点胶机械手的结构设计

点胶机的点胶部分的机械结构设计【优秀】【word+4张CAD图纸全套】【毕业设计】

【带开题报告+评阅人意见表+实习报告+题目申报表+外文翻译】【39页@正文11600字】【详情如下】【需要咨询购买全套设计请加QQ1459919609】

Study of precision micro-holes in borosilicate glass using micro EDM combined with micro ultrasonic vibration machining.pdf

中期自查表.doc

前期材料.doc

实习报告.doc

封面.doc

工程图12.DWG

工程图13.DWG

工程图14.DWG

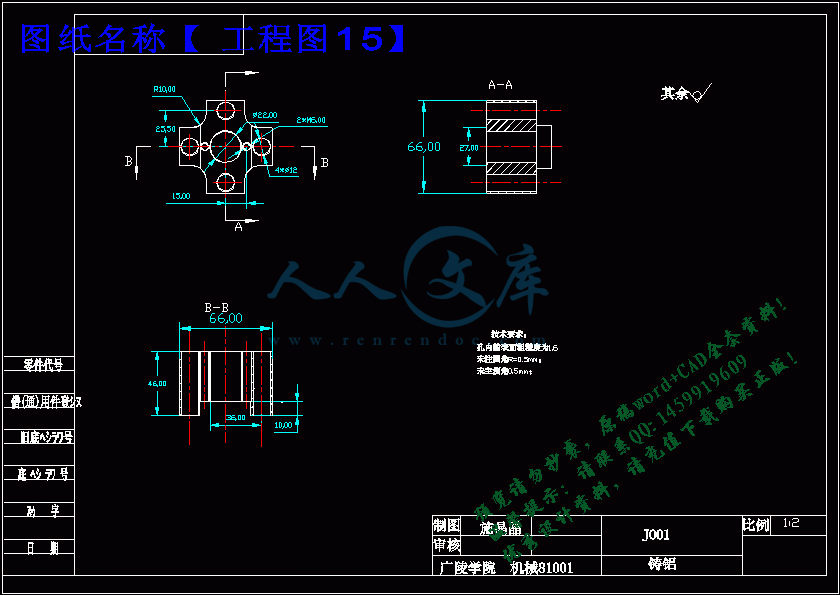

工程图15.DWG

开题报告.doc

指导教师审阅意见表.doc

正文.doc

目 录.doc

答辩结果表.doc

翻译.doc

评阅人意见表.doc

题目申报表.doc

题目申报表

设计(论文)题 目 点胶机的点胶部分的机械结构的设计

题目简介:

点胶机又称涂胶机、滴胶机、打胶机、灌胶机等,专门对流体进行控制。并将流体点滴、涂覆于产品表面或产品内部的自动化机器,可实现三维、四维路径点胶,精确定位,精准控胶,不拉丝,不漏胶,不滴胶。点胶机主要用于产品工艺中的胶水、油漆以及其他液体精确点、注、涂、点滴到每个产品精确位置,可以用来实现打点、画线、圆型或弧型。

现在根据用户的需求,对AB胶水进行点胶机械手的设计,根据胶水的性质,我们选择丝杆推胶,于是我进行大体设计,确定标准件的种类,非标准件材料的选择,于是再进行非标准件的设计,画出二维图纸,进行受力计算,确定标准件的具体型号。对于无法确定的尺寸,而我们把三维图形画出来,并且装配好之后再量取数据。对于一些设计不合理的零件,我们边设计边修改。

审核意见:

审核人签名:

年 月 日

题目类型--1、为结合科研;2、为结合生产实际;3、为结合大学生科研训练计划;

4、为结合学科竞赛;5、模拟仿真;6、其它

题目来源--A.指导教师出题 ; B.学生自定、自拟

开题报告

设计(论文)题 目点胶机的点胶部分的机械结构的设计

开题报告内容:(调研资料的准备与总结,研究目的、要求、思路与预期成果;任务完成的阶段、 内容及时间安排;完成毕业设计(论文)所具备的条件因素等。)

本毕业设计(论文)课题应达到的目的:

(1)培养学生的调查研究以及资料、信息的获取、分析等综合能力;

(2)培养学生的工程设计能力,主要包括设计、计算及绘图能力;

(3)培养学生的综合运用专业理论知识,分析解决实际问题的能力;

(4)培养学生的在设计过程中使用计算机的能力;

(5)培养学生的撰写设计说明书、论文的能力;

(6)培养学生创新能力和创新精神。

本毕业设计(论文)课题工作进度计划:

起止日期工 作 内 容

2014-02-22~2014-03-31

2014-04-1~2014-05-30

2014-06-01~2014-06-07

毕业设计开始,查阅中外文资料,完成外文翻译,完成实习调研和实习报告,完成开题报告;进行毕业设计,熟悉CAD、solidworks等画图软件接收毕业设计中期检查,根据设计要求,进行机械结构原理设计和结构设计,撰写毕业设计论文;修改完善毕业论文、准备毕业答辩、整理毕业设计期间的所有资料、成果并归档。

