中国矿业大学毕业设计任务书

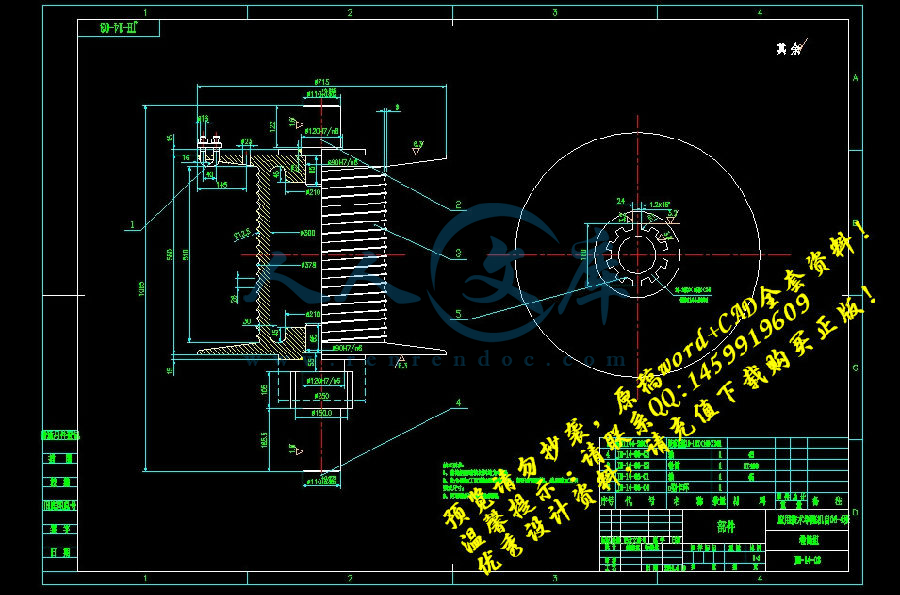

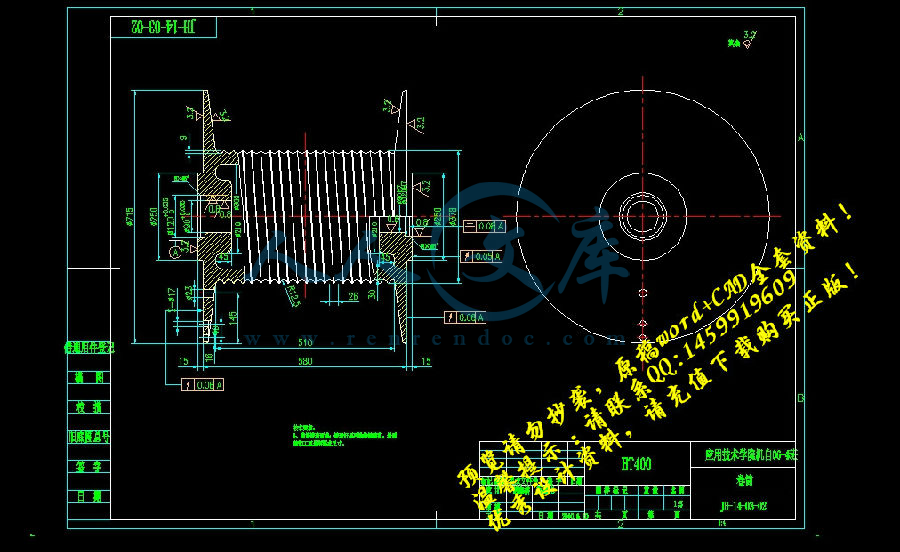

毕业设计题目:JH—14型回柱绞车

毕业设计专题题目:

毕业设计主要内容和要求:

设计的主要技术参数为

最大牵引力:

最大牵引速度:,最小牵引速度:,

容绳量:

此次设计的主要内容是回柱绞车电动机的选择,卷筒的设计、减速器的设计等。此次设计要求回柱绞车能够实现两种速度,可以满足不同条件、环境下的回柱,也可以实现回绳与放绳时速度的合理利用。在减速器的设计时要求采用蜗轮蜗杆传动、滑移双联齿轮传动,以及圆柱齿轮传动。滑移齿轮的传动要求采用拨叉拨动的方式来实现。在设计时还需要尽量考虑加工工艺,考虑材料的选用以及加工成本等因素。

