皮带运输机总体及传动设计

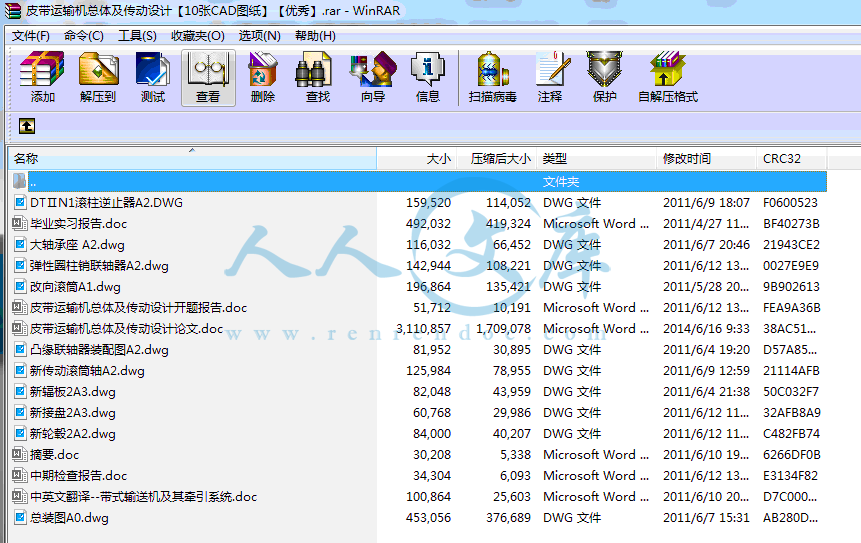

84页 31000字数+说明书+中英文翻译+开题报告+10张CAD图纸

DTⅡN1滚柱逆止器A2.DWG

中期检查报告.doc

中英文翻译--带式输送机及其牵引系统.doc

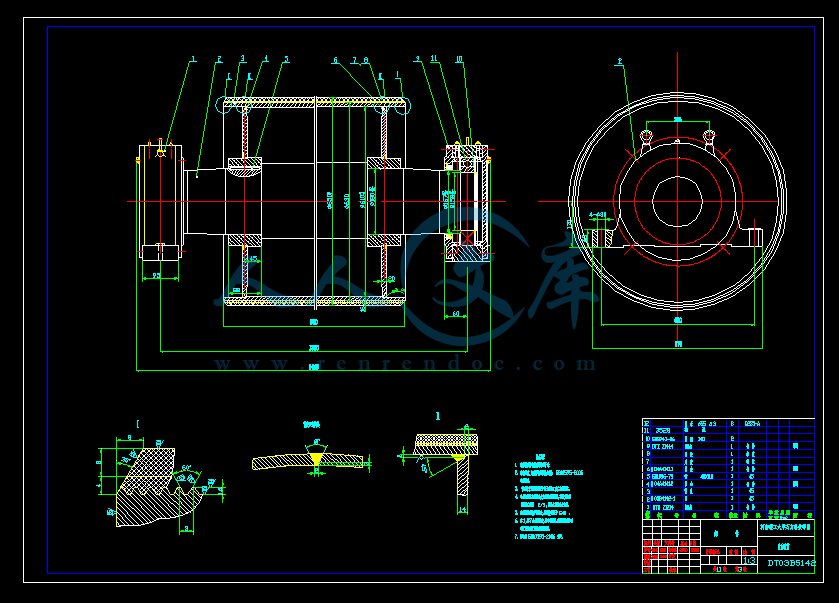

凸缘联轴器装配图A2.dwg

大轴承座 A2.dwg

弹性圈柱销联轴器A2.dwg

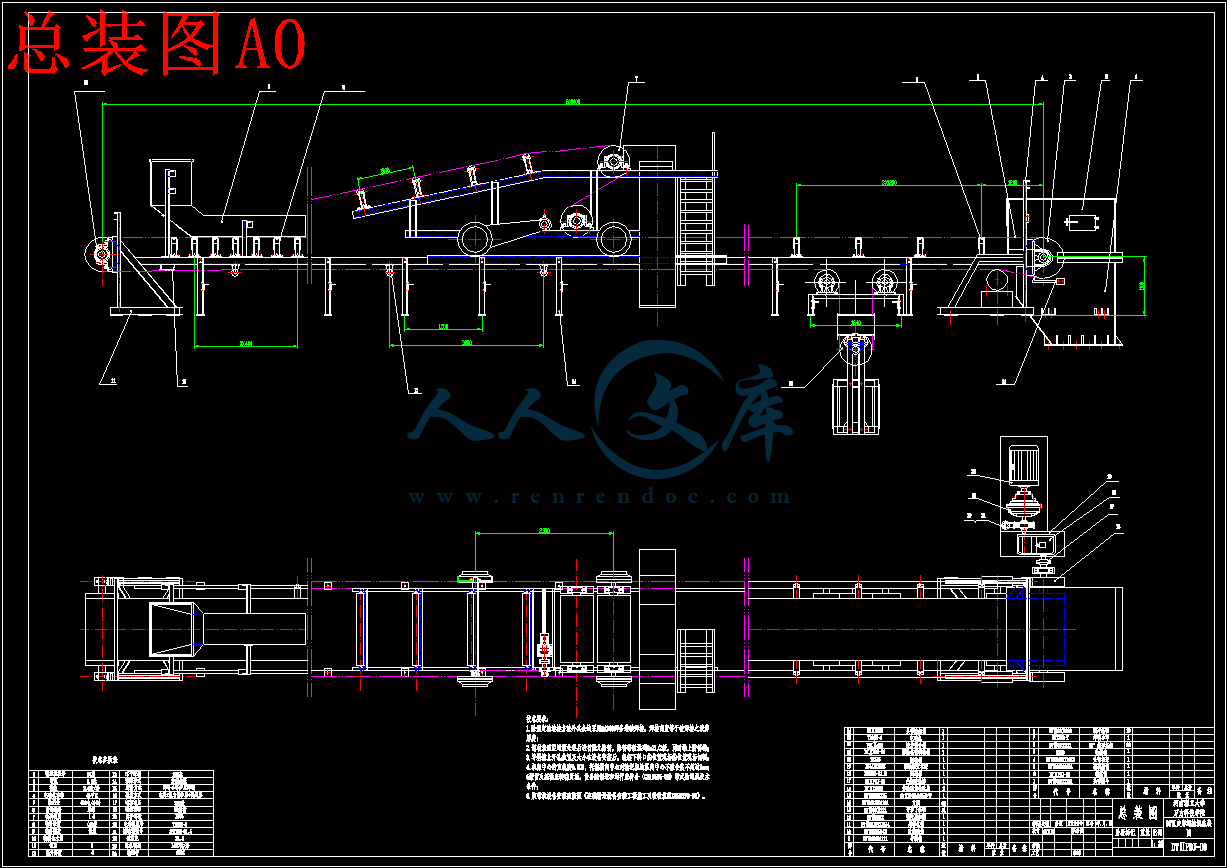

总装图A0.dwg

摘要.doc

改向滚筒A1.dwg

新传动滚筒轴A2.dwg

新接盘2A3.dwg

新轮毂2A2.dwg

新辐板2A3.dwg

毕业实习报告.doc

皮带运输机总体及传动设计开题报告.doc

皮带运输机总体及传动设计论文.doc

摘 要

带式输送机是广泛应用于煤炭、港口、建设、电厂等工业领域的连续输送设备,它具有运输效率高、运营成本低等优点。随着国民经济的发展,带式输送机的应用越来越广泛。近年来,随着工业技术的发展,带式输送机也不断朝着大运量、长距离、大倾角、高带速、投资费用少、运营费用低、工作可靠、维护方便等方向发展,对其设计技术的要求也越来越高。 为适应地形的要求,用输送带输送一定高度的带式输送机在很多方面有应用。本文着重讨论了带式输送机的结构原理、传动原理、设计计算法则、运行阻力的计算、各点张力的计算等内容,以及各种计算参数的设计计算和校核,尤其对输送带的选用、托辊的选用进行了详细的分析,使设计更加贴切接近实际问题。本文还分析了国内外带式输送机的现状及发展趋势,说明在现代高科技发展的情况下,带式输送机的发展潜力还是很大的。