文 献 综 述

a)引言

随着科技的不断进步,一些电子产品体型也来越小,而人们对产品大功能的期望却丝毫不减,于是我们得进入微型化加工安装时代。IPhone一家喻户晓的手机,其做工精细,对外形的胶合要求较高,胶合轨迹复杂,人工难以实现其高要求,必定用机器来代替,涂抹胶水的点胶机就需求量不断上升。

二、点胶机机械工作原理

利用松下伺服马达带动丝杆旋转推动挤压快来挤出胶水,同时利用电子气压阀开关来控制胶水口的开关。准备点胶的时候工作台处于初始状态,点胶开始的时候x、y同时运动到指定位置,于是z轴开始运动,将点针运动到待点胶处,胶口开关开启,于是边点胶,工作平台边移动,胶水均匀分不到指定位置,点胶完成,胶水A、B混合后点胶时,可同时挤出两种胶水,并且在螺旋点胶头里面混合均匀再点胶,开关胶水是利用高压气体带动气缸上下运动实现同时拖动点胶阀开闭。

三、点胶机的特点

结合了计算机控制和点胶两门技术。内设伺服闭环控制系统,优点:点胶轨迹是利用C语言编程的,应用点胶复杂轨迹的小型零件,每个自由度上配备有一个伺服器因此其运动轨迹比较精准,分辨率:0.001mm,可以以直线、圆弧等复杂轨迹运动。滴胶精度比较高,可达0.02克/滴,利用激光对刀,精确度高,可替代人工作业,实现机械化生产;单机即可操作,简单便利、高速精确;SD卡存储方式,方便资料管理及机台间文件传输;可搭载双组分泵送系统,构成双液全自动点胶机;可加装点胶控制器及点胶阀等配件构成落地式点胶设备;可搭载螺丝锁付机构,配置成自动锁螺丝机;可按需升级为在线机器人,用于各种自动化装配;承载能力强、加工空间大。

四、点胶机的发展概况

点胶机又称涂胶机、滴胶机、打胶机等,是专门对流体进行控制,并将流体点滴、涂覆于产品表面或产品内部的自动化机器。点胶机主要用于产品工艺中的胶水、油漆以及其他液体精确点、注、涂、点滴到每个产品精确位置,可以用来实现打点、画线、圆型或弧型。

精度要求还是有很大差距。双组份的点胶机目前国外的机器挺多,技术也相对成熟,只是价位太高。

国内双液点胶技术已经走向成熟,国内双液点胶机知名品牌深圳德信、胜翔自动化、

腾洲自动化、深圳世椿(SECOND-AUTO)、东莞赛恩斯(SES)、益达Y&D、欧宝(Oupel)、特盈(TWINWIN)、腾盛(TENSUN)、axxon轴心自控目前已经有专业双液设备存在,而且质量稳定,价格合适,很适合国内用户使用。

随着电子胶水的普遍应用,点胶设备的应用也会更加广泛和多样化。目前,单组份的点胶技术相对成熟,其发展方向是自动化和高精度。

五、点胶机的难点

点胶机最常遇到的问题是阀门问题,下列为解决胶阀使用时经常发生的问题的有效方法。

胶阀滴漏此种情形经常发生予胶阀关毕以后。95%的此种情形是因为使用的针头口径太小所致。

太小的针头会影响液体的流动造成背压, 结果导致胶阀关毕后不久形成滴漏的现象。过小的针头也会影响胶阀开始使用时的排气泡动作.只要更换较大的针头即可解决这种问题。锥形斜式针头产生的背压最少, 液体流动最顺畅。液体内空气在胶阀关毕后会产生滴漏现象, 最好是预先排除液体内空气,或改用不容易含气泡的胶.或先将胶离心脱泡后在使用。

出胶大小不一致

当出胶不一致时主要为储存流体的压力筒或空气压力不稳定所产生。

进气压力调压表应设定于比厂内最低压力低10至15psi.,压力筒使用的压力应介于调压表中间以上的压力, 应避免使用压力介于压力表之中低压力部分。

胶阀控制压力应至少60psi以上以确保出胶稳定。

最后应检查出胶时间.若小于15/1000秒会造成出胶不稳定.,出胶时间愈长出胶愈稳定。

流速太慢

流速若太慢应将管路从1/4” 改为3/8”。

管路若无需要应愈短愈好。

除了改管子,还要改出胶口和气压,这样完全加快流速。

流体内的气泡

过大的流体压力若加上过短的开阀时间则有可能将空气渗入液体内. 解决方法为降低流体压力并使用锥形斜式针头。

胶水堵塞

此种情形主要因过多的湿气或重复使用过的瞬间胶。应确保使用新鲜的瞬间胶。将管路以未含湿气的Aceton丙酮彻底清洗过。使用的空气应确定完干燥且于厂内空压与胶阀系统间加装过滤器。(以上方法如仍然无效,则应使用氮气) 。

七、研究手段

根据机械设计、机械原理、工程力学、尺寸公差、工程材料,利用CAD、solidworks辅助设计,大体原理设计、具体零件设计、样品安装检验、修改完善、样品安装检验直至完善样品、再根据经验实现设计,大批量生产。。.