设计的绞车要求具有防爆能力,设计图纸量折合成A0图纸不少于3张半,设计说明正文不少于70页。另外还要求翻译一篇近三年来发表过的并且与本人设计有关的英文论文或专著,中文译文必内容不少于3000汉字。

摘 要

目前,矿山广泛使用的JH系列回柱绞车多是由JM慢速绞车演变而来的,具有速度低、结构紧凑、牵引力大等特点。主要应用于煤矿井下采煤工作面回柱放顶之用,同时也可用于上山、下山、平巷等综采工作面设备的搬迁。由于它的高度较低重量又轻,特别适用于薄煤层和急倾斜煤层采煤工作面,以及各种采煤工作面回收沉入底板或被矸石压埋的金属支柱。

本次设计的JH-14型回柱绞车是在我去年毕业实习时所实践的回柱绞车的基础上,再查阅参考有关资料后结合我的一些想法所设计的。在减速器的设计过程中,主要采用了蜗轮蜗杆传动、双联滑移齿轮传动、圆柱齿轮传动等传动方式,利用拨叉拨动小滑移双联齿轮的方式来实现变速,而且在拨叉的设计中,我采用了手柄摇动转盘的方式来实现拨叉的水平移动。在设计卷筒时,考虑到卷筒设计精度要求不太高,因此将以往的卷筒通轴改为在卷筒两端利用过盈配合及焊接的方式来分别固定轴,避免了材料的浪费。

本次的设计主要特征就是能实现变速,既能满足不同环境下绞车的使用,也实现绞车在回绳和放绳时可以利用不同的速度达到快速回柱。

关键词:JH-14回柱绞车; 双联齿轮; 变速

ABSTRACT

At present, JH prop-drawing winch which evolved from JM Slow Speed Winch is widely in mine. This machine with advantage of slow speed, compact structure and big traction force. The prop-drawing winch is mainly used to prop drawing and caving roof in coal working face, but also can be used to relocate the equipment in fully mechanized coal face,such as uphill, downhill, and level gallery working face. Because of its low height and light weight, The prop-drawing winch is suitable for the thin coal seam and steep coal seam, and recovering the various metal pillar which Sinking into the floor or buried by gangue.

The JH-14 prop-drawing winch is designed based on my Practice on graduation practice last years and consulting large numbers of information, Which also combines many of my new ideas. The design process in the speed reducer, mainly used in the worm-gear transmission, double-slip gear transmission and column gear transmission etc transmission way. slide the small double-gear with the fork-lever to achieve Speed Change. But also in the fork-lever of the design, I used the handle shake rotary table to achieve the fork-lever horizontal movement. The prop-drawing winch drum in the design, taking into account the design precision need not too high,so I put a drum axis change into connection of drum and axis with interference fitting and welding in Both ends of the drum, reduced the Materials of axis, to avoid the waste of materials.

The main features of the design is to achieve speed change, it can satisfy the different working environment, but also to make the prop-drawing winch use different speeds to achieve the rapid return to prop drawing in the back rope and up rope.