本文研究了一般固定式带式输送机的设计理论,并根据所设计的要求再结合目前国内的目前的技术要求组装了一套倾角为0度的固定式带式输送机,说明了这套设计符合设计参数的要求

关键字:输送机 发展 结构原理 计算和校核

Abstract

Taking style to transport machine is broad apply to industry field continuation such as coal , port construction, electric power plant transports equipment , that it has transportation is efficient , is in motion and do business cost low grade merit. The application with the development of national economy, taking style to transport machine is more and more broad. In recent years , with the development of industrial technology,the cost direction such as low , working reliably , defending to go to the lavatory taking style to transport machine bringing speed along also unceasingly to grand fortune amounts , long distance , big dip angle , height , investing in cost stopping being in motion and doing business, develops , designs that the technology request is also more and more high to the person. For the request adapting to landform's, use conveyer belt to transport certain altitude's taking style to transport machine having in many aspects applying. Content such as the main body of a book being emphasized having discussed structure principle , drive principle taking style to transport machine , being designing the calculation calculating a law , running resistance's , every tension calculation, calculating and proofreading the parametric design secretly scheming against as well as various, has carried out detailed analysis on the conveyer belt selecting and using , selecting and using supporting a roller especially , has used the problem designing especially appropriate approximation reality. The main body of a book has been analysed taking style to transport machine current situation and developing trend at home and abroad, the potential taking style to transport is still very big under explanation condition developing in modern high technology.

The general stationary type the main body of a book has been studied takes style to transport the machine design theory , in the light of designed that together request still be tied in wedlock is at present domestic at present the technology has demanded assembling to copy a dip angle once for 14 degree of stationary type takes style to transport machine , the cover having explained this has designed that according with the request designing a parameter's.

