生成进 行研究;为提 高驱动性能 及使用连接方便的 智能化,对反 馈控制、电 机参数的自适 应运算、自 动识别负载自动选 定模型、自整 定等进行研 究;还有智能 化的自动编 程、智能化的人机界面、智能诊断、智能监控等方面的研究。 B、数控系统开放化研究 主要表现在:数 控系统的开发在 统一的运行平台上 ,面向机床厂家和最终拥护,通过改变、增加或剪裁结构对象(数控对象),形成系列化,并可 方便地将用户 的特殊应用 和技术诀窍集 成到控制系 统中,快速实现不 同品种、不同 档次的开放 式数控系统, 形成具有鲜 明个性的名牌产品 。目前开放式 数控系统的 体系结构规范 、通行规范 、配置规范、运行 平台、数控系 统功能库以 及数控系统功 能软件开发 工具等是当前研究的核心。 C、数控装备的网络化将极大地满足生产线制造系统、制造企业对信息集成的需求,也是实现新的制造模式的基础单元。 二、加工中心的分类 (1)按主轴加工时的空间位置分类有:卧式和立式加工中心。 15 河南理工大学万方科技学院本科毕业论文 卧式加工中心, 是指主轴轴线水 平设置的加工中心 。卧式加工中心一般具有 35 个运动坐标轴,常见的是三个直线运动坐标轴和一个回转运动坐标轴(回转工作台),它能在工件一次装夹完成除安装面和顶面以外的其余 4 个面的加工,最适合加工箱体类工件。它与力式加工中心相比,结构复杂,占地面积大,质量大,价格高。 立式加工中心, 立式加工中心主 轴的轴线为垂直设 置,其结构多为固定立柱 式,工作台为 十字滑台, 适合加工盘类 零件,一般 具有 3个直线运动坐标轴,并可在工作台上安置一个水平轴的数控转台(第 4轴)来加工 螺旋类零件。 立式加工中 心结构简单 ,占地面积 小,价格低,配备各种附件后,可进行大部分工件的加工。 大型龙门式加工 中心,主轴多为 垂直设置,尤其使 用于大型或形状复杂的工 件,像航空、 航天工业及 大型汽轮机上 的某些零件 的加工都需要用这类多坐标龙门式加工中心。 五面加工中心, 这种加工中心具 有立式和卧式加工 中心的功能,在工件一次 装夹后,能完 成除安装面 外的所有五个 面的加工, 这种加工方式可以 使工件的形状 误差降到最 低,省去二次 装夹工作, 从而提高生产效率,降低加工成本。 (2)按工艺用途分类有: 镗铣加工中心, 分为立式樘铣加 工中心、卧式樘铣 加工中心和龙门樘铣加工 中心。其加工 工艺以樘铣 为主,用于箱 体,壳体以 及各种复杂零件特殊曲线和曲面轮廓的多工序加工,适合多品种小批量生产。 复合加工中心, 主要指五面复合 加工,主轴头可自 动回转,进行立,卧加工,在主轴自动回转后,在水平和垂直方向实现知道变换。 (3

- 温馨提示:

1: 本站所有资源如无特殊说明,都需要本地电脑安装OFFICE2007和PDF阅读器。图纸软件为CAD,CAXA,PROE,UG,SolidWorks等.压缩文件请下载最新的WinRAR软件解压。

2: 本站的文档不包含任何第三方提供的附件图纸等,如果需要附件,请联系上传者。文件的所有权益归上传用户所有。

3.本站RAR压缩包中若带图纸,网页内容里面会有图纸预览,若没有图纸预览就没有图纸。

4. 未经权益所有人同意不得将文件中的内容挪作商业或盈利用途。

5. 人人文库网仅提供信息存储空间,仅对用户上传内容的表现方式做保护处理,对用户上传分享的文档内容本身不做任何修改或编辑,并不能对任何下载内容负责。

6. 下载文件中如有侵权或不适当内容,请与我们联系,我们立即纠正。

7. 本站不保证下载资源的准确性、安全性和完整性, 同时也不承担用户因使用这些下载资源对自己和他人造成任何形式的伤害或损失。

人人文库网所有资源均是用户自行上传分享,仅供网友学习交流,未经上传用户书面授权,请勿作他用。

川公网安备: 51019002004831号

川公网安备: 51019002004831号