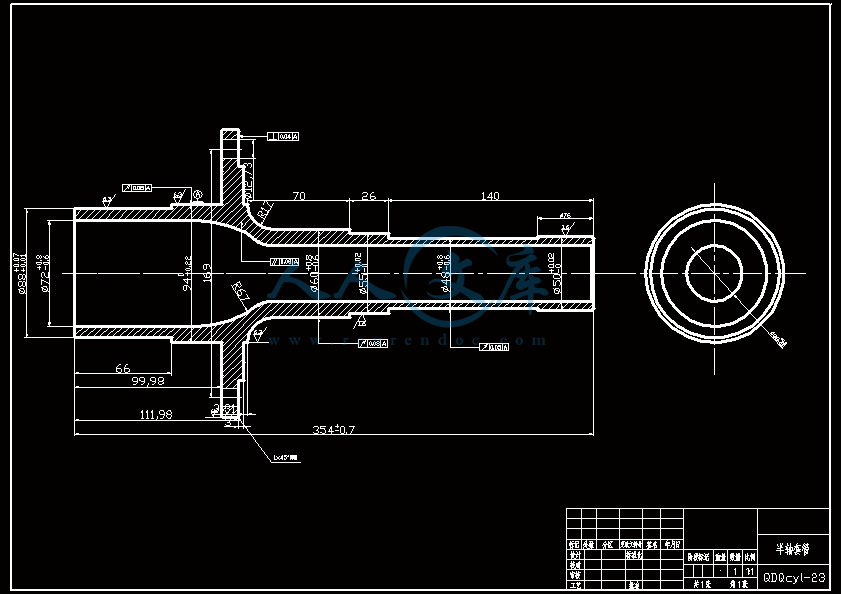

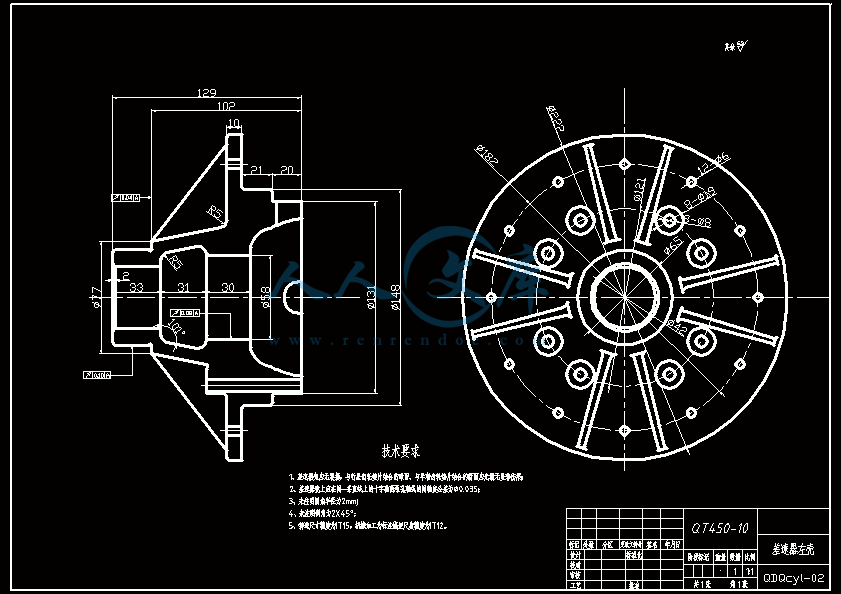

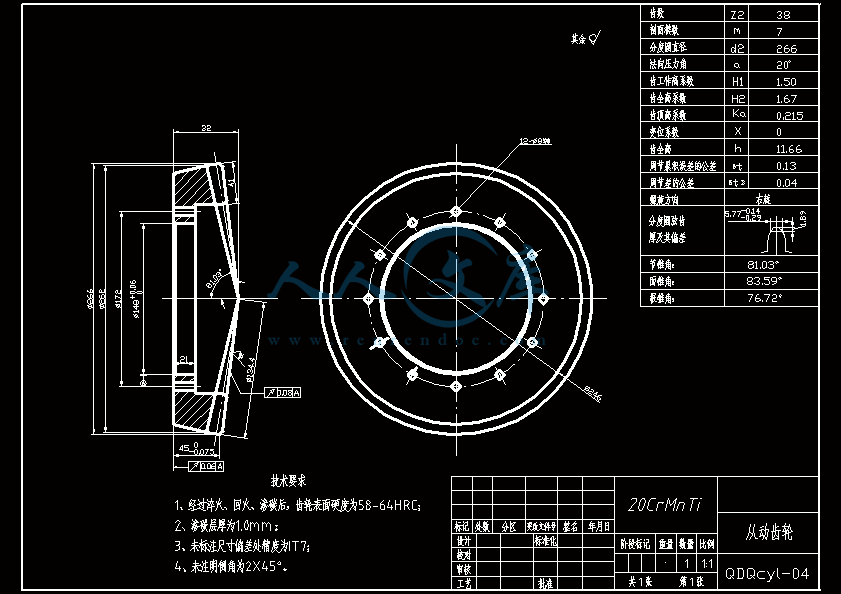

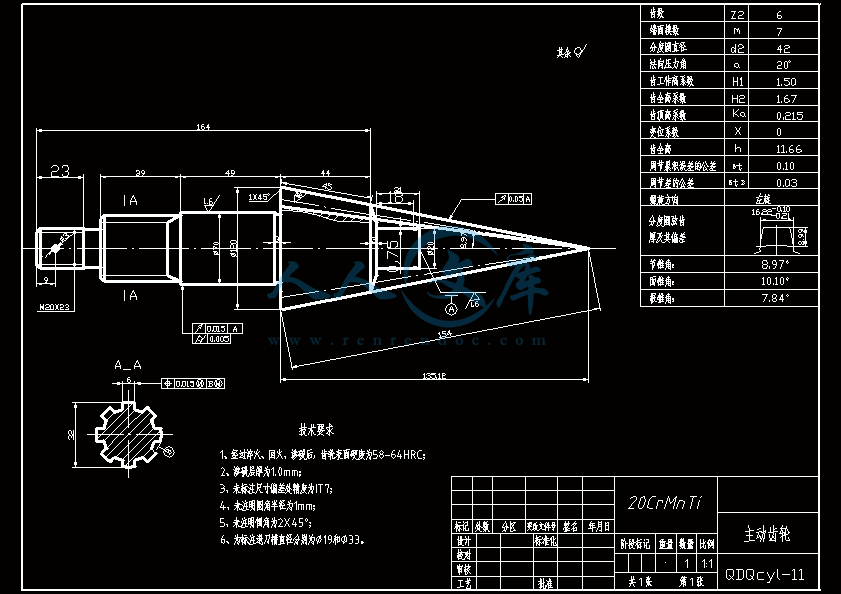

轻型货车5.5吨级驱动桥设计、HQ1080车用5.5吨级驱动桥设计【含CAD图纸、说明书】

收藏

资源目录

压缩包内文档预览:

编号:19435814

类型:共享资源

大小:4.85MB

格式:ZIP

上传时间:2019-05-23

上传人:机****料

认证信息

个人认证

高**(实名认证)

河南

IP属地:河南

50

积分

- 关 键 词:

-

含CAD图纸、说明书

HQ1080车用5.5吨级驱动桥设计

HQ1080轻型货车用5.5吨级驱动桥设计【

CAD图纸】

HQ1080轻型货车用5.5吨级驱动桥设计

- 资源描述:

-

- 内容简介:

-

附 录附录A 外文文献原文A1 Establish and research on CA/CAE sysytem of automobile drive axle housing based on virtual prototype technologyVirtual prototype refer to a model which is in the step of product progress, occurring in the computer realm, aiming at the optimization based on the CAD model used to stimulating analysis product. Virtual prototype in mainly used for test which was failed by physical test. Based on the result which is drawn from the stimulation result, it is easy to modify and guide design, until reach the optimistic design Automobile drive axle housing is a main part of a mobile. disconnect drive axle housing is used for bearing the mobiles weight ,transferring the load to the wheels Drawing force, braking force lateral force and vertical force are transferred to frame and compartment by drive axle housing. So drive axle housing is either a bearing or a transmission item. If not correctly designed or some problem occurred while manufacturing, drive axle housing may deformed or fracture. As a traditional design method is so costly that is necessary to introduce the virtual prototype technology.A1.1 design scheme Traditional design method for drive axle housing is firstly giving a scheme ,manufacturing , a sample item then a series test (such as stiffness test bending fatigue test and static strenth test )is carried out Apparently this method is very money consuming ,and the final parameter may be not optimal .if adopt the Virtual prototype technology stimulazing kinds of working condition of drive axle housing ,and draw a series of optimal parameters .Based on these parameter the physical machine are carried out to do physical test .this method can save time ,cutting the cost ,thus bring in huge benefit to the enterprise.Modern trial production progress vary largely to the traditional one .As depicted ,in the picture ,A loop is absent in the traditional drive axle housing making virtual prototype can assess the cost quality and manufacturability on the computer. If the assessment is not satisfying, it is necessary to adjust .repeat a loop until reach a ideal parameter.This scheme design a software terrace, providing a interface for Solidworks patron and Nastron ,using superiority of this professional software ,and develop these software ,but a drive axle housing product design terrace.Considering the question of improving the analysis efficiency and simplifying finite element ,this system adopt a method which uses parametric modeling that is totally different from do make up for CAD model .And the CAD model is only used for oversight A1.2 Parameterized Modeling by SolidWorksThey are all available for second-time development of SolidWorks for the softwares that support OLE and COM. Because of design requirements, the development software of the system is Delphi and second development software of SolidWorks is OLE. The copyright of SolidWorks is 2006. To use this method, it must be registered for auto-severed including files sldworks.tlb and element files that filenames are SldWorks_TLB.pas severed by SolidWorks under Delphi program environment, and they are available after programs are complied.The topology structure of SolidWorks is typically five layers topology structure. A part is consist of bodies, and bodies include surfaces, and surfaces include edges, and edges include curves and points. It may use record in delphi to define bodies, surfaces and points these data structure and apply respectively to store topology information. The steps of the parameterized modeling of CAD by SolidWorks are as follows: firstly, it must be defined correctly for the relationship between automobile dimension and other dimensions. Secondly, initialize the various record and auto-product the drawing of axle housing using API function. Lastly, it is available for users to check the CAD model and modify various dimensions on the plate. The program can auto-modify the other relative dimensions and redraw the picture in SolidWorks by using the relationships that have been defined previously. A1.3 Patran & Nastran FEA analysisA1.3.1 PCL programMSC/PATRAN provides a fully