Key words: Transport machine Develop Structure principle

Secretly scheme against and school core

目录

前 言1

1 绪 论3

1.1 皮带运输机的概况3

1.1.1 皮带运输机的发展史3

1.1.2皮带运输机基本结构4

1.1.3 矿用皮带运输机各机型介绍5

1.2 皮带运输机的发展趋势10

1.2.1国外皮带运输机技术的现状10

1.2.2国内皮带运输机技术的现状11

1.2.3 国内外皮带运输机技术的差距12

1.2.4 煤矿皮带运输机技术的发展趋势16

2 皮带运输机的设计计算18

2.1已知原始数据及工作条件18

2.2输送带宽度的确定及核算19

2.2.1带速的确定19

2.2.2带宽的确定20

2.2.3输送带宽度的核算22

2.3圆周驱动力23

2.3.1计算公式23

2.3.2主要阻力计算24

2.3.3特种主要阻力计算26

2.3.4特种附加阻力计算27

2.3.5倾斜阻力计算28

2.4传动功率计算29

2.4.1 传动滚筒轴功率()计算29

2.4.2 电动机功率计算29

2.5输送带张力计算30

2.5.1阻力计算31

2.5.2 输送带不打滑条件校核34

2.5.3 输送带下垂度校核35

2.5.4输送带强度校核计算36

2.6拉紧力计算36

2.7传动滚筒,改向滚筒合张力计算37

2.7.1改向滚筒合张力计算37

2.7.2 传动滚筒合张力计算37

2.8 传动滚筒最大扭矩计算37

3 皮带运输机的传动原理38

3.1胶带的摩擦传动原理38

3.2传动装置的牵引力41

4 传动装置的选用与设计43

4.1 电机的选用43

4.2 减速器的选用44

4.2.1 传动装置的总传动比44

4.3 液力偶合器47

4.4 联轴器48

5皮带运输机部件的选用52

5.1 输送带52

5.1.1 输送带的分类:54

5.1.2 输送带的连接56

5.2 传动滚筒57

5.2.1 传动滚筒的作用及类型57

5.2.2 传动滚筒的选型及设计58

5.2.3 传动滚筒结构64

5.2.4传动滚筒的直径验算65

5.3 拉紧装置66

5.4 制动装置69

5.5装载装置71

5.6 清扫装置72

5.7机架73

5.8改向滚筒74

5.9驱动装置架76

总 结78

致 谢79

参考文献80

1.1 皮带运输机的概况

1.1.1 皮带运输机的发展史

皮带运输机是由承载的输送带兼作牵引机构的连续运输设备,可输送矿石、煤炭等散装物料和包装好的成件物品。由于它具有运输能力大、运输阻力小、耗电量低、运行平稳、运输过程中对物料的损伤小、运营成本低等优点,被广泛应用于国民经济各部门。

皮带运输机对建设现代化矿井有重要作用。皮带运输机是煤矿最理想的高效连续运输设备,与其他运输设备(如机车类)相比,具有输送距离长、运量大、连续输送等优点,而且运行可靠,易于实现自动化和集中化控制,尤其对高产高效矿井,皮带运输机已成为煤炭开采机电一体化技术与装备的关键设备。随着我国高产高效矿井的出现,原有的皮带运输机无论是主参数还是运行性能都已不能满足要求,必须向长距离、高带速、大运量、大功率的大型化方向发展,并要改善和提高运行性能,确保安全可靠。

中国古代的高转筒车和提水的翻车,是现代斗式提升机和刮板输送机的雏形;17世纪中,开始应用架空索道输送散状物料;19世纪中叶,各种现代结构的输送机相继出现。1868年,在英国出现了皮带运输机;1887年,在美国出现了螺旋输送机;1905年,在瑞士出现了钢皮带运输机;1906年,在英国和德国出现了惯性输送机。此后,输送机受到机械制造、电机、化工和冶金工业技术进步的影响,不断完善,逐步由完成车间内部的输送,发展到完成在企业内部、企业之间甚至城市之间的物料搬运,成为物料搬运系统机械化和自动化不可缺少的组成部分。 1.1.3 矿用皮带运输机各机型介绍

(一) 固定高强度皮带运输机

这是目前煤矿井下用量最多的一种机型,主要用于水平或倾角小于18゜的场合。由于受到输送带强度及零部件的限制,单机长度不宜过长,国内现在钢绳芯带最高为ST4000,整芯带为PVG3150S,高强度机械接头要靠进口,为了降低胶带强度,减小驱动装置尺寸,国内外通常采用中间直线摩擦驱动和中间卸载式驱动,并采用软起动技术。国内现有近10种软起动方式,较好地解决了大型输送机的起动问题。目前国内井下使用的输送机的最大主参数为:运量Q=1000~3000t/h,运距L=1000~5000m,带速V=2.5~4.5m/s,驱动总功率N=750~2000kW,倾角已达30゜,国外皮带运输机的主参数为:运距L=30.4 km,运量Q=37500 t/h,带速V=6~15 m/s,带宽B=4 m。

(二) 可伸缩皮带运输机

该机型主要用于煤矿采煤工作面顺槽输送原煤,当输送能力和运距较大时,可配中间驱动装置来满足要求。美国、德国、英国等国家的一些厂商公司都可为各种生产规模的高产高效工作面提供配 套的顺槽用可伸缩皮带运输机,其主参数为:运量Q=2 000t/h,运距L=5 000m,带速v=3.5~4 m/s,驱动总功率N=2400 kW。1998年的 “九五”行业重点攻关课题《高产高效工作面顺槽配套可伸缩皮带运输机》,可满足国内年产200万t级高产高效工作面配套,其主参数为:运量Q=1600~2000 t/h,运距L=2500m,带速B=3.5~4 m/s,装机总功率N=1200kW,带宽B=1.2 m,输送倾角β≤1゜。在2001年完成了工业性试验,同年10月份通过了中国煤炭工业协会的技术鉴定。今年又有一条年产800万t的高产高效工作面用可伸缩皮带运输机研制成功,其主参数为:运量Q=2500 t/h,运距L=3 000 m,带速V=3.5 m/s, 带宽B=l400m,输送倾角β ≤3゜,功率N=3×375 kW,整芯带PVGl800S,设有储带仓,机尾可随采煤工作面的推进伸长或缩短,结构紧凑,可不设基础,直接在巷道底板上铺设,也可悬吊在巷道的顶板上,机架轻巧,拆装十分方便。输送带一般采用整芯带,用机械接头联结,与山西晋城矿务局从ACE公司引进的一台可伸缩皮带运输机的主参数基本一致。