本课题要研究或解决的问题和拟采用的研究手段(途径)

主要研究内容:

2、两自由度风洞实验运动装置机械结构的构型选择;

3、两自由度风洞实验运动装置机械结构的转动运动分析;

4、两自由度风洞实验运动装置机械结构的完整机械系统;

5、两自由度风洞实验运动装置机械结构的力学分析;

6、根据分析结果采用ADAMS软件对两自由度风洞实验运动装置机械结构进行优化。

研究工作步骤:

1、查阅相关的文献资料,熟悉和掌握机构理论和方法,清晰设计思路;

2、根据设计要求,进行探针标定装置原理设计和结构设计;

3、采用ADAMS软件进行运动学和动力学分析优化;

4、整理资料,准备写设计说明书。

5、完善毕业论文,准备答辩。

中文摘要

点胶机又称涂胶机、滴胶机、打胶机、灌胶机等,专门对流体进行控制。并将流体点滴、涂覆于产品表面或产品内部的自动化机器,可实现三维、四维路径点胶,精确定位,精准控胶,不拉丝,不漏胶,不滴胶。点胶机主要用于产品工艺中的胶水、油漆以及其他液体精确点、注、涂、点滴到每个产品精确位置,可以用来实现打点、画线、圆型或弧型。

现在根据用户的需求,对AB胶水进行点胶机械手的设计,根据胶水的性质,我们选择丝杆推胶,于是我进行大体设计,确定标准件的种类,非标准件材料的选择,于是再进行非标准件的设计,画出二维图纸,进行受力计算,确定标准件的具体型号。对于无法确定的尺寸,而我们把三维图形画出来,并且装配好之后再量取数据。对于一些设计不合理的零件,我们边设计边修改。

ABSTRACT

Also known as glue dispenser machine, dispensing machine, plastic machine, plastic irrigation machines, specialized fluid control.And a fluid drip, coated on the interior surface of the product or product automation machines, enabling three-dimensional, four-dimensional path dispensing, accurate positioning, precise control of glue, not drawing, not leak glue,no epoxy.Dispensing technology products are mainly used in glues, paints and other liquid precise point, injection, coating, drip into the precise location of each product can be used to achieve the RBI, drawing a line, circle or arc.

Now according to the user's needs, AB glue dispensing robot be designed according to the nature of glue, we chose to push plastic screw, so I carried out the general design, determine the type of standard parts, non-standard pieces of material choice, so then non-standard design, draw two-dimensional drawings, conducted by the force calculations to determine the specific type of standard parts.For unable to determine the size, but we have drawn three-dimensional graphics, and the amount of data after re-assembled. For some poorly designed parts, we edge to edge design modifications.中文摘要