Keywords:JH-14 prop-drawing winch;double-slip gear;speed change

目 录

1 绪论……………………………………………………………………………………………1

1.1 引言………………………………………………………………………………………1

1.2 概述………………………………………………………………………………………1

1.2.1 绞车概况……………………………………………………………………………1

1.2.2 回柱绞车概况………………………………………………………………………2

1.3 国内外绞车的发展………………………………………………………………………3

1.4 JH-14型回柱绞车的技术特点……………………………………………………………4

2 总体设计………………………………………………………………………………………4

2.1设计总则…………………………………………………………………………………5

2.2 设计条件…………………………………………………………………………………5

2.3 传动方案的设计…………………………………………………………………………5

2.4电动机的设计选择………………………………………………………………………5

2.4.1电动机输出功率的计算………………………………………………………………5

2.4.2确定电动机的型号……………………………………………………………………6

2.4.3牵引钢丝绳直径的确定及滚筒直径的确定…………………………………………7

2.5滚筒的设计计算…………………………………………………………………………8

2.5.1滚筒直径……………………………………………………………………………8

2.5.2滚筒宽度……………………………………………………………………………8

2.5.3滚筒的外径………………………………………………………………………9

2.5.4验算滚筒的平均速度…………………………………………………………………9

3 减速器设计…………………………………………………………………………………10

3.1 减速器总体设计…………………………………………………………………………10

3.1.1 减速器概述…………………………………………………………………………10

3.1.2 减速器设计…………………………………………………………………………10

3.2 减速器参数确定…………………………………………………………………………10

3.2.1 总传动比及传动比分配……………………………………………………………11

3.2.2 传动装置运动参数的计算…………………………………………………………11

3.3 圆弧蜗轮蜗杆的设计计算………………………………………………………………12

3.3.1 蜗杆传动概述………………………………………………………………………12

3.3.2 蜗杆传动的失效形式………………………………………………………………13

3.3.3 蜗杆传动的材料选定………………………………………………………………13

3.3.4 蜗杆传动的结构……………………………………………………………………14

3.3.5 蜗杆传动的主要参数和几何尺寸计算……………………………………………15

3.3.6 蜗杆传动的润滑……………………………………………………………………18

3.4 滑移齿轮的设计计算……………………………………………………………………18

3.4.1 齿轮传动类型………………………………………………………………………18

3.4.2 滑移齿轮概述………………………………………………………………………20

3.4.3 滑移齿轮传动设计计算及强度校核………………………………………………20

3.5 大小齿轮的设计计算……………………………………………………………………26

3.5.1 齿轮传动概述………………………………………………………………………26

3.5.2 齿轮材料选择………………………………………………………………………27

3.5.3 齿轮传动设计及强度校核…………………………………………………………28

3.6 过桥齿轮的设计计算……………………………………………………………………33

3.7 减速器传动轴的设计与校核……………………………………………………………33

3.7.1 蜗杆轴的设计计算…………………………………………………………………33

3.7.2 蜗轮轴的设计计算…………………………………………………………………39

3.8 键的选择及强度校核……………………………………………………………………45

3.8.1 蜗轮轴小滑移齿轮处………………………………………………………………46

3.8.2 蜗轮轴蜗轮处………………………………………………………………………46

3.8.3 大滑移齿轮轴大滑移齿轮处………………………………………………………47

3.8.4 大滑移齿轮轴小齿轮处……………………………………………………………47

3.8.5 第四轴轴过桥齿轮处………………………………………………………………48

3.9 轴承的选择及强度校核…………………………………………………………………48

3.9.1 蜗杆轴上轴承的选择及强度校核…………………………………………………49

3.9.2 蜗轮轴上轴承的选择及强度校核…………………………………………………52

3.9.3 其它轴上轴承的选择………………………………………………………………55

3.10 减速器中拨叉的设计…………………………………………………………………56

3.11 减速器其他部件的设计………………………………………………………………57

3.11.1 通气器……………………………………………………………………………57

3.11.2 油标………………………………………………………………………………57

3.11.3 减速器箱体的设计………………………………………………………………57

4 卷筒齿轮设计………………………………………………………………………………58

4.1 总体设计…………………………………………………………………………………58

4.2 卷筒轴的设计及校核……………………………………………………………………59

4.3 卷筒轴轴承的选择及校核………………………………………………………………64

4.4 大齿轮处键的选择………………………………………………………………………67

5 回柱绞车其它部件…………………………………………………………………………67

5.1 联轴器……………………………………………………………………………………67

5.2 制动器……………………………………………………………………………………68

5.3 底座………………………………………………………………………………………69

6 回柱绞车的润滑与密封……………………………………………………………………69

7 回柱绞车的安装、操作与维护………………………………………………………………70

7.1 回柱绞车的装配、调整及试运转………………………………………………………70

7.2 回柱绞车的安装、固定与操作…………………………………………………………72

7.2.1 回柱绞车的安装与固定……………………………………………………………72

7.2.2 回柱绞车的操作规程………………………………………………………………73

7.3 绞车的维护、拆卸与修理………………………………………………………………75

参考文献………………………………………………………………………………………76

英文原文………………………………………………………………………………………77

中文译文………………………………………………………………………………………81

致 谢…………………………………………………………………………………………87

1 绪 论

1.1引言

煤炭是我国的基础能源和重要原料,是当前我国能源的主要组成部分之一,在国民经济中占有重要的战略地位,这就是中国的国情。过去以至未来可预见的几十年内,煤炭仍是我国的重要能源,以煤炭为主的能源结构将难以改变,煤炭工业的地位空前提高。但是目前我国的煤炭工业的发展远不能满足整个国民经济的发展需要。因此必须以更快的速度发展煤炭工业。然而,高速发展煤炭工业的出路在于煤炭工业的机械化。