(三) 大倾角上、下运皮带运输机

该机型是国家“七五”攻关项目,其关键技术“双排交错深槽V型托辊组”已申请专利。到目前为止,已投入使用50多台,其中倾角为25゜的有11台,26゜~28゜的有5台,30゜的有2台,基本上形成了定型产品,在国内处于领先水平。近年来,根据国内煤矿皮带运输机现状,许多煤矿纷纷要求推广使用大倾角上运皮带运输机。在大倾角上运皮带运输机研制成功的基础上,进行大倾角上运皮带运输机系列化设计,扩大使用范围,以满足不同带宽、功率、运量、运距的需要,改进和研制不同带宽的双排V形深槽托辊组,最大限度地提高导来摩擦系数,从而扩大了输送机输送倾角范围,使输送倾角提高到了30゜,下运输送机倾角也可达-25゜,并使大倾角上运皮带运输机系列既能实现软起动和均载,又能改善逆止性能。

在原有基础上,又对大倾角上运皮带运输机进行系列化设计,使输送机带宽由800mm增加到1 200mm,功率从160 kW增加到1 500 kW,运距达到1 500m以上,带速从2 m/s提高到3.15 m/s,运量从300t/h提高到630t/h,原煤允许含水量从10%放宽到20%。

(四) 水平转弯输送机

法国、前苏联、奥地利、德国、美国等国家都很重视水平转弯皮带运输机的理论研究和试验,并已在各行各业得到了广泛应用。1963年法国在地铁工程中首次设计安装了一台水平转弯皮带运输机,其主参数为:运距L=700m,带速V=1.7 m/s,带宽B=800 mm,转弯半径R=700m,提升高度H=3 m,运量Q=300 t/h。1980年法国为某矿铺设了一条水平转弯皮带运输机,其主参数为:机长L=11.12 km,高差H=5.77m,最大坡度为30%,运量Q=560 t/h,用以运送镍矿石。据统计,法国制造使用的水平转弯皮带运输机长度占全世界总长度的20%。

我国对水平转弯皮带运输机的研究较早,但发展并不快,主要原因是用户对该机型认识不够,当时国内也没有成熟的应用实例。到了20世纪90年代,国内试制成功了水平转弯的转角装置,输送机通过转角装置的转载来改变运行方向,该机型在煤矿井下已成功应用。我国的陶庄、协庄和良庄等煤矿,也都先后使用了多台水平转弯皮带运输机,并取得了良好的经济效益。

2001年,水平转弯皮带运输机被应用在地铁工程施工中,隧道长度2 000m,多处转弯,最小水平弯曲半径为360 m。其主参数为:机长L=2000m,运量B=180~200 t/h,带速V=1.6 m/s,带宽B=650mm,多处转弯,目前该机运行正常。