ABSTRACT

目 录

第一章 绪论 ……………………………………………………………………1

1.1点胶机特点 ……………………………………………………………………1

1.2 工作原理 ………………………………………………………………………1

1.3 常见问题 ………………………………………………………………………1

1.4 厂商需点胶水类型 ……………………………………………………………3

1.5 厂商胶量要求 …………………………………………………………………3

第二章 点胶机械手零件的设计 …………………………………………………4

2.1 概念设计 ………………………………………………………………………4

2.1.1 点胶方式选择 ………………………………………………………………4

2.1.2 模型设计 ……………………………………………………………………4

2.1.3 标准件的名称确定 …………………………………………………………4

2.2 实体设计 ………………………………………………………………………5

2.2.1 胶管夹具设计 ………………………………………………………………5

2.2.2 混合胶管的选择 ……………………………………………………………7

2.2.3 气缸的选择 …………………………………………………………………8

2.2.4 气缸与Y型点胶阀连接件的设计 …………………………………………9

2.2.5 点胶气缸固定基座的设计 ………………………………………………10

2.2.6 点胶旋转片的设计…………………………………………………………11

2.2.7点胶蝇嘴固定座的设计……………………………………………………12

2.2.8 点胶安装板的设计…………………………………………………………13

2.2.9 滚珠丝杆的选择……………………………………………………………14

2.2.10 导柱的设计 ………………………………………………………………19

2.2.11 导套的设计 ………………………………………………………………20

2.2.12 代号为J004的零件是设计………………………………………………20

2.2.13 锁紧座的设计 ……………………………………………………………21

2.2.14 代号为J001的零件是设计………………………………………………22

2.2.15 推杆的设计 ………………………………………………………………23

2.2.16 推胶头的设计 ……………………………………………………………24

2.2.17 代号为J006的零件的设计 ……………………………………………25

2.2.18代号为J005的零件的设计 ………………………………………………26

2.2.19代号为J007的零件的设计 ………………………………………………27

2.2.20 滑板的设计………………………………………………………………27

2.2.21 电机的选择 ………………………………………………………………28

2.2.22 联轴器的选择 ……………………………………………………………29

第三章 实体图片…………………………………………………………………32

第四章 总结………………………………………………………………………34

参考文献……………………………………………………………………………35

第一章 绪论

点胶机又称涂胶机、滴胶机、打胶机、灌胶机等,专门对流体进行控制。并将流体点滴、涂覆于产品表面或产品内部的自动化机器,可实现三维、四维路径点胶,精确定位,精准控胶,不拉丝,不漏胶,不滴胶。点胶机主要用于产品工艺中的胶水、油漆以及其他液体精确点、注、涂、点滴到每个产品精确位置,可以用来实现打点、画线、圆型或弧型。

如今根据市场特定的需求,改进现有点胶机,用于专业的不同的胶水点胶。

1.1点胶机特点

可替代人工作业,实现机械化生产;单机即可操作,简单便利、高速精确;SD卡存储方式,方便资料管理及机台间文件传输;可搭载双组分泵送系统,构成双液全自动点胶机;可加装点胶控制器及点胶阀等配件构成落地式点胶设备;可搭载螺丝锁付机构,配置成自动锁螺丝机;可按需升级为在线机器人,用于各种自动化装配;承载能力强、加工空间大。

1.2工作原理

伺服电机带动螺杆转动推进各活塞,将胶压进与活塞室相连的进给管中,当活塞处于上冲程时不挤胶,当活塞向下推进滴胶针头时,胶从针嘴压出。滴出的胶量由活塞下冲的距离决定,可以手工调节,也可以在软件中自动控制。

1.3常见问题

点胶机最常遇到的问题是阀门问题,下列为解决胶阀使用时经常发生的问题的有效方法。

胶阀滴漏此种情形经常发生予胶阀关毕以后。95%的此种情形是因为使用的针头口径太小所致。

太小的针头会影响液体的流动造成背压, 结果导致胶阀关毕后不久形成滴漏的现象。过小的针头也会影响胶阀开始使用时的排气泡动作.只要更换较大的针头即可解决这种问题。锥形斜式针头产生的背压最少, 液体流动最顺畅。液体内空气在胶阀关毕后会产生滴漏现象, 最好是预先排除液体内空气,或改用不容易含气泡的胶.或先将胶离心脱泡后在使用。

参考文献

[1].《公差配合与技术测量基础》的教学心得 【作者】姚新华;2009年04期

[2].《公差配合与技术测量》课程的教改实践 【作者】梁亚芹;2009年04期

[3].职业教育《公差配合与测量技术》教学方法探索 【作者】朱墩子;2008年30期

[4].高职《公差配合与技术测量》课程的教学方法探讨 【作者】强军;2008年32期

[5].《公差配合与技术测量》课程教改的思考【作者】林景凡;2009年08期

[6].三自由度机械手运动学分析 【作者】 张敏; 石秀华; 杜向党; 贾锐; 2005年01期

[7].搬运机械手的运动学分析 【作者】 李桂莉; 武洪恩; 刘志海;2007年02期

[8].一种搬运机械手的运动学仿真研究 【作者】 席思文; 李伟光; 罗玮韬; 朱火美;2009年02期

[9].采用牛顿-欧拉法的排爆机器人机械手动力学分析 【作者】 杨武; 蒋梁中;2010年06期

[10]. 基于Pro/E和ADAMS五自由度机械手的运动学分析及仿真 【作者】 张海平; 孔庆忠; 郑海龙; 杨雄; 李果;2009年02期

[11].基于创新能力培养的《机械原理》作业的设计 【作者】 刘玉; 蒋红旗;2011年01期

[12].机械原理实验教学新体系【作者】 阎绍泽; 季林红; 申永胜; 索双富;2004年02期

[13].机械原理与机构创新设计 【作者】 袁爱霞; 高中庸; 李宝灵;2007年06期

[14].“机械原理”课程改革的实践与探索【作者】 陈文华; 陈秀宁;2001年01期

[15].基于学生创新素质培养的机械原理课程案例教学研究【作者】刘扬;唐芬南; 贺兵; 2009年04期

川公网安备: 51019002004831号

川公网安备: 51019002004831号