目录

第1章 绪论··················································································1

1.1引言·························································································1

1.2复摆颚式破碎机的特点 ··································································2

1.3国内外颚式破碎机的发展及现状·························································4

第2章 总体设计············································································8

2.1复摆鄂式破碎机的基本结构····························································· 8

2.2复摆鄂式破碎机的工作原理···························································· 10

第3章 主要参数的确定·································································12

3.1已知参数··················································································12

3.2部分结构参数的确定·····································································12

3.3工作参数的确定··········································································15

3.4电动机的选择·············································································16

3.5四连杆机构各杆长度的确定·····························································17

3.6破碎力的计算············································································ 17

3.7各部件受力分析···········································································18

第4章 传动装置的设计·································································20

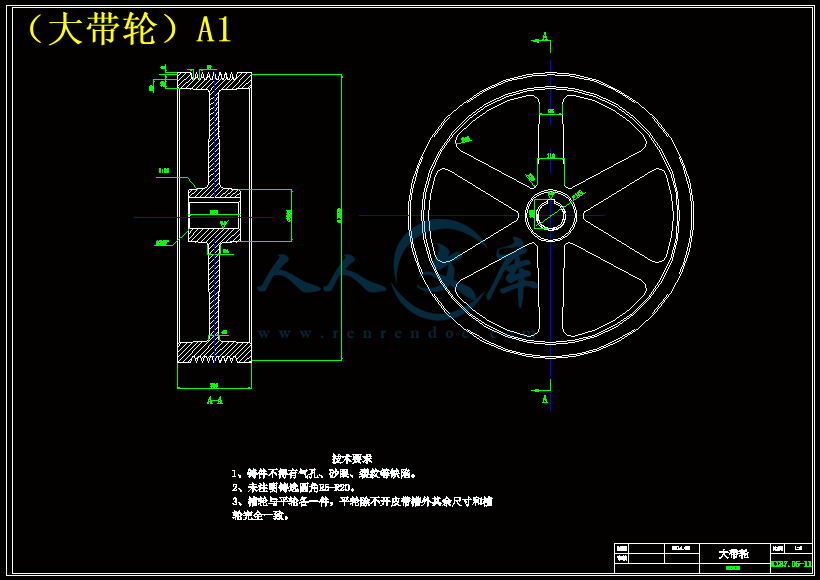

4.1带轮的设计················································································20

4.2飞轮的设计··············································································· 24

4.3偏心轴的设计·············································································26

4.4轴承的选择与校核········································································29

4.5键的校核···················································································31

4.6轴承座的设计·············································································32

4.7配重的选择················································································32

4.8外形尺寸的设计···········································································33

第5章 各基本构件的设计······························································36

5.1动鄂的设计···············································································36

5.2齿板的设计················································································39

5.3推力板的设计·············································································40

5.4调整装置的设计···········································································42

5.5破碎腔型的设计···········································································44

5.6机架的设计···············································································45

第6章 复摆鄂式破碎机的安装························································48

6.1破碎机的安装·············································································48

6.2机架的安装···············································································48

6.3偏心轴和机架的安装·····································································49

6.4肘板的安装···············································································49

6.5动鄂的安装···············································································49

6.6齿板的安装···············································································50

第7章 颚式破碎机的磨损······························································51

7.1齿板的磨损分析··········································································51

7.2颚板磨损机制·············································································52

7.3颚板材质的选择··········································································53

第8章 破碎机出口扬尘的解决和噪声防治········································54

8.1破碎机出口扬尘的解决··································································54

8.2破碎机的噪声危害及防治途径···························································55

第9章 颚式破碎机的使用·····························································56

9.1颚式破碎机的操作········································································56

9.2颚式破碎机的维护与保养·······························································57

总结···························································································59

鸣谢···························································································60

参考文献·····················································································61