(五) 下运皮带运输机

长距离、大运量、较大倾角的下运皮带运输机的使用,可较大幅度地减少开采区的巷道工程量,降低基建费用和缩短施工周期,发电运行时还可向电网输电,具有较大的经济效益,是一种极具发展前途的节能设备。但由于带速高,移动部分和转动部分的惯性很大,其下滑的惯性力矩也很大,生产中经常出现打滑、滚料、飞车等事故,因此制动是关键问题。目前国内外煤矿常用的制动方式有液力制动装置、液压制动装置和盘式制动装置等3种。带液力制动系统的下运机是国家“六五”重点科技攻关项目,主要是通过在输送机的驱动装置中安装液力制动系统,分2步实现制动,即先由该系统将输送机运行速度减慢(加速度保持在0.1~0.3 m/s2的范围内),降至额定速度的1/3,然后由机械抱闸最终制动,当井下发生突然停电事故时,仍可实现二级制动。目前能够达到的主参数为:倾角β=-25 法国、前苏联、奥地利、德国、美国等国家都很重视水平转弯皮带运输机的理论研究和试验,并已在各行各业得到了广泛应用。1963年法国在地铁工程中首次设计安装了一台水平转弯皮带运输机,其主参数为:运距L=700m,带速V=1.7 m/s,带宽B=800 mm,转弯半径R=700m,提升高度H=3 m,运量Q=300 t/h。1980年法国为某矿铺设了一条水平转弯皮带运输机,其主参数为:机长L=11.12 km,高差H=5.77m,最大坡度为30%,运量Q=560 t/h,用以运送镍矿石。据统计,法国制造使用的水平转弯皮带运输机长度占全世界总长度的20%。

我国对水平转弯皮带运输机的研究较早,但发展并不快,主要原因是用户对该机型认识不够,当时国内也没有成熟的应用实例。到了20世纪90年代,国内试制成功了水平转弯的转角装置,输送机通过转角装置的转载来改变运行方向,该机型在煤矿井下已成功应用。我国的陶庄、协庄和良庄等煤矿,也都先后使用了多台水平转弯皮带运输机,并取得了良好的经济效益。

2001年,水平转弯皮带运输机被应用在地铁工程施工中,隧道长度2 000m,多处转弯,最小水平弯曲半径为360 m。其主参数为:机长L=2000m,运量B=180~200 t/h,带速V=1.6 m/s,带宽B=650mm,多处转弯,目前该机运行正常。

(五) 下运皮带运输机

长距离、大运量、较大倾角的下运皮带运输机的使用,可较大幅度地减少开采区的巷道工程量,降低基建费用和缩短施工周期,发电运行时还可向电网输电,具有较大的经济效益,是一种极具发展前途的节能设备。但由于带速高,移动部分和转动部分的惯性很大,其下滑的惯性力矩也很大,生产中经常出现打滑、滚料、飞车等事故,因此制动是关键问题。目前国内外煤矿常用的制动方式有液力制动装置、液压制动装置和盘式制动装置等3种。带液力制动系统的下运机是国家“六五”重点科技攻关项目,主要是通过在输送机的驱动装置中安装液力制动系统,分2步实现制动,即先由该系统将输送机运行速度减慢(加速度保持在0.1~0.3 m/s2的范围内),降至额定速度的1/3,然后由机械抱闸最终制动,当井下发生突然停电事故时,仍可实现二级制动。目前能够达到的主参数为:倾角β=-25゜,运量Q=1 500 t/h,带速V=3.15 m/s,运距L=2000m。

阻尼式下运皮带运输机也具有较为广阔的应用前景,它在输送带底面施加阻尼力来抵消载荷下运时产生的下滑力,其驱动装置可以布置在输送机的下端,使电动机在驱动中始终保持电动状态,改善了输送带受力情况,同时可解决下运可伸缩皮带运输机不易伸缩的难题。在倾角不大于16゜的下运工况均可应用,其防下滑的阻尼力可随时任意调整,十分灵活方便。这种皮带运输机不仅具有胶带张力小,结构简单,可实现长距离运输等优点,而且具有软起动和功率平衡功能,安全保护设施完善,微机控制、传感器监测,能满足煤矿防爆要求。目前该机已有多台在井下使用,运行情况良好。

(六) 管状皮带运输机

20世纪70年代末,日本管状皮带运输机进入实际应用阶段,并逐步形成了一套设计理论和系列产品,在32个国家获得专利,向12个国家和地区转让了此项技术,形成了国际性的管状皮带运输机学术团体,每年由Bridge Stone公司主办一次管状皮带运输机技术研讨会。