functions program language for users, as PCL. PCL provide abundant of tables and menus and allow users to read and write all information in Patran database, which structure is similar with C language. The paper develops the analysis module of the automobile drive axle housing, which includes parameterize modeling, ALE, material definition, load cases definition, Nastran analysis submitted and results post-possessing and other functions.There are no special develop environment in PCL, generally the codes are written in test editor and saved as *.pcl format, and then the files are pre-compiled as *.cpp format in DOS, and debug them in Patran at last. The detail operates are as follows:Pre-compile *.pcl file:cpp *.pcl *.cppdebug *.cpp file in patran:!input *.cppWhen starting, Patran will execute init.pcl file under its root catalogue. The file includes two commands:!INPUT p3prolog.pcl and !IPUT p3epilog.pcl. As pre-compile these two files when Patran starts. Users can write commands to initialize Patran starting viewport. For example, write commands:!iput C:MSC.SoftwareMSC.Patran2005_r2 rearhouse.cpp and rearhouse.init() in p3epilog.pcl, in which, rearhouse.cpp is the second-time development program for automobile drive axle housing. It will influence the starting speed, for this, users can write self-definition functions and compile them into a database, which Patran can call directly. The method is that:Input commands in Patran:!COMPLIE rearhouse.cpp into rearhouse.plb!library rearhouse.plb!llibrar keepopen rearhouse.plbAs this, Patran can load including files when it starts and the speed is rather fast. For initialize the viewport, users need to input that: rearhouse,init().A1.3.2 Program Design FlowcharThe FEA parameterize modeling part is implemented as follows:Input various key parameters into delphi, and they will be compiled and format a file whose suffix is .cpp. The contents of init.pcl can be modified by dephi. As that, users can enter Patran by click “FEA parameterize modeling” in this system, and they will see a new file, whose drawing zone has complete FEA module. The program parts dont need to communicate with users and just like a back program. In this progress it will need API function of Windows system. Due to they require high communicate for ALE, material definition, load cases definition, Nastran analysis submitted and results post-possessing and other functions, which are not convenient for delphi to control directly, these parts will be written by PCL. Patran may copy the .CPP files to the catalog such as “C:MSC.SoftwareMSC.Patra2005_r2”, and modify the relative contents in init.pcl file. Allowing for the special features of housing modeling and computing speed of computers, the program all use shell elements to simulate housing. Therefore it use sgm_const_surface_extrude() to product shell function when modeling, and use fem_create_mesh_surf_4() to mesh when FEA meshing. A1.4 Software application exampleThis software is established by the delphi computer language. After enter the system, preliminary design of automobile drive axle housing by basis mechanics must be completed to define the key dimension, then CAE/CAD modeling and analyzing of various operating conditions should be starting. The software interface is shown in the Figure A1, Figure A2 shows the solid model of axle housing by SolidWorks parameterized modeling.Figure A1 The software interfaceFigure A2 The solid model of axle housingTable A1 illustrates material parameters whichComponentMaterialModulus of elasticityPoisson ratioDensityDrive axle housingQT400-151.962E8 KPa0.37.8E-6 kg/mm3Half axle casing45Mn22.1E8 KPa0.287.9E-6 kg/mm3Five operating conditions are analyzed by Patran&Nastran in this system, which are shown in Figure A5, static of 2.5 times full load, driving by the maximum drawing force, brake of full load, turning around of full load, brake of full load in turning around. Longitudinal direction, side direction, vertical direction and revolve of longitudinal direction constraints are laid on at the center of steel plate spring. Load is laid on at the half axle casing, which