矿山机械主要面向能源、交通和原材料基础工业部门服务,主要任务是为煤炭、钢铁、有色金属、化工、建材和核工业等部门的矿山开采和原材料的深加工,以及为铁路、公路、水电等大型工程的施工提供先进、高效的技术装备。矿山机械是机械工业中一个品种繁多、设备结构复杂、需求量大、使用面广的机械行业。矿山机械按其用途大致可分为采掘设备、提升设备、窄轨运输设备、破碎粉磨设备、矿用筛分设备、洗选设备和焙烧设备等7大类,30小类,700多个品种和数千种规格。

矿山机械在经济建设、科技进步和社会发展中占有十分重要的地位和作用,属于国民经济的支柱行业。矿山机械制造业是国家建立独立工业体系的基础,也是衡量一个国家工业实力的重要标志。根据国家重点支持能源、交通和原材料等基础工业发展的产业政策,矿山机械作为这些基础工业的支柱应优先得到国家的重点支持,以得到进一步发展和提高,为煤炭、金属和非金属矿山的开发提供更多的具有国际先进水平的优质、高效设备,满足国民经济发展对能源和原材料的需要。我国绞车的发展大致分为三个阶段。20世纪50年代主要是仿制设计阶段;60年代,自行设计阶段;70年代以后,我国进入标准化、系列化设计阶段。

1.2概述

1.2.1绞车概况

绞车又称为卷扬机,是用卷筒缠绕钢丝绳或链条以提升或牵引重物的轻小型起重设备。目前国内最大的船用液压拖缆绞车是350T的由泰兴市依科攀船舶设备有限公司设计的。

1)绞车的特点和用途:

绞车具有以下特点:通用性高、结构紧凑、体积小、重量轻、起重大、使用转移方便,被广泛应用于建筑、水利工程、林业、矿山、码头等的物料升降或平拖,还可作现代化电控自动作业线的配套设备。有0.5吨~350吨,分为快速和慢速两种。其中高于20吨的为大吨位绞车,绞车可以单独使用,也可作为起重、筑路和矿井提升等机械中的组成部件,因操作简单、绕绳量大、移置方便而广泛应用。绞车主要技术指标有额定负载、支持负载、绳速、容绳量等。

2)绞车的分类

绞车按照动力分为手动、电动、液压三类。从用途上分类可分为建筑用绞车和船用绞车。

绞车按照功能可以分为:船用绞车、工程绞车、矿用绞车、电缆绞车等。

按照卷筒形式分为单卷筒和和双卷筒。

按照卷筒分布形式有分为并列双卷筒和前后双卷筒。

手动绞车:

手动绞车的手柄回转的传动机构上装有停止器(棘轮和棘爪),可使重物保持在需要的位置。装配或提升重物用的手动绞车还应设置安全手柄和制动器。手动绞车一般用在起重量小、设施条件较差或无电源的地方。

电动绞车:

电动绞车广泛用于工作繁重和所需牵引力较大的场所。单卷筒电动绞车的电动机经减速器带动卷筒,电动机与减速器输入轴之间装有制动器。为适应提升、牵引和回转等作业的需要,还有双卷筒和多卷筒装置的绞车。一般额定载荷低于10T的绞车可以设计成电动绞车。

液压绞车:

液压绞车主要是额定载荷较大的绞车,一般情况下10T以上到5000T的绞车设计成液压绞车。其结构主要由液压马达(低速或高速马达)、液压常闭多片式制动器、行星齿轮箱、离合器、卷筒、支撑轴、机架、压绳器(选配)等组成。液压马达具有很高的机械效率,起动扭矩大,并可根据工况要求带不同的配流器,还可根据用户需要设计阀组直接集成于马达配油器上,如带平衡阀、过载阀、高压梭阀、调速换向阀或其他性能的阀组,制动器、行星齿轮箱等直接安装于卷筒内,卷筒、支撑轴、机架根据力学要求设计,整体结构简洁合理并具有足够的强度和刚性。因而该系列绞车在结构上具有紧凑、体积小、重量轻、外形美观等特点,在性能上则具有安全性好、效率高、起动扭矩大、低速稳定性好、噪音小、操作可靠等特点。值得一提的是液压马达高的容积效率和美国SUN公司优质的平衡阀解决了一般绞车都存在的二次下滑和空钩抖动现象,使得该系列液压绞车的提升、下放和制动过程平稳,带离合器的绞车还可实现自由下放。安装于配流盘上的集成阀组则有效地简化了用户的液压系统。由于该系列绞车具备上述优点,使其广泛应用于船舶、铁路、工程机械、石油、地质勘探、冶金等行业,其优良性能得到了用户的认可。

1.2.2回柱绞车概况

回柱绞车又称慢速绞车,是供煤矿井下采煤工作面回柱放顶之用。由于它的高度较低重量又轻,特别适用于薄煤层和急倾斜煤层采煤工作面,以及各种采煤工作面回收沉入底板或被矸石压埋的金属支柱。随着机械化采煤程度的提高,它越来越多地被广泛用于机械化采煤工作面,作为安装、回收牵引各种设备和备件。

JH14型回柱绞车是一种有效的矿山辅助设备。该型绞车主要应用于回柱放顶之用,同时也可用于上山、下山、平巷等综采工作面设备的搬迁,比如液压支架、溜槽等。此外,拉紧皮带机机头、运料、调度车辆等工作都可以用这种绞车来完成。在港口、码头、建筑工地、工厂企业,这种回柱绞车也可以发挥作用。可见,回柱绞车在煤炭行业、机械行业,包括部分其他行业都有着不可忽视的地位。参考文献:

[1] 成大先编.机械设计手册.北京:化学工业出版社,2004

[2] 广西大学《实用机械零件手册》编写组. 实用机械零件手册.南宁:广西科学技术出版社,1991

[3] 胡宗武,汪西应,汪春生编.起重机设计与实例.北京:机械工业出版社,2005

[4] 李宜民,王慕龄,宫能平编.理论力学.徐州:中国矿业大学出版社,1996

[5] 刘鸿文编.简明材料力学.北京:高等教育出版社,1997

[6] 甘永立编.几何量公差与检测.上海:上海科学技术出版社,2001

[7] 程志红主编.机械设计.南京:东南大学出版社,2006

[8] 王启广编.现代设计理论.徐州:中国矿业大学出版社,2005

[9] 刘德喜编.采掘机械.北京:煤炭工业出版社,2004

[10] 王洪欣,冯雪君编.机械原理.南京:东南大学出版社,2005

[11] 冯之敬.机械制造工程原理.北京:清华大学出版社,2001

[12] 程志红,唐大放编.机械设计课程上机与设计.南京:东南大学出版社,2006

[13] 李国华 张永忠编.机械故障诊断.北京:化学工学出版社,2009

[14] 王绍定编.矿用小绞车[M].北京:煤炭工业出版社,1981

[15] 白杰平,伍峰,潘英编.机械工程科技英语.徐州:中国矿业大学出版社,2001

[16] 王碧琮编.大型绞车的安装.北京:煤炭工业出版社,1959

[17] 万建民,赵连春.JH-14型回柱绞车的改进设计.煤矿机电.2003,(1):39-40

[18] 孙晓东,魏桂清,孙长江. JM2-14型回柱绞车的结构改进.煤矿机械.1999,(3),36

[19] 朱兴民,杨玉芳.双联齿轮在回柱绞车设计中的应用.河北煤炭.1997,(1):50-51

[20] 李景奇.少齿差行星传动在回柱绞车上的应用.煤矿机械.2001,(1):36

[21] 中国矿业大学机械制图教材编写组.画法几何及机械制图.徐州:中国矿业大学出版社,2002

[22] 吴宗泽编.机械设计师手册.北京:机械工业出版社,2002

[23] 王少怀编.机械设计师手册.北京:电子工业出版社,2006

川公网安备: 51019002004831号

川公网安备: 51019002004831号