据不完全统计,自20世纪70年代以来,日本国内共生产皮带运输机1 000多台,最大运量Q=3 000 t/h,最大机长L=3 414 m,最大输送倾角α=35゜42’。90年代初,我国首台管状皮带运输机在淮南矿务局新庄孜矿地面使用,用于输送原煤,运量Q=600 t/h,运输长度L=227.65 m,总提升高度H=6.52 m,带速V=175 m/min,绕过了精煤仓,有一个圆心角为40.15゜、曲率半径R=115 m的垂直弯曲段。该机的优点是:封闭输送物料;可弯曲和大倾角输送;可分别利用胶带的上、下分支同时输送物料;断面积小;整机移动方便,重量轻,环保;可以减少转载环节,便于实现控制等。其缺点为:对输送物料的块度有一定要求;不适于多点受、卸料;不适于给料不均匀的场合。这3点,正是井下皮带运输机的特点,因此,管状皮带运输机不适于井下输送。在经济性方面,如果采用进口胶带,就输送机本身而言:当机长L<200 m时,为普通带的2.5倍;当机长L>200m时,为普通带的2倍。胶带国产化后,费用会有所下降。目前沈阳胶带股份有限公司可生产配套的胶带。如果将含走廊及转载点的整个运输系统进行比较,则费用基本相同。

(七) 压皮带运输机

压皮带运输机也是为增大输送倾角而设计的,1979年美国大陆输送机设备公司开始研制压皮带运输机,并于1983年研制出压带式大倾角皮带运输机HAC,这台样机的输送倾角为30゜~60゜,最大输送能力为2 900 t/h,其压带是通过旋转的托辊组加载的。此后,大陆公司已生产40多台HAC。1991~1994年德国的MAN TAKPR FODERTECHNIK公司研制了3台用于卸船机的压皮带运输机。前苏联和日本等国也研制了这种皮带运输机。国内生产的压皮带运输机倾角可达90゜,物料最大块度可达300 mm。这种输送机由于本身结构的缺陷和经济上的原因,目前还没有在煤矿井下应用。

(八) 垂直提升输送机

国外从20世纪60年代末开始发展垂直提升技术,德国Trellex Flexowell公司一直从事这种机型的研制,其产品已有5万余台,分布于90多个国家和地区,应用于各行各业。1996年5月,该公司成功地将料袋式垂直提升技术应用于美国纽约北部一个水库开发的隧道竖井开采中,该料袋式输送机的连续垂直提升高度为208m,带速2.42 m/s。

我国由于垂直提升技术起步晚,该技术在煤矿井下应用尚属空白。根据我国大型煤矿的情况,若要满足主井提升需要,主参数必须满足运量Q≥1200 t/h,高度H≥400m。垂直提升输送机目前存在输送带的阻燃性、安全性、冷粘技术、国产化、清扫以及整机凸弧段的抛料等问题。

2001年在上海地铁施工设计了一条垂直提升输送机,其主参数为:额定连续输送量Q=180~200t/h,输送水平距离L=8.96 m,垂直提升高度H≥25 m,带速V=1.25 m/s,带宽B=1 000 mm,驱动功率N=45 kW,目前该机正在使用中。

1.2 皮带运输机的发展趋势

1.2.1国外皮带运输机技术的现状

国外皮带运输机技术的发展很快,其主要表现在2个方面:一方面是皮带运输机的功能多元化、应用范围扩大化,如高倾角带输送机、管状皮带运输机、空间转弯皮带运输机等各种机型;另一方面是皮带运输机本身的技术与装备有了巨大的发展,尤其是长距离、大运量、高带速等大型皮带运输机已成为发展的主要方向,其核心技术是开发应用于了皮带运输机动态分析与监控技术,提高了皮带运输机的运行性能和可靠性。目前,在煤矿井下使用的皮带运输机已达到表1所示的主要技术指标,其关键技术与装备有以下几个特点

(1)设备大型化其主要技术参数与装备均向着大型化发展,以满足年产300~500万t以上高产高效集约化生产的需要。

(2) 应用动态分析技术和机电一体化、计算机监控等高新技术,采用大功率软起动与自动张紧技术,对输送机进行动态监测与监控,大大地降低了输送带的动张力,设备运行性能好,运输效率高。