resulting stress is inconsistent with actual condition, bringing no impact on stress of other parts of axle housing. The result shows that Tresca stress on wheel side is larger in Table A3.Table A2 The stress of axle housing of 5 operating conditionsStatic of 2.5 times full loadDriving by the maximum drawing forceBrake of full loadTurning around of full loadBrake of full load in turning aroundStress in critical section1758793.5158205The allowable stress of axle housing is 400MPa, the design is very safe, which shown in the Table A2. Figure 8 illustrates the distribution of stress nearby the steel plate spring. Figure A3 The distribution of stress nearby the steel plate springTable A3 illustrates the former 9th order natural frequency of automobile drive axle housing by this system.Table A3 The former 9th order natural frequencyOrder123456789Frequency181.47265.91433.24614.33658.761119.911661347.41399.6Since the road is not absolutely smooth, automobile natural frequency often occur between 120Hz. Resonance of axle housing wont be caused. This result is reasonable. Figure A4 The 1st order mode of vibration附录B 外文文献中文翻译A1 基于虚拟样机技术的汽车驱动桥桥壳CAD/CAE系统的建立于研究虚拟样机是指在产品设计阶段,在计算机世界中,以优化设计思想为指导,以产品CAD模型为基础,利用各种相关CAE分析软件,进行产品主要性能仿真分析的数字模型。虚拟样机主要进行对物理样机而言难以进行的试验,根据虚拟样机反馈的仿真结果,修正、指导设计,直至获得系统级的优化设计方案。 驱动桥桥壳是汽车上主要零件之一,非断开式驱动桥壳起着支承汽车荷重的作用,并将载荷传给车轮。作用在驱动车轮上的牵引力、制动力、侧向力和垂向力也经过桥壳传到悬架及车架或车厢上。因此,桥壳既是承载件又是传力件。如设计不当或制造工艺有问题时,会使桥壳变形或折断。传统桥壳设计方法代价过于昂贵,因此有必要引进虚拟样机技术。A1.1 设计方案以往的桥壳设计方法都是先提出一种方案,制造出物理样机,然后通过刚度试验、静强度试验、弯曲疲劳寿命试验等多次破坏性的物理试验来确定其性能参数、材料特性。显然这种方法的代价是相当昂贵的,而且最后得出的参数也不一定是最优的。如果采用虚拟样机技术先对驱动桥桥壳工作的各种工况进行仿真,在计算机里面通过参数优化得出一组合理的设计参数值,然后再根据这组合理的参数值制造出物理样机做物理试验。这种方法节省时间,降低成本,将为企业带来巨大的经济效益。现代模式的新产品试制过程,和传统的新产品试制过程有很大不同。A循环部分为汽车驱动桥桥壳新产品试制传统方法中所无,即虚拟样机部分。虚拟样机可对设计质量、成本、可制造性(制造工艺性)等指标在计算机上进行评价,当评价不满意时,进行修改设计,重复A循环,直到获得理想的参数为止。本方案设计开发一个软件平台,提供SolidWorks、Patran&Nastran的接口,利用两种专业应用软件在CAD建模和有限元分析方面的优势,分别对二者进行二次开发,建立一个针对汽车驱动桥桥壳产品的数字化设计平台。考虑到提高有限元软件的分析效率和有限元模型的简化问题,本系统采用在Patran中单独参数化建模的方法,而不是直接修改简化CAD模型,而CAD模型只用于观察装配干涉和生成二维生产图。A1.2 SolidWorks参数化建模凡支持OLE和COM编程的开发工具均可用于SolidWorks的二次开发。由于设计需要本系统采用Delphi作为开发工具,运用OLE自动化技术对SolidWorks进行二次开发。SolidWorks版本为2006版。采用这种方法必须在Delphi编程环境中注册由SolidWorks提供的自动化服务类型库文件sldworks.tlb,生成名为SldWorks_TLB.pas的单元文件,并在编译程序时引用之方可。SolidWorks的拓扑结构为典型的五层式拓扑结构。一个零件对象由体构成,体中含面,面中含边,边中含曲线和顶点。可用delphi中的record记录定义体、面、点数据结构,分剔用于存储各自拓扑信息。在SolidWorks中CAD参数化建模过程如下:首先,定义好驱动尺寸和其余尺寸间的关系。其次,初始化各record,利用API函数自动生成桥壳实体图形。最后,用户可以在本软件平台上检查CAD模型并修改各尺寸参数,程序利用预先定义好的各尺寸间的关系,自动修改桥壳其余相关尺寸,在SolidWorks中重画桥壳图形。A1.3 Patran&Nastran有限元分析。A1.3.1 PCL编程MSC/PATRAN为用户提供了一种全功能的编程语言,即PCL(PATRAN command language)lsi。PCL提供了丰富的表格和莱单库,使用户可以方便快捷的编制Motif界面,允许用户读写Patran数据库中的全部信息,其结构和C语言类似。本文利用PCL语言开发包括参数化建模、自动网格划分、定义材料、定义工况、提交Nastran分析和结果后处理等功能的汽车驱动桥桥壳分析模块。PCL没有专门的集成开发环境,一般都是在文本编辑器中编写代码,并将文本保存为*.pcl格式,然后在DOS环境中将文件预编译为*.cpp格式,最后在Patran中调试*.cpp文件。具体操作如下:Patran每次启动都会执行其根目录下的init.pcl文件,该文件中包含两个命令:!!INPUT p3prolog.pcl和!!INPUT p3epilog.pcl。即在Patran启动时预编译p3prolog.pcl和p3epilog.pcl文件。用户可以在此二文件中写入命令初始化Patran启动界面。如在p3epilog.pcl中写入命令:!input C:MSC.SoftwareMSC.Patran2005_r2rearhouse.cpp和rearhouse.init0,其中rearhouse.cpp为汽车驱动桥桥壳分析二次开发程序。会影响Patran的启动速度,用户可以先将自己编写的函数编译到一个数据库中,Patran可直接调用。方法如下:在Patran命令行中输入如下命令:!!COMPILE rearhouse.cpp into rearhouse.plb$编译形成用户化库在init.pcl文件中输入如下内容:!!library rearhouse.plb! !library keepopen rearhouse.plb如此,Patran肩动时自动加载库文件,速度很快,用户要初始化界面只需在命令行中输入:rearhouse.init0。按有限元分析一般流程,本文有限元参数化建模部分的实现如下:在delphi中输入各关键参数,经过delphi编译后生成一个后缀名为.cpp的文件,并由delphi程序控制修改init.pcl文件内容,初始化Patran。即用户从此软件系统中点击“有限元参数化建模”按钮就会自动进入patran中,并看到一个新建的文件,其绘图区中已有自动建模完毕的有限元分析模型。在Patran看来这部分程序不需要同用户交互操作,就像一个后台程序。在此过程中需用到Windows系统的API函数。其余网格划分、定义工况、定义材料

- 温馨提示:

1: 本站所有资源如无特殊说明,都需要本地电脑安装OFFICE2007和PDF阅读器。图纸软件为CAD,CAXA,PROE,UG,SolidWorks等.压缩文件请下载最新的WinRAR软件解压。

2: 本站的文档不包含任何第三方提供的附件图纸等,如果需要附件,请联系上传者。文件的所有权益归上传用户所有。

3.本站RAR压缩包中若带图纸,网页内容里面会有图纸预览,若没有图纸预览就没有图纸。

4. 未经权益所有人同意不得将文件中的内容挪作商业或盈利用途。

5. 人人文库网仅提供信息存储空间,仅对用户上传内容的表现方式做保护处理,对用户上传分享的文档内容本身不做任何修改或编辑,并不能对任何下载内容负责。

6. 下载文件中如有侵权或不适当内容,请与我们联系,我们立即纠正。

7. 本站不保证下载资源的准确性、安全性和完整性, 同时也不承担用户因使用这些下载资源对自己和他人造成任何形式的伤害或损失。

人人文库网所有资源均是用户自行上传分享,仅供网友学习交流,未经上传用户书面授权,请勿作他用。

川公网安备: 51019002004831号

川公网安备: 51019002004831号