第1章 绪论

1.1 引言

凡是外力将大颗粒物料变成小颗粒物料的过程称为破碎,破碎所使用的机械为破碎机。物料碎磨得目的是:增加物料的比表面积;制备混凝土骨料与人造沙;使矿石中有用成分解离;为原料的下一步加工作准备或便于使用。

物料的破碎是许多行业(如冶金、矿山、建材、化工、陶瓷、筑路等)产品生产中不可缺少的工艺过程。由于物料的物理性质和结构差异很大,为适应各种物料的要求,破碎机的品种也是五花八门的。就金属矿选矿而言, 破碎是选矿厂的首道工序,为了分离有用矿物,不但分为粗碎、中碎、细碎, 而且还要磨矿。因为磨矿是选矿厂的耗能大户(约占全厂耗电的50%),为了节能和提高生产效率,所以提出了“多碎少磨”的技术原则。这使破碎机向细碎、粉碎和高效节能方向发展。另外随着工业自动化的发展,破碎机也向自动化方向迈进(如国外产品已实现机电液一体化、连续检测,并自动调节给料速率、排矿口尺寸及破碎力等)。随着开采规模的扩大, 破碎机也在向大型化发展,如粗碎旋回破碎机的处理能力已达6000t/h。至于新原理和新方式的破碎(如电、热破碎) 尚在研究试验中,暂时还不能用于生产。对粗碎而言,目前还没有研制出更新的设备以取代传统的颚式破碎机和旋回式破碎机主要是利用现代技术,予以改进、完善和提高耐磨性,达到节能、高效、长寿的目的。细碎方面新机型更多些。总的来看,值得提出的有:颚式破碎机、圆锥破碎机、冲击式破碎机和辊压机。

颚式破碎机是一种最古老的破碎机,第一台颚式破碎机是有美国人E.W.Blake发明的。但由于它的结构简单,工作安全可靠,处理物体范围大,很适宜破碎硬的物料,因此颚式破碎机在冶金,煤炭,化工,建材等工矿企业中被广泛的应用,但是其破碎比小,破碎后的物料粒度不均匀,它是间歇工作,有空转行程,但是对于物料的粗碎和中碎,却是一种比较好的方法,所以在工矿企业中仍然被广泛的应用。但是,复摆颚式破碎机也有它的缺点:非连续性破碎、效率较低,破碎比较小,给矿不均匀引起颚板磨损不均匀等。针对其缺点,各国都在以下几方面加以改进:优化结构与运动轨迹;改进破碎腔型,以增大破碎比, 提高破碎效率, 减少磨损, 降低能耗, 现已普遍应用高深破碎腔和较小啮角; 改进了动颚悬挂方式和衬板的支承方式,改善了破碎机性能;颚板采用了新的耐磨材料, 降低了磨损消耗;提高了自动化水平(可自动调节、过载保护、自动润滑等)。同时也出现了一些新的机型,如双腔双动颚式破碎机,其破碎比可达20~50,排料口调节方便,产量大;双腔回转破碎机,兼有颚式破碎机与圆锥破碎机的性能,其产量较同规格的颚式破碎机高50%还有筛分颚式破碎机,把筛分和破碎结合为一体,不仅可简化工艺流程,且能及时将已达粒度要求的物料从破碎腔中排出,减轻了破碎机的堵塞和过粉碎,提高了生产能力,降低了能耗。

破碎机出口扬尘非常严重,从破碎机出来的块状和粉末状物料直冲矿石输送皮带,部分物料飞溅或滚淌到地面上,地面堆积厚厚一层物料,部分粉状物料飞扬在空中,给生产带来了很大的不便。较多的粉尘而直接影响安全生产和员工的健康,因此要采用相应的防尘设施是破碎机一个重大而不可忽略的问题。

现代的设计应以人为本,面对服务对象,面对市场、面对循环经济、面对矿产资源利用的大趋势,面对环保、搞全性能、全生命的设计。所以做好复摆颚式破碎机的设计,让它更好的为生产服务,提高生产效率。

川公网安备: 51019002004831号

川公网安备: 51019002004831号