(3)采用多机驱动与中间驱动及其功率平衡、输送机变向运行等技术,使输送机单机运行长度在理论上已有受限制,并确保了输送系统设备的通用性、互换性及其单元驱动的可靠性。

(4)新型、高可靠性关键元部件技术。如包含CST等在内的各种先进的大功率驱动装置与调速装置、高寿命高速托辊、自清式滚筒装置、高效贮带装置、快速自移机尾等。如英国FSW生产的FSW1200/(2~3)×400(600)工作面顺槽皮带运输机就采用了液粘差速或变频调速装置,运输能力达3000 t/h以上,它的机尾与新型转载机(如美国久益公司生产的S500E)配套,可随工作面推移而自动快速自移、人工作业少、生产效率高。

参考文献

[1] 机械工程手册、电机工程手册编辑委员会.机械工程手册—机械产品(二)[M].机械工业出版社.1982年8月.

[2] 范祖尧等.现代机械设备设计手册—非标准机械设备设计[M].机械工业出版社.2000年6月.

[3] 唐金松.简明机械设计手册(第二版)[M].上海科学技术出版社.2002年6月.

[4] 北京起重机机械研究所、武汉丰凡科技开发有限责任公司.DTⅡ(A)型皮带运输机机械设计手册[M].冶金工业出版社.2003年8月.

[5] 机械工业部设计单位联合设计组.ZJT1A-96皮带运输机设计选用手册[M].黄河水利出版社.1998年10月.

[6] 机械化运输设计手册编委会.机械化运输设计手册[M].机械工业出版社.1997年5月.

[7] 张钺.新型皮带运输机设计手册[M].冶金工业出版社.2001年2月.

[8]《运输机械设计选用手册》编组委.运输机械设计选用手册(上、下)[M].化学工业出版社.1999年1月.

[9] 毋虎城.矿山运输与提升设备[M].煤炭工业出版设.2004年5月.

[10] 上海煤矿机械研究所.煤矿机械设计手册[M].1972年.

[11] 于学谦.矿山运输机械[M].中国矿业大学出版社,1998年.

[12] 北起所.DTⅡ型皮带运输机设计选用手册[M].冶金工业出版社.1994年.

[13] 北起所.DTⅡ型皮带运输机平行轴驱动装置设计选用手册[M].机械工业部.1997年.

[14] 孔庆华,刘传绍.极限测量与测试技术基础[M].同济大学出版社.2002年.

[15] 机械设计手册编写组.机械设计手册[M].化学工业出版社.2002年.

[16] 中国纺织大学工程图学教研室.画法几何及工程制图[M].上海科技出版社.2000年.

[17] 张文芳,段志强,边会杰.皮带运输机防跑偏辊及清扫器的使用与研究[J]. 河北煤炭.2002,5:9-10.

[18] 尹万涛,胡述记,米迎春.皮带运输机自动调偏装置的改进设计[J].郑煤科技.2005,3:42-44.

[19] 李红玉.皮带运输机自动调偏滚筒.矿业快报.2004,4(4):36.

[20] 张广文.起井下胶带输送机火灾事故的剖析与经验教[J].煤矿安全,2001,32(10):46-47.

[21] 李铁东,姜卫东.西沟矿下运皮带运输机系统的设计及应用[J].煤矿机械,2004(9):8-9.

[22] 刘训涛,毛君.皮带运输机断带抓捕器研究[J].矿山机械,2005(2):41-42.

[23]毛君,刘训涛.皮带运输机断带保护系统的研究[J].煤矿机械,2004,(11):99-100.

[24] 陈炳耀,祁开阳.皮带运输机输送带与滚筒之间的打滑分析[J].煤矿机械,2003(5):49-51.

[25] 罗云.21世纪安全管理科学展望[J].中国安全科学学报,2000,10(1):27-31.

[26] 禹金云.机械安全技术趋向分析[J].中国安全科学学报,2004,14(4):54-56.

[27] 王传海,张卫国.皮带运输机断带及飞车制动保护装置[J].矿业安全与环保2003,30(3):40-46.

川公网安备: 51019002004831号

川公网安备: 51019002004831号